Gamma'-phase intensified cobalt-based superalloy and preparation method thereof

A high-temperature alloy and cobalt-based technology, which is applied in the field of high-temperature alloys, can solve the problems of limiting the application of new cobalt-based superalloys, difficult and easy precipitation of secondary equivalence, and achieve good application prospects and high temperature bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

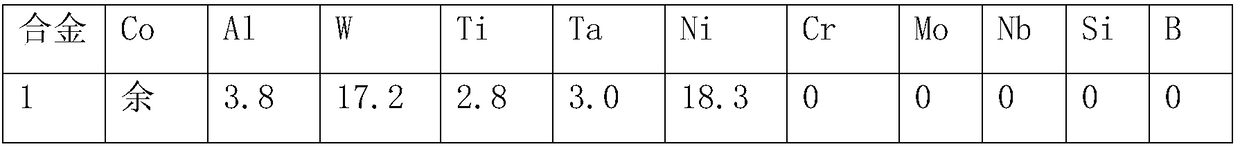

Embodiment 1

[0024] Weigh high-purity elemental metals such as Co, Al, W, Ti, Ta and Ni according to the composition shown in alloys 1 to 3 in Table 1; place the metal raw materials weighed above in a vacuum arc melting furnace, The alloy is smelted in a protective atmosphere, and the current of the melting arc is controlled at 350A. After the alloy is completely liquefied, it is kept for 60 seconds, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the above smelting steps 12 times to ensure the uniformity of the alloy, and finally obtain a cobalt-based superalloy ingot; in a high-purity Ar protective atmosphere, keep the above-prepared cobalt-based superalloy ingot at a solution temperature of 1300°C 24 hours, air cooling; then heat preservation at an aging temperature of 900°C for 50 hours, quenching and cooling, to obtain a γ' phase-strengthened cobalt-based superalloy.

Embodiment 2

[0026] Weigh high-purity elemental metals such as Co, Al, W, Ti, Ta and Ni according to the composition shown in alloys 4 to 6 in Table 1; place the metal raw materials weighed above in a vacuum arc melting furnace, The alloy is smelted in a protective atmosphere, and the current of the melting arc is controlled at 300A. After the alloy is completely liquefied, it is kept for 30 seconds, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the above steps 8 times to ensure the uniformity of the alloy, and finally obtain a cobalt-based superalloy ingot. In a protective atmosphere of high-purity Ar, the above-prepared cobalt-based superalloy ingot was kept at a solid solution temperature of 1270°C for 24 hours, then air-cooled; then kept at an aging temperature of 1150°C for 50 hours, quenched and cooled to obtain γ 'Phase strengthening of cobalt-based superalloys.

