Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "High initial modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyimide fibre containing benzimidazole structure and preparation method thereof

InactiveCN101200822AEnhanced interactionHigh tensile strengthMonocomponent synthetic polymer artificial filamentFiberImide

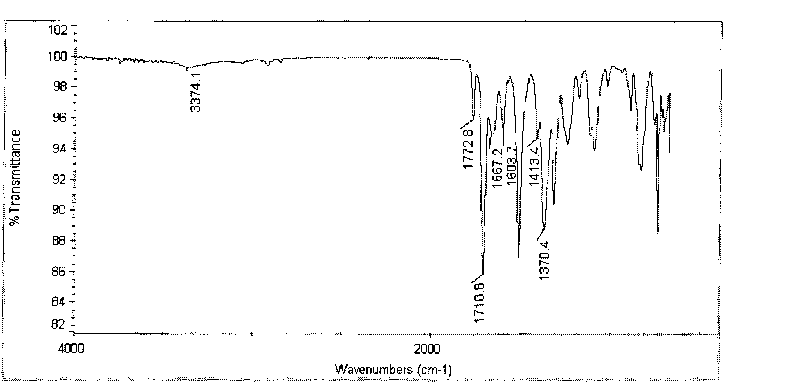

The invention discloses polyimide fiber with benzimidazole structure, which is characterized in that the infrared spectrum of the fiber is provided with character absorption peaks of imide ring of 1776-1774cm<-1>, 1726-1722cm<-1> and 1378-1373cm<-1> within the wave number range of 1300-1800cm<-1> and N-H functional group absorption wide peaks in the imidazole structure within the wave number range of 3000-3750cm<-1>. The tensile strength is 0.73-1.53GPa. The initial modulus is 45.2-220GPa. The invention also provides a preparation method of the fiber. The fiber disclosed by the invention contains the benzimidazole structure with secondary amine hydrogen. Therefore, compared with PMDA-ODA polyimide fiber prepared with the same process, the tensile strength can be improved by nearly three times at the most, the initial modulus can be improved by more than twenty times at the most, and the heat resistance is further improved. The preparation method provided by the invention has the advantages of mature technology and easy control. The cost can be kept at a relative low level.

