Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "High molding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D printing composition as well as preparation method and applications thereof

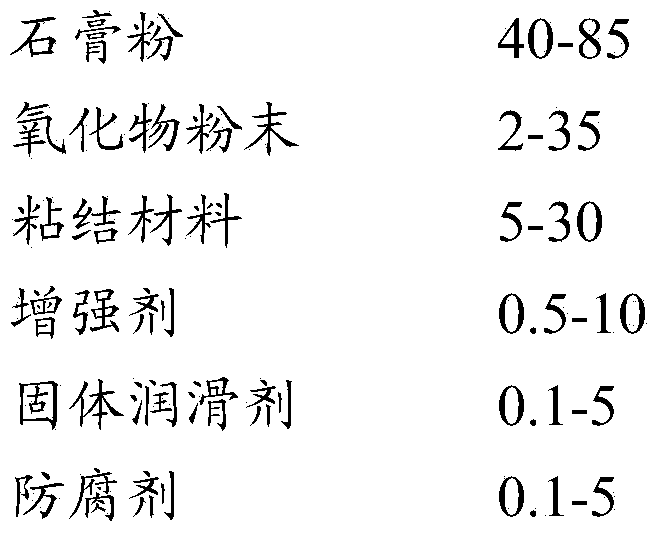

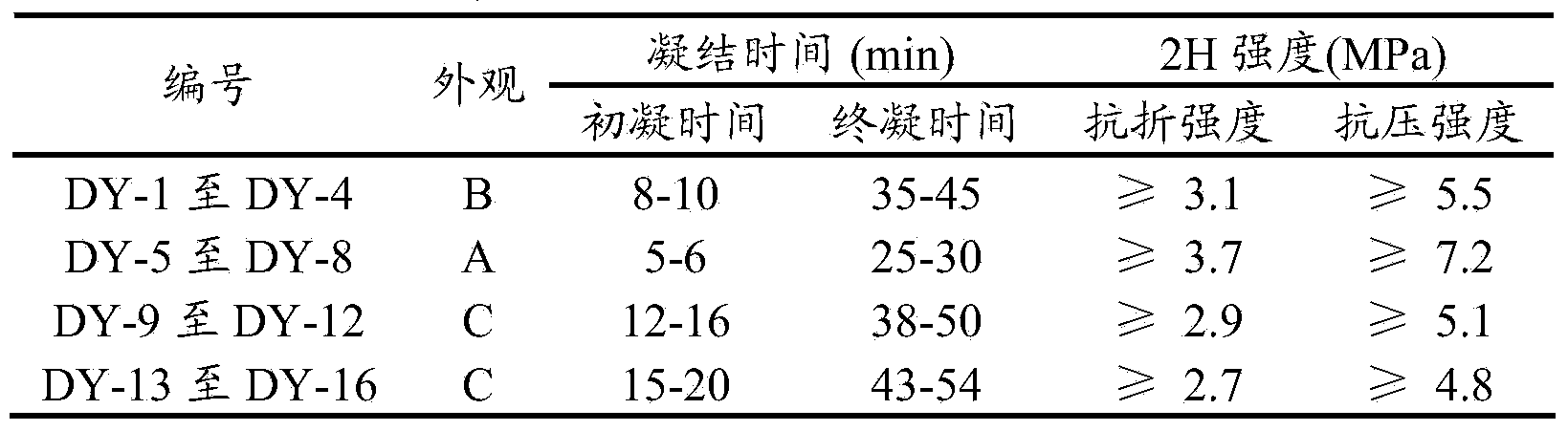

InactiveCN104230289AReduce manufacturing costRaw materials are cheap and easy to getPreservativeUltimate tensile strength

The invention relates to a 3D printing composition as well as a preparation method and applications thereof. The composition comprises gypsum powder, oxide powder, a binding material, a fortifier, a solid lubricant and a preservative, and preferably comprises auxiliaries. The composition is low in cost, good in stability, high in forming strength, good in tenacity, difficult to deform, can be used in the field of 3D printing technology, and the preparation method has the advantages of being pollution-free, green, environment-friendly and the like. Therefore, the 3D printing composition as well as the preparation method and applications thereof have excellent scientific research values and industrial application potential.

Owner:王娟 +1

Preparation technique of waste residue composite light-weight thermal-insulation wallboard

ActiveCN102863189ALow costCost enoughSolid waste managementCeramic shaping apparatusAggregate (composite)Engineering

The invention discloses a preparation technique of a waste residue composite light-weight thermal-insulation wallboard, which comprises the following steps: preparing a waste residue base material; preparing a composite admixture A; preparing waste residue light-weight aggregate; preparing a composite admixture B; preparing a wallboard blank material; preparing a wallboard blank; putting the wallboard blank in a curing chamber, and curing in a 75-80 DEG C saturated steam environment for 4-5 hours; and when the difference between inside temperature and outside temperature of the curing chamber is 25-40 DEG C, putting the wallboard blank outside the chamber, and demolding to obtain the waste residue composite light-weight thermal-insulation wallboard. According to the preparation method disclosed by the invention, the wallboard blank can be cured and demolded within 8.5-12 hours, and the demolded wallboard can be immediately put into engineering use, thereby shortening the processing cycle, and preparing the high-strength favorable-water-resistance light-weight wallboard under the conditions of changing wastes into valuable substances and using low production cost. The wallboard can be widely used in various types of construction engineering.