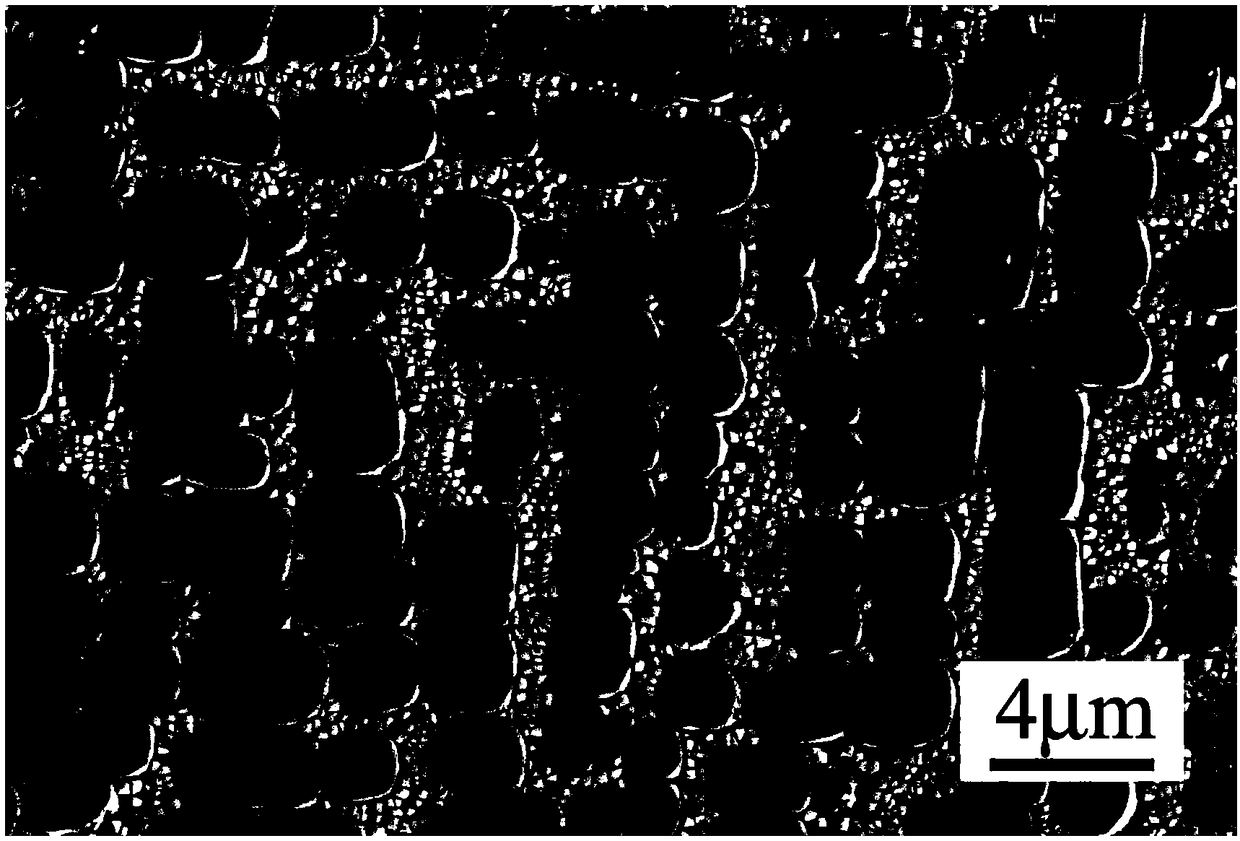

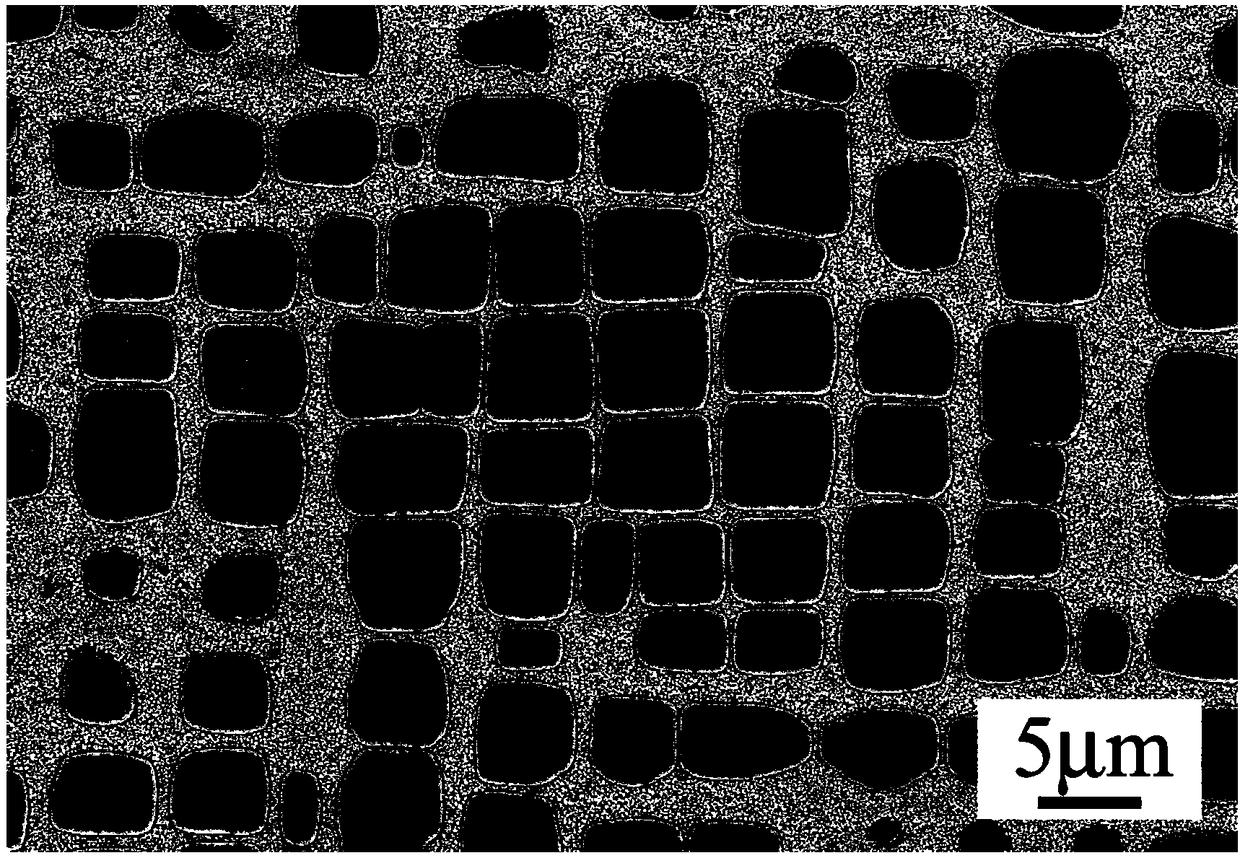

[0027] Such as figure 1 As shown in the scanning electron micrograph of...

Embodiment 3

[0030] Weigh high-purity elemental metals such as Co, Al, W, Ti, Ta, Ni and Cr according to the composition shown in alloys 7 to 8 in Table 1; place the above-mentioned weighed metal raw materials in a vacuum arc melting furnace, The alloy is smelted in a protective atmosphere of pure Ar, and the current of the melting arc is controlled at 280A. After the alloy is completely liquefied, it is kept for 30 seconds, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the above steps 8 times to ensure the uniformity of the alloy, and finally obtain a cobalt-based superalloy ingot. In a protective atmosphere of high-purity Ar, the cobalt-based superalloy ingot prepared above was kept at a solution temperature of 1250°C for 24 hours, then air-cooled; then kept at an aging temperature of 1000°C for 50 hours, quenched and cooled to obtain γ 'Phase strengthening of cobalt-based superalloys.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com