High-temperature-stability gamma'-phase-reinforced cobalt-base high-temperature alloy and preparation method thereof

A high-temperature stable, high-temperature alloy technology, applied in the field of new materials, can solve the problems of limited temperature-bearing capacity and inability to further improve high-temperature strength, and achieve the effect of high-temperature strength and temperature-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

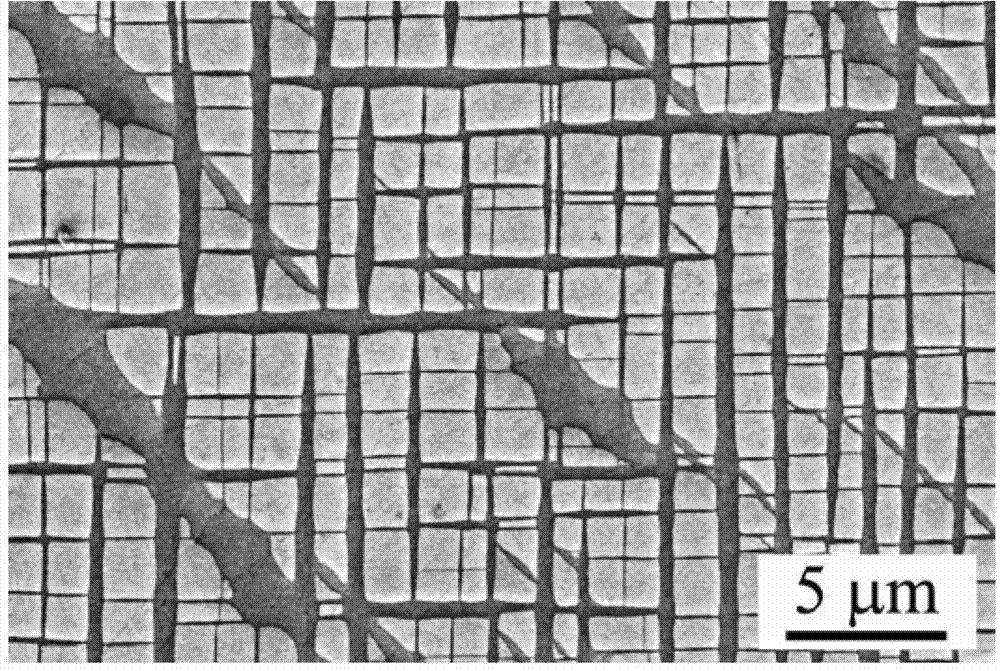

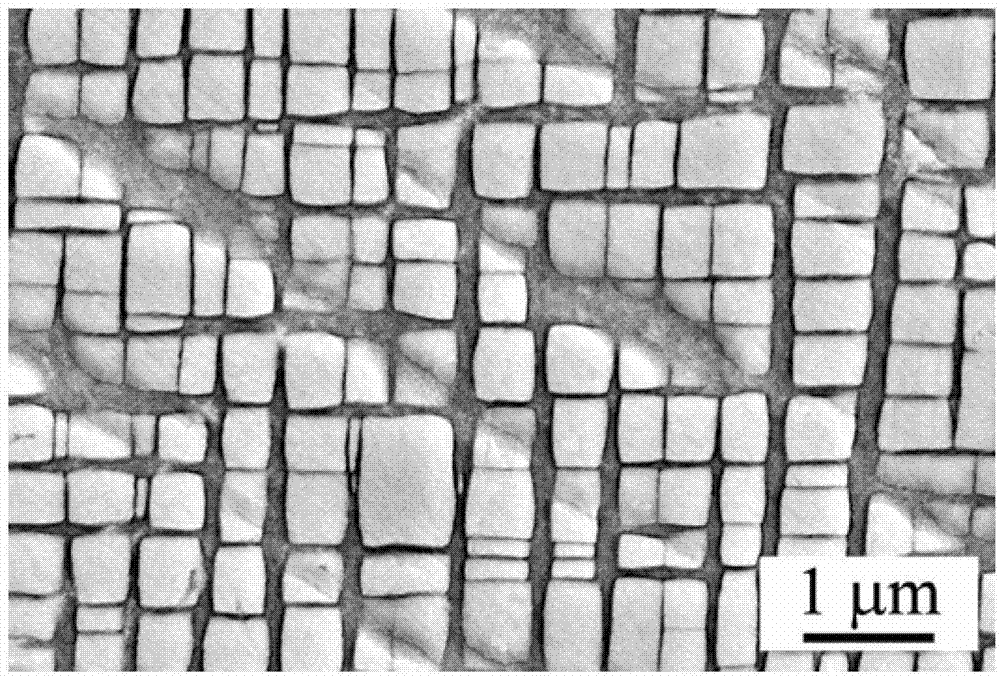

Image

Examples

Embodiment 1

[0030] Weigh high-purity elemental materials such as Co, Al, W, Ta, and Ti according to the composition ratio shown in Alloy 1 in Table 1; put the high-purity elemental materials weighed above into a vacuum induction furnace, and evacuate to 5× 10 -2 Below Pa, then heat up to 1500°C, cast after smelting for 20 minutes, and melt into a cobalt-based superalloy ingot; heat preservation at melting temperature for 24 hours, air cooling; then heat preservation at 1000°C aging temperature for 50 hours, quenching and cooling, to obtain a high-temperature stable γ' phase-strengthened cobalt-based superalloy.

Embodiment 2

[0032] Weigh high-purity elemental materials such as Co, Al, W, Ta, and Ti according to the composition ratio shown in alloy 2 in Table 1; put the high-purity elemental materials weighed above into a vacuum induction furnace, and evacuate to 5× 10 -2 Below Pa, then heat up to 1540°C, cast after smelting for 20 minutes, and melt into a cobalt-based superalloy ingot; heat preservation at melting temperature for 24 hours, air cooling; then heat preservation at 1000°C aging temperature for 50 hours, quenching and cooling, to obtain a high-temperature stable γ' phase-strengthened cobalt-based superalloy.

[0033] The DSC test was carried out on the alloys of the examples to determine the dissolution temperature of the γ' phase. The γ' phase dissolution temperature of alloy 2 is 1184°C, which is significantly higher than that of Ishida et al. Cobalt-base alloy with high heat resistance and high strength and process for producing the same; Chinese Patent, Publication No. 101248198...

Embodiment 3

[0035] Weigh high-purity elemental materials such as Co, Al, W, Ta, and Ti according to the composition ratio shown in alloys 3 to 6 in Table 1; put the high-purity elemental materials weighed above into a vacuum induction furnace, and evacuate to 5×10 -2 Below Pa, then heat up to 1530°C, cast after smelting for 30 minutes, and melt into a cobalt-based superalloy ingot; heat preservation at the melting temperature for 24 hours, air cooling; then heat preservation at the aging temperature of 1050°C for 30 hours, quenching and cooling, and obtain a high-temperature stable γ' phase-strengthened cobalt-based superalloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com