Owner:杜世永

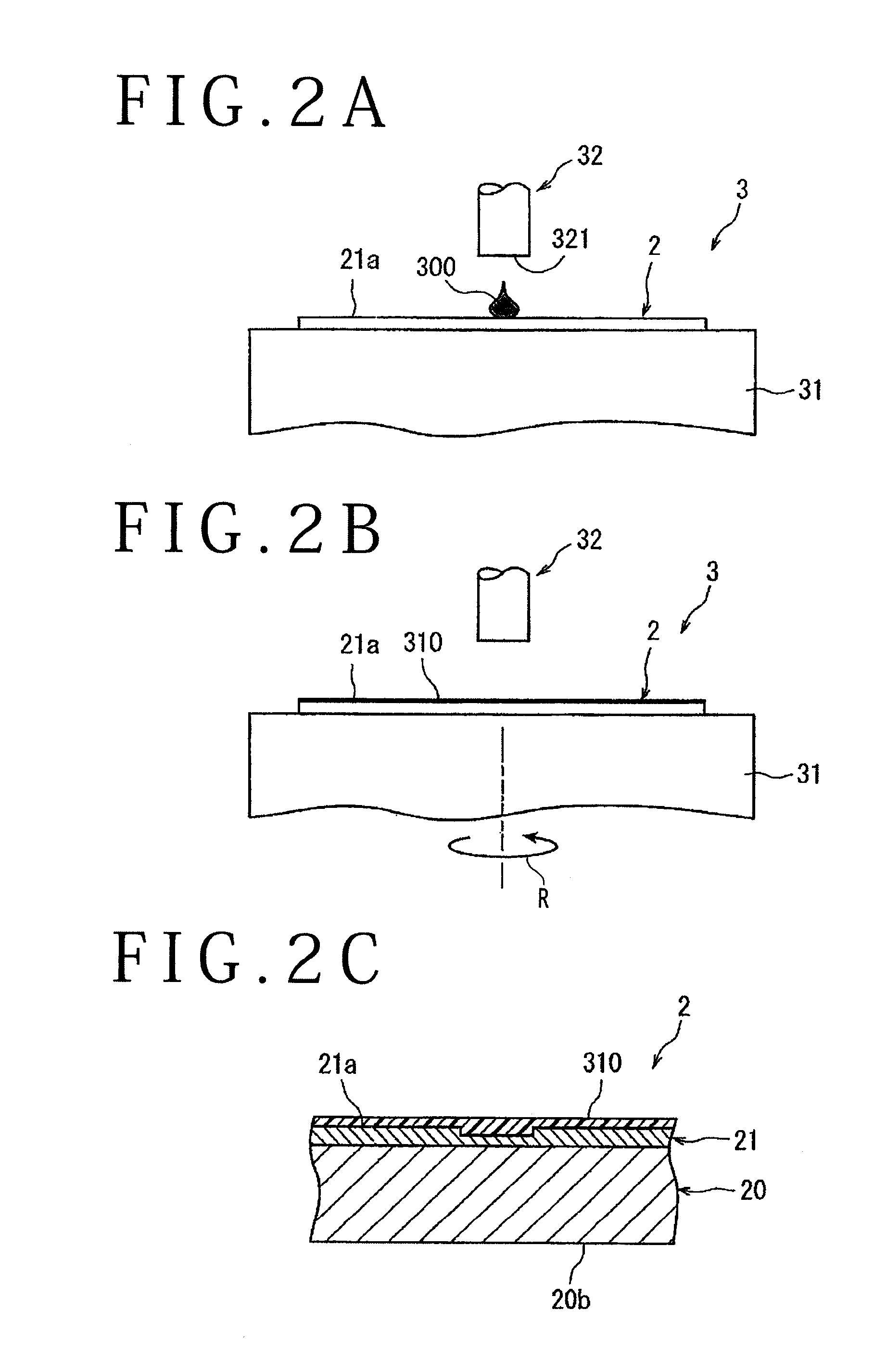

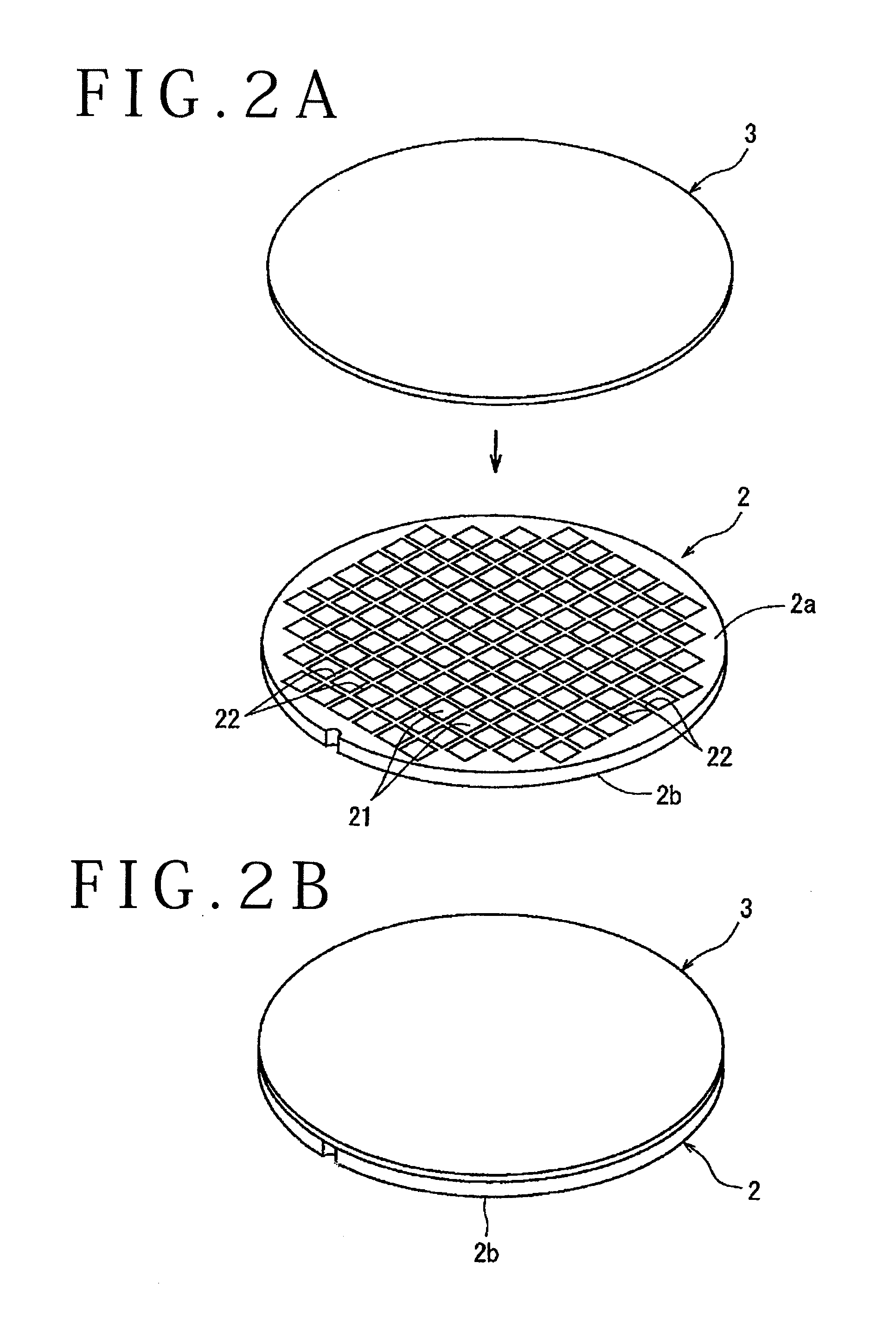

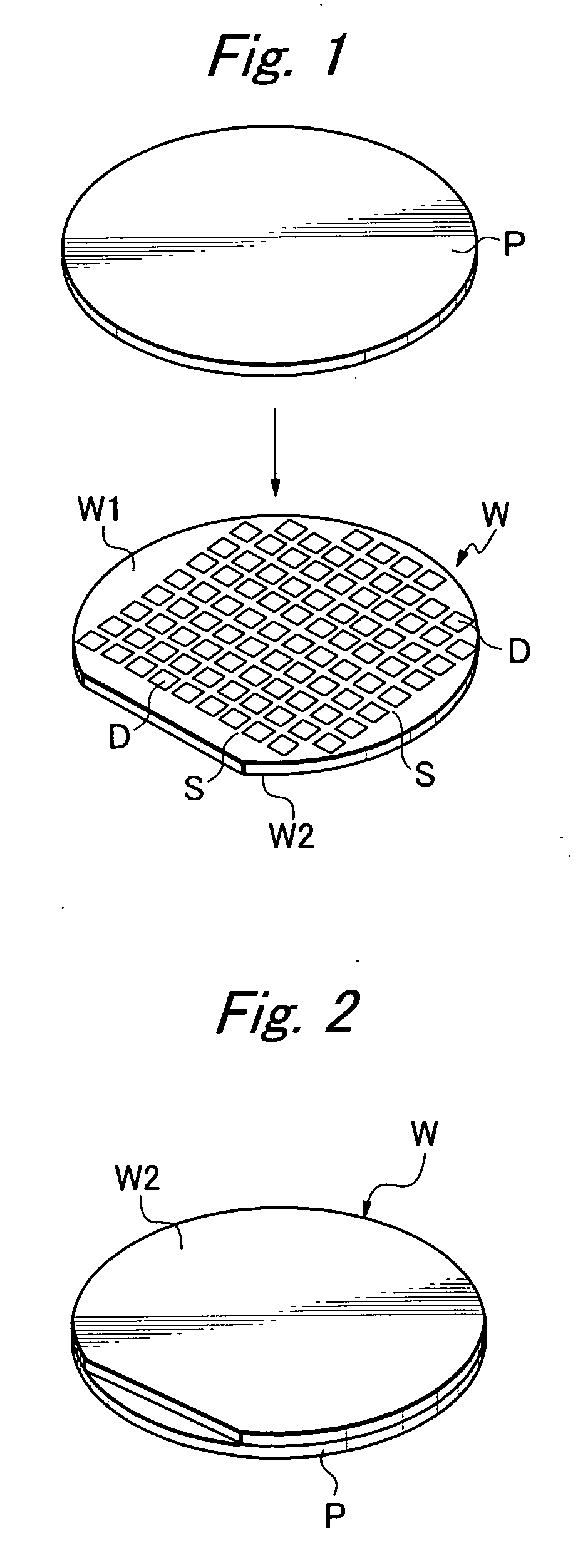

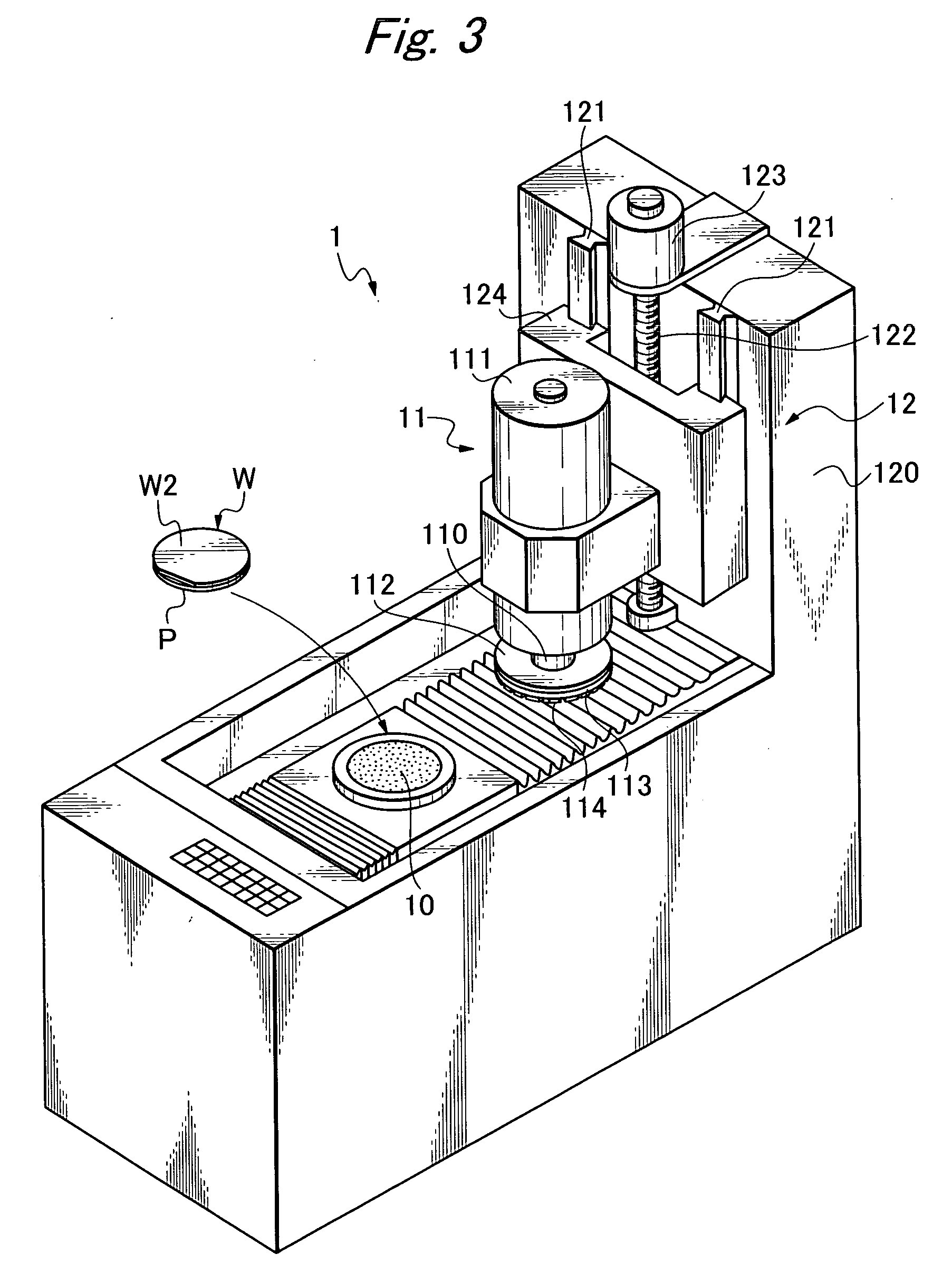

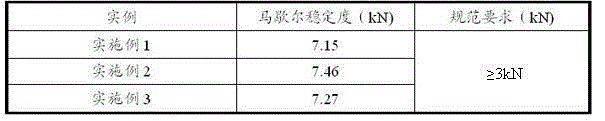

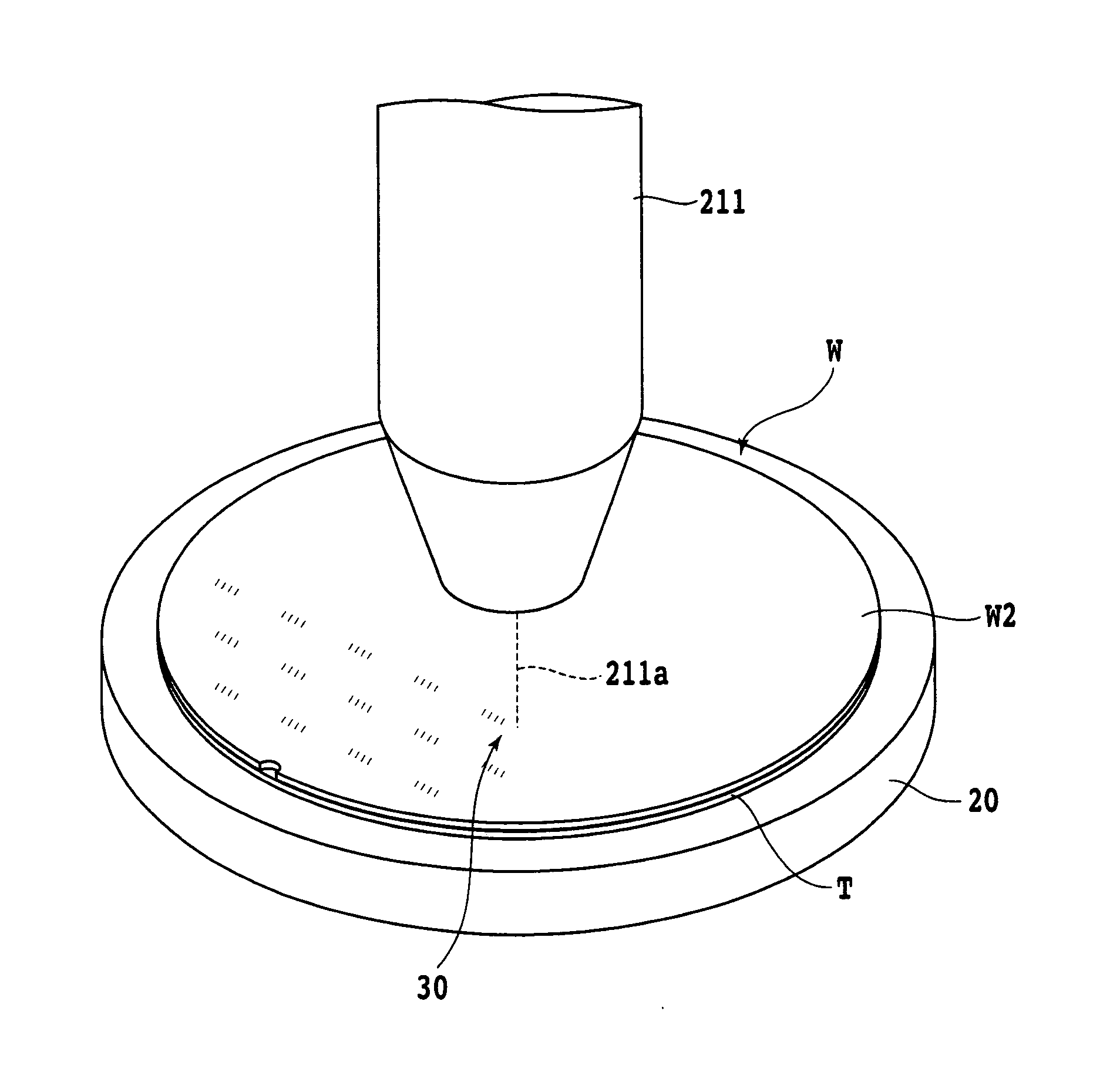

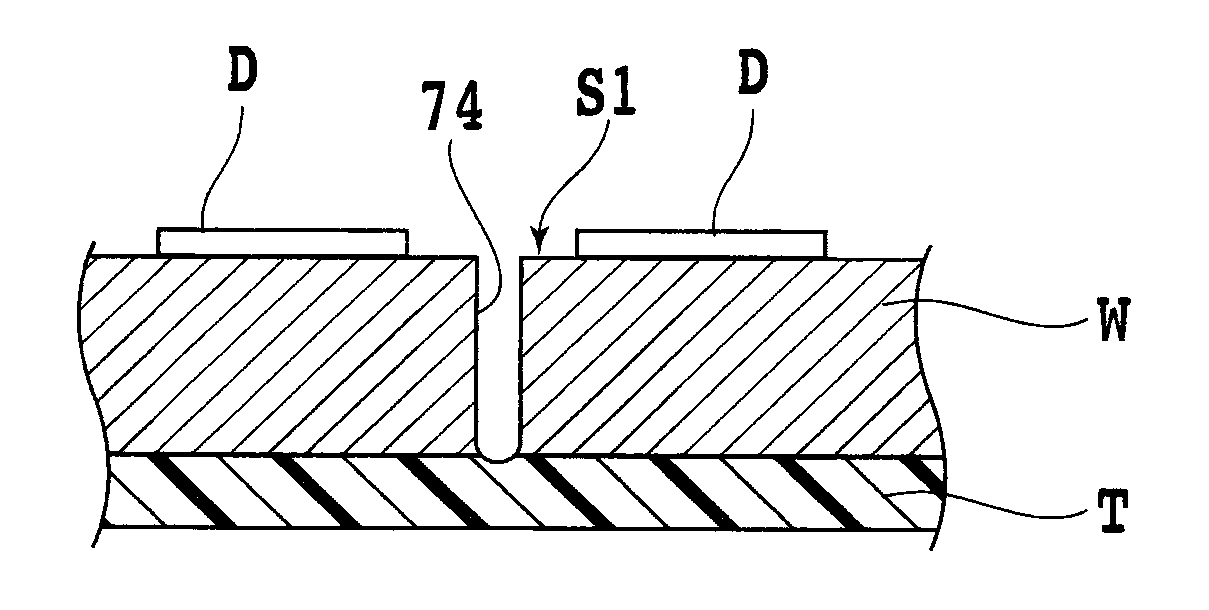

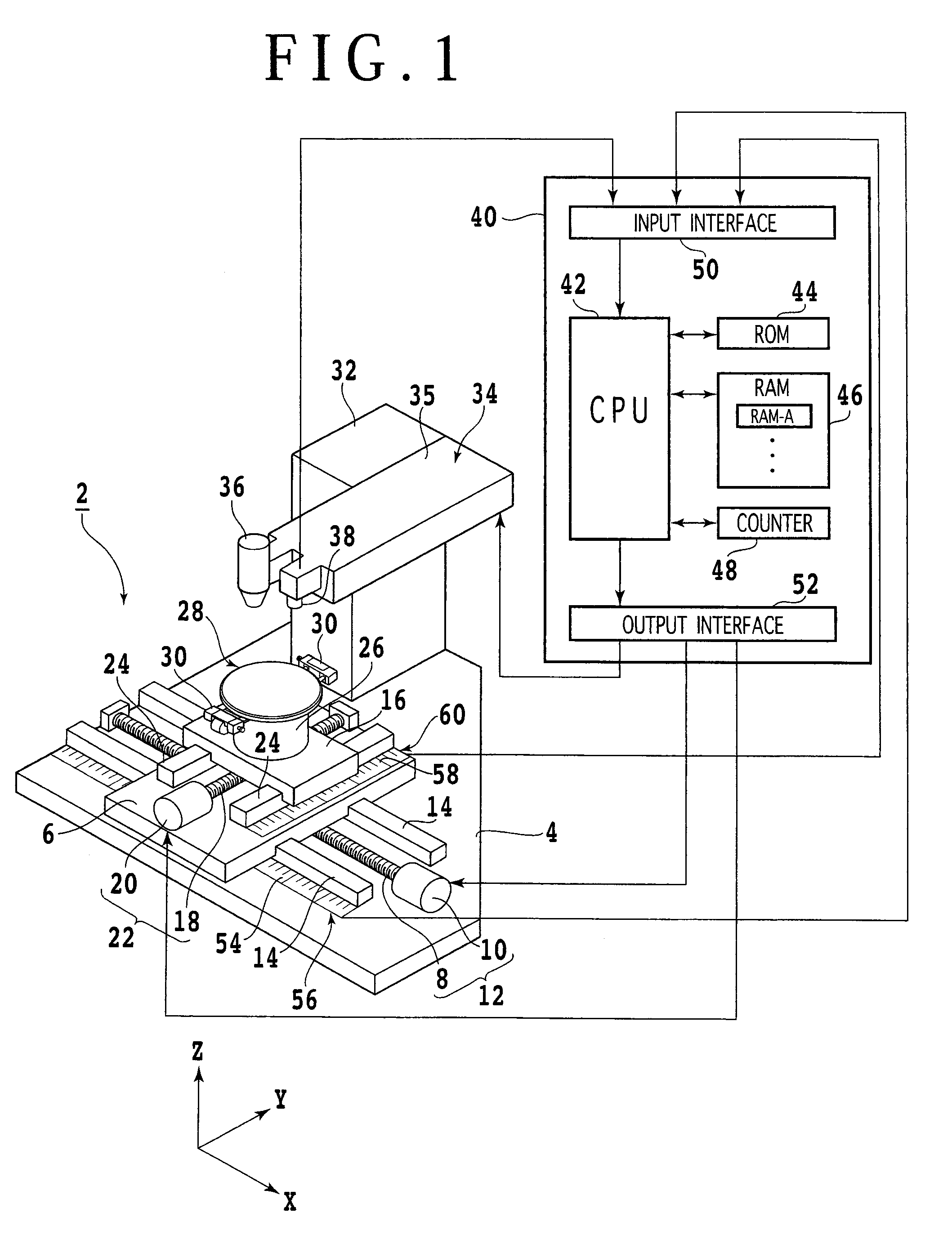

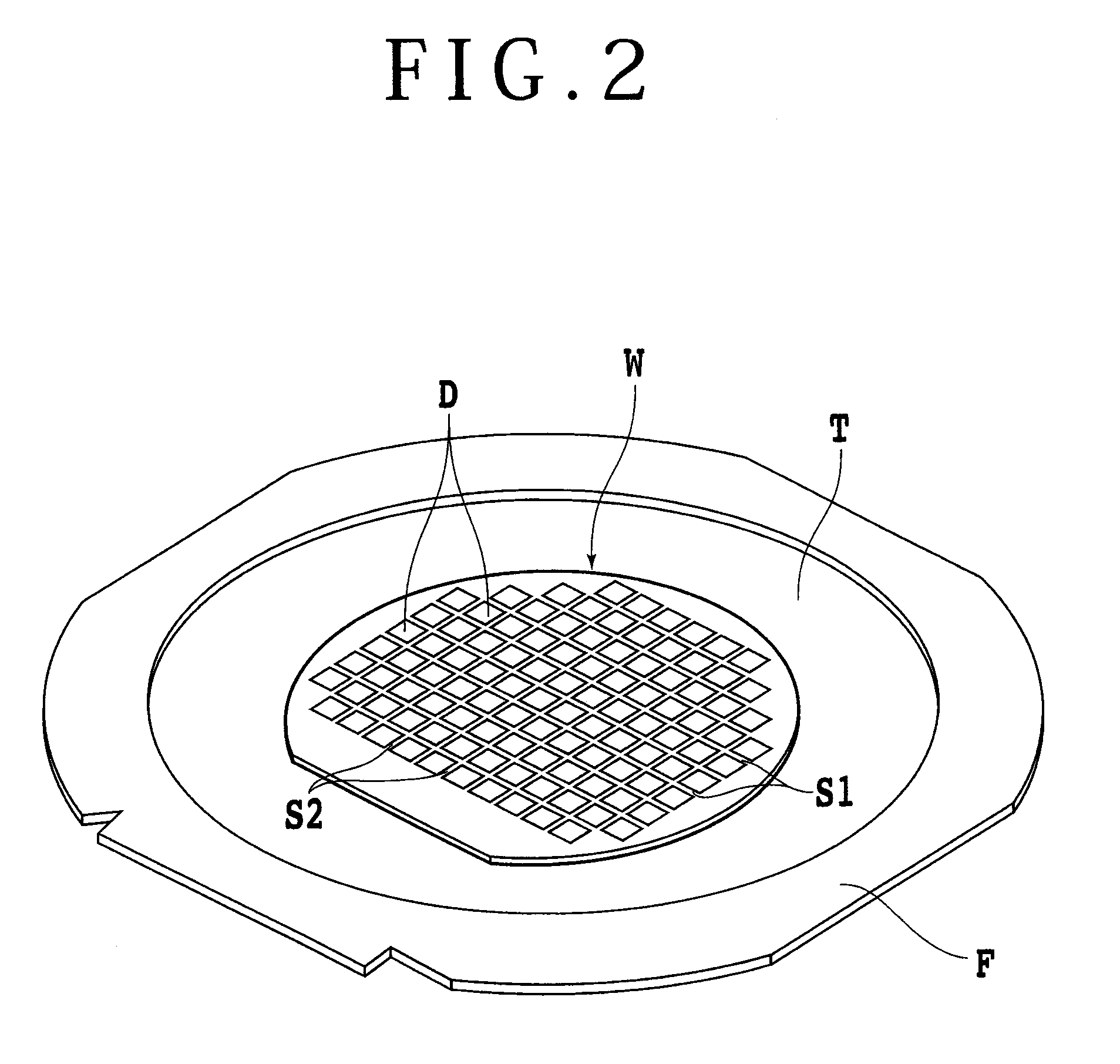

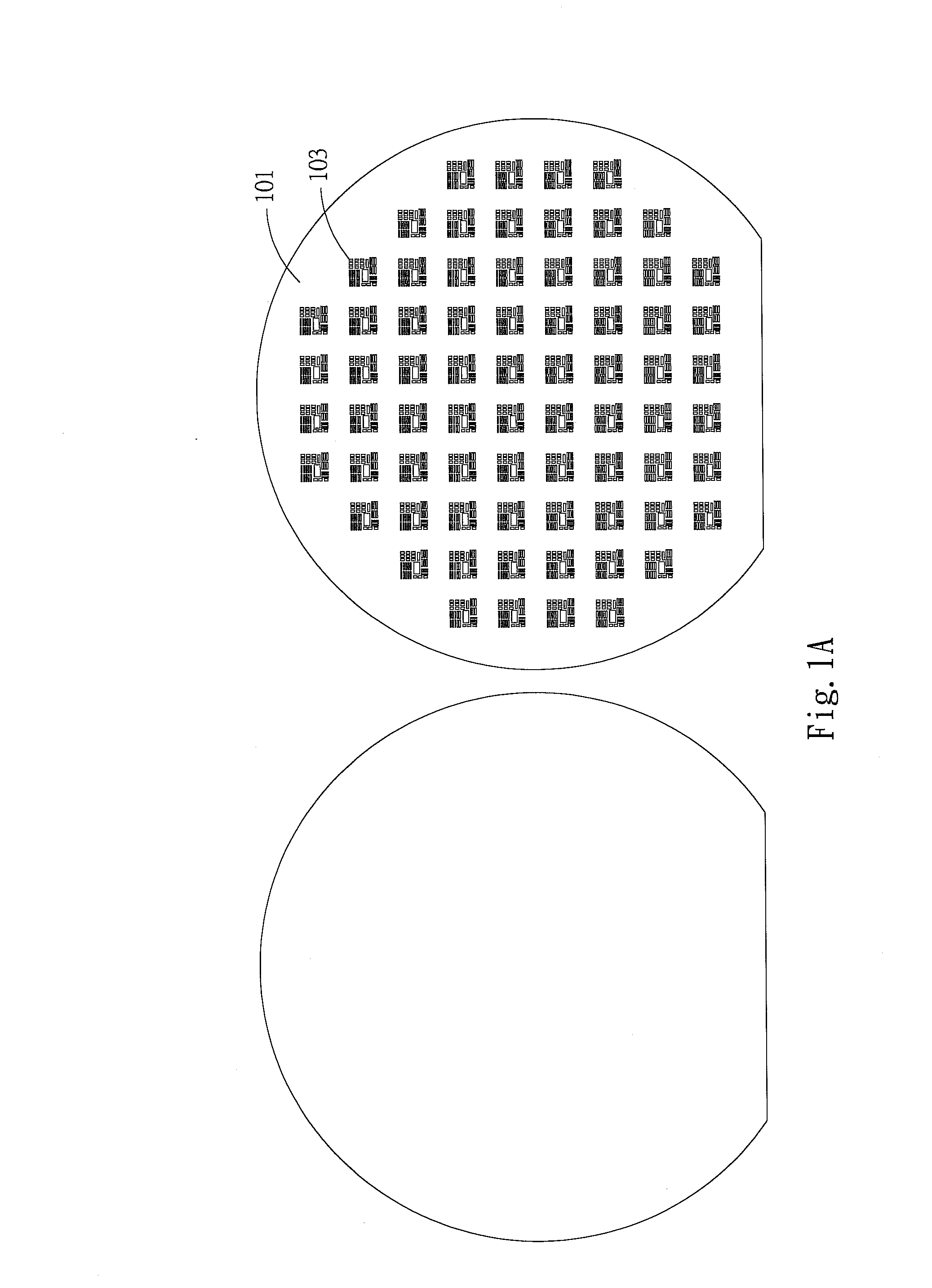

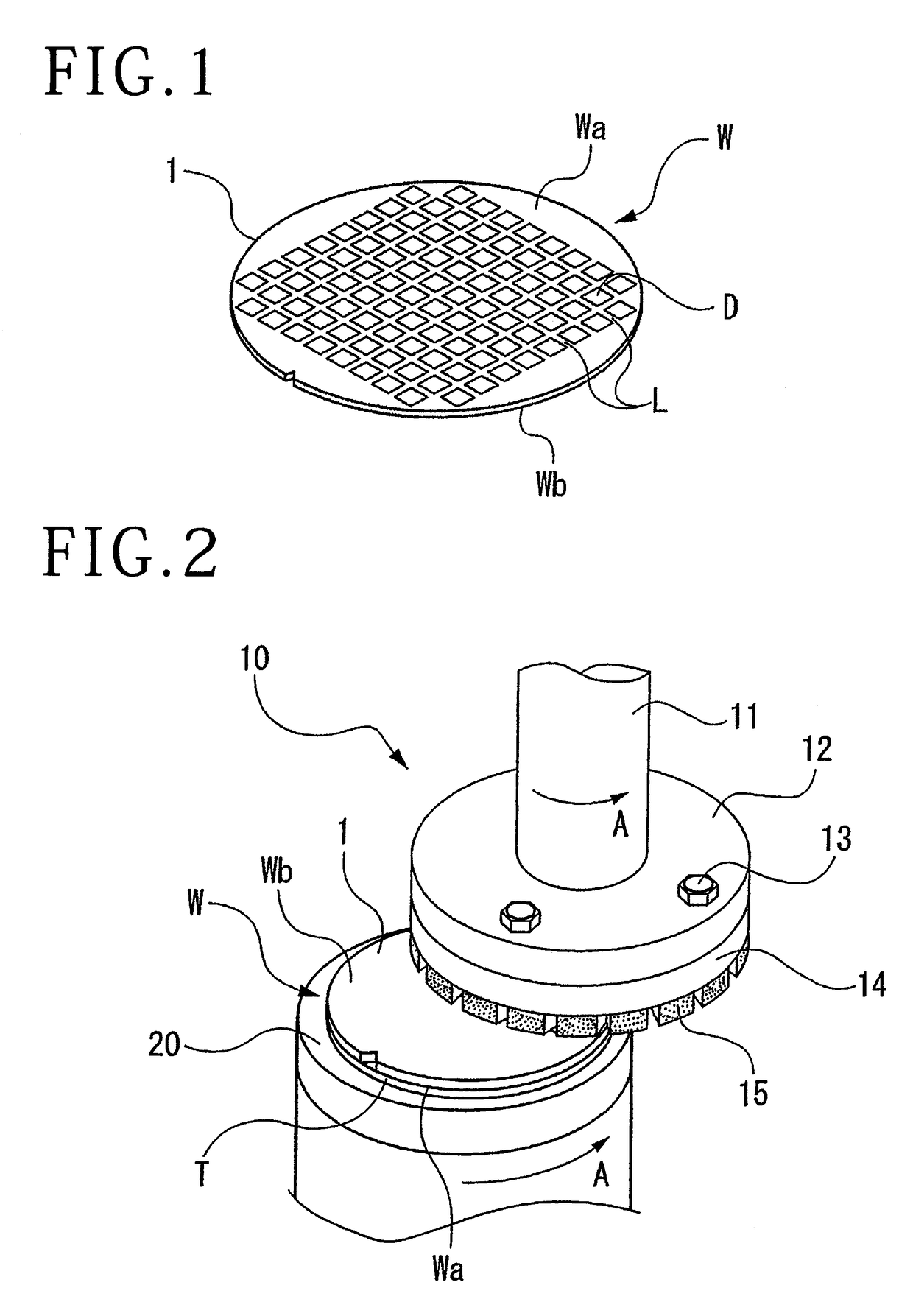

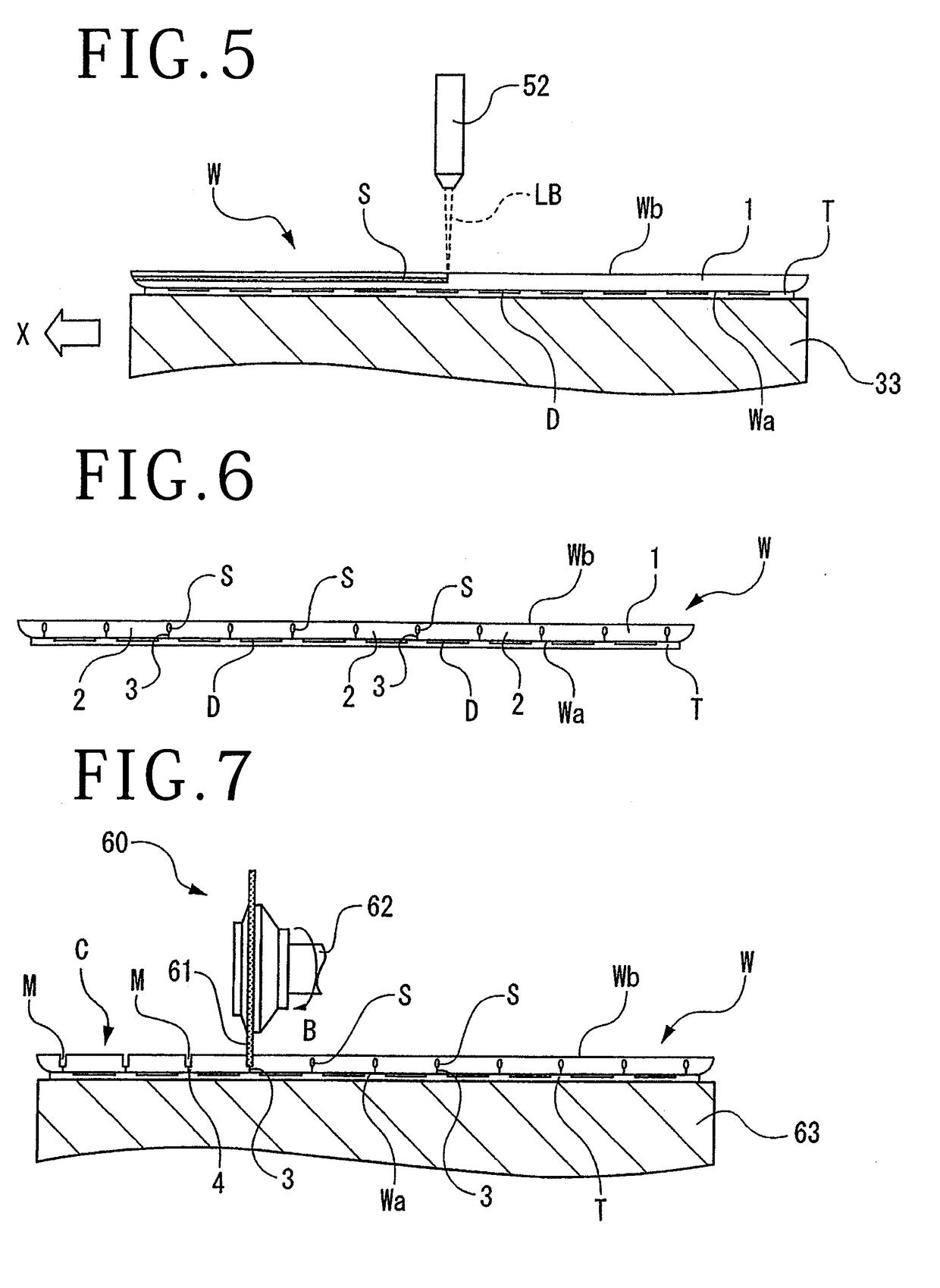

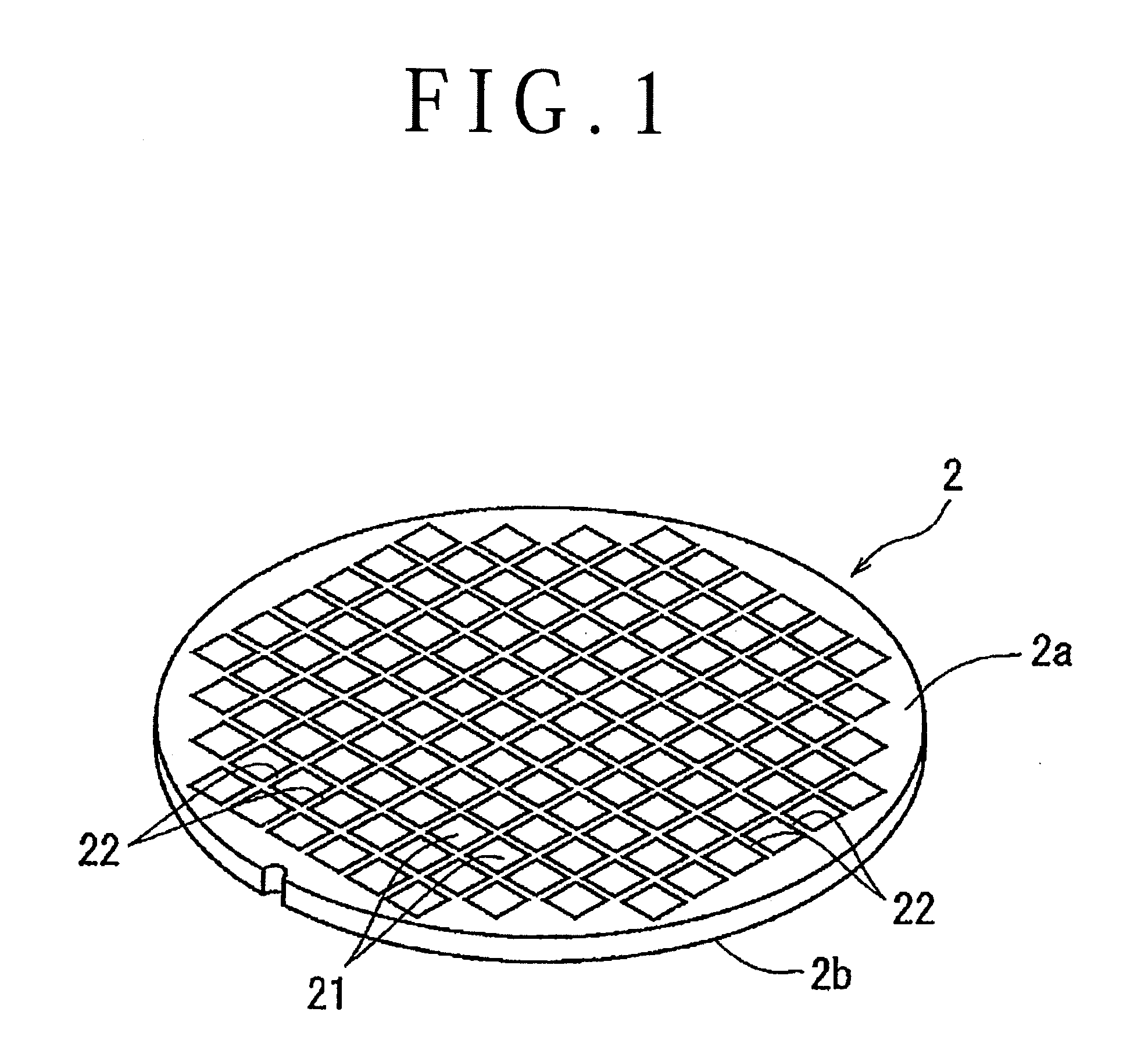

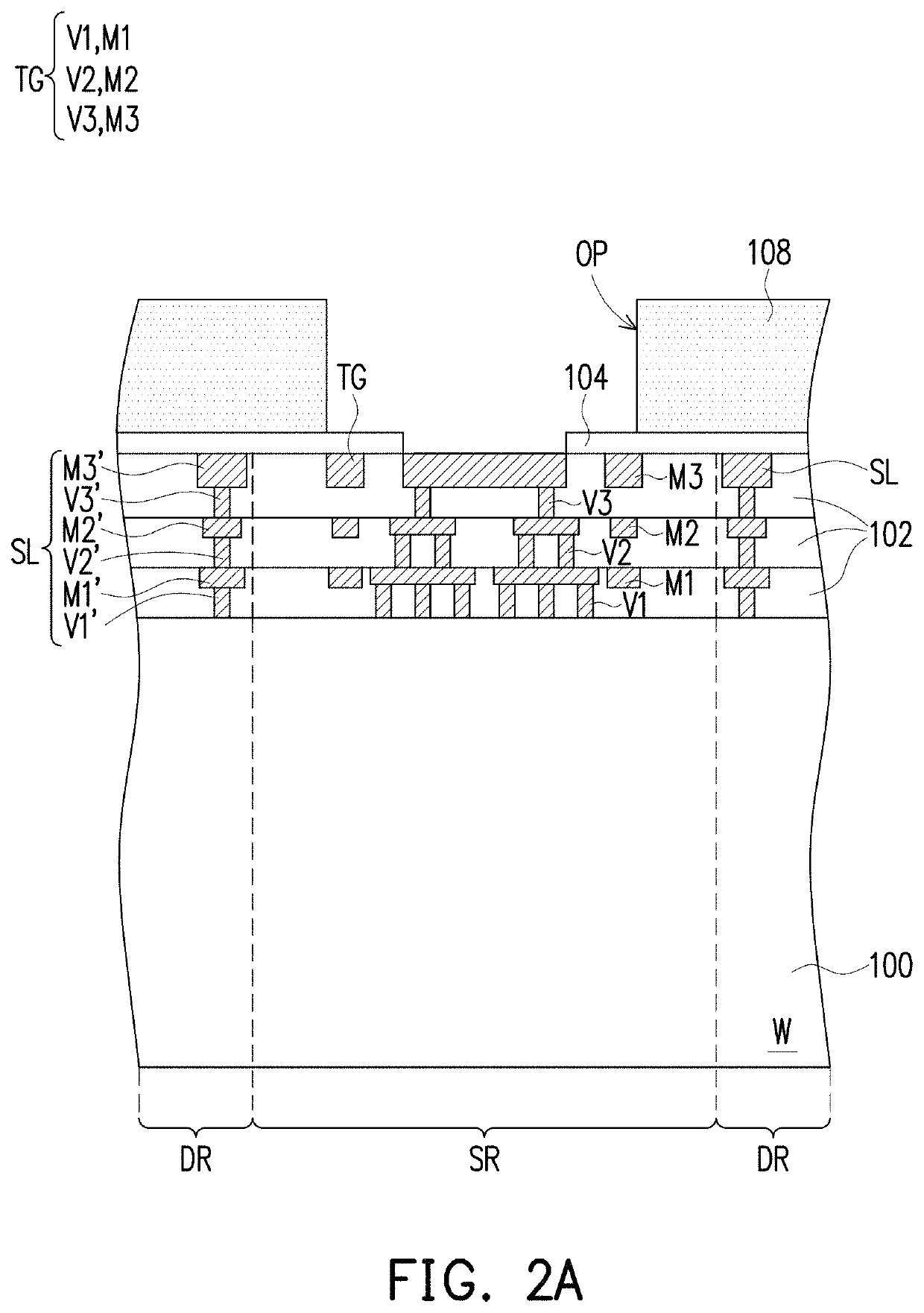

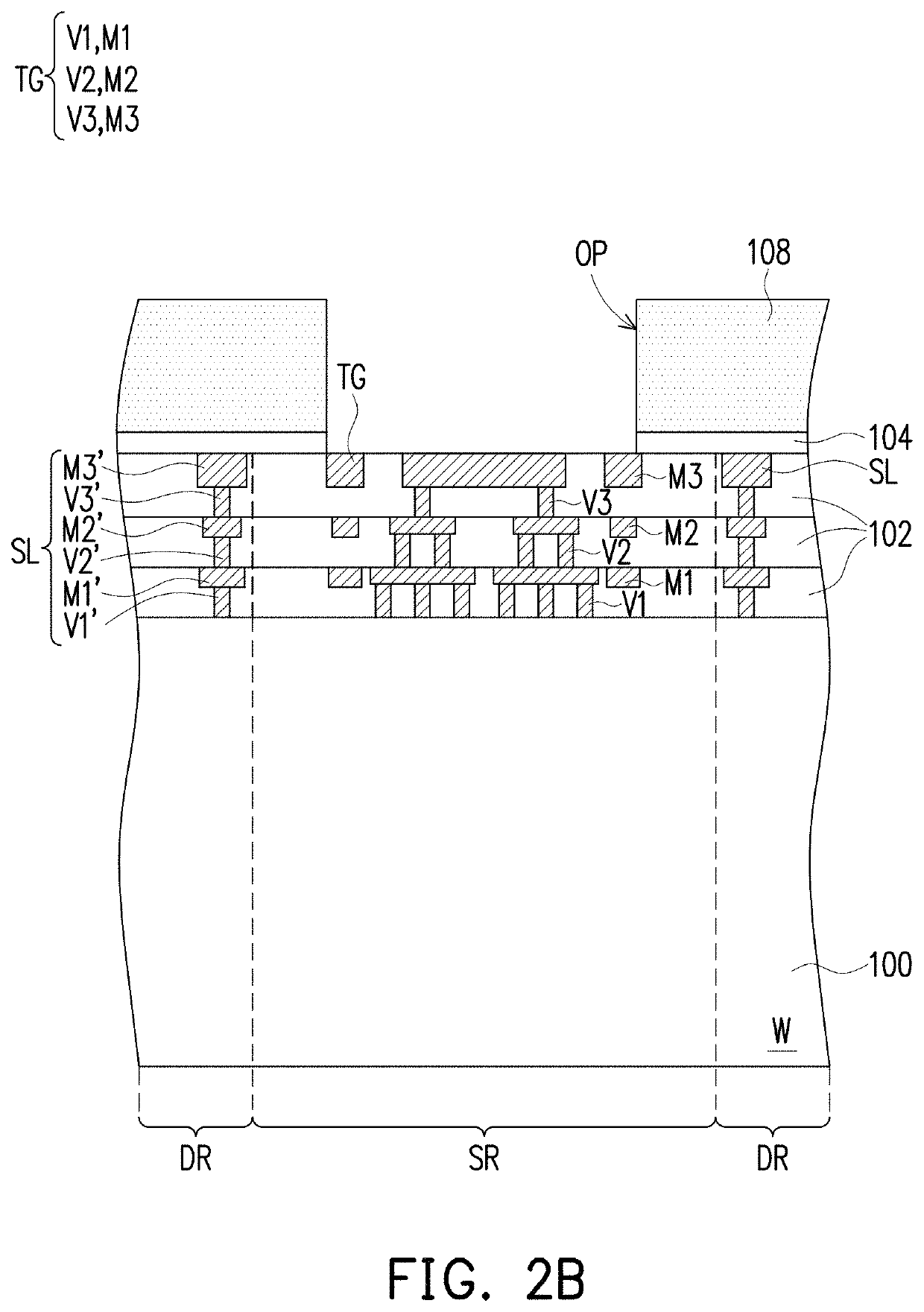

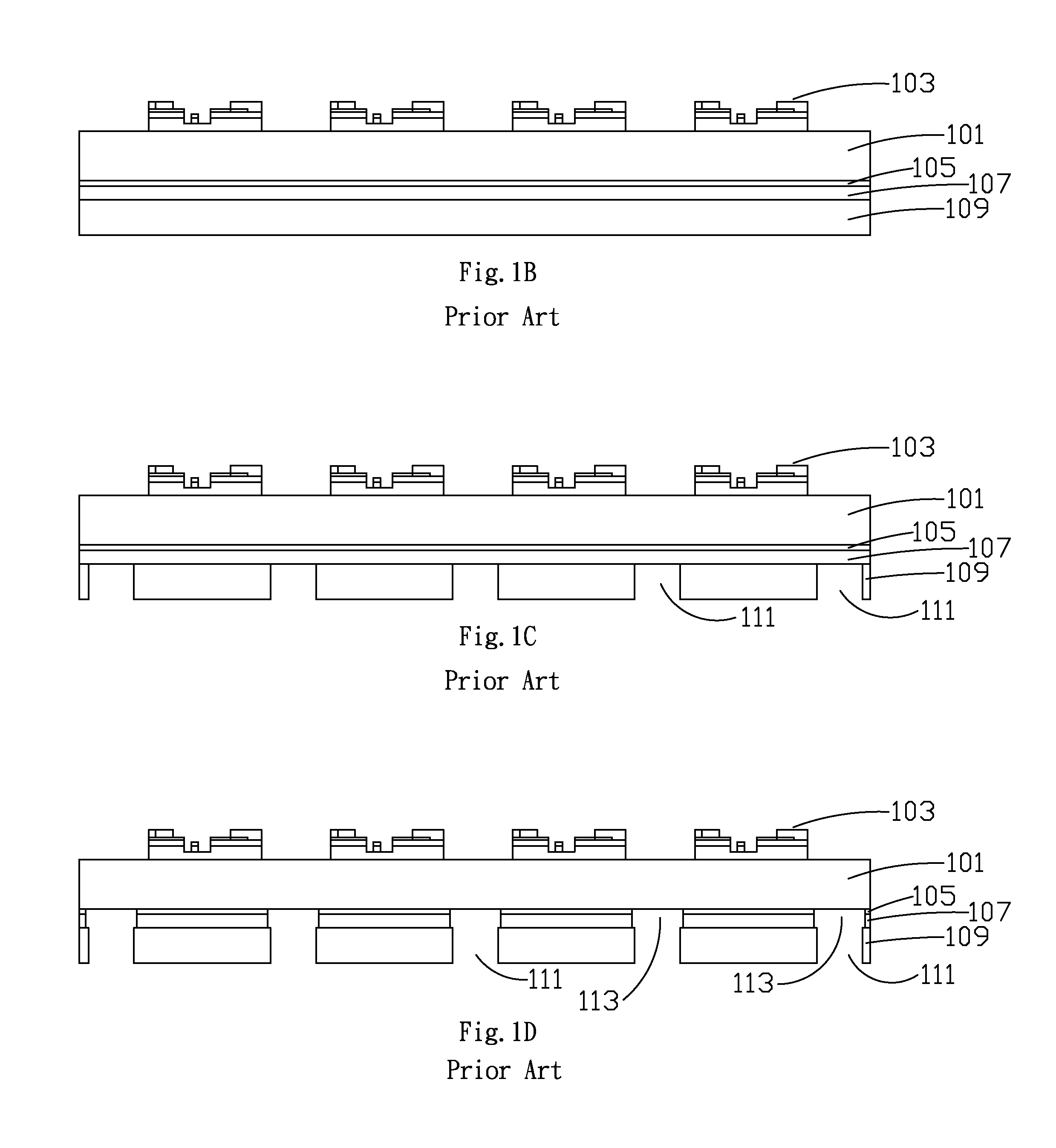

Wafer processing method

ActiveUS20140141596A1Reduced strengthReliably divide a wafer into the individual devicesSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesEngineeringLaser beams

A wafer processing method divides a wafer into individual devices along crossing streets formed on the front side of the wafer. The wafer has a substrate and a functional layer formed on the front side of