Joined E-belt

A combined belt and tear-resistant technology, which is applied in the direction of transmission belts, belts/chains/gears, mechanical equipment, etc., can solve the problems of increased bending stress of combined belts, cracks in the connecting layer, large working load and torque, etc. Achieve the effect of reducing bending stress, good dimensional stability and low running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

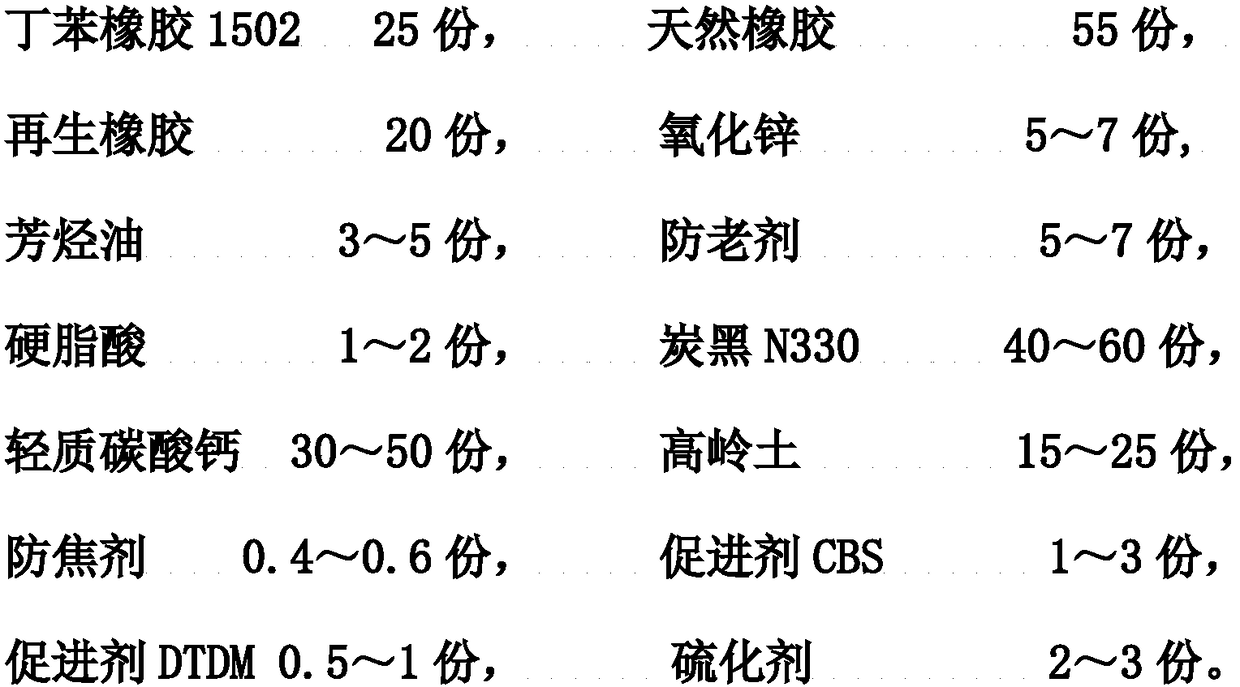

Embodiment 1

[0027] see figure 1 , the E-type combined belt of the present invention comprises a connecting layer 2, and three V-belts 1 bonded with the connecting layer 2 by vulcanization, and the E-shaped combined belt has a top width B of 38mm and a pitch BV of 32mm, the height H is 23mm, and the angle is 40°; the V-belt 1 is made from the following raw material components in parts by weight: styrene-butadiene rubber 1502 25 parts, natural rubber 55 parts, regenerated rubber 20 parts, zinc oxide 6 4 parts, aromatic hydrocarbon oil 4 parts, antioxidant 6 parts, stearic acid 2 parts, carbon black N330 50 parts, light calcium carbonate 35 parts, kaolin 20 parts, anti-scorch agent 0.5 parts, accelerator CBS 2 parts, accelerator DTDM0 .8 parts, 2.5 parts of vulcanizing agent, 2.5 parts of wear-resisting agent; Described connection layer 2 is made of the tear-resistant rubber layer 21 of inner layer and the flexible polyester-cotton cloth layer 22 of outer layer, tear-resistant rubber layer 2...

Embodiment 2

[0029] The difference from Example 1 is that in this example, the raw material components of the wear-resistant rubber belt are: 5 parts of zinc oxide, 3 parts of aromatic oil, 5 parts of anti-aging agent, 1.2 parts of stearic acid, carbon black 40 parts of N330, 30 parts of light calcium carbonate, 15 parts of kaolin, 0.4 parts of anti-scorch agent, 1 part of accelerator CBS, 0.5 parts of accelerator DTDM, 2 parts of vulcanizing agent, 2 parts of wear-resistant agent; the tear resistance of the inner layer of the connection layer 2 The thickness of the cracked rubber layer 21 is 2.5mm, and the raw material components of the tear-resistant rubber layer belt are: 4 parts of zinc oxide, 0.5 part of magnesium oxide, 3 parts of aromatic oil, 5 parts of anti-aging agent, and 10 parts of adhesive RF , 0.5 parts of stearic acid, 35 parts of carbon black N330, 20 parts of carbon black N660, 10 parts of white carbon black, 3 parts of resin 203, 3 parts of comaron, 0.2 parts of anti-scor...

Embodiment 3

[0031] The difference from Example 1 is that in this example, the raw material components of the wear-resistant rubber belt are: 7 parts of zinc oxide, 5 parts of aromatic oil, 7 parts of anti-aging agent, 1.5 parts of stearic acid, carbon black 60 parts of N330, 50 parts of light calcium carbonate, 25 parts of kaolin, 0.6 parts of anti-scorch agent, 3 parts of accelerator CBS, 1 part of accelerator DTDM, 3 parts of vulcanizing agent, 3 parts of wear-resistant agent; the tear resistance of the inner layer of the connection layer 2 The thickness of the cracked rubber layer 21 is 4.5mm, and the raw material components of the tear-resistant rubber layer belt are: 6 parts of zinc oxide, 1.5 parts of magnesium oxide, 5 parts of aromatic oil, 7 parts of anti-aging agent, and 15 parts of adhesive RF , 0.8 parts of stearic acid, 45 parts of carbon black N330, 25 parts of carbon black N660, 15 parts of white carbon black, 5 parts of resin 203, 5 parts of solid Marone, 0.5 parts of anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com