High-temperature alloy with low stacking fault energy, structural part and application of high-temperature alloy

A technology of high-temperature alloys and structural parts, which is applied in the direction of supporting components of blades, engine components, machines/engines, etc., to achieve excellent process performance, improve process performance, and improve high-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

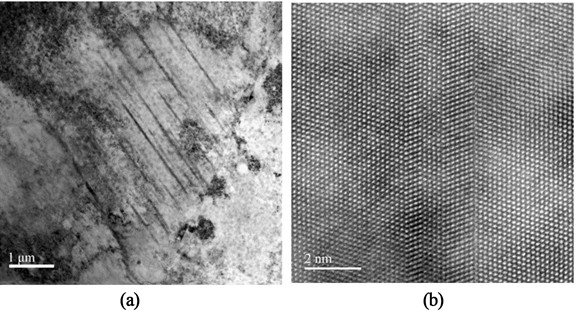

Image

Examples

preparation example Construction

[0090] In a specific embodiment of the present invention, the preparation method of the forging comprises:

[0091] (a) distributing ingredients according to the low-stacking-fault-energy high-temperature alloy composition, and performing melting to obtain ingots;

[0092] (b) After homogenizing the ingot, forging and forming, and then performing heat treatment.

[0093] In a specific embodiment of the present invention, the conditions of the homogenization treatment include: heat preservation treatment at 1100-1150°C for 24-36 hours, and heat preservation treatment at 1170-1190°C for 36-48 hours.

[0094] In a specific embodiment of the present invention, the preparation method of the casting comprises:

[0095] According to the high-temperature alloy composition with low stacking fault energy, vacuum induction melting is carried out, heat treatment is carried out after casting, and castings are obtained.

[0096] In a specific embodiment of the present invention, the prepa...

Embodiment 1~7

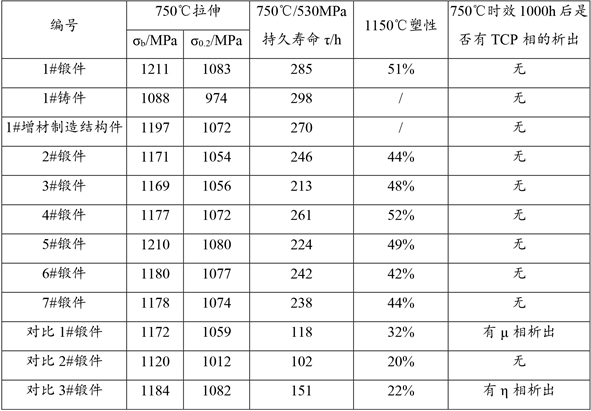

[0104] Examples 1 to 7 respectively provide superalloys 1# to 7# and their preparation methods. The measured composition of superalloys is shown in Table 1. In addition, the alloy preparation methods of Comparative 1# to Comparative 3# are the same as those of Examples 1 to 7, except that the composition of the superalloy is different.

[0105] A method for preparing a superalloy, comprising the steps of:

[0106] (1) Weigh a certain amount of smelting raw materials that can obtain C, Co, Cr, W, Al, Ti, Nb, Ta, Mo, B, Zr, Fe, Mg and Ni elements according to the element ratio principle of superalloy, Including the base material and volatile elements, the base material is placed in the crucible of the vacuum induction furnace, and the volatile elements are placed in the feeder, and then vacuumed to start vacuum induction melting. When the vacuum degree is less than 3Pa, power on to heat up, and then refine for 40 minutes after full melting (gradually reduce the power) until the...

Embodiment 8

[0112]This embodiment provides a high-temperature alloy casting with low stacking fault energy, and its preparation method includes the following steps:

[0113] Referring to the element ratio principle of superalloy 1# in Example 1, the vacuum induction melting technology was used to cast according to a specific mold, followed by heat treatment to obtain a superalloy casting. The heat treatment conditions are: after 1100~1150°C for 2 hours, air cool to room temperature, then after 1050~1100°C for 2 hours, air cool to room temperature, then heat to 600~680°C for 20 hours, air cool, then heat to 750~800°C Cool to room temperature in air after 10 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com