Aramid 1313/MWCNT (Multi-Walled Carbon Nanotube) nano fibers and preparation method thereof

A multi-walled carbon nanotube and nanofiber technology, applied in fiber processing, filament/thread forming, single-component polyamide rayon, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

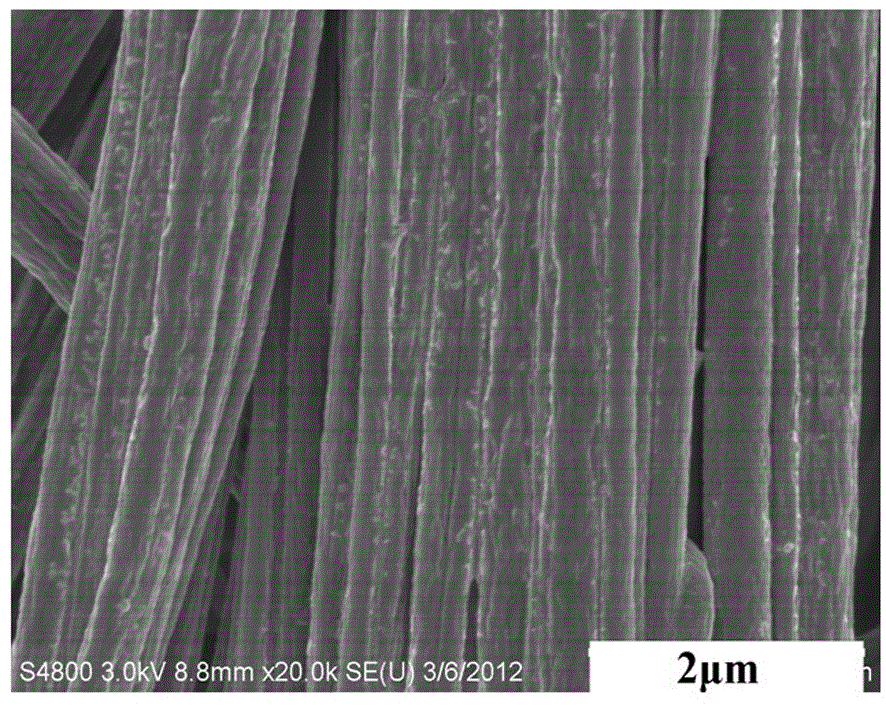

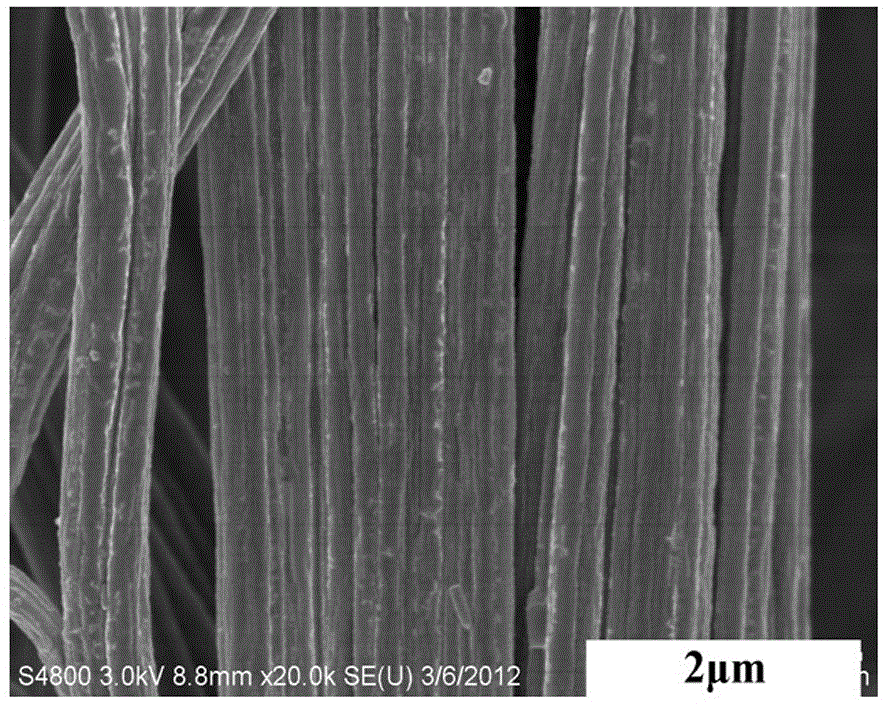

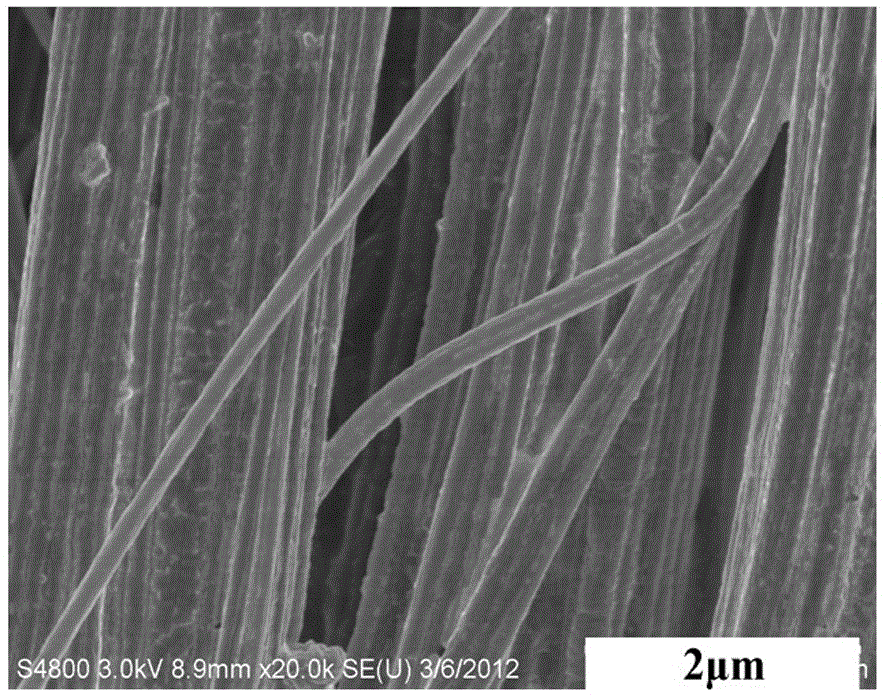

Image

Examples

Embodiment 1

[0034] Example 1: Use a mixed acid solution composed of 65% nitric acid and 95% sulfuric acid to ultrasonically oxidize MWNTs, centrifuge the mixed acid solution containing MWNTs, separate MWNTs from the acid solution, and wash MWNTs repeatedly with deionized water , until the pH value of the cleaning solution is 7, and dry the pretreated MWNTs at 90°C. Weigh a certain amount of treated carbon nanotubes and add to SOCl 2 and DMF mixed solution (MWNTs: SOCl 2:DMF=0.2g:30ml:3ml), magnetically stirred at 65°C for 24h, centrifuged to separate MWNTs from the mixed solution, rinsed with THF, and then air-dried in a fume hood to obtain MWNTs-COCl. Then add MWNTs-COCl to the mixed solution of TritonX-100 and DMF (MWNTs-COCl:TritonX-100:DMF=0.2g:20ml:40ml), and pass into N 2 protection, stirred at 120°C for 48 hours, and then centrifuged the mixed solution, rinsed the separated MWNTs with DMF, and then air-dried in a fume hood to obtain MWNTs grafted with TritonX-100. A certain amou...

Embodiment 2

[0040] Example 2: A certain amount of MWNTs grafted with TritonX-100 was weighed, added to DMAc solvent, and treated with ultrasonic waves for 30 minutes to obtain MWNTs / DMAc solution.

