Preparation process of multifunctional polyester low-elasticity composite filament

A polyester low-elasticity and preparation technology, which is applied in the field of preparation of multi-functional polyester low-elastic composite yarns, can solve the problems of limited air permeability and hygroscopicity, poor air permeability, poor hygroscopicity, high modulus of polyester fibers, etc., and achieve dyeing performance Stability, warmth retention, low elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

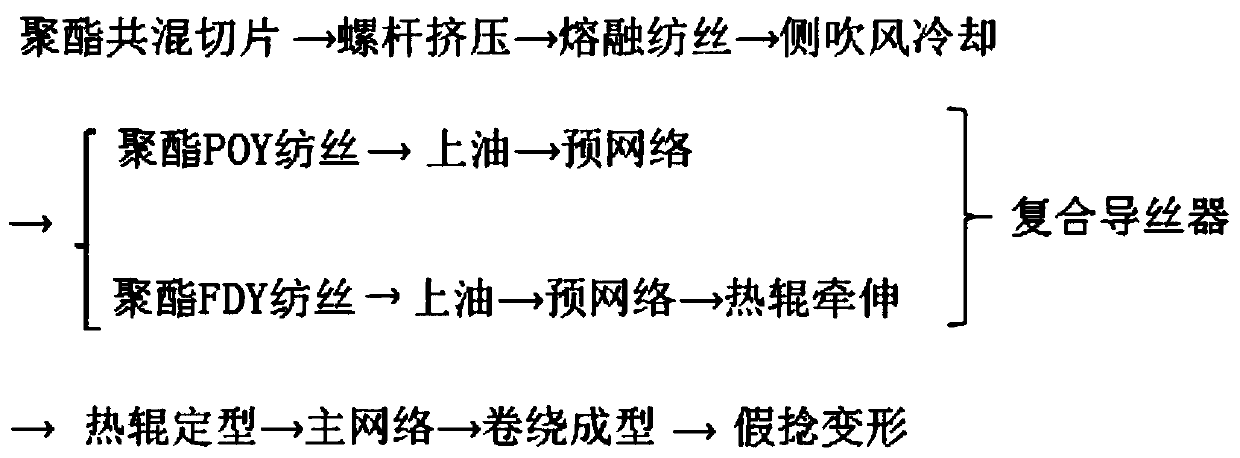

[0028] Such as figure 1 Shown, a kind of preparation technology of multifunctional polyester low-elastic composite yarn comprises the following steps:

[0029] (1) Preparation of polyester blend chips

[0030] Pass the polyester wet slice through the wet slice silo and enter the pre-crystallization stage. The pre-crystallization temperature is 170°C, and the pre-crystallization time is 14 minutes. After pre-crystallization, pre-crystallized PET slices are obtained, and then 85% of the pre-crystallized PET slices are , 5% flame retardant masterbatch, 5% hydrophilic masterbatch and 5% antibacterial masterbatch were dried separately, the drying temperature was 180°C, and the drying time was 5h. mixed, and then extruded and granulated to obtain polyester blended chips;

[0031] (2) Melt spinning

[0032] Two parallel melt-spinning processes are adopted, one of which is POY melt-spinning process, and the other is FDY melt-spinning process; the melt-spinning process is: feeding p...

Embodiment 2

[0038] A preparation process of multifunctional polyester low-elastic composite yarn, comprising the following steps:

[0039] (1) Preparation of polyester blend chips

[0040] Pass the polyester wet chip through the wet chip silo and enter the pre-crystallization stage. The pre-crystallization temperature is 173°C and the pre-crystallization time is 15 minutes. After pre-crystallization, pre-crystallized PET chips are obtained, and then 88% of the pre-crystallized PET chips are , 4% flame retardant masterbatch, 4% hydrophilic masterbatch and 4% antibacterial masterbatch were dried separately, the drying temperature was 182°C, and the drying time was 4h. mixed, and then extruded and granulated to obtain polyester blended chips;

[0041] (2) Melt spinning

[0042] Two parallel melt-spinning processes are adopted, one of which is POY melt-spinning process, and the other is FDY melt-spinning process; the melt-spinning process is: feeding polyester blend chips into Screw extrud...

Embodiment 3

[0048] A preparation process of multifunctional polyester low-elastic composite yarn, comprising the following steps:

[0049] (1) Preparation of polyester blend chips

[0050] Pass the polyester wet slice through the wet slice silo and enter the pre-crystallization stage. The pre-crystallization temperature is 175°C and the pre-crystallization time is 12 minutes. After pre-crystallization, pre-crystallized PET slices are obtained, and then 90% of the pre-crystallized PET slices are , 2% flame retardant masterbatch, 5% hydrophilic masterbatch and 3% antibacterial masterbatch were dried separately, the drying temperature was 185°C, and the drying time was 4h. mixed, and then extruded and granulated to obtain polyester blended chips;

[0051] (2) Melt spinning

[0052] Two parallel melt-spinning processes are adopted, one of which is POY melt-spinning process, and the other is FDY melt-spinning process; the melt-spinning process is: feeding polyester blend chips into Screw extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com