Owner:SINOSELEN HI TECH

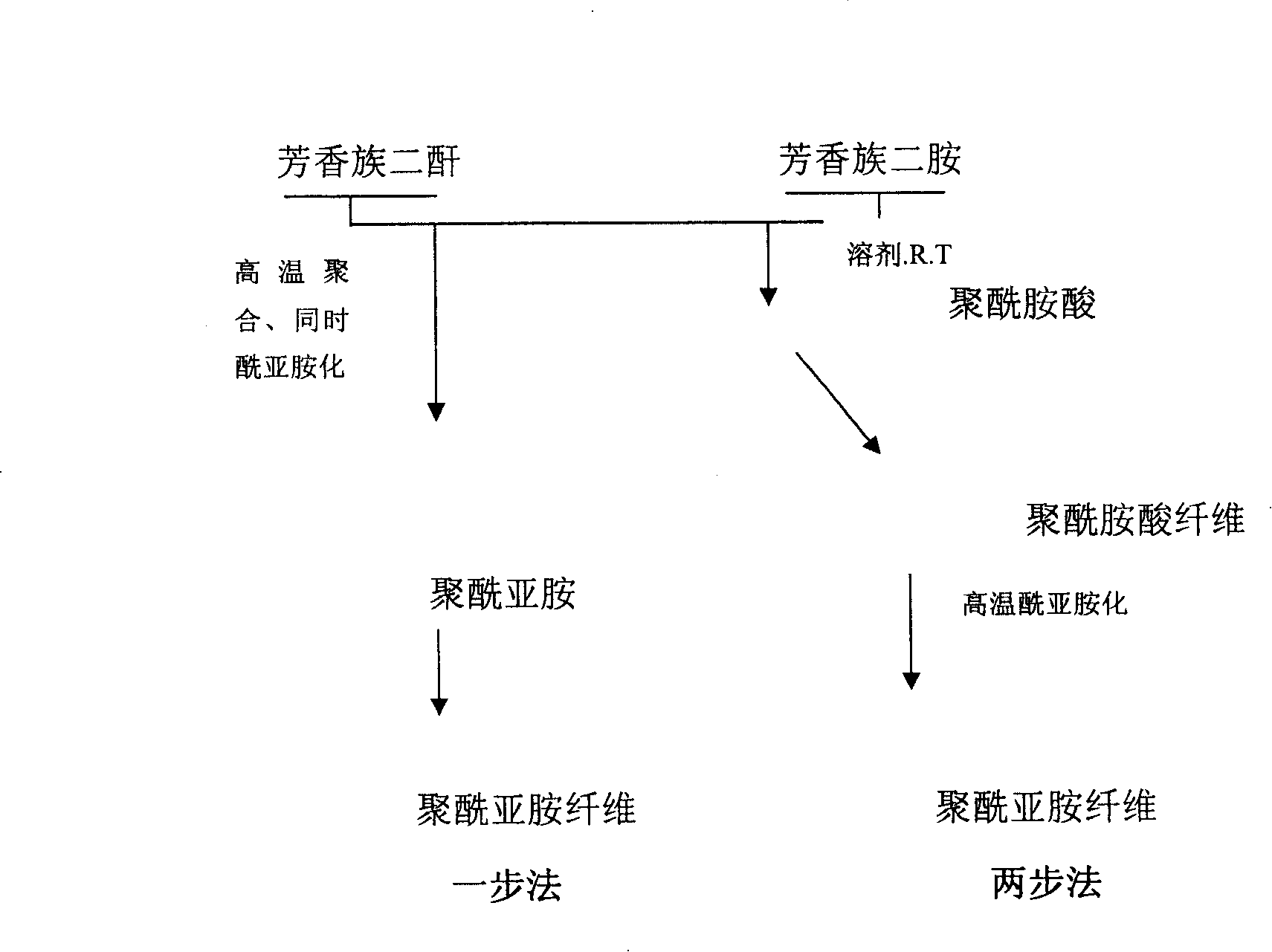

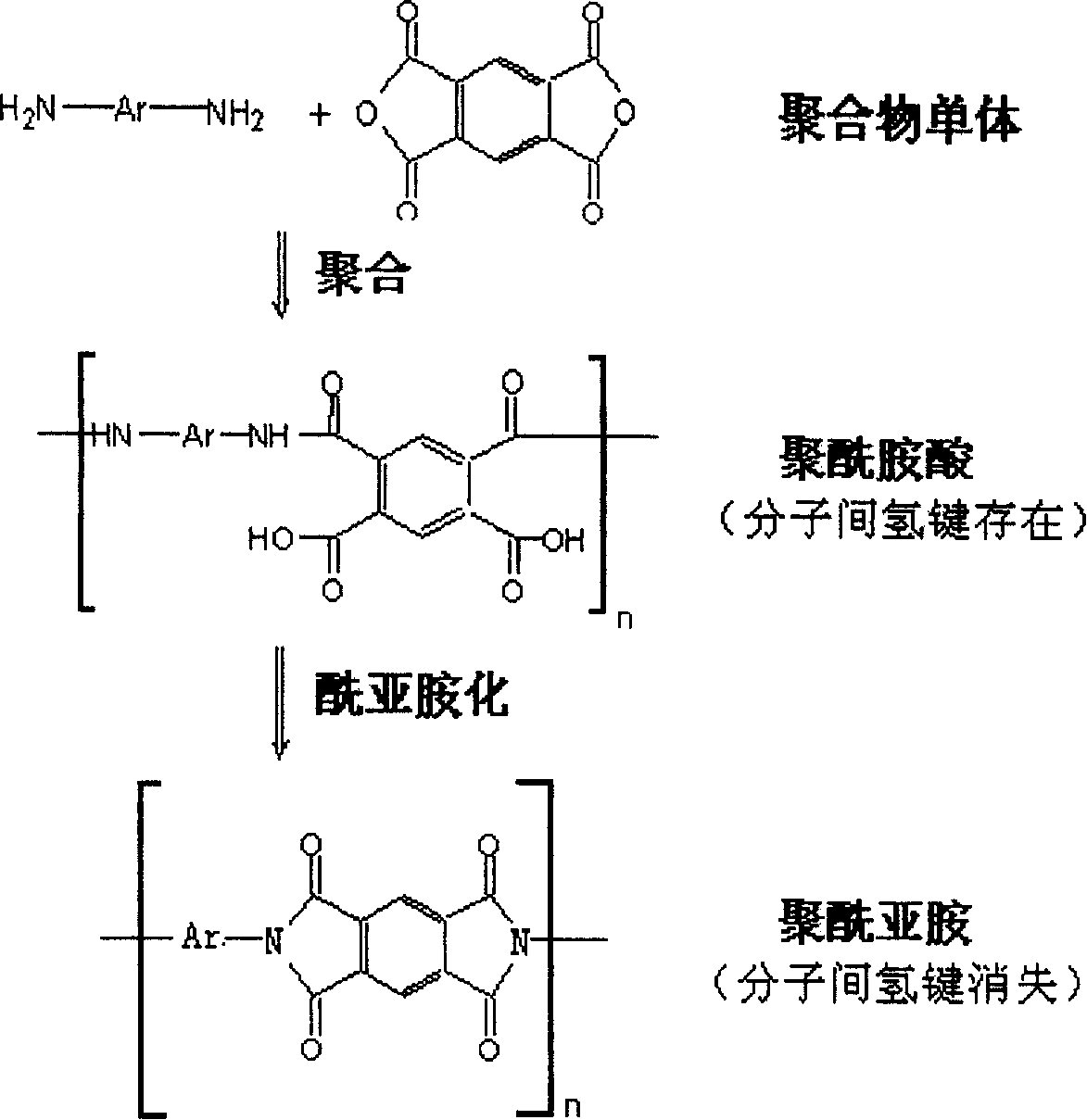

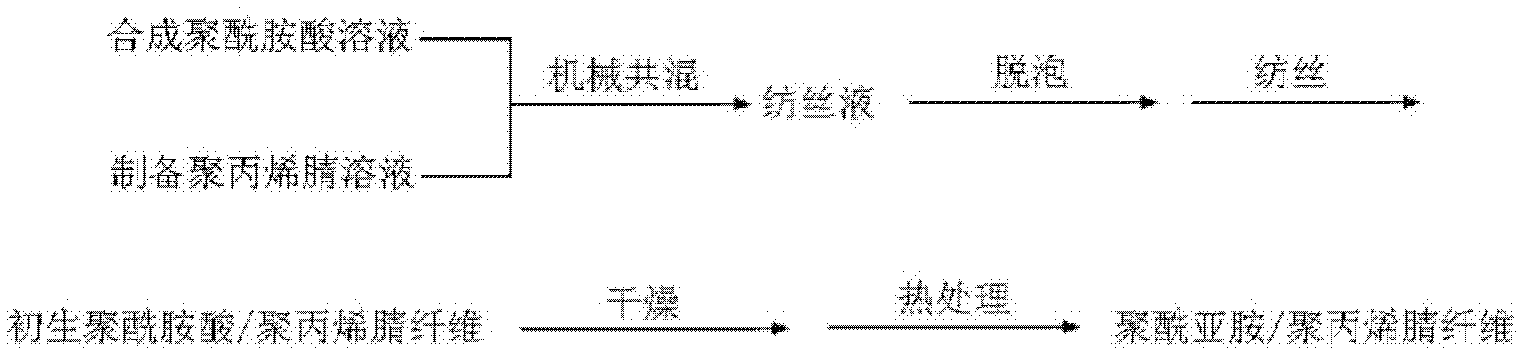

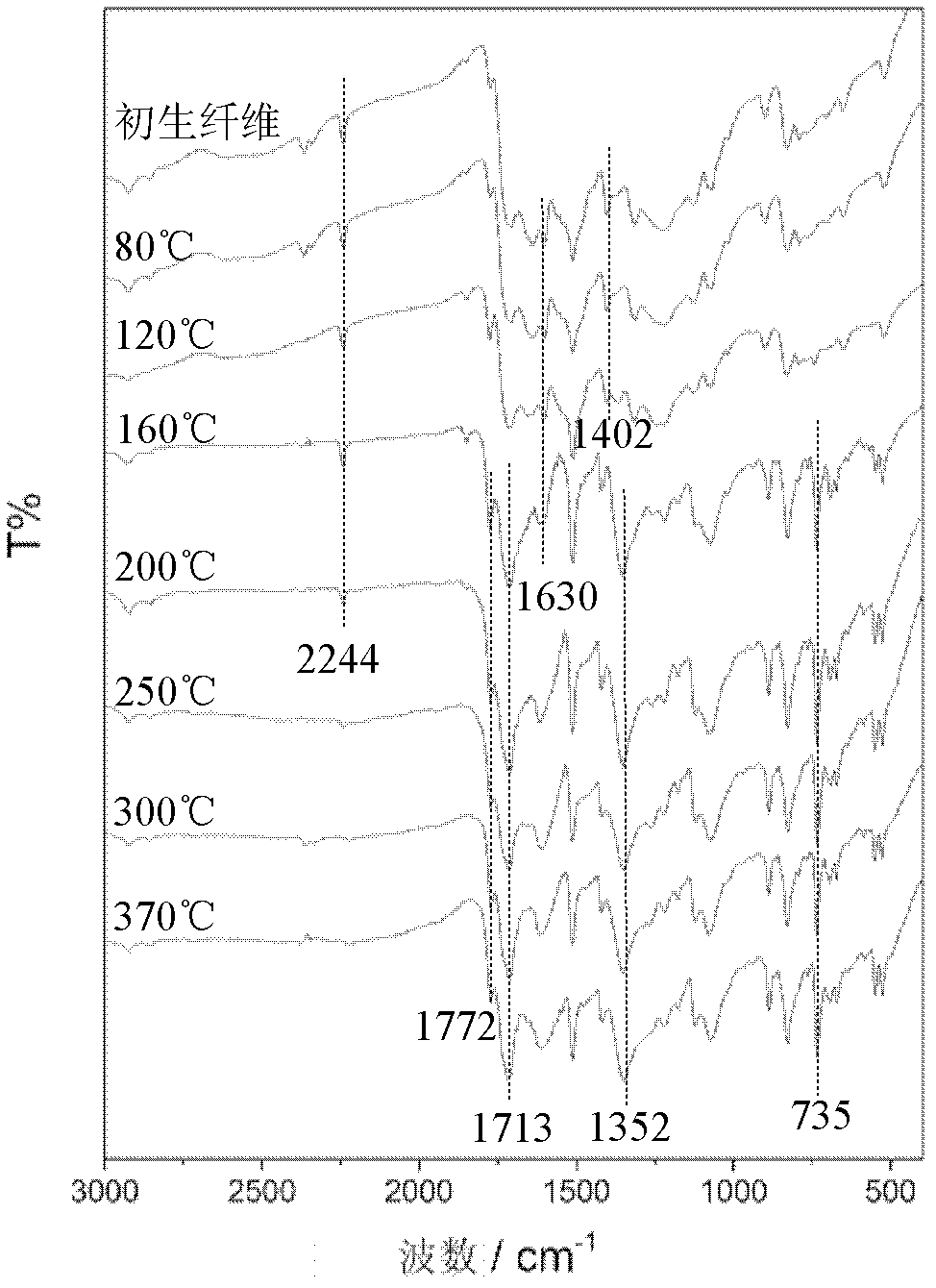

Polyimide/polyacrylonitrile blended fiber and preparation method thereof

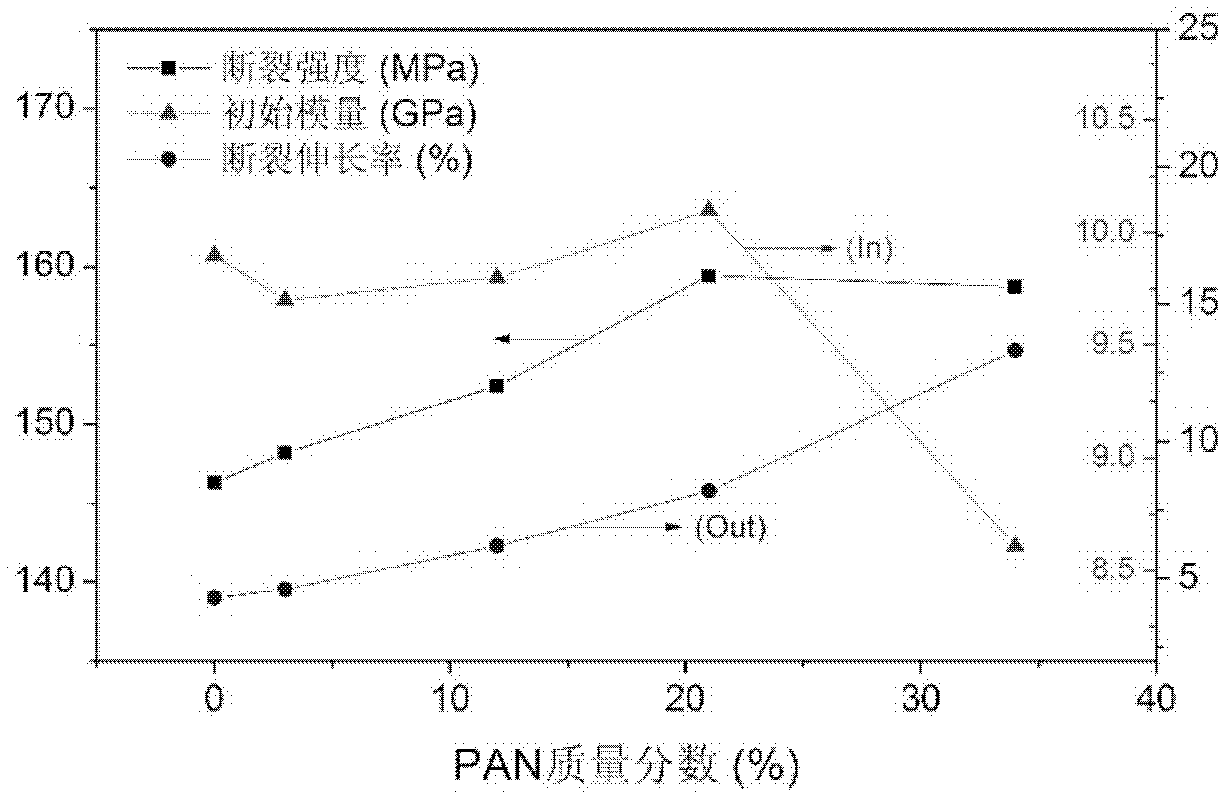

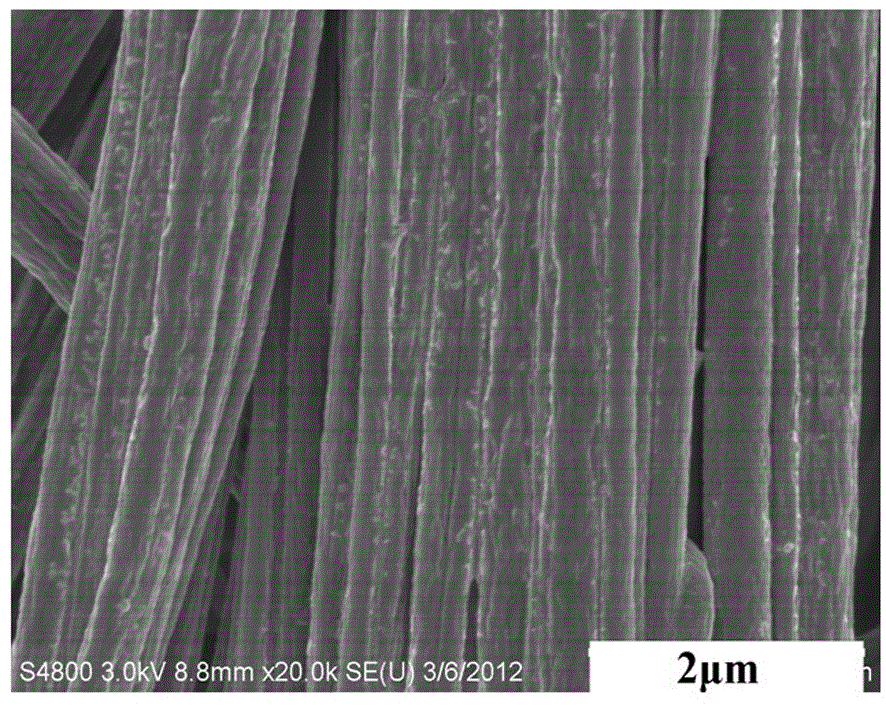

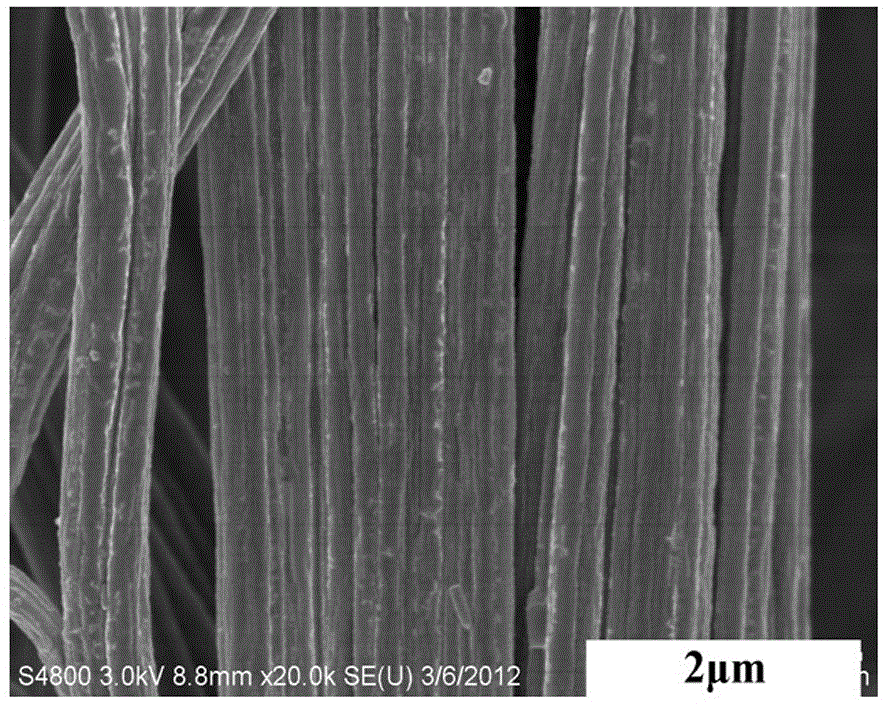

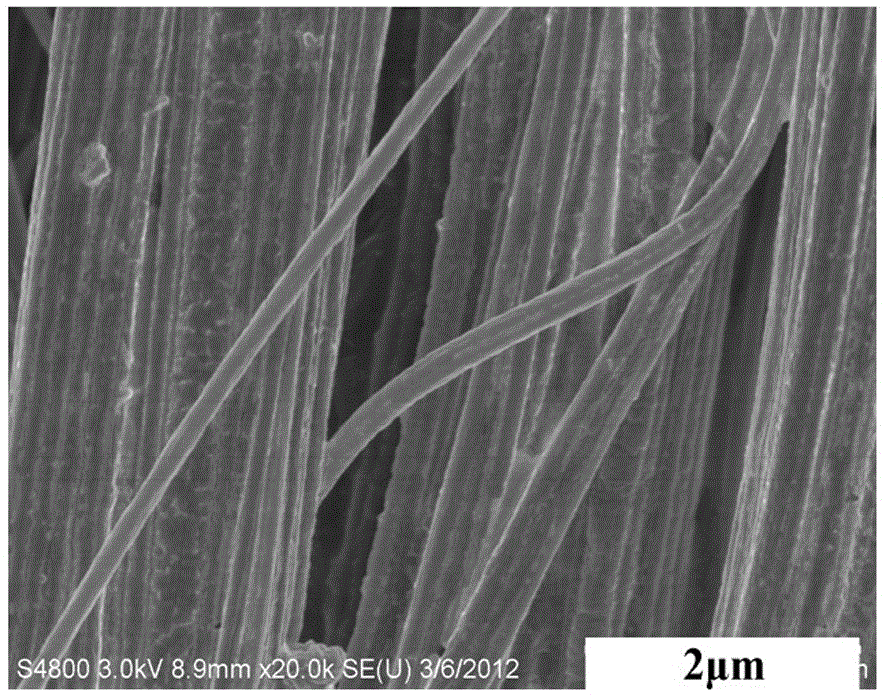

ActiveCN102618964AHigh breaking strengthHigh initial modulusArtificial filament heat treatmentWet spinning methodsChemistryMoisture

A polyimide / polyacrylonitrile blended fiber and a preparation method belong to the technical field of blended fibers. The preparation method includes respectively preparing PAA (poly acrylic acid) liquor and PAN (polyacrylonitrile) liquor; blending the PAN liquor with the mass ranging from 3% to 40% of that of total PAA / PAN blended components and the PAA liquor to obtain spinning liquid precursor; removing bubbles in a vacuum manner, realizing wet-method spinning to obtain a PAA / PAN as-formed blended fiber; and realizing heat treatment for the as-formed blended fiber, removing moisture and solvent, completing a pre-oxidation process for the PAN component in the blended fiber and an imide cyclization process for the poly acrylic acid in the blended fiber, and obtaining the PI (polyimide) / PAN fiber. By means of comparing performances of a single component and the blended fiber under identical treatment conditions, a blended system capable of keeping an excellent mechanical performance of the fiber is obtained, and an excellent economic benefit is realized as compared with a PI fiber.

Owner:BEIJING UNIV OF CHEM TECH

Aramid 1313/MWCNT (Multi-Walled Carbon Nanotube) nano fibers and preparation method thereof

InactiveCN102877152APlay a reinforcing roleAvoid reunionFilament/thread formingStretchingSpinningElectrospinning

The invention discloses aramid 1313 / MWCNT (Multi-Walled Carbon Nanotube) nano fibers and a preparation method thereof. The preparation method comprises the following steps of: obtaining MWCNTs grafted with octyl phenoxy poly ethoxy; uniformly dispersing the grafted MWCNTs into a solvent by ultrasonic treatment so as to obtain a solution containing the MWCNTs; obtaining a dissolution system containing halide, adding aramid 1313 fibers into the dissolution system and stirring to dissolve the aramid 1313 fibers so as to obtain a solution containing the aramid 1313 fibers; mixing the two solutions to obtain a spinning solution; by adopting an electrostatic spinning method, obtaining a nano fiber felt of which the fibers are directionally arranged; and obtaining the strengthened nano fiber felt by adopting thermal stretching treatment. According to the invention, the aramid 1313 / MWCNT nano fibers are obtained; the orientation degree of the aramid 1313 is improved; and the tensile breaking strength and the initial modulus of the fiber felt are improved.

Owner:SUZHOU UNIV

Preparation method of waterborne phosphorus-silicon flame-retardant polyurethane coating material

ActiveCN108059913AIncreased light transmittance of the coatingAddressing transparencyFireproof paintsHeat resistant fibresPolyesterCross-link

The invention discloses a preparation method of a waterborne phosphorus-silicon flame-retardant polyurethane coating material. The preparation method is characterized by comprising the following steps: adding 33-57 parts of anhydrous phosphorus-containing polyester polyol by mass, 10-29 parts of polydimethylsiloxane by mass and 5-15 parts of a solvent by mass into a reactor, uniformly stirring, adding 15-30 parts of diisocyanate by mass and 0.01-0.05 part of a catalyst by mass, heating to 60-90 DEG C, and reacting for 1-2h; adding 1-4 parts of a small molecular chain extender by mass, 2-8 parts of a hydrophilic chain extender by mass and 0.1-0.8 part of a cross-linking agent by mass, heating to 75-90 DEG C, reacting for 2-4h, cooling to room temperature, and adding a neutralizer to make pHto be 6-7; adding 1-4 parts of deionized water by mass, stirring into an emulsion, performing vacuum distillation to remove the solvent to obtain the waterborne phosphorus-silicon flame-retardant polyurethane coating material. The waterborne phosphorus-silicon flame-retardant polyurethane coating material is suitable to be used as a surface covering material for textiles, leather, wood and steelstructural buildings, and has high transparency and flexibility.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

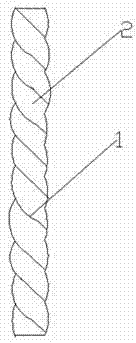

Polyvinyl alcohol fiber oil pattern harness cord thread and its preparing method

The present invention relates to a kind of oiled polyvinyl harness flex for jacquard and its production process. The oiled polyvinyl harness flex is produced with light yellow polyvinyl yarn and white filtering polyvinyl yarn as material and through twisting, sizing and wax oil soaking. The produced oiled polyvinyl harness flex has yellow and white pattern, modulus 10-20 % higher than that of available one, small extension and less moisture influence.