the substrate. The individual devices are formed from the functional layer and are partitioned by the streets. A laser beam is applied along the streets from the front side of the functional layer to thereby remove the functional layer along the streets. A resist film is formed on the front side of the functional layer except on each street. The substrate of the wafer is plasma-etched along each street where the functional layer is absent to the depth corresponding to the finished thickness of each device, thereby forming a division groove along each street and also etching off a modified layer formed on the opposite sides of each street.

Owner:DISCO CORP

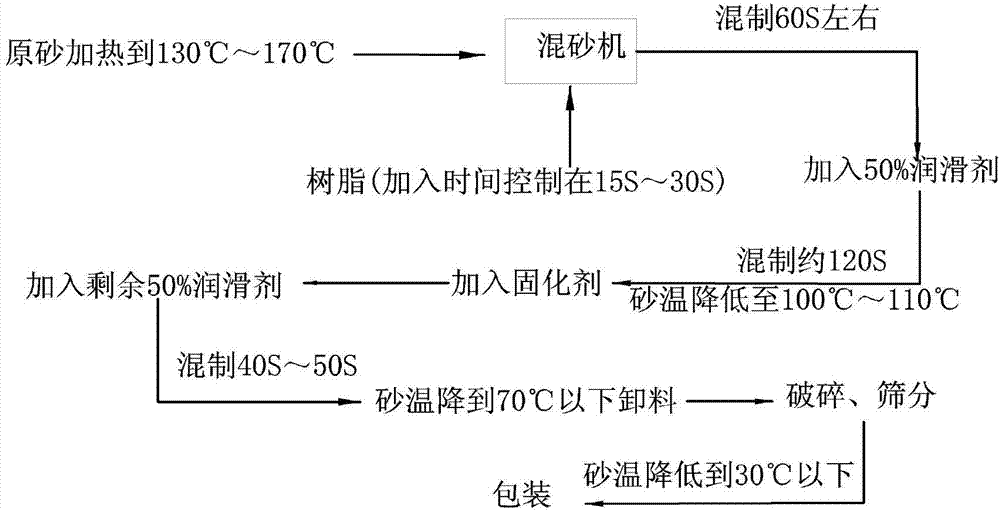

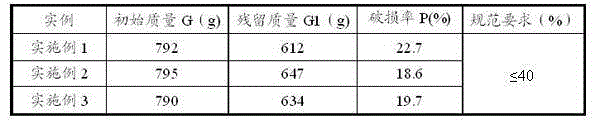

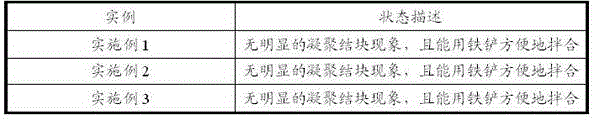

Easy-to-fill precoated sand and preparation process thereof

ActiveCN103658506AHigh molding strengthHigh temperature strengthFoundry mouldsMould handling/dressing devicesUltimate tensile strengthHot Temperature

The invention discloses easy-to-fill precoated sand and a preparation method thereof. Raw materials comprise roughing sand, phenolic resin, curing agents, lubricating agents and additives. The preparation method comprises the following steps that the roughing sand is heated to 130 to 170 DEG C, then, the phenolic rein, a half quantity of the lubricating agents, the curing agents and the rest half quantity of lubricating agents are sequentially added, finally, the discharging is carried out, and then, crushing, sieving and package are carried out. Through the improvement on the raw material ingredients and the preparation process, the forming intensity of the precoated sand is high, the high-temperature intensity is high, the deformation quantity is small, the flowability is good, complicated sand cores can be produced, the surface smoothness of the molding sand is good, the collapsibility performance is excellent, castings can be easily subjected to the vibration sand falling treatment, the precoated sand gas producing quantity is reduced, and the high-temperature performance and other casting performance of the precoated sand are improved.

