Nickel-cobalt-based high-temperature alloy with favorable structure stability and easiness for processing

A high-temperature alloy and stability technology, which is applied in the field of nickel-based high-temperature alloys, can solve the problems of reducing the thermal processing performance of alloys, and achieve the effects of improving microstructure stability, excellent machinability, and inhibiting the coarsening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention adopts vacuum induction furnace melting, casts into the alloy shown in Table 1 with chemical composition.

[0038] Table 1 The chemical composition (wt.%) of alloy of the present invention and comparative alloy

[0039]

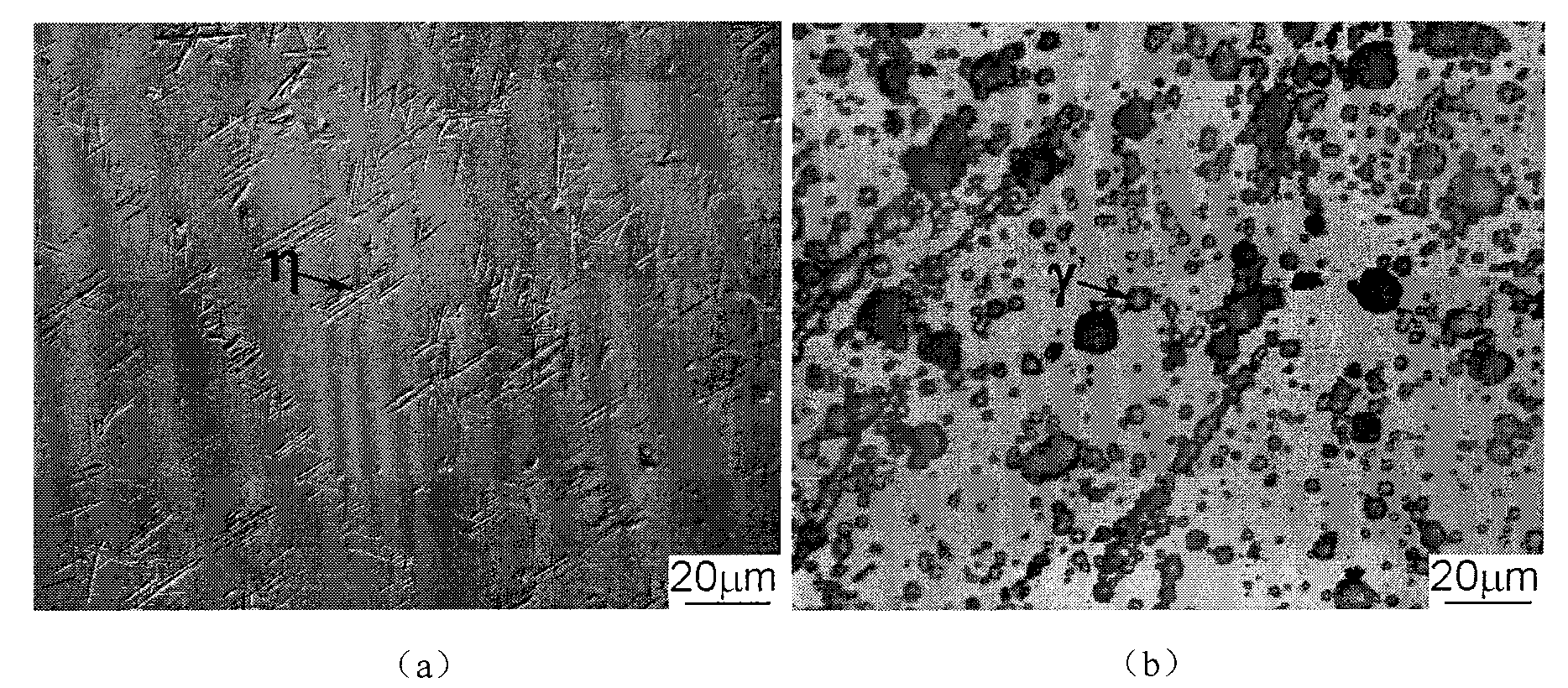

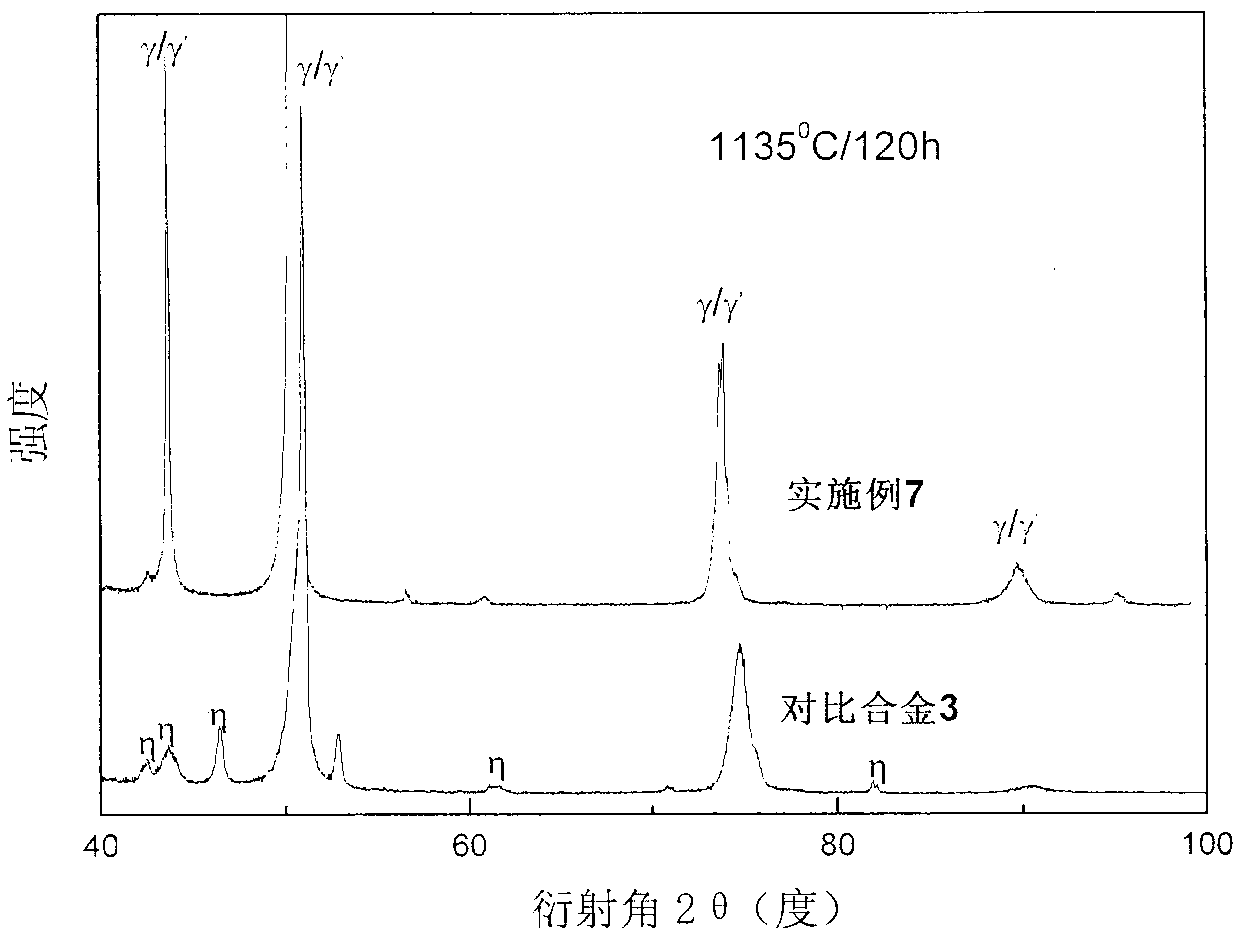

[0040] The alloy of the invention has good structural stability, mainly because the precipitation of η phase is suppressed by controlling the Ru content in the alloy of the invention. like figure 1 As shown, a large amount of η phase exists in the grain boundary and in the grain of Ru-free comparative alloy 3, while in the alloy example 7 of the present invention containing Ru, no η phase is observed. In addition, the structural stability of the alloys of the invention and comparative alloys after heat treatment was also evaluated. The alloy of the invention and the comparison alloy are quenched in water at 1200°C / 1h, and then aged in the temperature range of 700°C to 1200°C for 1 to 1000 hours. The X-ray diffraction pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com