Owner:倪轮官 +1

Preparation method of knitted wool-like warm fabric

InactiveCN105332155AGood dissipationHigh pectinWeft knittingBiochemical fibre treatmentYarnPolymer science

The invention relates to a preparation method of a knitted wool-like warm fabric. The preparation method comprises the following steps: (1) raw material selection; (2) spinning technology implementation; (3) weaving technology implementation; (4) printing, dyeing and after-finishing. The knitted wool-like warm fabric is formed by performing the after-finishing, such as knitting, dyeing, carbon grinding and softening, on hemp / cotton / polypropylene fiber blended yarns and polyolefin elastic fibers, namely confirmable elastic fibers, which serve as raw materials. By the adoption of hemp, a product can realize antibacterial, health care and anti-ultraviolet functions; cotton fibers are high in hygroscopicity and spinnability; the polypropylene fibers are poor in heat conductance and high in heat insulation property; by the blending of the three types of fibers, a product has the functions of heat insulation, moisture absorption, breathing, bacteria prevention and ultraviolet resistance; by the weaving of the polyolefin elastic fibers, the product is extremely high in elasticity and conformality. The product is soft, fine, breathable, relaxing, high in heat retention property and suitable for making high-end warm coats or skirts, is a high-quality antibacterial, health care and warm fabric which has a wide market development prospect.

Owner:JIANGSU YDTEX GRP LTD

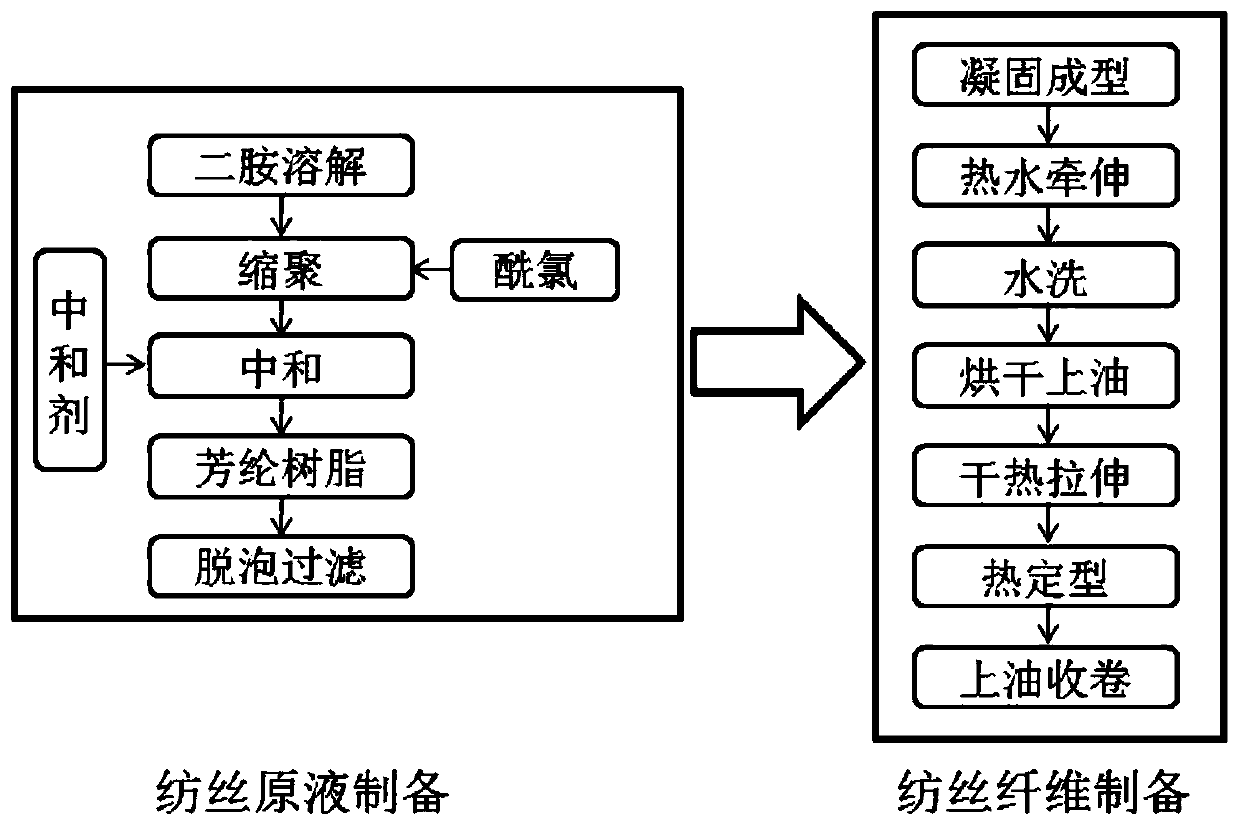

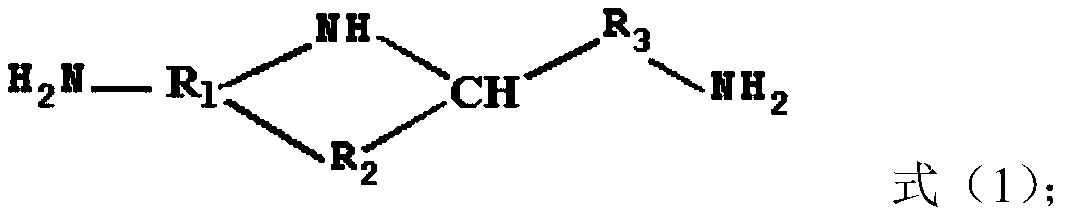

Preparation method of heterocyclic aramid 1313 fiber

ActiveCN110565197AHigh mechanical strengthEasy to manufactureArtificial filament washing/dryingMonocomponent copolyamides artificial filamentHeat resistanceDry heat

The invention provides a preparation method of heterocyclic aramid 1313 fiber. The preparation method of the heterocyclic aramid 1313 fiber includes the following steps that aromatic diamine A and aromatic diamine B are dissolved in an amide-type polar solvent, and a mixed solution is frozen for cooling and then mixed with molten isophthaloyl chloride for reaction under a low temperature environment to obtain a heterocyclic aramid 1313 solution; a neutralizing agent is used for to neutralization and impurity removal of the heterocyclic aramid 1313 solution to obtain a spinning dope; the spinning dope is subjected to high-temperature vacuum defoaming and filtering, then passes through a spinneret and a layer of air, enters into a first-stage coagulation bath, and is subjected to a second-stage coagulation bath, hot water drawing, water washing, drying, oiling, dry heat stretching, heat setting, cooling and oiling, and winding to obtain the heterocyclic aramid 1313 fiber. The preparation method of the heterocyclic aramid 1313 fiber can improve the mechanical strength, initial modulus, and heat resistance of aramid fiber, is conducive to the preparation of high-performance meta-aramid products, and lays a foundation for the application of the aramid 1313 fiber in more demanding fields.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