Owner:ANSHUN UNIV

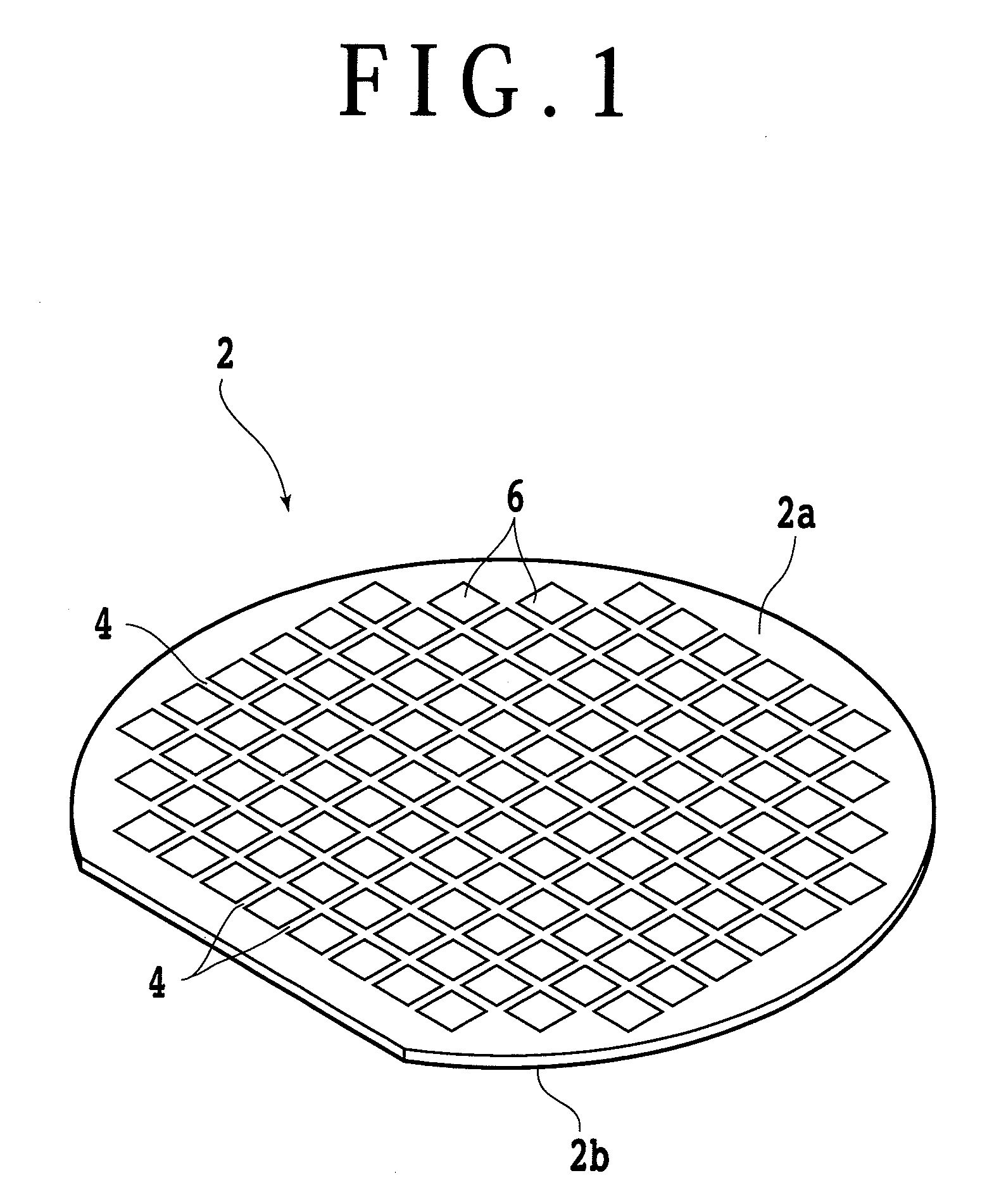

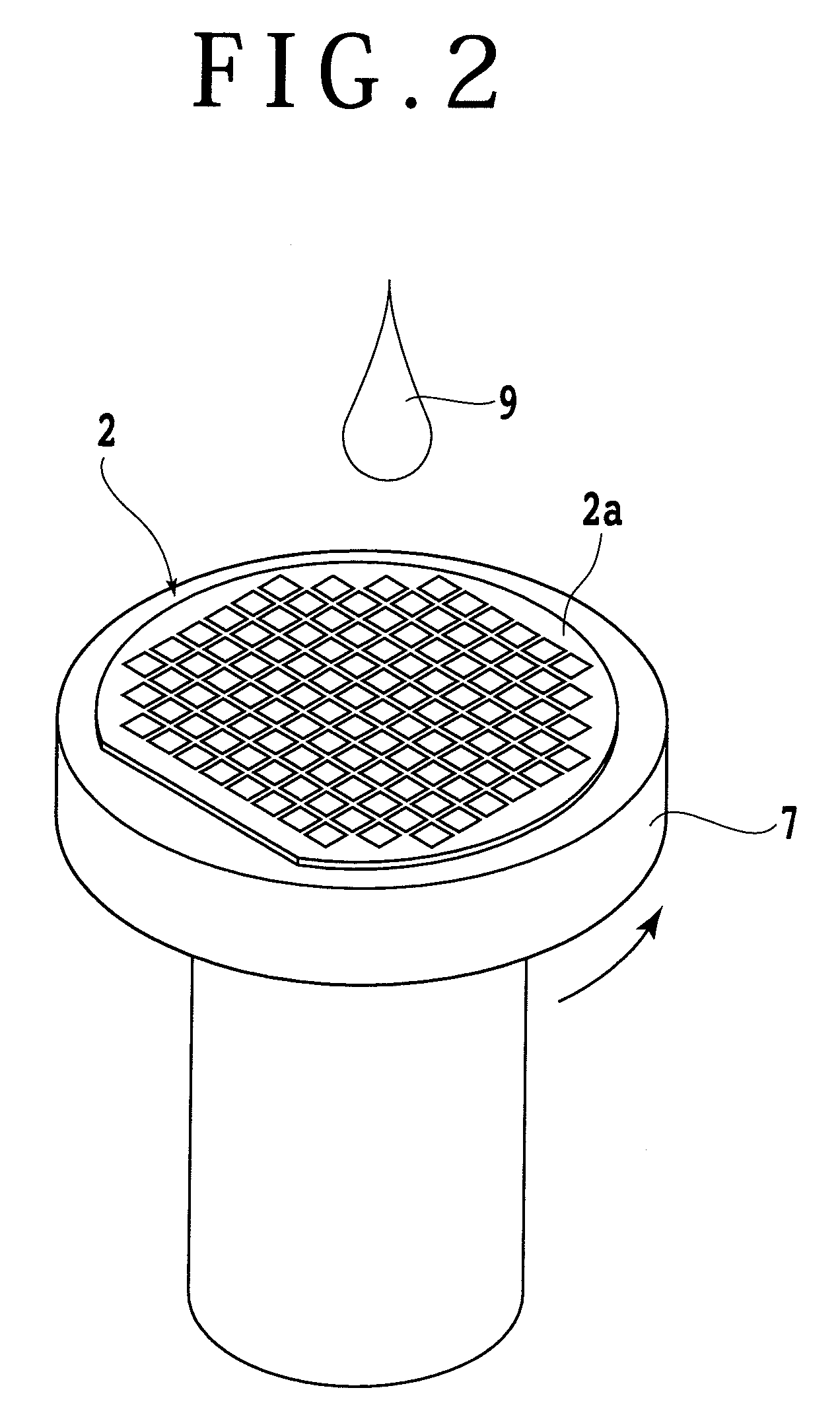

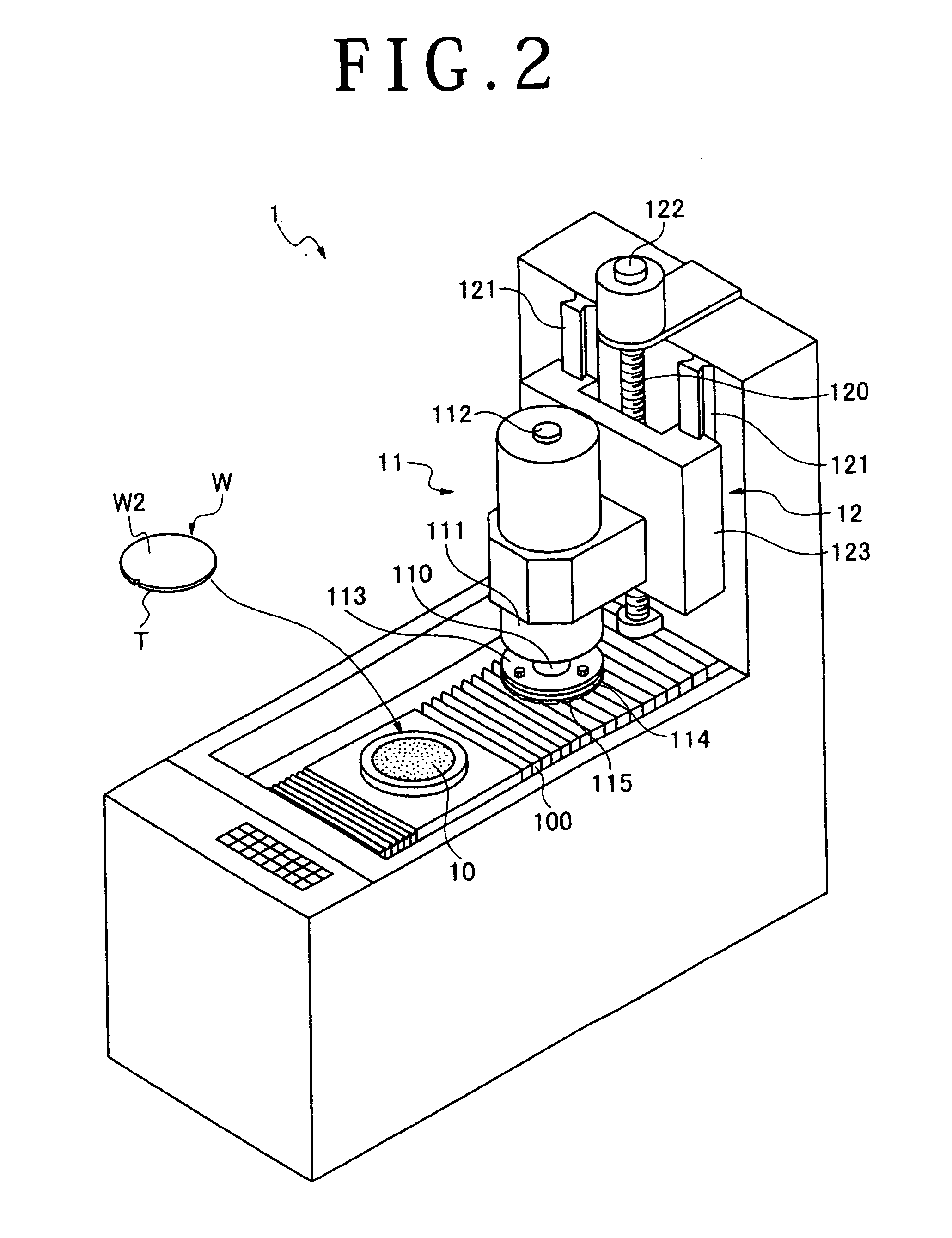

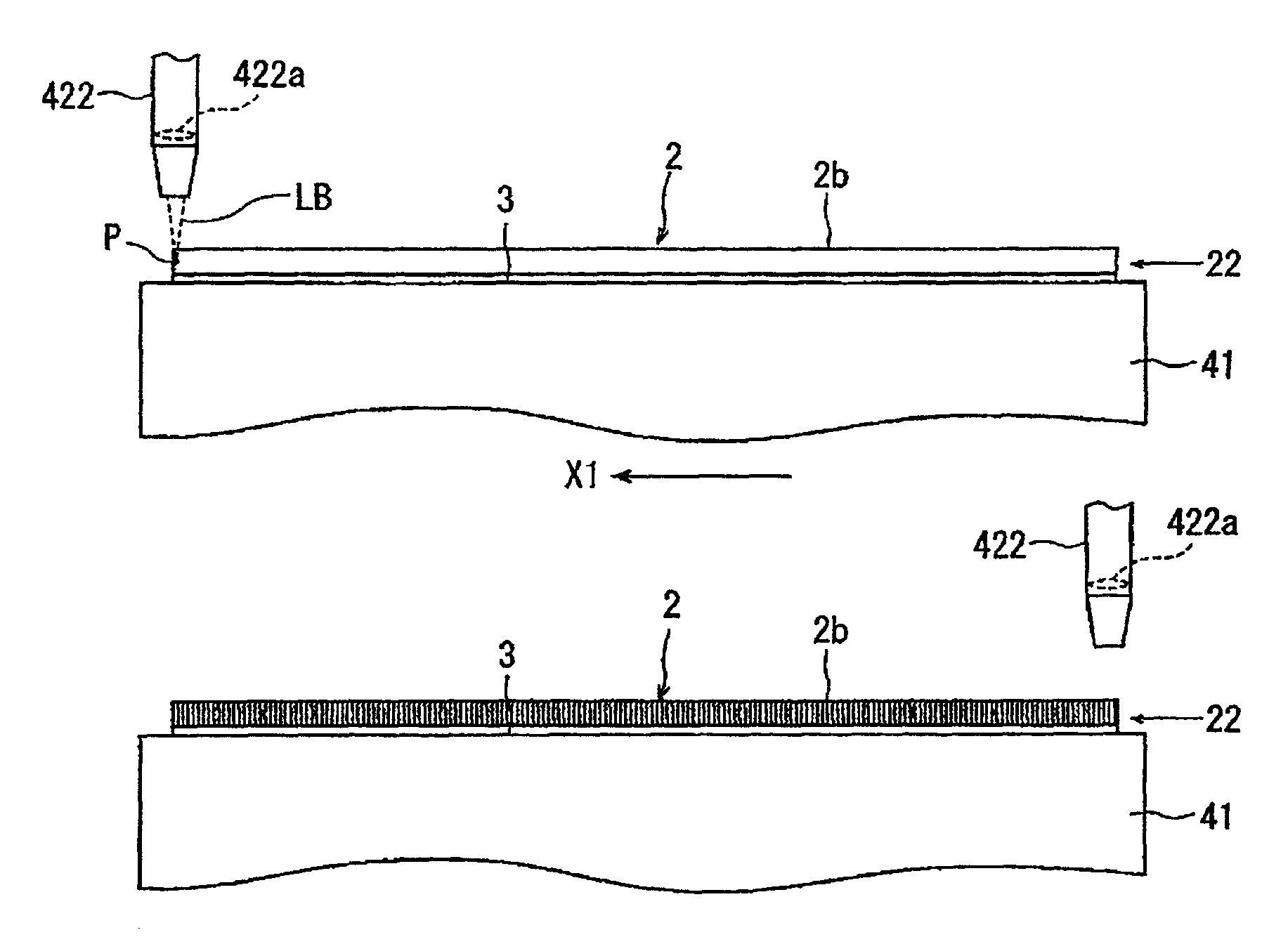

Wafer processing method

ActiveUS20140248757A1High molding strengthImprove productivitySemiconductor/solid-state device manufacturingLaser beam welding apparatusPulsed laser beamSplit lines

A wafer processing method for dividing a wafer along a plurality of division lines to obtain a plurality of individual chips. The wafer processing method includes a filament forming step of applying a pulsed laser beam having a transmission wavelength to the wafer along each division line in the condition where the focal point of the pulsed laser beam is set inside the wafer in a subject area to be divided, thereby forming a plurality of amorphous filaments inside the wafer along each division line, and an etching step of etching the amorphous filaments formed inside the wafer along each division line by using an etching agent to thereby divide the wafer into the individual chips along the division lines.

Owner:DISCO CORP

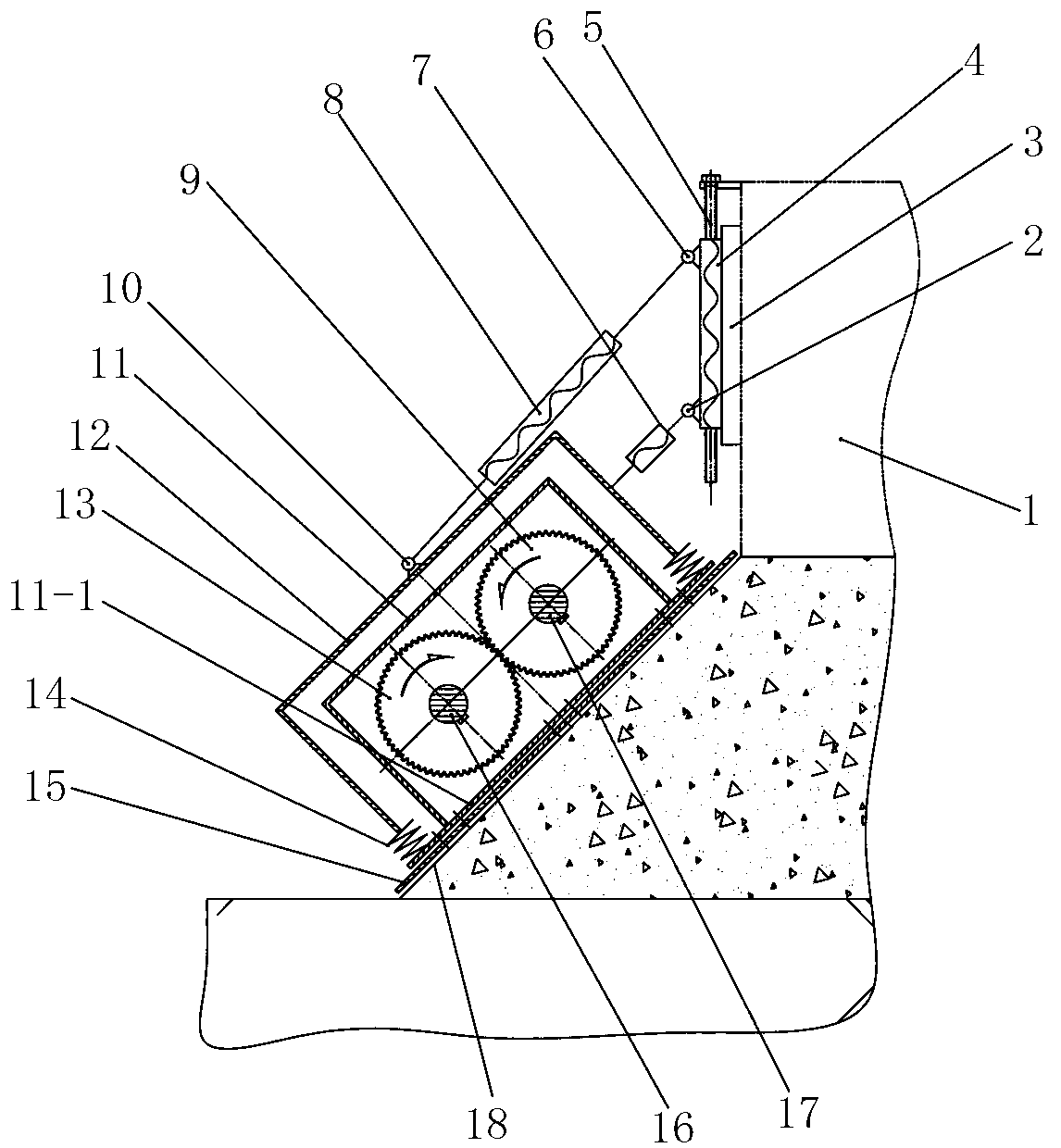

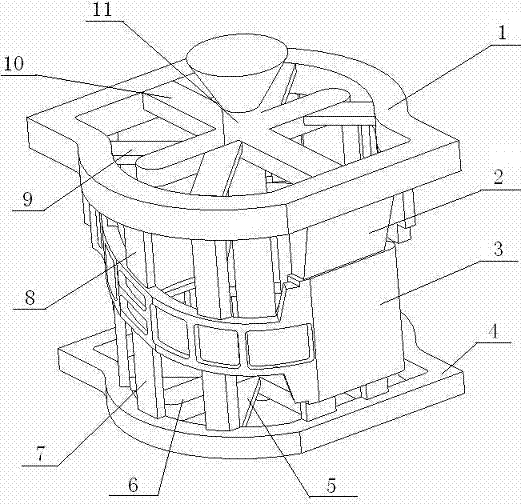

Roadbed slop vertical vibrating compacting device

The invention discloses a roadbed slop vertical vibrating compacting device which comprises a vertical vibrating mechanism aslant connected to the side wall of a working device, wherein the vertical vibrating mechanism comprises a vibrating box body, a rotating shaft I and a rotating shaft II which are mutually parallel are rotatably connected into the vibrating box body, a synchronizing wheel I is arranged on the rotating shaft I, a synchronizing gear II meshed with the synchronizing gear I is arranged on the rotating shaft II, an eccentric block I is arranged on the rotating shaft I, an eccentric block II is arranged on the rotating shaft II, a tamping plate supporting against a roadbed slope is connected to a bottom plate of the vibrating box body, and a drive device used for driving the rotating shaft I or rotating shaft II to rotate is arranged on the tamping plate. The roadbed slop vertical vibrating compacting device is capable of carrying out effective vibrating compaction on the roadbed slope, and is good in use effect, easy to operate and convenient to popularize and use.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

