Nanometer composite material and preparation method thereof, vulcanized rubber and applications thereof

A technology of nanocomposite materials and vulcanized rubber, which is applied in the fields of fibrous fillers, transportation and packaging, and treatment of dyed organic silicon compounds. It can solve the problems of poor processing performance, large dynamic heat generation, and high cost, and achieve excellent wear resistance. Wet skid resistance, rolling resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

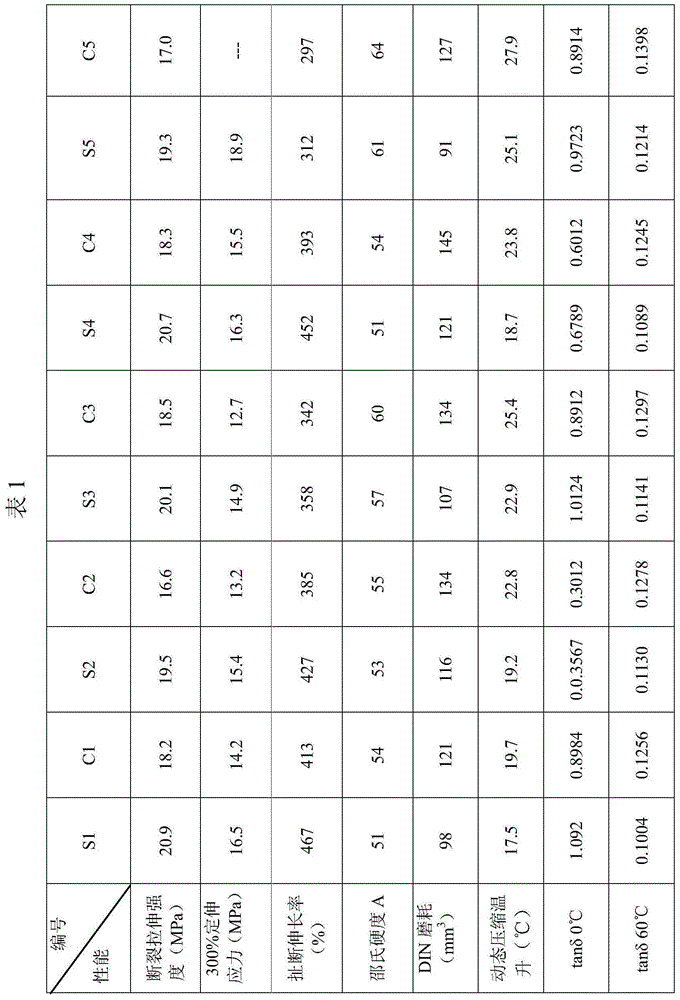

Examples

preparation example Construction

[0028] The present invention also provides the preparation method of above-mentioned nano composite material, described method comprises the following steps:

[0029] (1) white carbon black and graphene oxide are mixed in water, and the mixture obtained is spray-dried to obtain a solid;

[0030] (2) The solid obtained in step (1) is mixed with a surface modifier, and then dried.

[0031] According to the present invention, the white carbon black, graphene oxide and surface modifier and the weight ratio of white carbon black, graphene oxide and surface modifier are the same as above.

[0032] In step (1), the weight ratio of the white carbon black, graphene oxide and water is not particularly limited, as long as the white carbon black, graphene oxide and water can be uniformly mixed to form a suspension. Preferably, the weight ratio of the white carbon black, graphene oxide and water is 1:(0.03-0.10):(14-30), more preferably 1:(0.03-0.07):(18-27).

[0033] In step (1), the wa...

Embodiment 1

[0062] This example is used to illustrate the nanocomposite provided by the present invention and its preparation method and the vulcanized rubber provided by the present invention.

[0063] (1) Mix 40 g of white carbon black, 1.2 g of graphene oxide and 780 ml of deionized water, and mechanically stir at 45° C. for 3.5 hours at a stirring speed of 420 rpm to obtain a suspension. Then, the obtained suspension was spray-dried to obtain 40.6 g of solid powder. Wherein, the spray drying speed is 22000 rpm, and the spray drying temperature is 80°C.

[0064] (2) Dissolve 2.0g of methacrylic acid in 40ml of acetone, spray evenly on the surface of the solid powder obtained in step (1), and dry at 90°C for 3.5 hours to obtain a modified white carbon black-graphene oxide nanocomposite Material F1. After removing unreacted methacrylic acid, the nanocomposite F1 was measured by infrared spectroscopy (IR), and in the IR spectrum 1635cm -1 and 2960cm -1 The absorption peaks attributed ...

Embodiment 2

[0071] This example is used to illustrate the nanocomposite provided by the present invention and its preparation method and the vulcanized rubber provided by the present invention.

[0072] (1) Mix 50 g of white carbon black, 2 g of graphene oxide and 1050 ml of deionized water, and mechanically stir at 30° C. at a stirring speed of 380 rpm for 2.5 hours to obtain a suspension. Then, the obtained suspension was spray-dried to obtain 50.4 g of solid powder. Wherein, the speed of spray drying is 18000 rpm, and the temperature of spray drying is 85°C.

[0073] (2) Dissolve 3g of 3-mercaptopropionic acid in 45ml of acetone, spray evenly on the surface of the solid powder obtained in step (1), and dry at 95°C for 2.5 hours to obtain a modified silica-graphene oxide nanocomposite Material F2. After removal of unreacted 3-mercaptopropionic acid, the nanocomposite F2 was measured by infrared spectroscopy, 2560cm in the IR spectrum -1 Absorption peaks attributable to sulfhydryl gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com