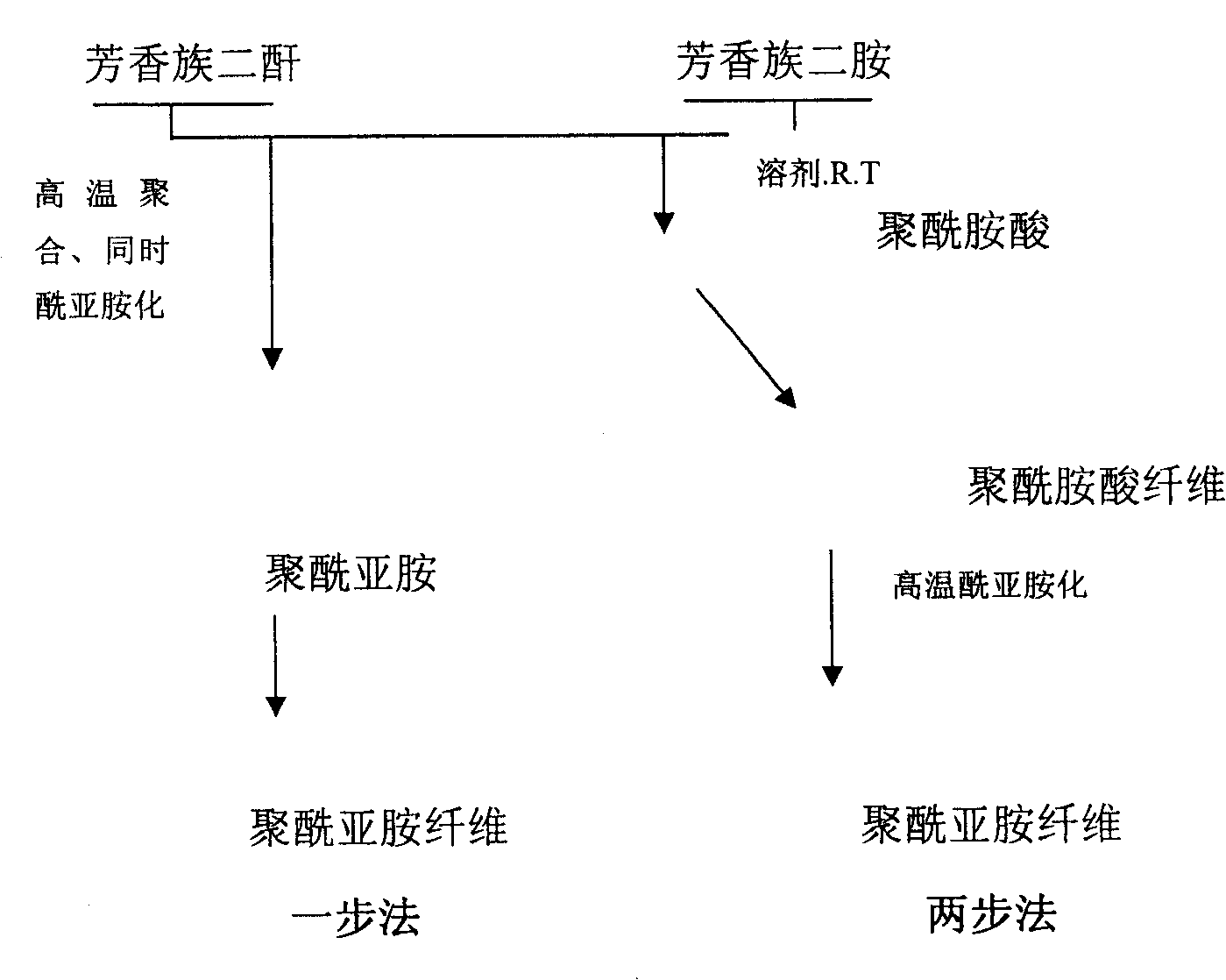

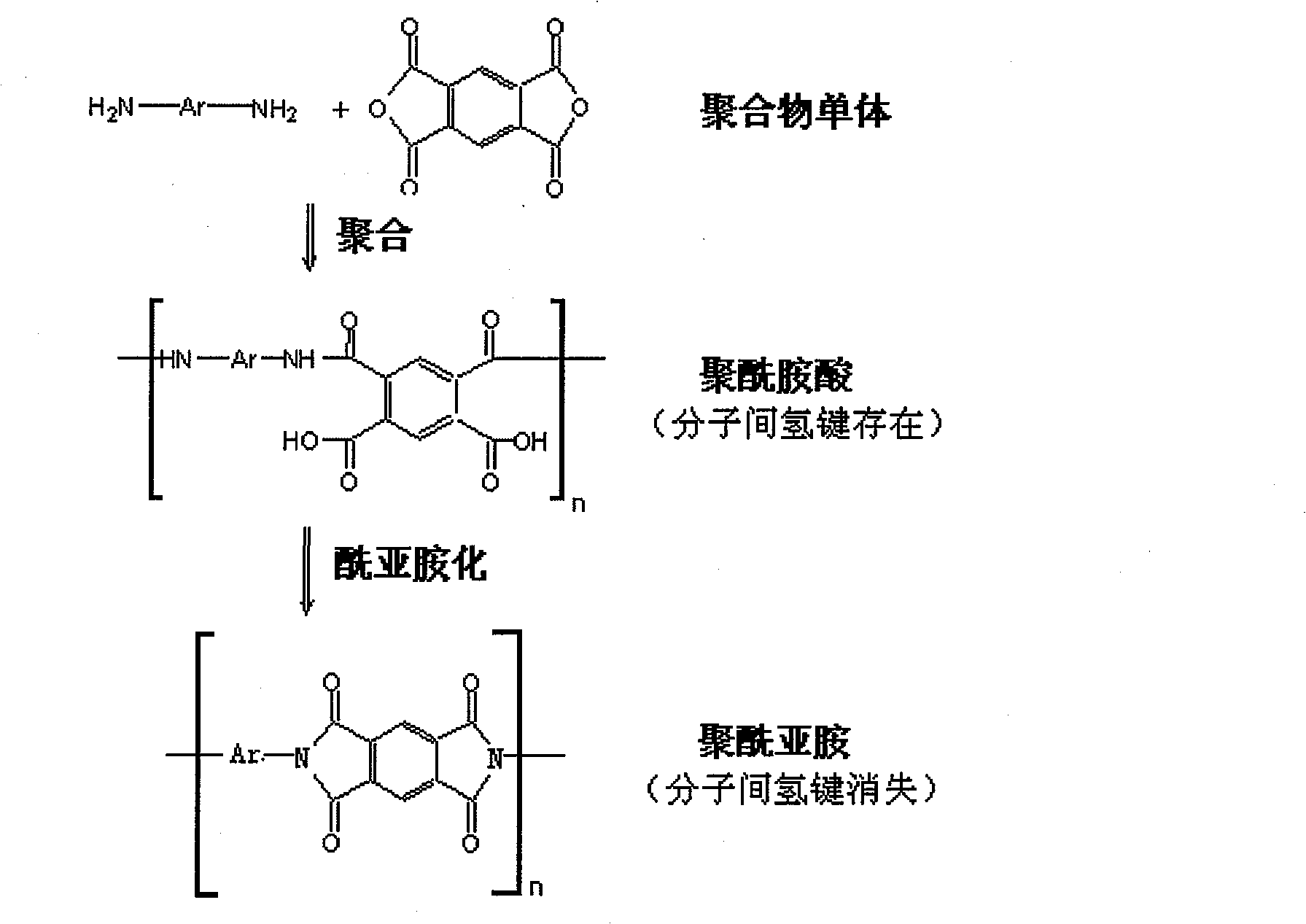

Polyimide fiber containing amido link structure and preparation method thereof

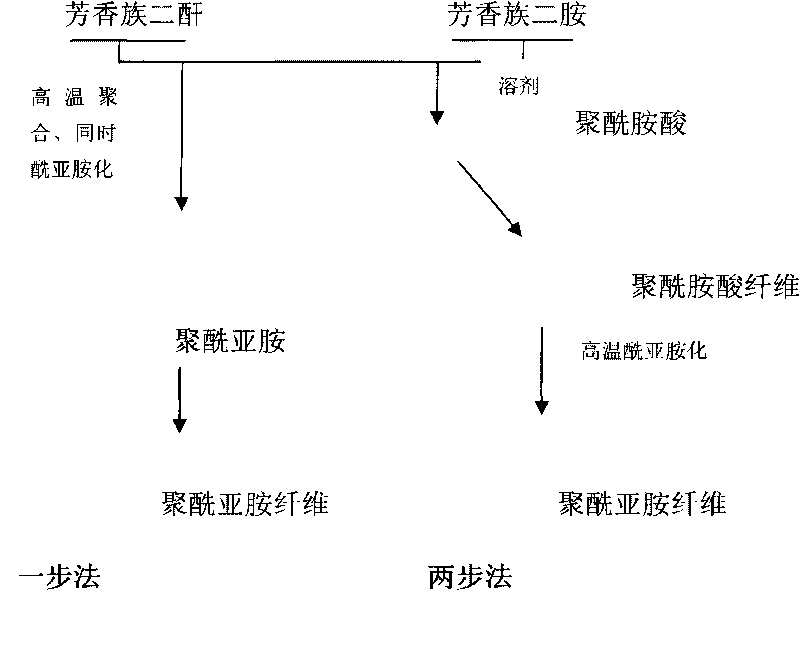

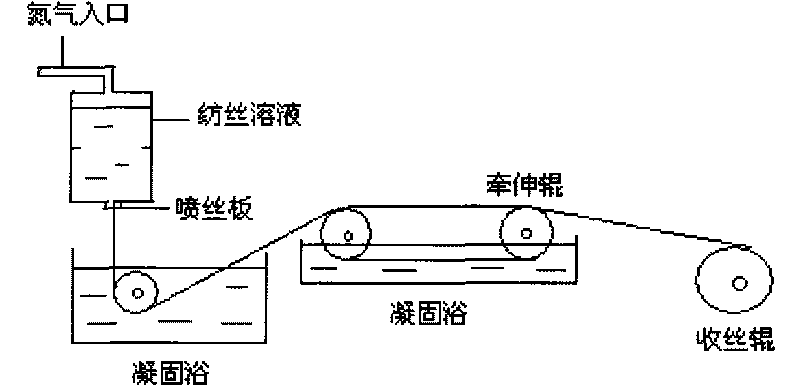

InactiveCN101709515AEnhanced interactionHigh tensile strengthMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberPolyamic acid

The invention relates to a polyimide fiber containing an amido link structure and a preparation method thereof. The polyimide fiber containing an amido link structure comprises the raw materials such as aromatic diamine and aromatic dianhydride which contain amido link structures and have the molar ratio of 1:1. The preparation method thereof comprises the following steps of: adding the aromatic diamine and the aromatic dianhydride which contain amido link structures into a solvent according to the molar ratio of 1:1, carrying out polyreaction, spinning obtained polyamic acid spinning solution according to the conventional wet or dry-jet wet process and obtaining the fiber after imidizating the obtained polyamic acid protofilament by adopting a heat imidization process. The obtained polyimide fiber has obviously-enhanced mechanical strength while maintaining other performances. The preparation method has easy control and can keep the cost at a lower level.

Owner:SINOSELEN HI TECH

Production technology of sound absorbing cotton formed by compounding short fiber and melt-blowing

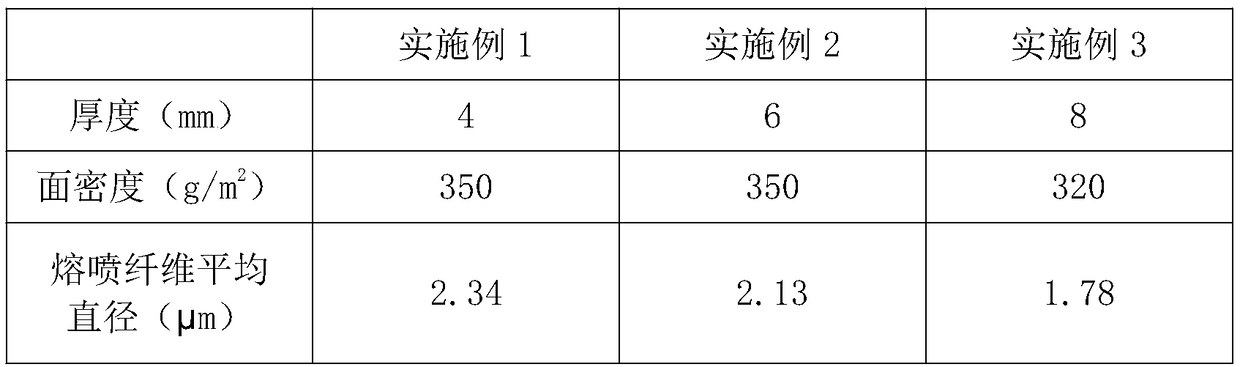

InactiveCN108823814AHigh sound absorption coefficientWide sound absorption frequencyMelt spinning methodsNon-woven fabricsEngineeringMelt blowing

The invention discloses a production technology of sound absorbing cotton formed by compounding short fiber and melt-blowing. Compared with a traditional technology, two-time opening technology, an airflow wind supplement conveying mechanism, double-roller receiving composite forming technology are mainly added. The production technology of the sound absorbing cotton formed by compounding the short fiber and melt-blowing has the advantages that equipment is advanced, the technology is simple, it is noticed that the temperature is controlled on the original basis, the prepared sound absorbing cotton not only has excellent properties of light weight, sound absorption, good sound insulation performance, good hydrophobicity, good plasticity, flame retardance and the like, but also is odorless,waterproof, dampproof, good in air permeability, anti-staining and antibacterial, and has a wide application prospect and market value.

Owner:芜湖跃飞新型吸音材料股份有限公司

Coating special for metal and production method thereof

InactiveCN108948904AGood light fastnessImprove outdoor aging performanceFireproof paintsAntifouling/underwater paintsMetal coatingGlass fiber

The invention relates to a metal coating, and in particular to a coating special for metal and a production method thereof. The coating special for metal contains the following raw materials in partsby weight: 50-60 parts of acrylic resin, 30-40 parts of polytetrafluoroethylene resin, 10-20 parts of inorganic montmorillonite, 10-20 parts of glass fiber, 20-25 parts of mica powder, 10-15 parts ofaluminium powder, 5-15 parts of ultraviolet shielding agent, 5-8 parts of butyl acetate, 3-5 pars of leveling agent, 2-3 parts of defoaming agent, 1-1.5 parts of dispersing agent, 0.8-1 part of anti-settling agent and 0.5-1 part of thickening agent. The prepared coating special for metal has excellent weatherability, fume resistance and self-cleanness, strong covering capability, good reflecting property for light and heat and strong corrosion protection; the surface of a metal workpiece processed by the coating is smooth, high in glossiness and uniform in color; and the dried paint film is excellent in chemical resistance.

