Production technology of sound absorbing cotton formed by compounding short fiber and melt-blowing

A composite molding and production process technology, applied in the field of non-woven fabrics, can solve the problems of sound absorption, sound insulation effect, low resilience and bulkiness, poor fiber compression resistance, etc., and achieve perfect compression resilience and air permeability Good, good sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

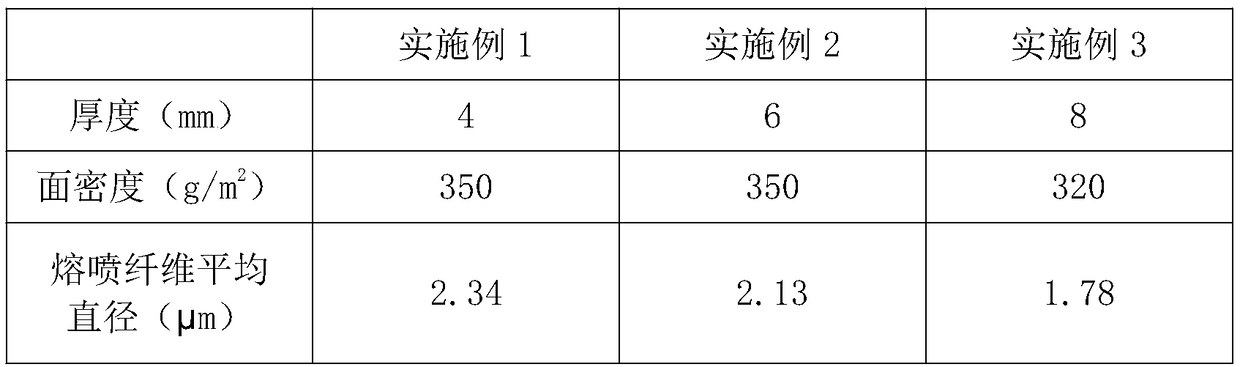

Embodiment 1

[0029] 1. Take three-dimensional crimped polyester hollow staple fibers and flame-retardant polyester staple fibers, with a diameter of 25 μm and a length of 60 mm, and first comb them into a single fiber state.

[0030] 2. Put the combed short fiber into the feeding roller of the opening device, the feeding speed is 5.8m / min, the width of the feeding opening is 1m, and it is opened twice through rough opening and fine opening.

[0031] 3. It is fed into the hot air flow of the melt-blown process through the nozzle pipe to form a uniformly dispersed mixed fiber flow, which is gathered in the middle of the double rollers under the action of stretching air, and the upper and lower surfaces are bonded to non-woven fabrics to produce melt-blown Composite material, in which the non-woven fabric is processed from polypropylene with a thickness of 0.15mm and an areal density of 15g / m 2 .

[0032] 4. Take PP polymer slices with a melt index of 150g / min and pass through a screw extrud...

Embodiment 2

[0037] 1. Take three-dimensional crimped polyester hollow staple fibers and flame-retardant polyester staple fibers, with a diameter of 25 μm and a length of 60 mm, and first comb them into a single fiber state.

[0038] 2. Put the combed short fiber into the feeding roller of the opening device, the feeding speed is 6.0m / min, the width of the feeding opening is 1.2m, and it is opened twice through rough opening and fine opening.

[0039] 3. It is fed into the hot air flow of the melt-blown process through the nozzle pipe to form a uniformly dispersed mixed fiber flow, which is gathered in the middle of the double rollers under the action of stretching air, and the upper and lower surfaces are bonded to non-woven fabrics to produce melt-blown Composite material, in which the non-woven fabric is processed from polypropylene with a thickness of 0.15mm and an areal density of 15g / m 2

[0040] 4. Take PP polymer slices with a melt index of 165g / min and pass through a screw extrud...

Embodiment 3

[0045] 1. Take three-dimensional crimped polyester hollow staple fibers and flame-retardant polyester staple fibers, with a diameter of 25 μm and a length of 60 mm, and first comb them into a single fiber state.

[0046] 2. Put the combed short fiber into the feeding roller of the opening device, the feeding speed is 6.2m / min, the width of the feeding opening is 1.2m, and the fiber is opened twice through rough opening and fine opening.

[0047] 3. It is fed into the hot air flow of the melt-blown process through the nozzle pipe to form a uniformly dispersed mixed fiber flow, which is gathered in the middle of the double drum under the action of stretching air, and the upper and lower surfaces are bonded to non-woven fabrics to obtain melt-blown Composite material, in which the non-woven fabric is processed from polypropylene with a thickness of 0.15mm and an areal density of 15g / m 2 .

[0048] 4. Take PP polymer slices with a melt index of 180g / min and pass through a screw e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com