Method for solidifying and sizing gel-spun fibers in production process of ultra-high molecular weight polyethylene (UHMWPE) fibers

An ultra-high molecular weight, polyethylene fiber technology, applied in the field of high-performance fibers, can solve the problems of poor product performance consistency, poor production stability, uneven fineness of finished products, etc., to achieve the effect of improved product performance, easy implementation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

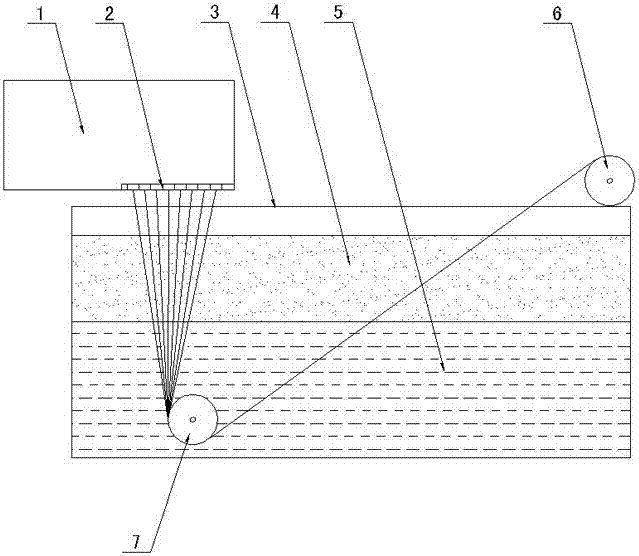

Image

Examples

Embodiment 1

[0030] Example 1: The ultra-high molecular weight polyethylene spinning stock solution with a relative molecular weight of 4 million enters the screw extruder, then enters the spinning box 1, and enters the cooling and shaping tank 3 through the spinneret assembly 2. The water seal 20cm of cooling sizing tank 3, the phase separation promotor 5 of cooling sizing tank 3 is methylene chloride, its effective thickness 30cm, 15 degrees of cooling temperature, the effective residence time of jelly silk in methylene chloride is 1 minute, The jelly yarn with an oil content of about 67% is formed, dropped into the barrel, and left to stand for 24 hours. After cold drawing-extraction-drying-multi-stage hot drawing-finished yarn winding, the final fiber strength is above 28CN / dtex , the modulus reaches above 1000 CN / dtex, and the fineness CV value is less than 1.5%.

Embodiment 2

[0031] Example 2: The ultra-high molecular weight polyethylene spinning stock solution with a relative molecular weight of 4 million enters the screw extruder, then enters the spinning box 1, and enters the cooling and shaping tank 3 through the spinneret assembly 2. The water seal 15cm of cooling shaping groove 3, the phase separation promotor 5 of cooling shaping groove 3 is tetrachlorethylene, and its effective thickness 30cm, cooling temperature 15 degree, the effective residence time of jelly silk in tetrachloroethylene is 40 seconds, The jelly yarn with an oil content of about 75% is formed, dropped into the barrel, and left to stand for 24 hours. After cold drawing-extraction-drying-multi-stage hot drawing-finished yarn winding, the final fiber strength is above 32CN / dtex , the modulus reaches above 1100 CN / dtex, and the fineness CV value is less than 1.3%.

Embodiment 3

[0032]Example 3: The ultra-high molecular weight polyethylene spinning stock solution with a relative molecular weight of 4.2 million enters the screw extruder, then enters the spinning box 1, and enters the cooling and shaping tank 3 through the spinneret assembly 2. The water seal 15cm of cooling shaping tank 3, the phase separation promotor 5 of cooling shaping tank 3 is trichlorotrifluoroethane, its effective thickness 35cm, 12 degrees of cooling temperature, the effective effect of jelly silk in trichlorotrifluoroethane The residence time is 35 seconds to form jelly filaments with an oil content of about 70%, fall into the barrel, and after standing for 24 hours, go through cold stretching-extraction-drying-multi-stage hot drawing-finished filament winding, and finally make fibers The strength is above 36CN / dtex, the modulus is above 1300 CN / dtex, and the fineness CV value is 0.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com