Owner:广西南宁维一防腐科技有限公司

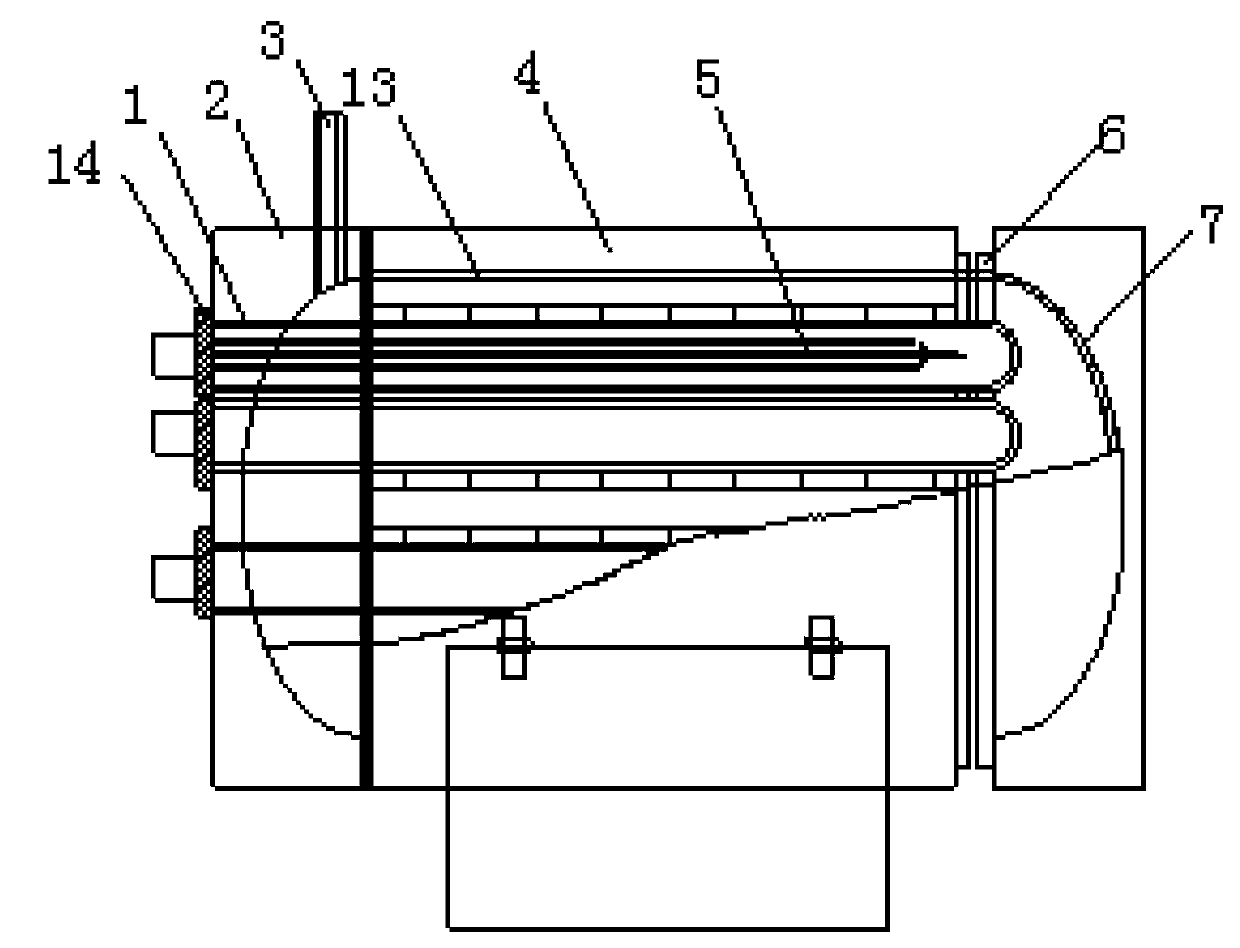

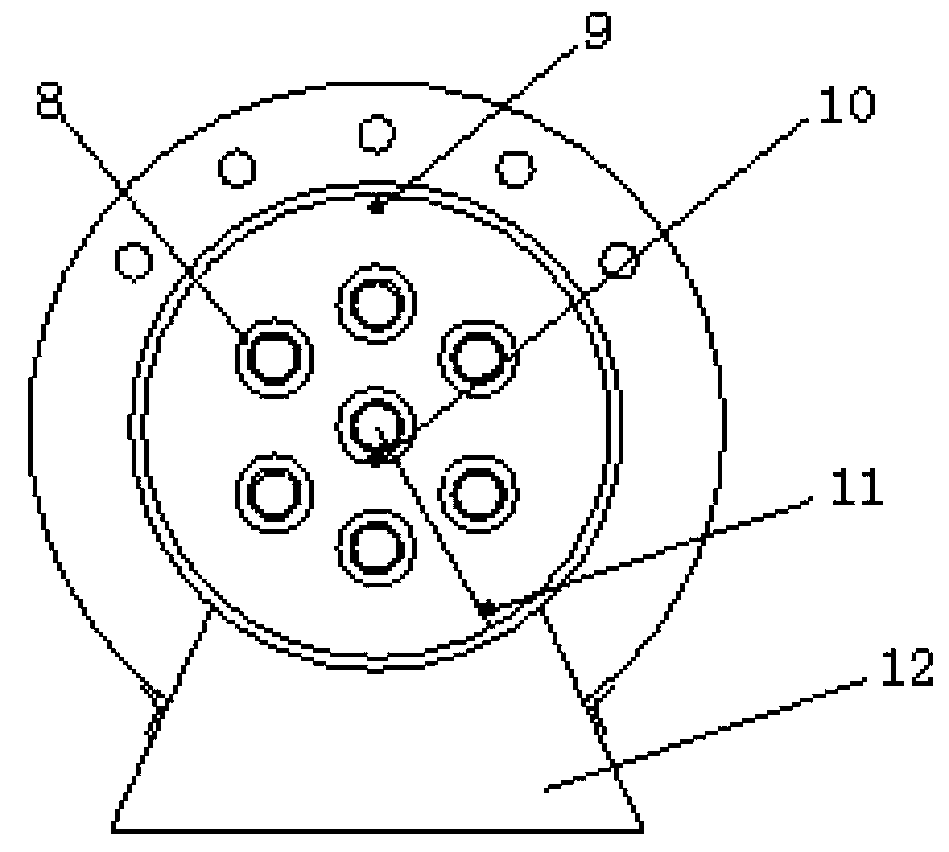

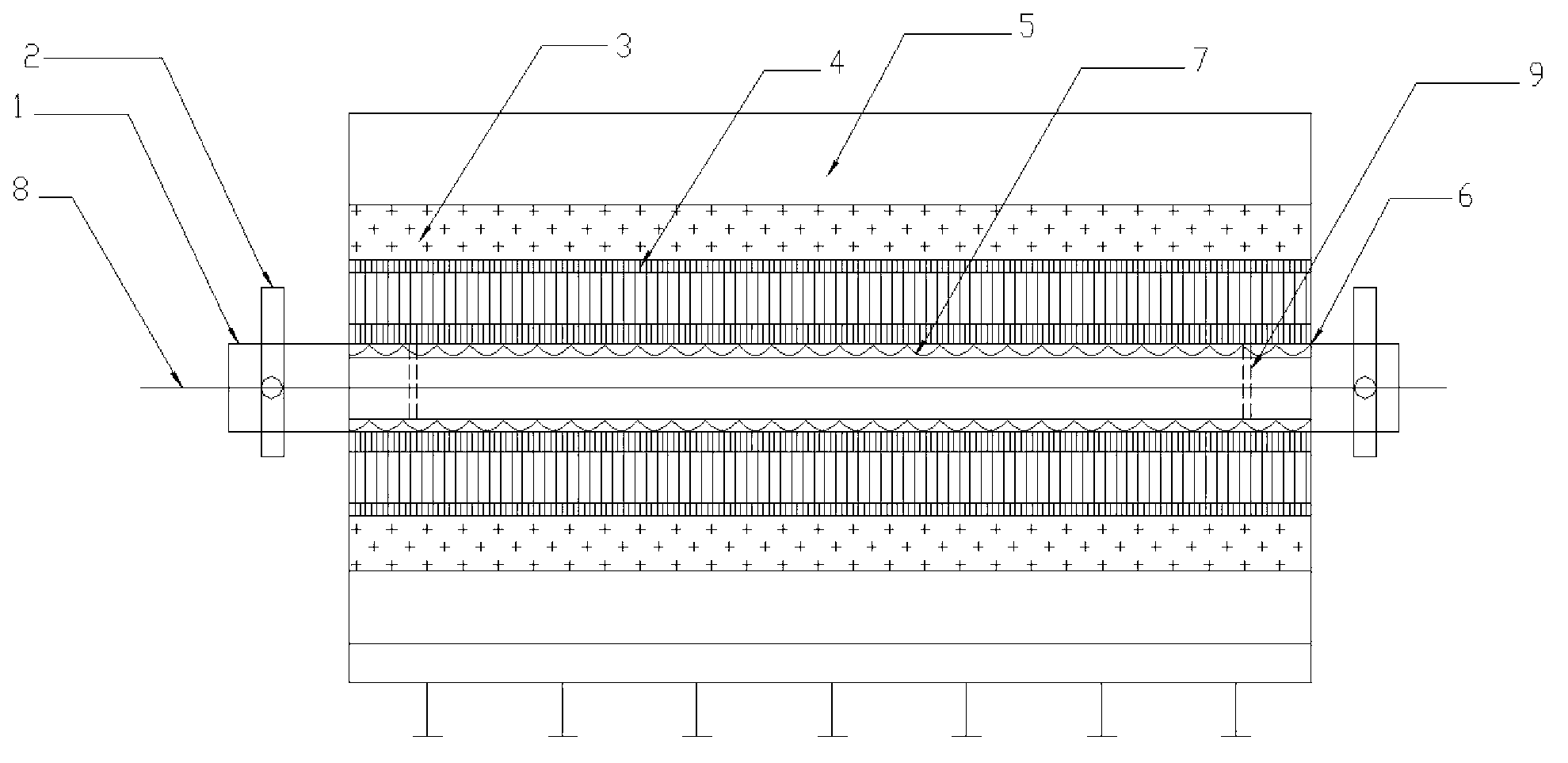

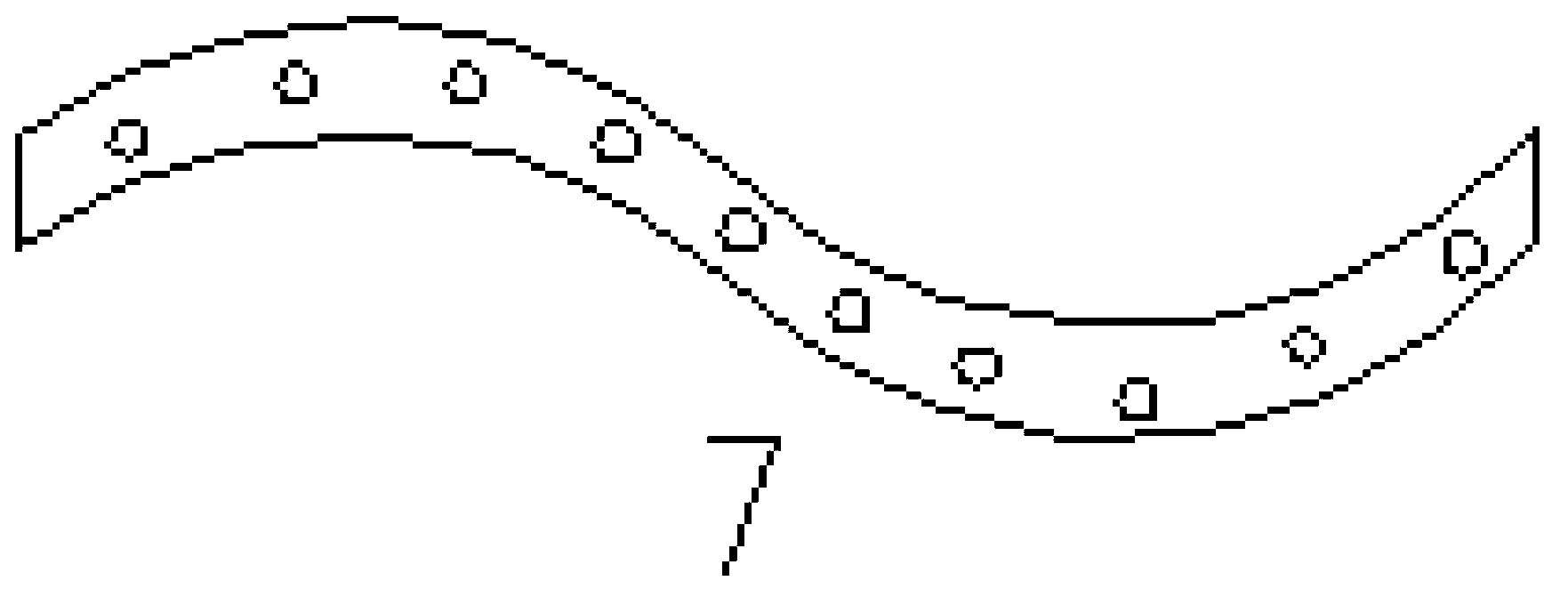

Vacuum imidizing furnace and imidizing method of polyamide acid fiber

ActiveCN103387670AGuaranteed Thermal CyclizationHigh temperature carbonization will not occurSynthetic polymer filament chemical after-treatmentFiberPolyamide

The invention provides a vacuum imidizing furnace comprising a hearth, an external heat insulating layer, a vacuumizing tube, a sealing device, 5-9 heating devices, a heating protective device, a net frame and an openable end enclosure, wherein the external heat insulating layer is arranged outside the hearth, the vacuumizing tube and the openable end enclosure are respectively arranged at the two ends of the hearth, the openable end enclosure is arranged at the open end of the hearth and is used for opening and closing the hearth, the heating devices are arranged in the hearth, the heating protective device is arranged outside the heating devices, the net frame is arranged outside the heating protective device, a fiber to be treated is sleeved outside the net frame, and the sealing device is arranged between the net frame and the hearth. By utilizing the vacuum imidizing furnace, the fiber can be thermally cyclized but cannot be oxidized, decomposed or carbonized at a high temperature, so that the mechanical performances of the prepared polyamide acid fiber can be improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

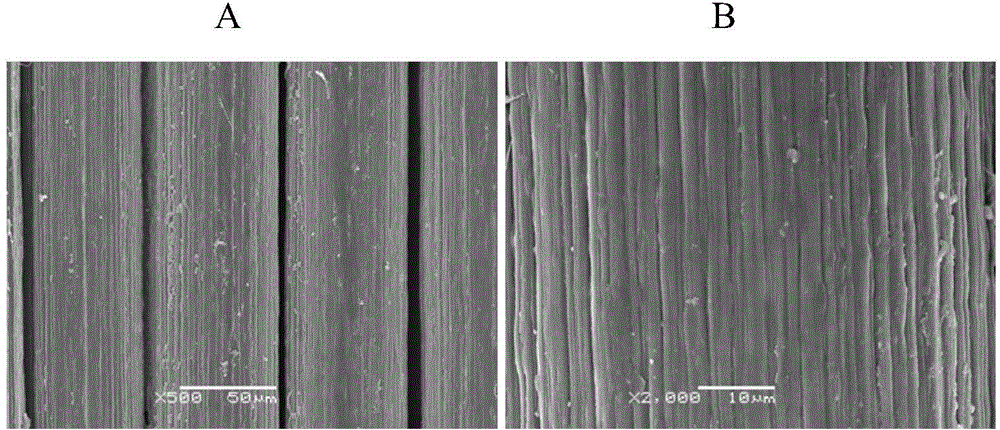

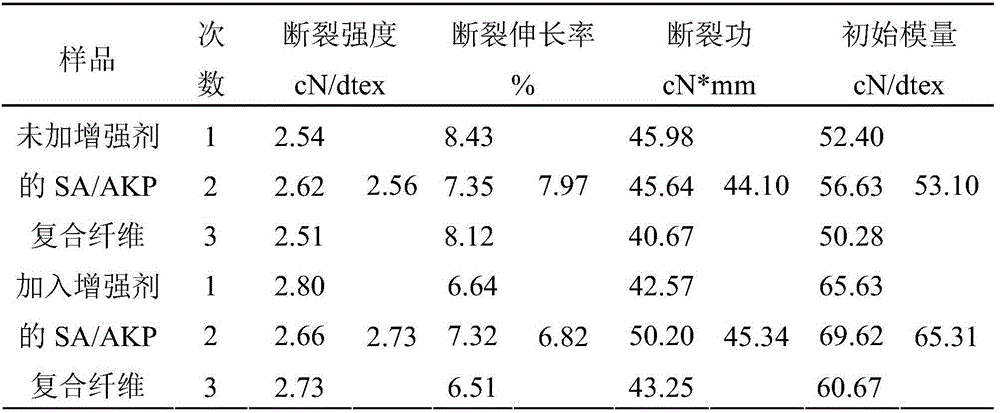

Preparation method of composite fiber for wig

ActiveCN104674375AImprove mechanical strengthImproves strength and modulusConjugated cellulose/protein artificial filamentsArtifical filament manufactureAldehydeHigh intensity

The invention relates to a preparation method of a composite fiber for a wig, and particularly relates to a preparation method of a composite fiber for a high-intensity seaweed / euphausiid protein simulation wig. The preparation method comprises the following step: adding a composite enhancer in the preparation process of a spinning solution, wherein the composite enhancer comprises the following components in percentage by weight: 70-90% of micromolecule dialdehyde and 10-30% of a hydrochloric acid and acetic acid mixture, wherein the volume ratio of hydrochloric acid to acetic acid in the mixture is (1 to 1) to (1 to 3). According to the method, natural environment-friendly degradable sodium alga acid and euphausia superb protein are compounded organically so as to prepare the simulation wig similar to real hairs in performance; the enhancer is added into the raw materials for improving the mechanical intensity of composite fibers; according to different thresholds of the added enhancer, the mechanical intensity can be improved by 1-7%.