Olefin purification adsorbent and method thereof for olefin purification technology

ActiveCN103495378AHigh molding strengthImprove purification effectOther chemical processesAdsorption purification/separationAdhesiveGas phase

The invention provides an olefin purification adsorbent and a method thereof for an olefin purification technology, relating to a method for removing trace of methyl alcohol, dimethyl ether and propionaldehyde from olefin material flow. According to the method, a microballoon adsorbent with certain size distribution is prepared by taking kaolin as an inert matrix, aluminum oxide or inorganic silicon-aluminum mixture as an adhesive, and submicron molecular sieve as an active component; under a gaseous phase or liquid phase working condition, the method is used for removing oxy-compound in olefin material flow by a high pressure low temperature adsorption and low pressure high temperature regeneration technology, so that the contents of components of the oxy-compound in the purified olefin product material flow are less than 1ppm (weight ratio), less ethylene and propylene components are lost, the requirements of the olefin purification technology on low pressure drop and large airspeed liquid phase operation are met, and the method can be used in industrial production.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

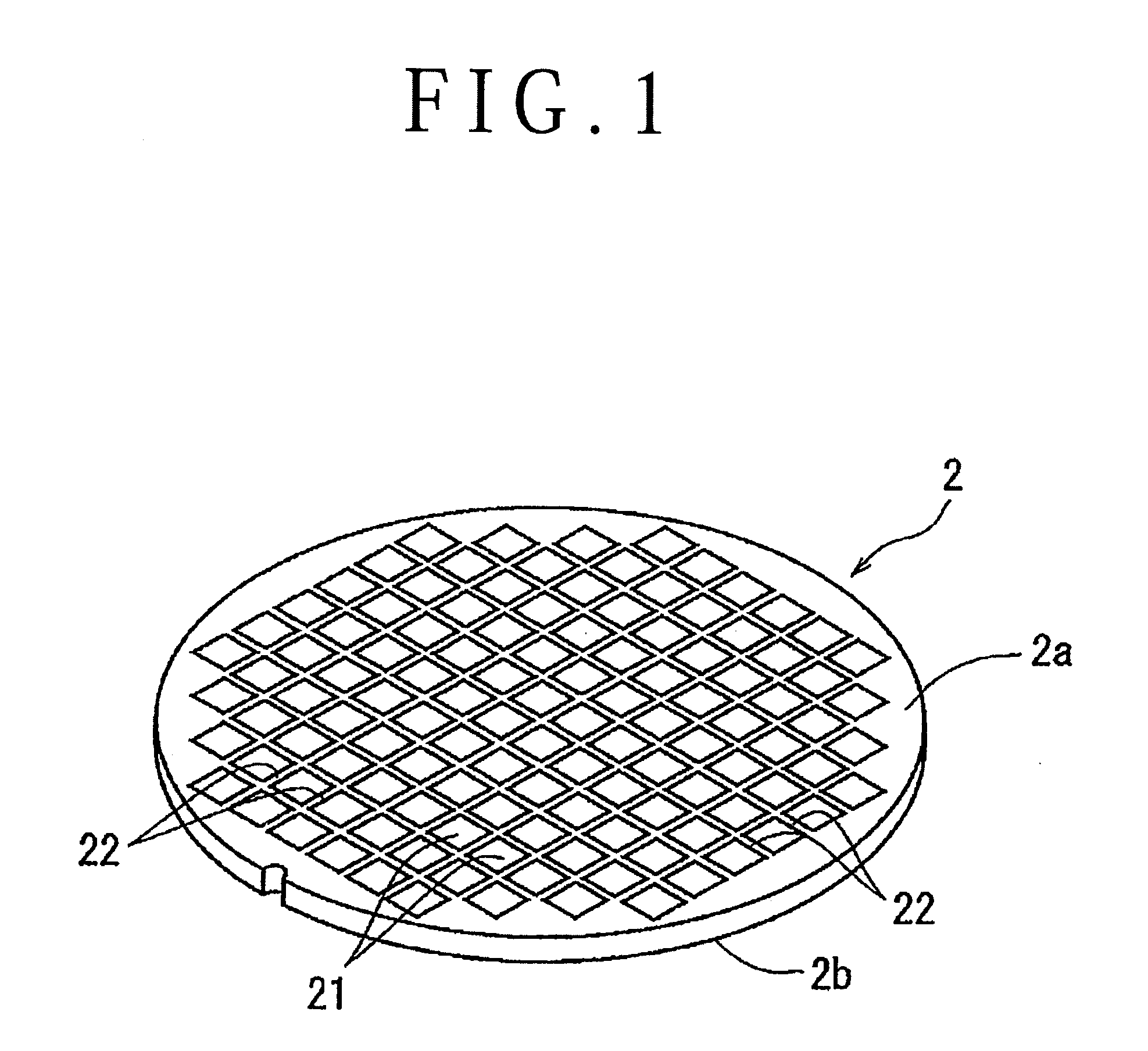

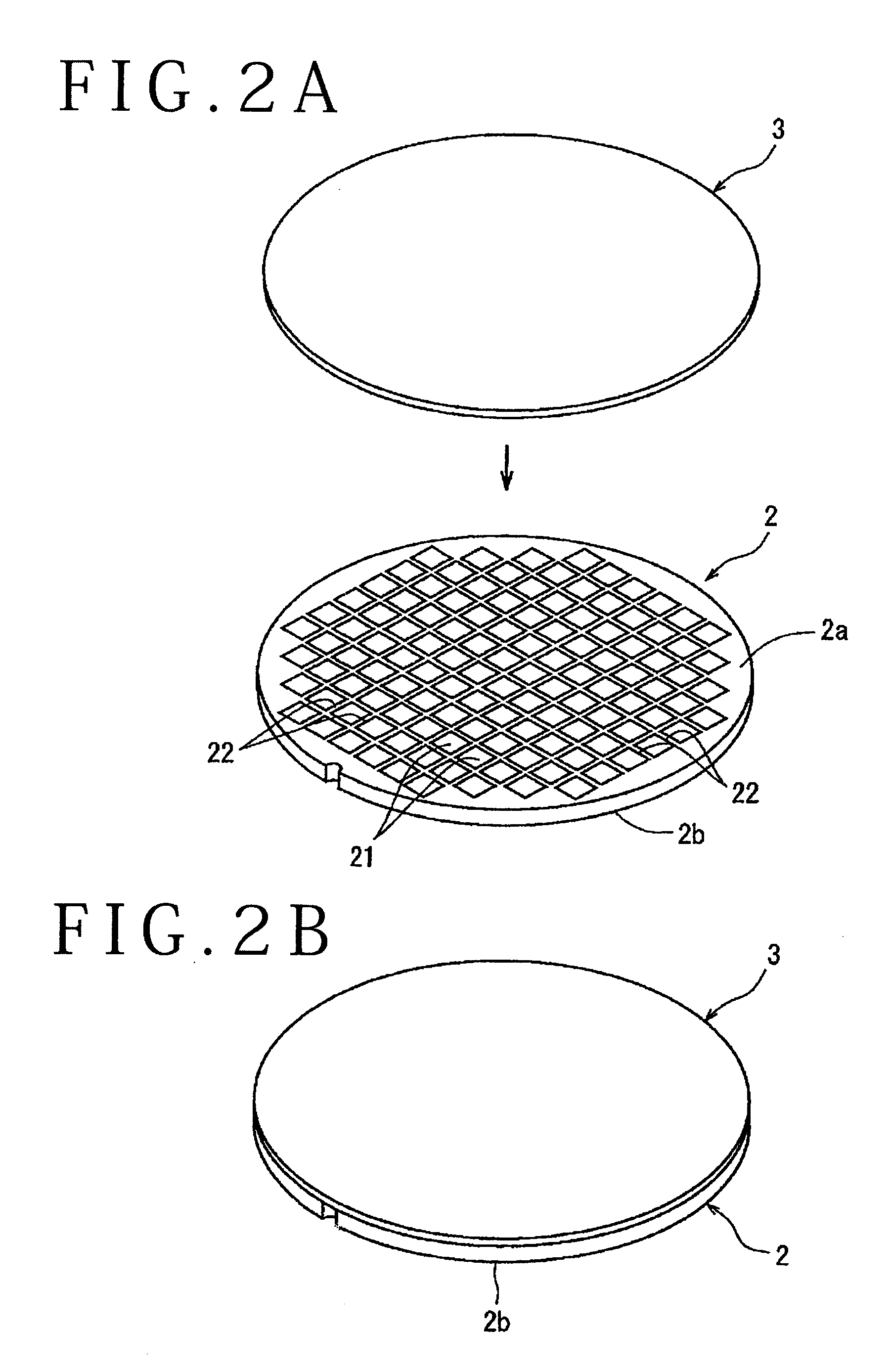

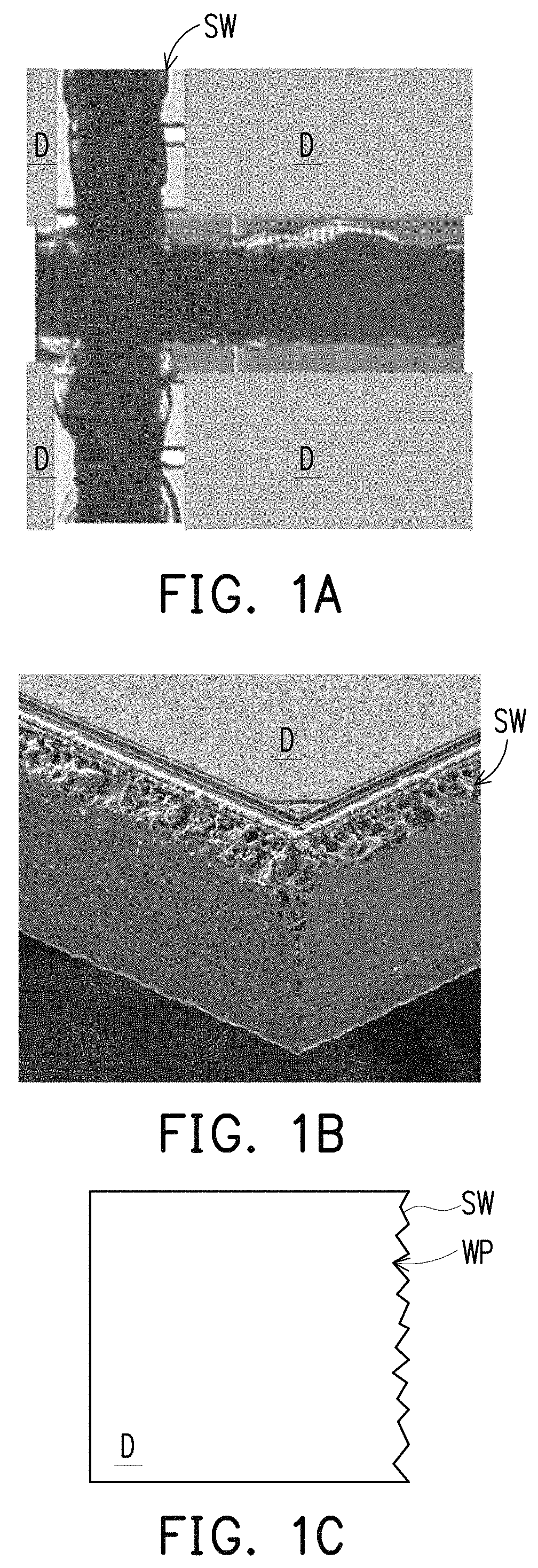

Wafer dividing method

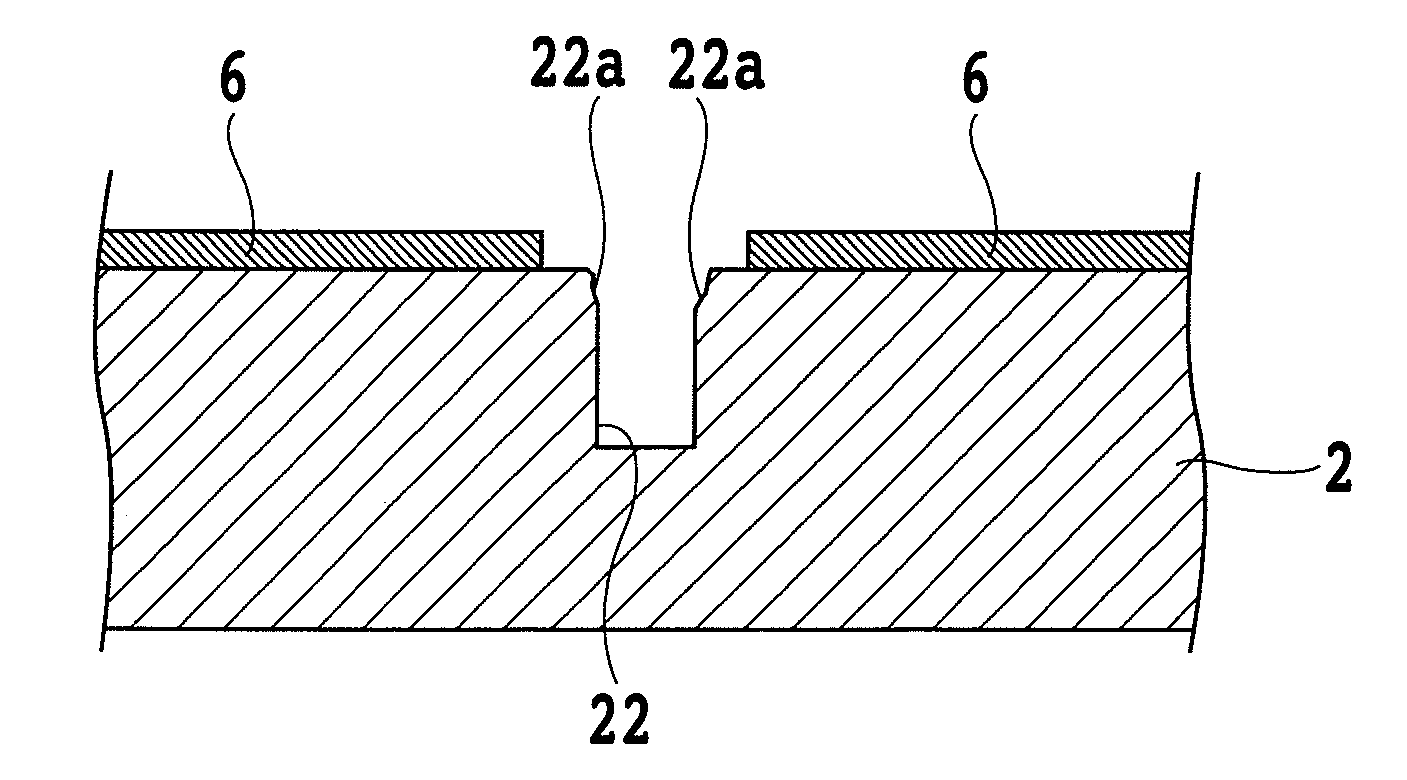

InactiveUS20090186465A1Improve die strengthHigh molding strengthSemiconductor/solid-state device manufacturingEngineeringPlasma etching

A wafer dividing method for dividing a wafer into individual devices, the front side of the wafer being formed with a plurality of crossing streets for partitioning a plurality of areas where the devices are respectively formed. The wafer dividing method includes the steps of coating the front side of the wafer with a protective film, cutting the front side of the wafer with the protective film along the streets to form a plurality of kerfs each having a depth corresponding to the finished thickness of each device, removing chipping from each kerf by plasma etching, attaching a protective tape to the front side of the wafer, grinding the back side of the wafer to expose each kerf to the back side of the wafer, thereby dividing the wafer into the individual devices, and removing a grinding strain from the back side of the wafer.

