Turbine blade adopting buckle fixing type ceramic armor

A turbine blade, fixed technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of low cooling effect and large cooling air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

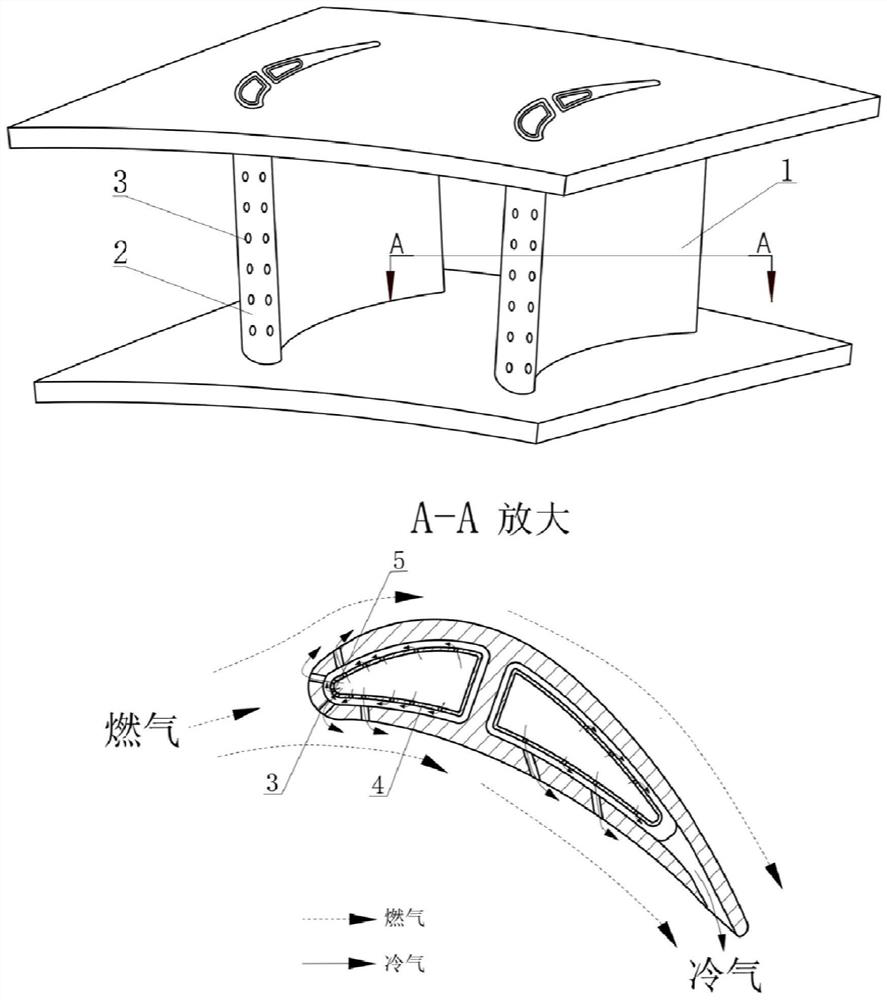

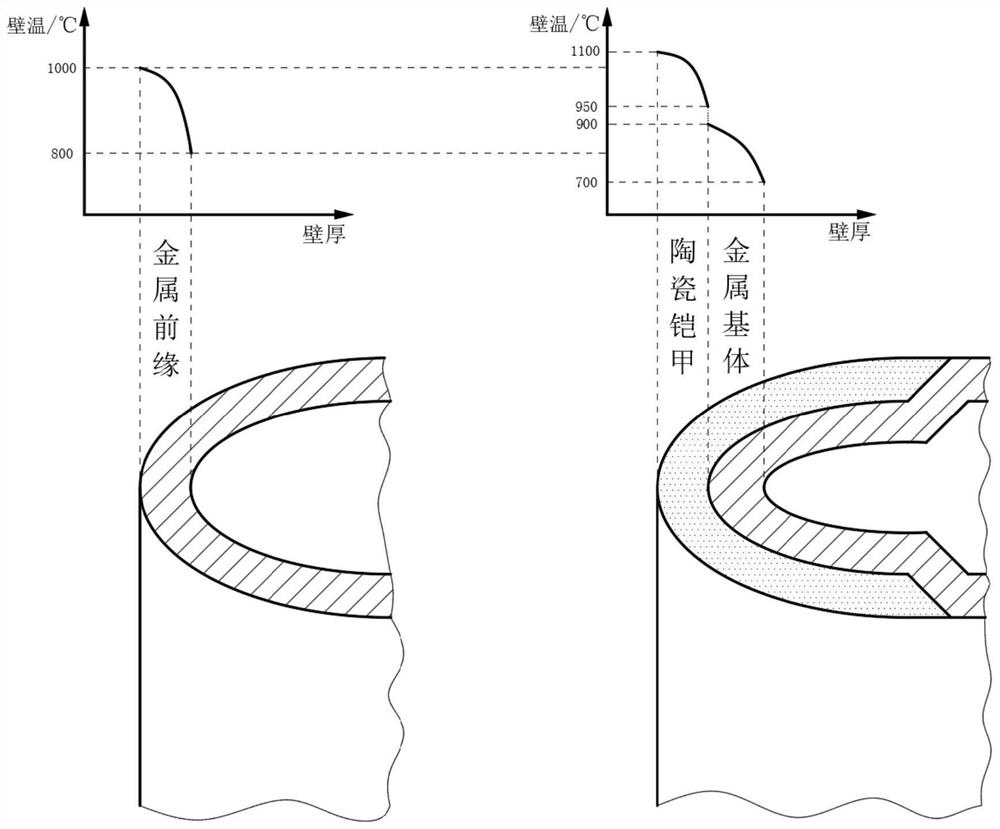

Method used

Image

Examples

Embodiment 1

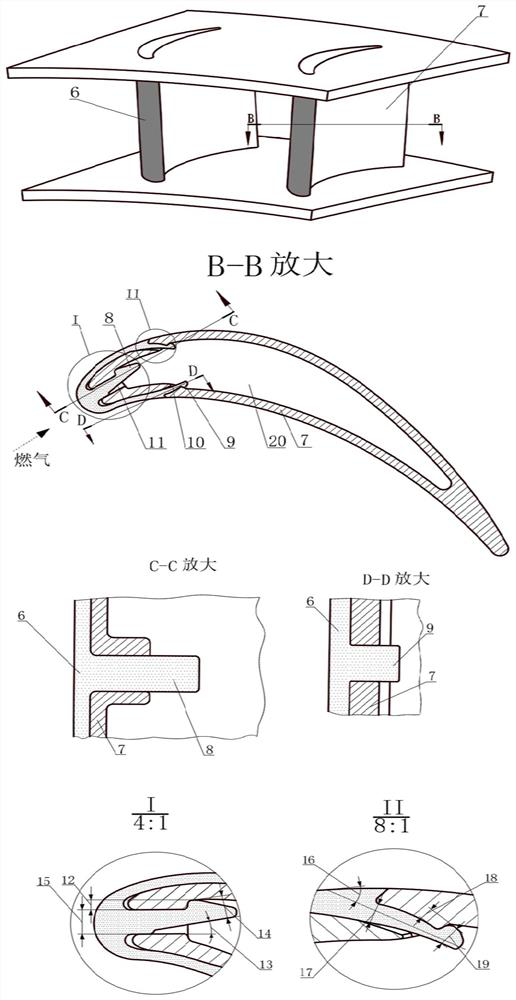

[0024] see figure 2 , the present embodiment provides a turbine blade using a leading edge fixing buckle 8 facing the blade back and an outer buckle-type blade body fixing buckle 9 . Its structure includes a leading edge 6 of ceramic matrix composite material and a metal matrix 7 . It is connected through the fixing buckle on the leading edge 6 of the ceramic matrix composite material and the corresponding fixing groove on the metal base 7 . In detail, the heads of the leading edge fixing buckle 8 and the blade body fixing buckle 9 are both facing the back of the blade, and the direction of the leading edge fixing buckle 8 is parallel to the incoming gas. The typical dimensions of this embodiment are: front edge fixed buckle boss width W 1 =0.5mm; front edge fixed buckle head inclination angle ∠θ 1 =15°; Width of front edge fixed buckle head W 2 =1.4mm; front edge fixed buckle width W 3 = 1.4 mm. The angle between the leaf body fixing buckle and the outer wall surface ∠...

Embodiment 2

[0026] see Figure 4 and Figure 5, the present embodiment provides a turbine blade with a leading edge fixing buckle 8 facing the blade pot and an inner buckle blade airfoil fixing buckle 9 . In this example, the direction of the leading edge fixing buckle 8 is parallel to the incoming gas flow, and the head of it and the inner buckle airfoil fixing buckle 9 both face the side of the blade pot. And fix the buckle boss width W towards the front edge of the leaf pot 7 The typical value range of 21 is W 7 = 0.3 mm ~ 1 mm. The typical dimensions of this implementation case are: the width W of the fixed buckle boss towards the front edge of the blade pot 7 =0.4mm; front edge fixed buckle head inclination angle ∠θ 1 =16°; Width of front edge fixed buckle head W 2 =1.2mm; front edge fixed buckle width W 3 = 1.2 mm.

[0027] Inner buckle blade body fixing buckle installation angle ∠θ 3 The typical value range of 22 is 12°~45°; 8 The typical value range of 23 is 0.3mm~1mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com