Owner:DALIAN POLYTECHNIC UNIVERSITY

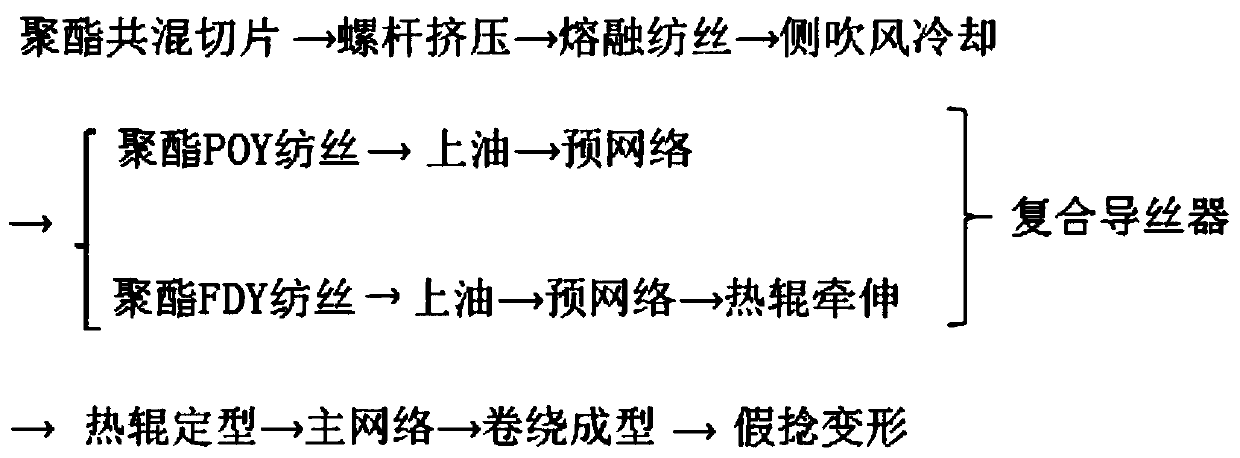

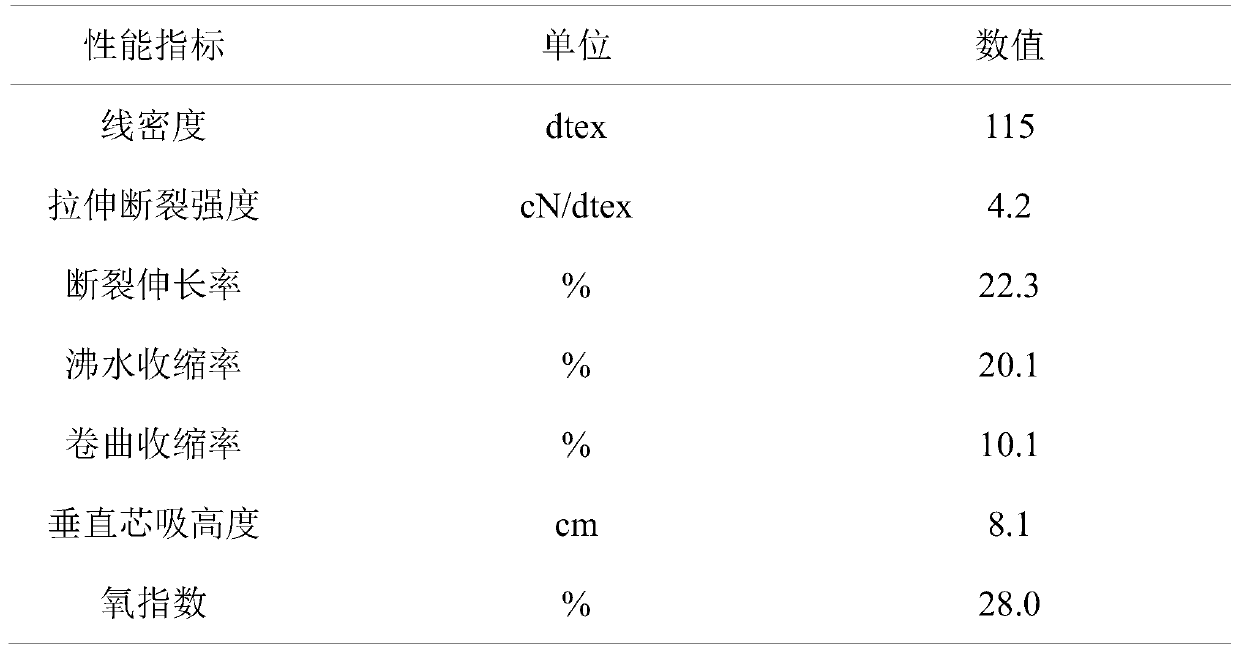

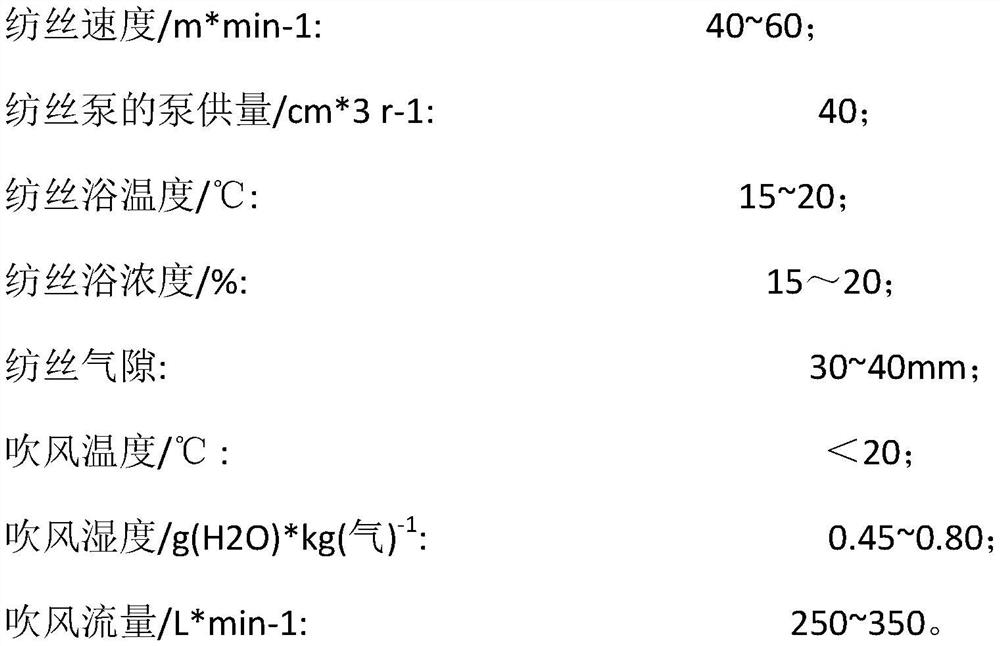

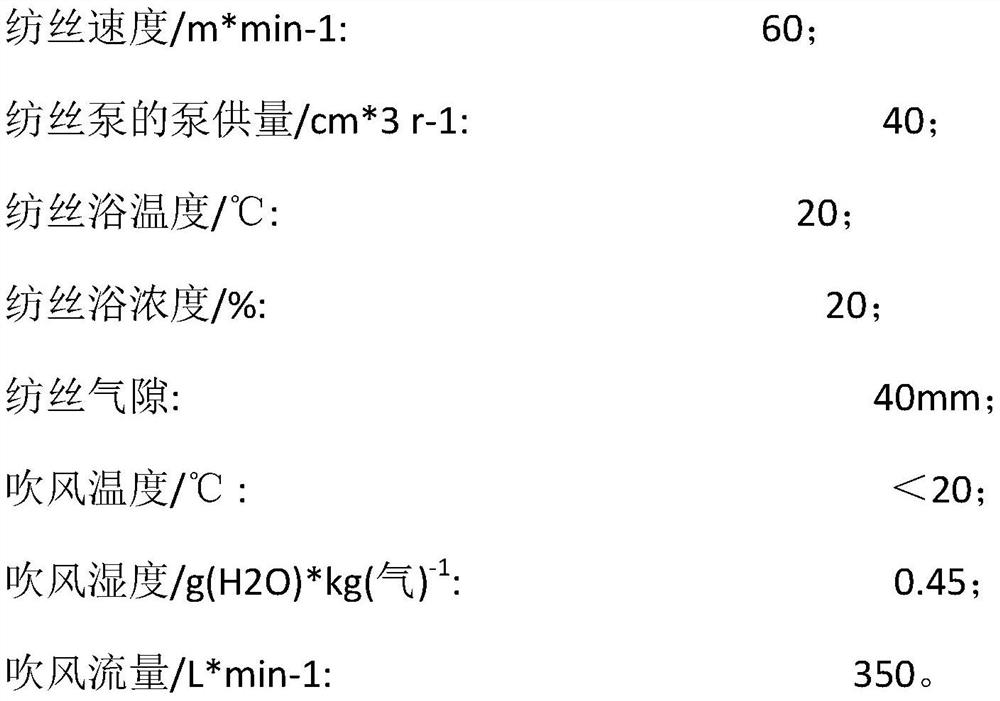

Preparation process of multifunctional polyester low-elasticity composite filament

InactiveCN110965165AVersatileImprove flame retardant performanceFlame-proof filament manufactureSpinning head liquid feederPolyesterPolymer science

The invention discloses a preparation process of a multifunctional polyester low-elasticity composite filament. The preparation process comprises the following steps that (1) blending of a pre-crystallized PET slice, a flame-retardant master batch, a hydrophilic master batch and an antibacterial master batch is carried out, and then extrusion granulation is performed to obtain a polyester blendedslice; (2) two parallel melt spinning processes are adopted, wherein one melt spinning processes is a POY melt spinning process, and the other is an FDY melt spinning process; the POY melt spinning process obtains polyester POY spinning, and the FDY melt spinning process obtains polyester FDY spinning; (3) the polyester FDY spinning is subjected to drafting to obtain polyester FDY drafting filaments; the polyester FDY drafting filaments and the polyester POY spinning are compounded to form composite filaments, and the composite filaments are shaped to obtain mixed filaments; and (4) the mixedfilaments are subjected to false twisting deformation to obtain the polyester low-elasticity composite filaments. The polyester low-elasticity composite filament not only has a high moisture absorption and sweat releasing effect, a flame retardant effect and an antibacterial effect, but also has high dyeing rate during dyeing, meanwhile, the filament has a fluffy and soft hand feeling, has certainelasticity, and expands the application range thereof.

Owner:苏州君辉纺织有限公司

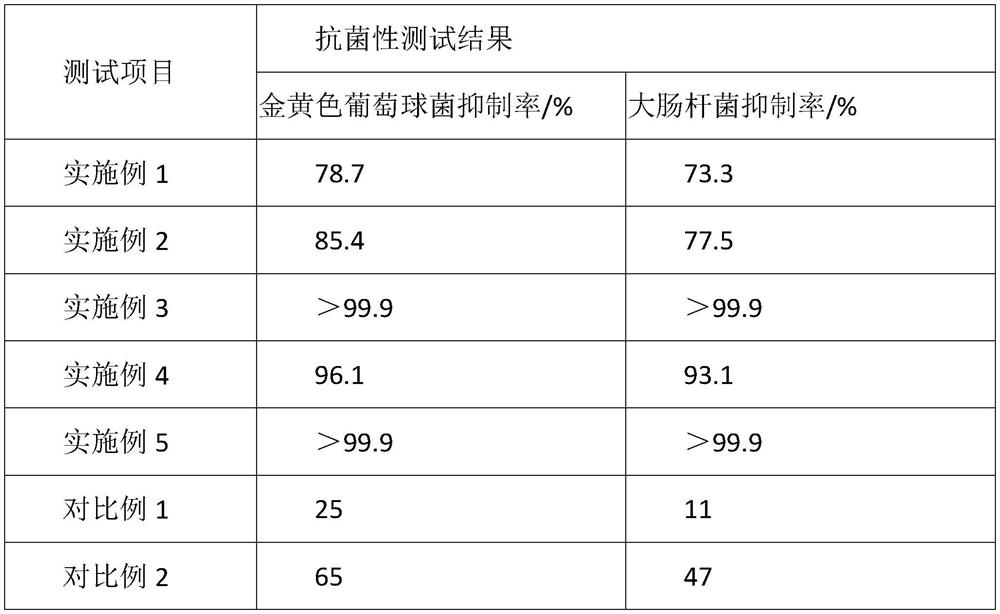

Lyocell fiber containing wormwood/radix isatidis/tea extract and preparation method thereof

InactiveCN112458564AImprove antibacterial propertiesGood biocompatibilityArtificial filaments from cellulose solutionsArtifical filament manufactureCellulosePolymer science

The invention provides Lyocell fiber containing wormwood / radix isatidis / tea and a preparation method thereof. The Lyocell fiber is characterized in that the Lyocell fiber is prepared by modifying porous molecular nests containing wormwood / radix isatidis / tea extract and polyvinyl alcohol (PVA), wherein the addition amount of the wormwood / radix isatidis / tea extract in the porous molecular nests in the production process accounts for 1-5wt% of the total amount of cellulose and polyvinyl alcohol raw materials, and the ratio of the addition amount of the polyvinyl alcohol (PVA) to the addition amount of cellulose is 1:9-1:1. The preparation method comprises the following steps that S1, plant extract is prepared; S2, the porous molecular nests are prepared; S3, a porous molecular nest PVA adhesive film is prepared; and S4, the composite Lyocell fiber is prepared. According to the preparation method, natural effective components of the wormwood, the radix isatidis and the tea with bacteriostatic, antiviral and antioxidant effects are introduced into the fiber, so that the fiber has good antibacterial effect and biocompatibility, and is very suitable for special textile materials for medical treatment and health care.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD +2

Solid phase polymerization technology of PET (polyethylene terephthalate) with high intrinsic viscosity

ActiveCN108084424AHigh initial modulusLow heat shrinkageMonocomponent polyesters artificial filamentSolid phasesNitrogen gas

A solid phase polymerization technology of PET (polyethylene terephthalate) with high intrinsic viscosity comprises the following steps: S1, a recycled PET material is pretreated and then molten, anda recycled PET melt is obtained; S2, the recycled PET melt is sent to a disc rotor type reactor or a cage-like reactor and heated to be molten, a PET melt is obtained, a tackifying nucleating agent isadded, the mixture is stirred uniformly, nitrogen is introduced at 240-260 DEG C, and the mixture is kept at the constant temperature for tackifying for 40 min; S3, the recycled PET melt obtained after tackifying polymerization is granulated, and regenerated PET granules are obtained and can be used in a spinning process. Recycled PET bottle chips or recycled pure PET fiber are used as raw materials, PET with high intrinsic viscosity is prepared through tackifying and solid phase polymerization, and the prepared product has high initial modulus, low heat shrinkage, fatigue resistance, water resistance and other excellent performance.

Owner:ANHUI DONGJIN RESOURCE REGENERATION SCI & TECH

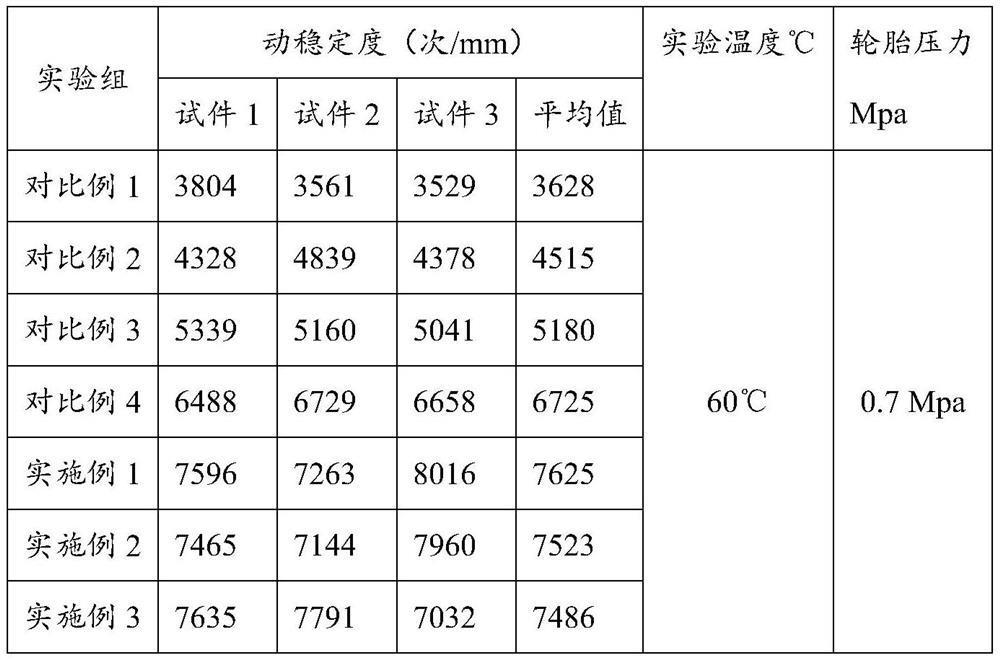

Composite fiber modified asphalt mixture with excellent performance, and preparation method thereof

The invention discloses a composite fiber modified asphalt mixture with excellent performance, and a preparation method thereof. The modified asphalt mixture is composed of, by weight, 4.5-6 parts of SBS modified asphalt, 8-12 parts of mineral powder, 90-100 parts of aggregate, and 0.2-0.4 part of a composite fiber stabilizer. The composite fiber stabilizer is composed of lignin fibers, polyacrylonitrile fibers and sepiolite fibers. The composite fiber stabilizer is prepared from the lignin fibers, the polyacrylonitrile fibers and the sepiolite fibers according to a certain ratio, the composite fiber stabilizer is added into the aggregate and then mixed with the SBS modified asphalt and the mineral powder to finally obtain the modified asphalt mixture. The composite fiber stabilizer is dispersed in the asphalt mixture and plays a role in complementing advantages and disadvantages in the aspect of improving the performance of the modified asphalt mixture, and the performance of the composite fiber stabilizer is greatly superior to that of the modified asphalt mixture and that of the modified asphalt mixture using a single fiber stabilizer; and great economic and social benefits are achieved in the aspects of reducing the construction cost, improving the use quality of the pavement and the like.