Owner:DISCO CORP

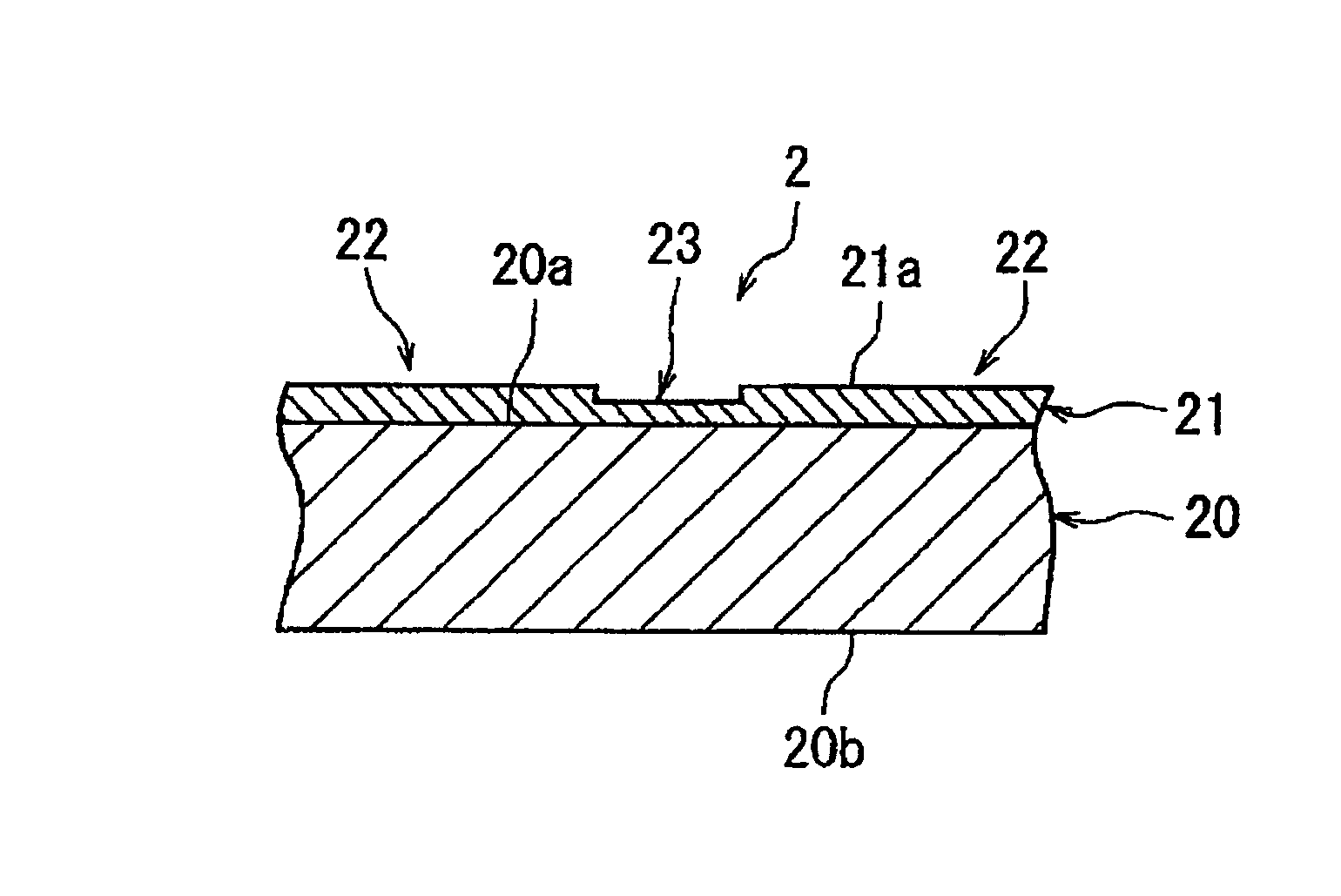

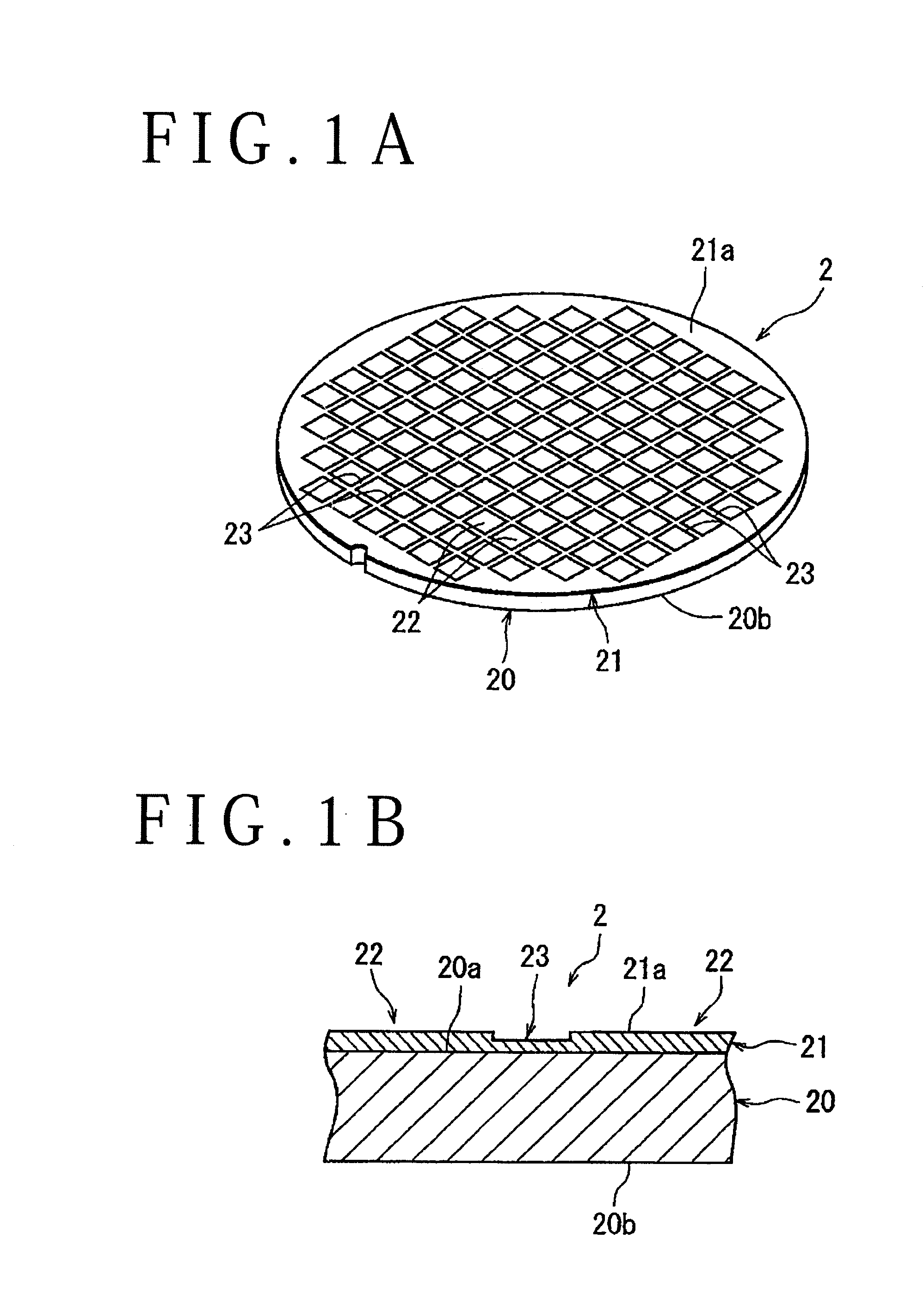

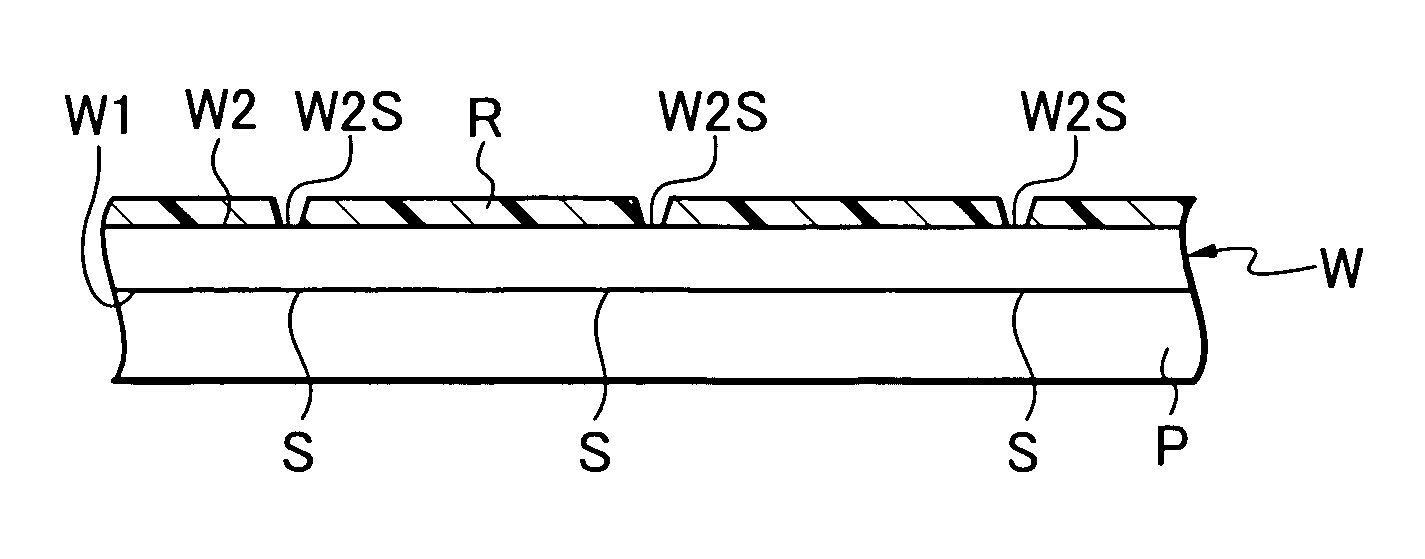

Method of dividing wafer

ActiveUS20060166465A1Remove stressEliminate needSemiconductor/solid-state device manufacturingResistProduction rate

To eliminate necessity of separation of a resist film in dicing by etching and thus improve productivity and die strength of a device, thickness of the resist film is adjusted such that when street-correspondent-areas are separated by etching, resist films coated on portions other than the street-correspondent-areas are not remained.

Owner:DISCO CORP

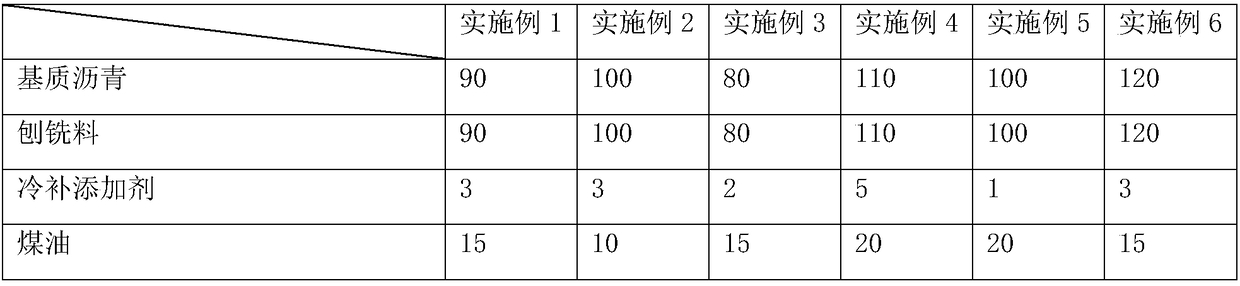

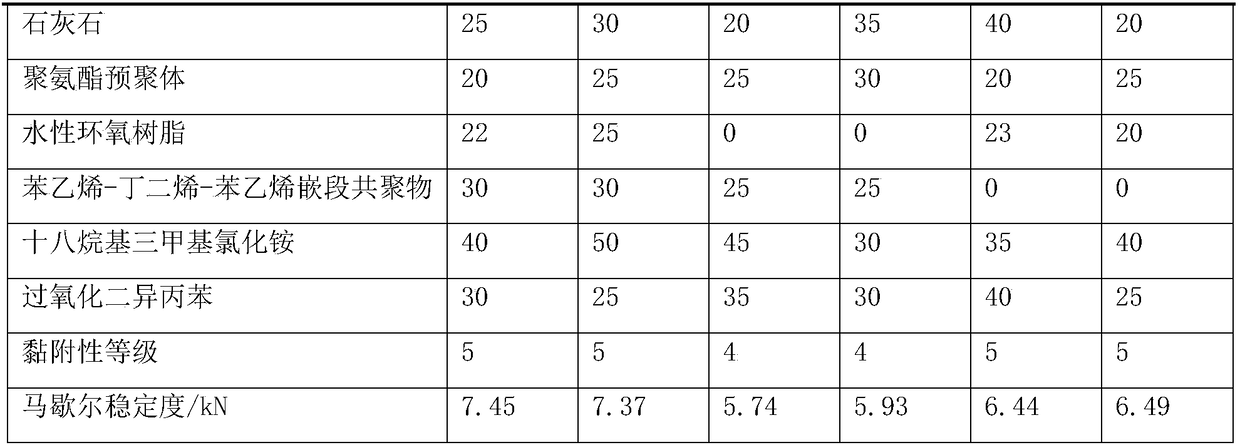

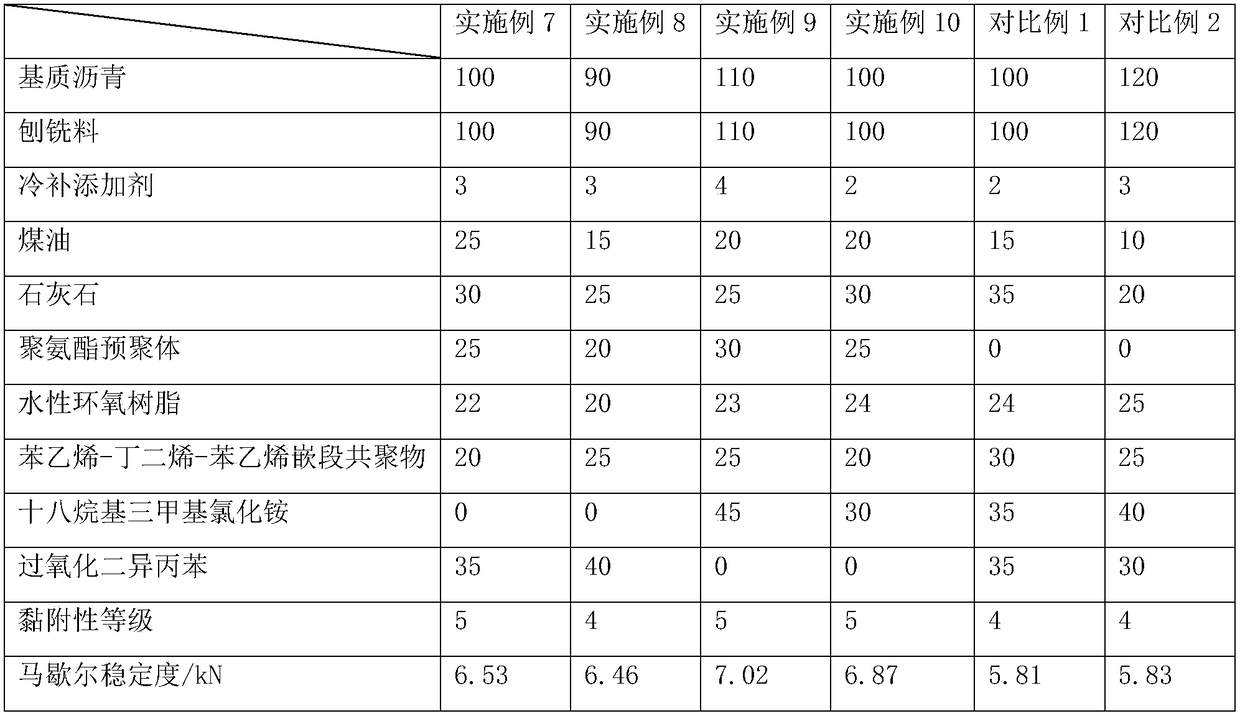

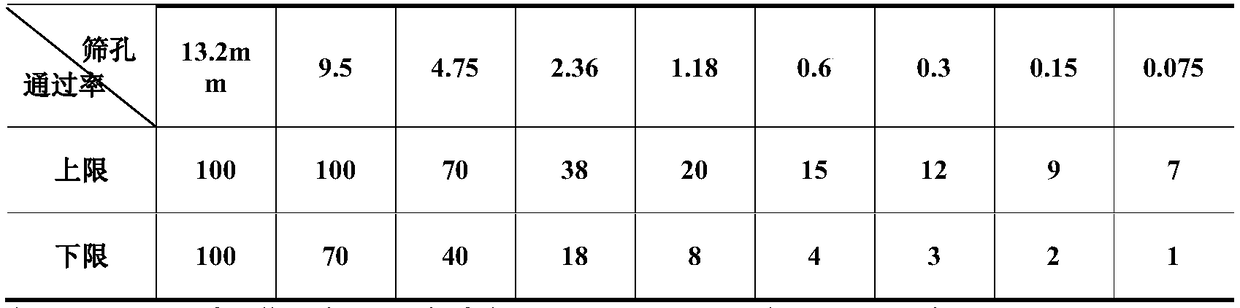

Crumb rubber powder composited regenerated all-weather road cold-patch material and production method thereof