[0041] Weigh a certain amount of anhydrous LiCl, dry it in vacuum at 120°C for 2 hours, then add it to DMAc to form a LiCl / DMAc solution system, weigh a certain amount of aramid 1313 fiber, add it to the LiCl / DMAc solution system, and heat it at 100°C Dissolve under stirring to form a transparent solution.

[0042] The MWNTs / DMAc solution and the aramid fiber 1313 / LiCl / DMAc solution were stirred and mixed for 30 minutes to prepare a mixed solution with a mass fraction of aramid fiber 1313 of 11%, a mass fraction of LiCl of 7wt%, and a mass fraction of MWNTs of 0.2wt%. Ultrasonic treatment for 45 minutes to obtain spinning solution.

[0043] At 25KV of spinning voltage, spinneret is internal diameter 0.85mm, spinning solution flow rate 0.3ml / h, collection roller rotating speed 7m / min, spinnere...

Embodiment 3

[0045] Example 3: A certain amount of MWNTs grafted with TritonX-100 was weighed, added to a DMAc solvent, and treated with ultrasonic waves for 45 minutes to obtain a MWNTs / DMAc solution.

[0046] Weigh a certain amount of anhydrous LiCl, dry it in vacuum at 120°C for 3 hours, then add it to DMAc to form a LiCl / DMAc solution system, weigh a certain amount of aramid 1313 fiber, add it to the LiCl / DMAc solution system, and heat it at 110°C Dissolve under stirring to form a transparent solution.

[0047] The MWNTs / DMAc solution and the aramid fiber 1313 / LiCl / DMAc solution were stirred and mixed for 45 minutes to prepare a mixed solution with a mass fraction of aramid fiber 1313 of 10%, a mass fraction of LiCl of 6wt%, and a mass fraction of MWNTs of 0.4wt%. Ultrasonic treatment for 60 minutes to obtain spinning solution.

[0048] At spinning voltage 23KV, spinneret is internal diameter 0.85mm, spinning liquid flow rate 0.2ml / h, collection roll rotating speed 6m / min, spinneret l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com