Owner:中电建路桥集团有限公司

Production method of PET industrial yarns

InactiveCN107338488AHigh degree of polymerizationImprove breaking strengthSpinning head liquid feederMonocomponent copolyesters artificial filamentYarnEngineering

The invention discloses a production method of PET industrial yarns. The method comprises the technological steps of (1) preparation of high-viscosity slices, (2) spinning, (3) drafting and (4) winding, wherein at the step (3), drafting, thermal shaping and loosening are conducted by six pairs of drafting rollers under a certain spinning speed. The invention aims to provide the production method of the PET industrial yarns. The method is used to prepare the PET industrial yarns with good shrinkage characters. The method is applicable to production of wide fabrics; and demands for film structure materials can be satisfied.

Owner:桐乡守敬应用技术研究院有限公司

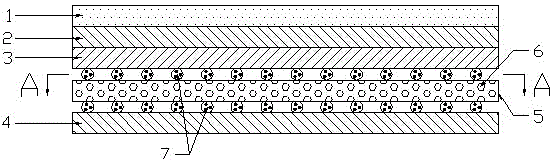

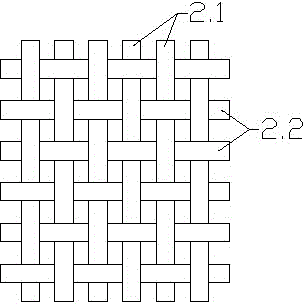

Odor-resistant and sun-resistant layered composite fabric

InactiveCN104249498AGood sun protectionImprove barrier propertiesSynthetic resin layered productsWoven fabricsEngineeringSilk fabric

The invention relates to odor-resistant and sun-resistant layered composite fabric. The odor-resistant and sun-resistant layered composite fabric sequentially comprises a sun-resistant layer (1), a fiber layer (2), a woven fabric layer (3), a polyurethane film layer (5) and a knitted fabric layer (4) from the outside to the inside, wherein a basal layer is compounded on the back surface of the knitted fabric layer; the basal layer comprises an infiltration-proof layer, and adopts the specific structure as follows: the infiltration-proof layer and a raising layer are compounded on the upper surface and the lower surface of the permeability-proof layer respectively; the infiltration-proof layer is made of silk fabric; the permeability-proof layer is made of an elastic rubber film. The odor-resistant and sun-resistant layered composite fabric has a sun-resistant function, has good air permeability, and has the characteristics of water resistance, air permeability, good elasticity and scratch resistance.

Owner:JIANGYIN ZEWAN TRADE

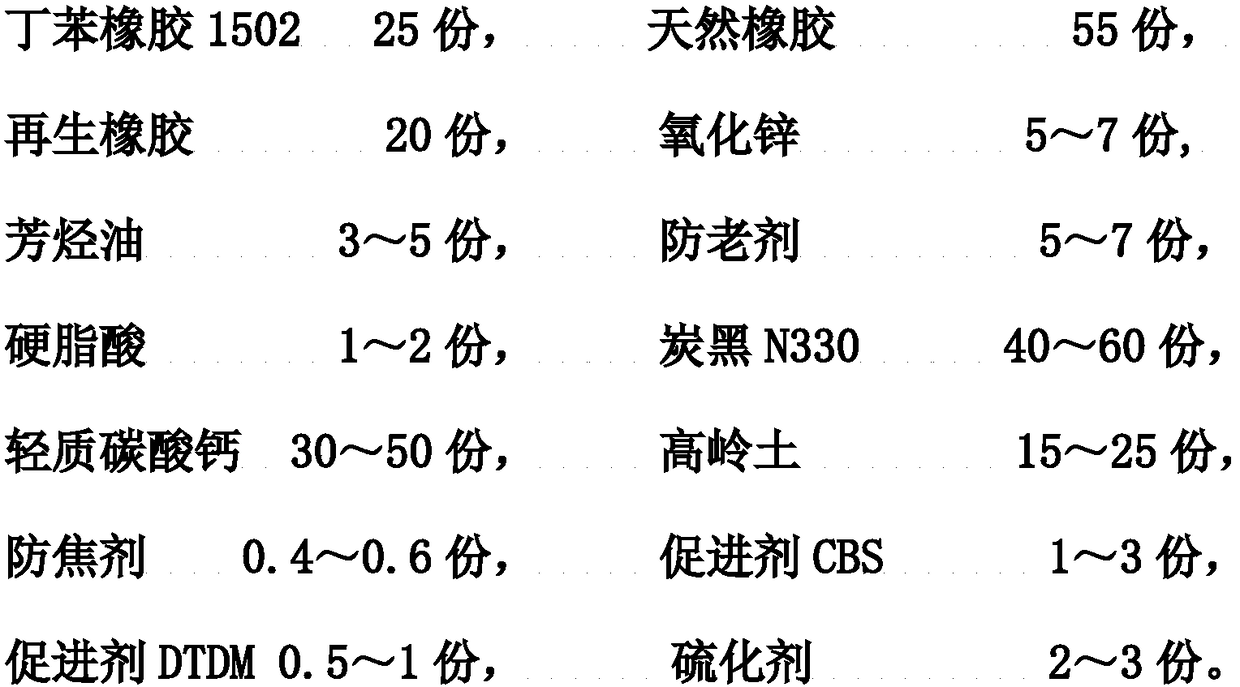

Joined E-belt

The invention relates to a joined E-belt. The joined E-belt comprises a connection layer and three V-belts which adhere to the connection layer through vulcanization; the connection layer is composedof an inner anti-tear rubber layer and an outer flexible polyester-mixed cotton cloth layer, and the anti-tear rubber layer and the flexible polyester-mixed cotton cloth layer are bonded through vulcanization; the anti-tear rubber layer is 2.5-4.5 mm thick, and the flexible polyester-mixed cotton cloth layer is 0.3-0.6 thick; each V-belt is composed of a rubber matrix and a framework arranged in the rubber matrix, the framework is formed by winding HMLS polyester fiber cotton ropes in the circumferential direction of the V-belt side by side, the diameter of the HMLS polyester fiber cotton ropes is 0.6-1.0 mm, and the winding density is 6-9 ropes per centimeter. The joined E-belt suitable for large-power transmission has the advantages of being high in strength, low in operation noise and long in service life.

Owner:ZHEJIANG FENFEI RUBBER & PLASTIC PROD CO LTD

Preparation method of funnel-web spider cobweb/silk fibroin composite film

The invention relates to a preparation method of a funnel-web spider cobweb / silk fibroin composite film, belonging to the field of silk fibroin film modification. The method aims to solve the problem of fewer crystalline regions, high breaking tendency under extremely low water content conditions, insufficient strength in a low-humidity environment, and poor compatibility with the common reinforcer in the silk fibroin film at present. The preparation method comprises the following steps: degumming silk, hydrolyzing to prepare a silk dissolved solution, drying to prepare a fibroin film, dissolving cobwebs in hexafluoroisopropanol, immersing the fibroin film in the cobweb protein in a plasma air atmosphere, and carrying out plasma grafting to prepare the funnel-web spider cobweb / silk fibroin composite film. The mechanical strength of the funnel-web spider cobweb / silk fibroin composite film is greatly enhanced, the fracture strength is enhanced by 30-35%, and the initial modulus is enhanced by 35-40%. The funnel-web spider cobweb / silk fibroin composite film is prepared by fully utilizing the silk and cobwebs, thereby saving the resources and being green and environment-friendly.

Owner:JIANGSU ZHENYU ENVIRONMENTAL PROTECTION TECH

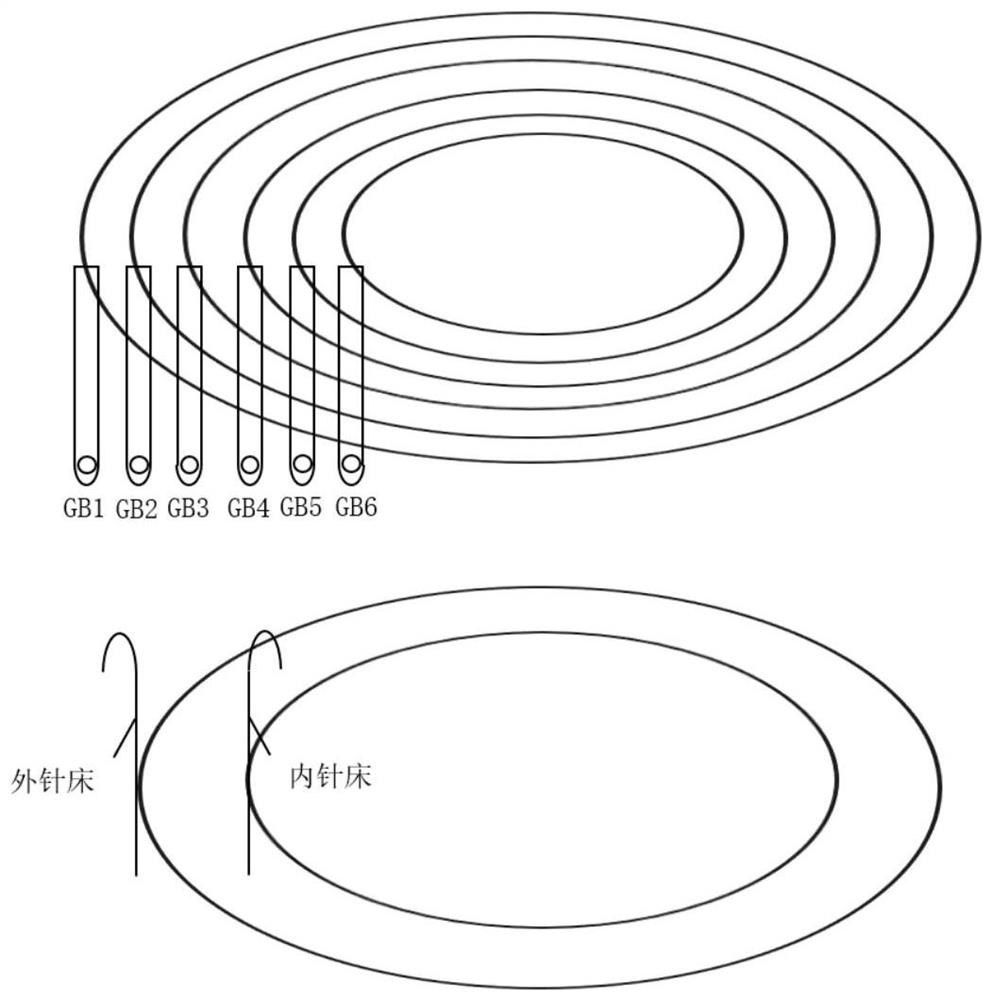

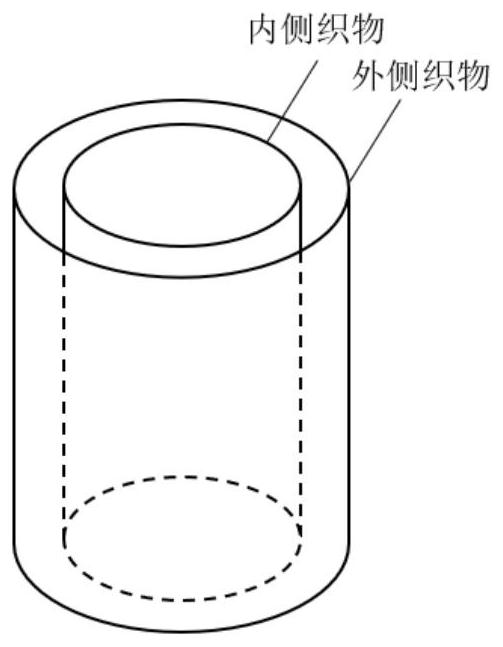

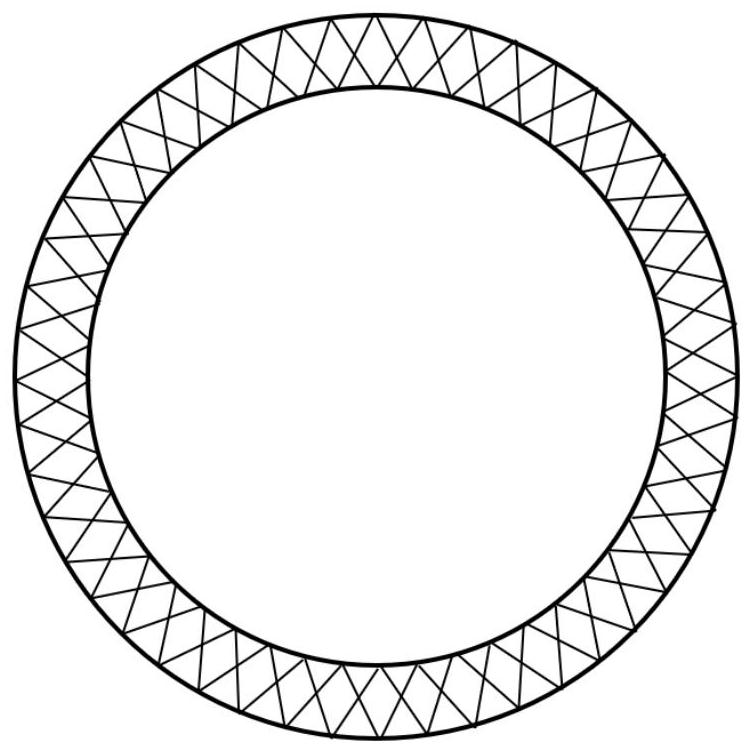

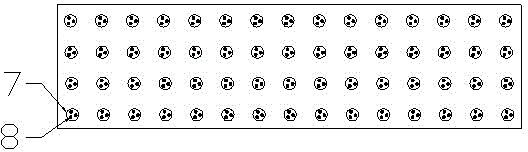

Cylindrical seamless warp-knitted interval protective cover and weaving method thereof

The invention discloses a cylindrical seamless warp-knitted interval protective cover and a weaving method thereof, and belongs to the technical field of warp-knitted fabric weaving. According to the weaving method of the cylindrical seamless warp-knitted spacer fabric, the cylindrical seamless warp-knitted spacer fabric is woven on a double-needle-cylinder warp knitting machine; the double-needle-cylinder warp knitting machine includes six annular guide bars which are sequentially arranged above a knitting needle from outside to inside, namely a guide bar GB1, a guide bar GB2 and a guide bar GB3 which are located on the upper portion of an outer needle cylinder and a guide bar GB4, a guide bar GB5 and a guide bar GB6 which are located on the upper portion of an inner needle cylinder. The double-needle-cylinder warp knitting machine is adopted for knitting, the special needle cylinder configuration and yarn guide needle arrangement mode is achieved, and the warp knitting seamless fabric with the structural effect and the functional effect is achieved; by utilizing the special configuration of the needle cylinders and a yarn guide needle, the inner side and the outer side of the fabric are of a cylindrical structure and are woven into a whole; and the inner side fabric and the outer side fabric are both of a mesh structure and are in one-to-one correspondence in position, and a tedious hole aligning procedure is not needed.

Owner:JIANGNAN UNIV

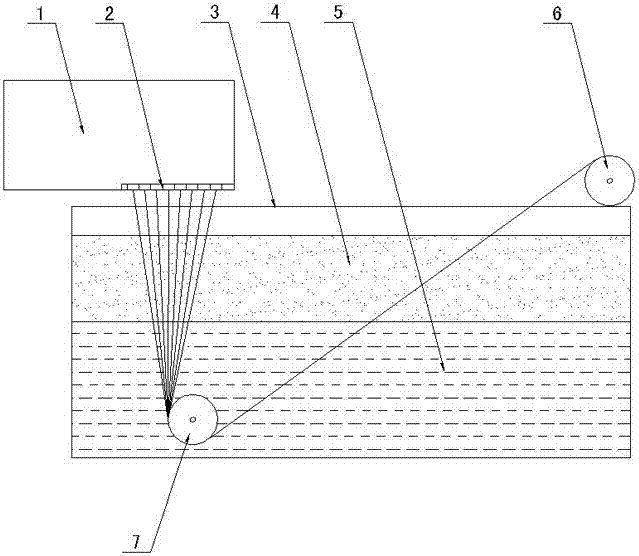

Method for solidifying and sizing gel-spun fibers in production process of ultra-high molecular weight polyethylene (UHMWPE) fibers

ActiveCN106978654AImprove performanceSimple processSynthetic polymer filament chemical after-treatmentParaffin oilsVolumetric Mass Density

The invention discloses a method for solidifying and sizing gel-spun fibers in a production process of ultra-high molecular weight polyethylene (UHMWPE) fibers. Cooling and sizing fluid in a cooling and sizing groove (3) is prepared from a lower phase separation accelerator (5) and an upper water seal (4), wherein the upper water seal (4) is used for cooling and sizing the gel-spun fibers; the lower phase separation accelerator (5) is used for accelerating phase separation so as to prompt paraffin oil on the surfaces of the gel-spun fibers to be separated out in an accelerating way, and forming porous and reticulated UHMWPE compact layers on the surfaces of the gel-spun fibers so as to increase the strength and initial modulus of the gel-spun fibers, enable the fineness consistency of finished products to be high and reduce strength fluctuation; the paraffin oil is separated out from the gel-spun fibers and is then dissolved in the phase separation accelerator so as to form lower mixed liquid, and the density of the lower mixed liquid is controlled to be greater than 1.1g / cm<3>; the gel-spun fibers are discharged out of the cooling and sizing groove (3), and the oil content of the gel-spun fibers is controlled to be within a range of 50-85%. After the structure is adopted, the method has the advantages of being simple in structure production process line, convenient in production and processing, high in strength and modulus, low in fineness dispersion, good in product performance consistency, and the like.

Owner:ZHEJIANG QIANXILONG SPECIAL FIBER

Production technology of crepe jacquard gold and silver fabric

The invention discloses a production technology of a crepe jacquard gold and silver fabric. The production technology includes warp yarn treatment and weaving, the temperature of a weaving workshop is25-26 DEG C, the humidity is 65-70%, the speed is 520 r / min, the rear beam height is 4 cm, the angle is 75 degrees, the loom tension of an upper weaving shaft is 600-670 kg*g, the loom tension of a lower weaving shaft is 250-300 kg*g, there is one 30# water pump, two 90# water pumps and two 40# nozzles, the water spraying angle is 85-90 degrees, the angle between water and waste edge yarn is 220-230 degrees, the angle between yarn and waste edge yarn is 240-255 degrees, the contact angle between the yarn and a reed is 280-295 degrees, and the leveling angle is 345 degrees. On the basis of digestion, absorption and improvement of equipment, the problem that warp is easy to break in the weaving process, the initial modulus of adopted metallic yarn is high, and the metallic yarn is not easyto stretch. Through optimization of the weaving process, the warp breakage rate is reduced, the weaving efficiency is improved, and the anti-wrinkle and non-ironing novel fabric with comfortable handfeeling and fine, smooth and soft texture is developed.

Owner:JIANGSU DESHUN TEXTILES

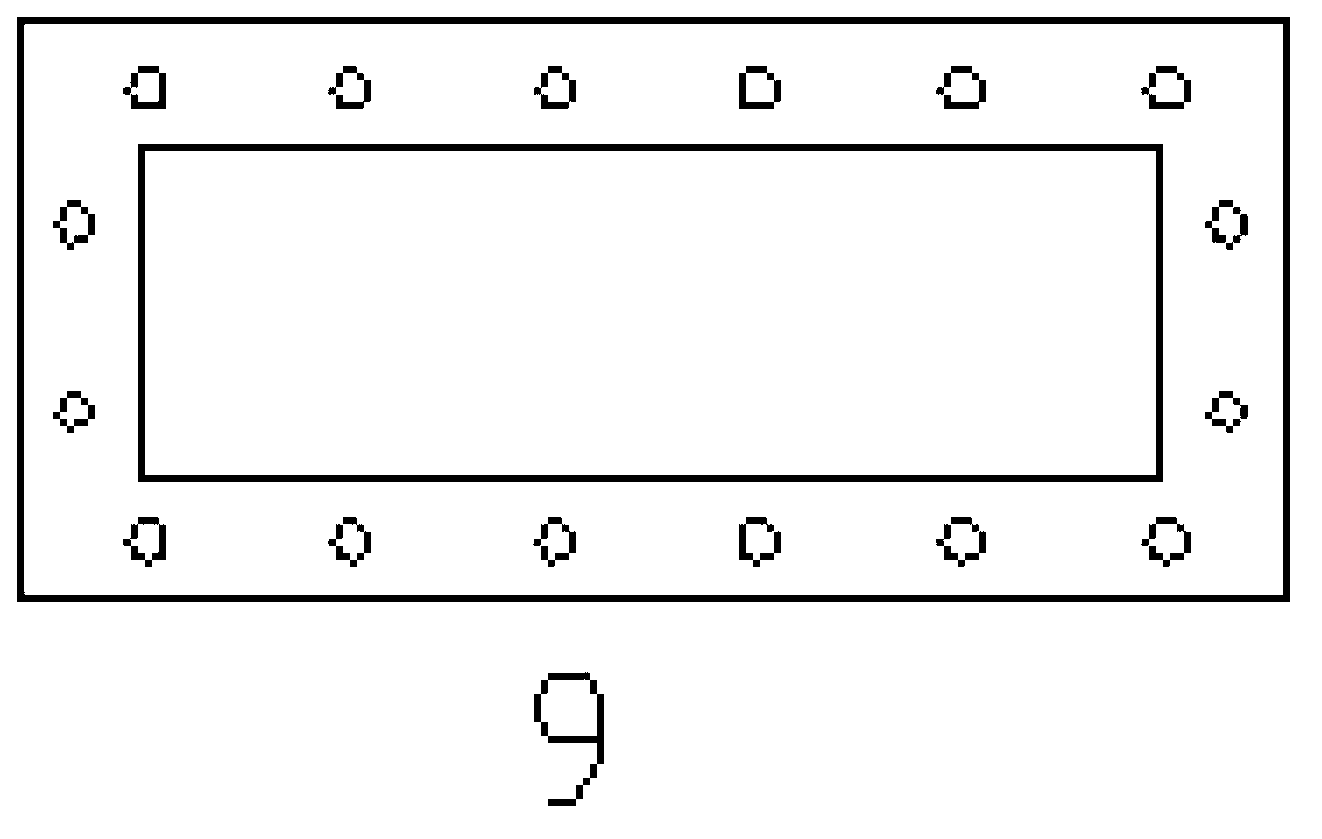

Polyimide fiber thermal drafting furnace and method

Provided is a polyimide fiber thermal drafting furnace and method. The polyimide fiber thermal drafting furnace comprises a hearth, an S-shaped inertia gas pipeline, a heating device, a heat insulation layer, a furnace body and an annular gas stream pipeline. The hearth comprises an inner hearth and a thermal treatment cavity. The thermal treatment cavity is arranged in the inner hearth. The S-shaped inertia gas pipeline is arranged between the inner hearth and the treatment cavity, and a plurality of gas outlet holes are arranged on the S-shaped inertia gas pipeline. The heating device is arranged on an outer wall of the hearth. The heat insulation layer is arranged on the outside of the heating device. The furnace body is arranged on the outside of the heat insulation layer. The annular gas stream pipeline is arranged at two ports of the hearth. In the polyimide fiber thermal drafting furnace, oxygen content in hearth gas can be lower than 10ppm, an inertia gas atmosphere in the hearth is guaranteed, polyimide fiber can not be subjected to oxygenolysis in a thermal drafting process, and the mechanical performance of the polyimide fiber is improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Polyimide fibre containing benzimidazole structure and preparation method thereof

InactiveCN101200822BEnhanced interactionHigh tensile strengthMonocomponent synthetic polymer artificial filamentImideFiber

The invention discloses polyimide fiber with benzimidazole structure, which is characterized in that the infrared spectrum of the fiber is provided with character absorption peaks of imide ring of 1776-1774cm<-1>, 1726-1722cm<-1> and 1378-1373cm<-1> within the wave number range of 1300-1800cm<-1> and N-H functional group absorption wide peaks in the imidazole structure within the wave number range of 3000-3750cm<-1>. The tensile strength is 0.73-1.53GPa. The initial modulus is 45.2-220GPa. The invention also provides a preparation method of the fiber. The fiber disclosed by the invention contains the benzimidazole structure with secondary amine hydrogen. Therefore, compared with PMDA-ODA polyimide fiber prepared with the same process, the tensile strength can be improved by nearly three times at the most, the initial modulus can be improved by more than twenty times at the most, and the heat resistance is further improved. The preparation method provided by the invention has the advantages of mature technology and easy control. The cost can be kept at a relative low level.

Owner:SINOSELEN HI TECH

Preparation method of high-intensity polyester fiber cord thread

The invention discloses a preparation method of a high-intensity polyester fiber cord thread. The preparation method includes the steps of: doubling polyester fiber filaments of which the surfaces are processed, twisting by using a twister with the twist of lower than 30 twist / meter, thermoforming, and twisting and molding by a closing machine; the prepared high-intensity polyester fiber cord thread is good in adhesiveness with rubber, high in intensity, good in heat-resistant performance, good in size stability and low in creep property.

Owner:TAIAN ROPE NET PLASTIC

Polypropylene, cotton fiber and collagen fiber blended yarn

InactiveCN103882577AImprove textureThe biggest advantage is the light textureYarnYarnPolymer science

The invention provides a polypropylene, cotton fiber and collagen fiber blended yarn. The polypropylene, cotton fiber and collagen fiber blended yarn comprises, by weight, 50-70 parts of polypropylene, 10-30 parts of cotton fibers and 10-30 parts of collagen fibers. The polypropylene, cotton fiber and collagen fiber blended yarn has the advantages that characteristics of the polypropylene, the cotton fibers and the collagen fibers are complementary to one another, and accordingly merits of the polypropylene, the cotton fibers and the collagen fibers can be played.

Owner:NANTONG MEIMING CHINLON

Polypropylene, jute fiber and copper ammonia fiber blended yarn

InactiveCN103882578AIn line with the trend of environmentally friendly clothingImprove textureYarnYarnCuprammonium rayon

The invention provides a polypropylene, jute fiber and copper ammonia fiber blended yarn. The polypropylene, jute fiber and copper ammonia fiber blended yarn comprises, by weight, 55-65 parts of polypropylene, 30-40 parts of jute fibers and 25-35 parts of copper ammonia fibers. The polypropylene, jute fiber and copper ammonia fiber blended yarn has the advantages that characteristics of the polypropylene, the jute fibers and the copper ammonia fibers are complementary to one another, and accordingly merits of the polypropylene, the jute fibers and the copper ammonia fibers can be played.

Owner:NANTONG MEIMING CHINLON

Method for manufacturing polyester double-point low-temperature high-strength adhesive lining cloth

InactiveCN101831809AReduce distortionGood dimensional stabilityFibre treatmentPolyesterHigh intensity

The invention relates to a method for manufacturing polyester double-point low-temperature high-strength adhesive lining cloth, comprising the following steps of: coating a punctiform high melting point polyester glue layer on treated base cloth; pouring low melting point polyester rubber powder when the high melting point polyester glue does not solidify completely; removing redundant low melting point polyester rubber powder which is not poured on the high melting point polyester glue line; and finally carrying out high-temperature molding. The method has the advantages that original color and luster of the cloth can be remained after bonding, and the cloth has better shape stability, washing size stability, moisture absorption and moisture conductivity and alkali resistance and solves the problem that fabric foaming of clothing occurs after daily washing for many times.

Owner:天津奔骜服饰有限公司

Fabric with characteristics of deodorizing, sun screening, good water resistance and good gas permeation

InactiveCN105415786AImprove waterproof performanceImprove breathabilitySynthetic resin layered productsProtective garmentPolyesterResin coating

The present invention relates to a fabric with characteristics of deodorizing, sun screening, good water resistance and good gas permeation. The fabric sequentially comprises a sun screening layer (1), a fiber layer (2), a woven fabric layer (3), a polyurethane film layer (5) and a knitted fabric layer (4) from outside to inside, wherein a base layer is compounded on the back surface of the knitted fabric layer, and comprises a polyester fabric layer, a resin coating material layer and a polyurethane coating, and the resin coating material layer and the polyurethane coating are sequentially coated on the polyester fabric layer from bottom to top. The fabric of the present invention has characteristics of sun screening, good gas permeation, and good water resistance.

Owner:顾方钟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com