ActiveCN103145376AImproves rutting resistanceTake advantage ofSolid waste managementThermodynamicsProcess engineering

The invention relates to a crumb rubber powder composited regenerated all-weather road cold-patch material which is characterized by comprising the following components in percentage by weight: 0.9-1.2% of diesel oil, 0.2-0.3% of cold-patch additive, 3.5-4.0% of matrix asphalt, 0.5-0.8% of crumb rubber powder, 20-35% of asphalt road milling waste material, 1-2% of mineral powder, and the balance of new aggregate. The invention further discloses a production method of the crumb rubber powder composited regenerated all-weather road cold-patch material. The invention has double advantages of efficiently using waste tires and road milling waste materials, so that the environmental pollution caused by waste tires and road milling waste materials is effectively reduced, and the resources are saved. Meanwhile, the crumb rubber powder composited regenerated all-weather road cold-patch material provided by the invention has the advantages of simple production method, convenience in storage and transport, strong anti-track performance, good agglomerating performance, high forming strength, low temperature operation, good performance and the like.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST

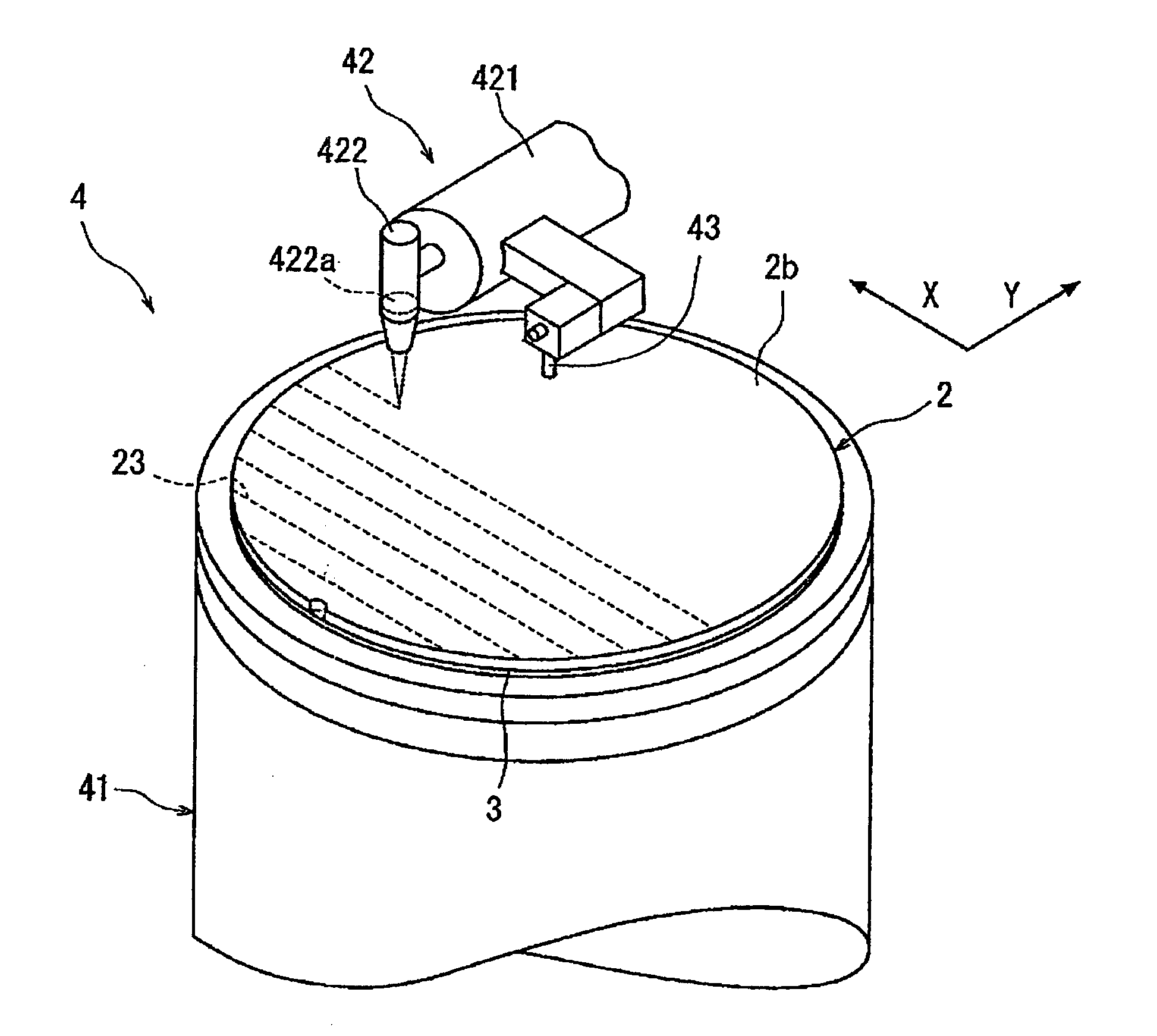

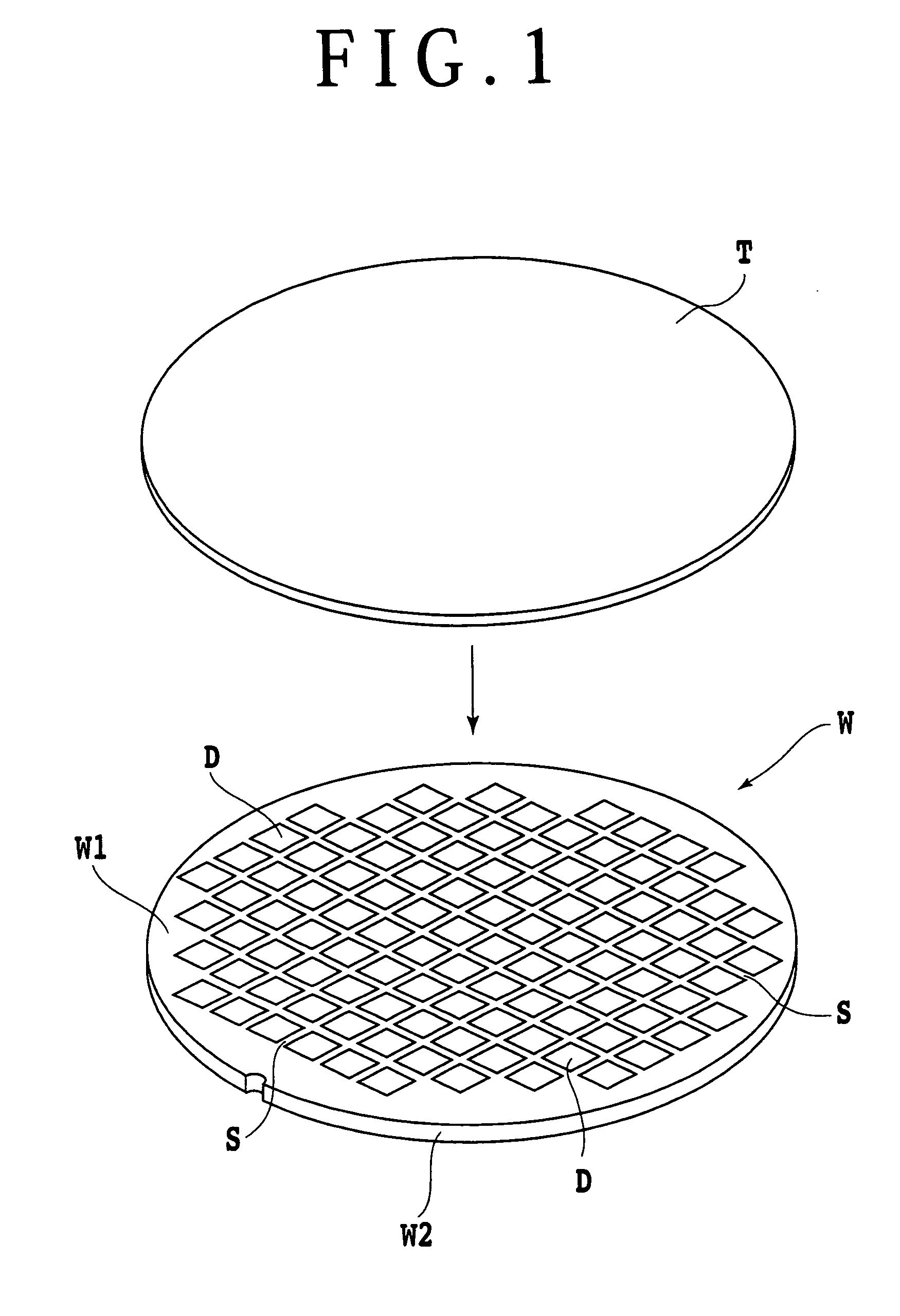

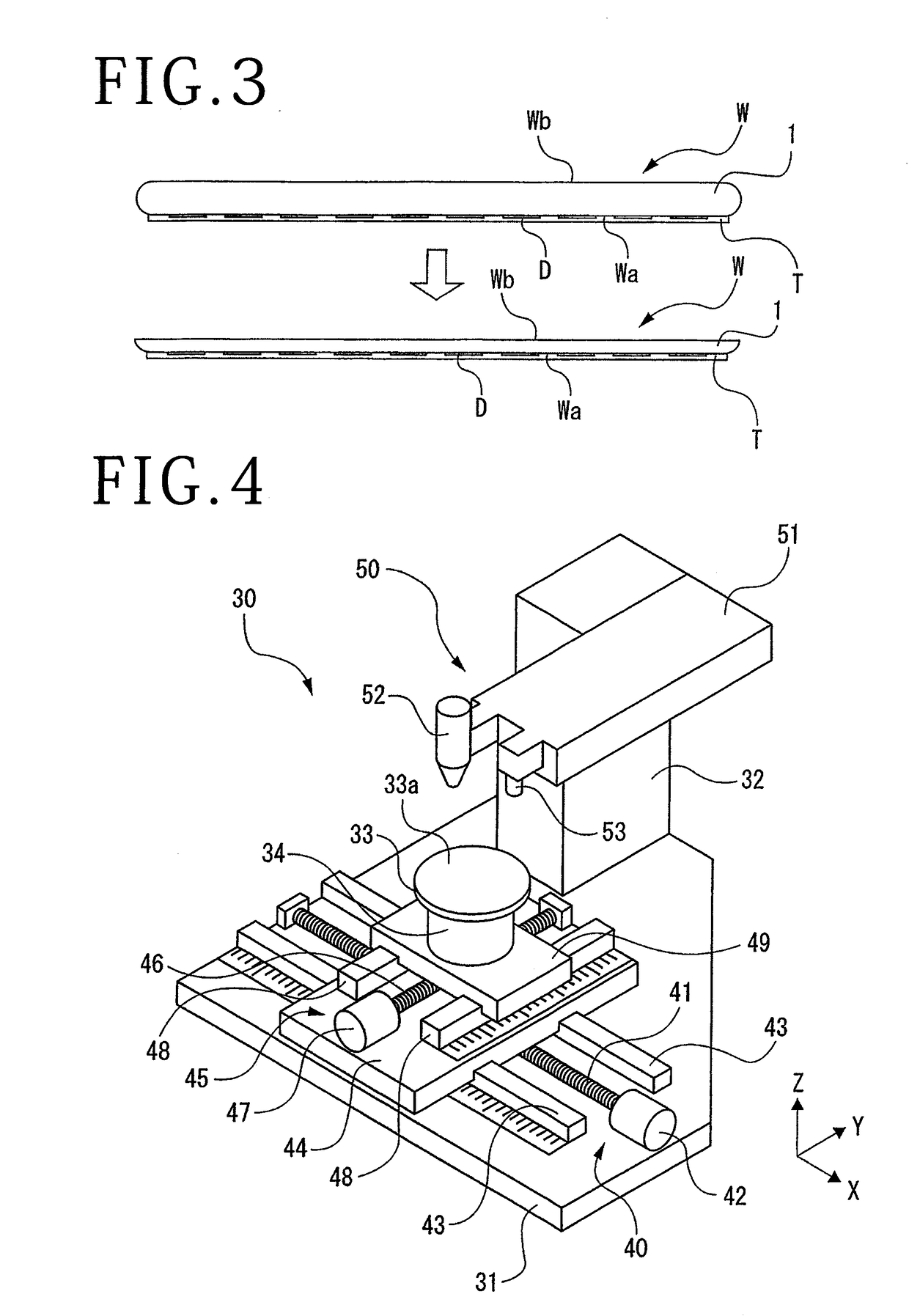

Making method for product information

ActiveUS20080176376A1Improve marking efficiencyImprove productivityPolishing machinesSemiconductor/solid-state device manufacturingDevice formEngineering

A product information marking method including a back side grinding step for grinding the back side of a wafer having a plurality of devices formed on the front side so as to be partitioned by a plurality of separation lines, thereby obtaining a desired thickness of the wafer. After performing the back side grinding step, a marking step for marking product information on the back side of each device by applying a laser beam to the back side of the wafer is performed before separating the devices from each other. Thus, the product information is marked on each device in the stage of the wafer.

Owner:DISCO CORP

Guided missile launching canister and manufacturing method thereof

InactiveCN111023894AReduce weightLabor-saving operationBarrelsLaunching weaponsSolid structureMetallic materials

The invention discloses a guided missile launching canister and a manufacturing method thereof, and belongs to the technical field of guided missile ejector system fittings. The guided missile launching canister comprises a canister body and a guide rail assembly, wherein the canister body is manufactured from a composite material; the guide rail assembly is manufactured from a composite material;the canister body and the guide rail assembly are integrally formed; a cavity is arranged in the canister body; the guide rail assembly is connected to the inner wall of the cavity; the guide rail assembly is used for controlling a launch form and interpenetration of a cable and electronic parts and components; and the guide rail assembly is of a hollow structure. The guided missile launching canister solves the technical problems that the guided missile launching canister is manufactured from a metal material, is great in weight, and is labor-wasting in operation, and weight of the launchingcanister is increased as the guide rail is of a solid structure in the prior art. According to the guided missile launching canister disclosed by the invention, the canister body and the guide rail assembly are manufactured from the composite material, and are integrally formed, so that integral weight of the launching canister is ensured to be small, and operations are labor-saving; and the guide rail assembly which is of a hollow structure is connected in the canister body, so that weight of the lunching canister is reduced.

Owner:TIANJIN ISTAR ADVANCED MATERIAL TECH CO LTD

Method for preparing high-strength water-permeable brick by compounding gangue steel slag and wheat straw ash

The invention discloses a method for preparing a high-strength water-permeable brick by compounding gangue steel slag and wheat straw ash. The method comprises the following steps: sieving gangue andsteel slag according to grain diameter, with the sieved gangue and steel slag as aggregates on the surface layer and the bottom layer of a water-permeable brick correspondingly, carbonizing wheat straws in a carbonizing furnace, mixing with resin, and performing surface modification on the aggregates on the surface layers. The strength and the wear resistance of concrete can be greatly enhanced within the proper mixing amount range, the specific gravity of the water-permeable brick is greatly reduced, high adaptability in the processes of transportation, construction and the like is achieved,and the effect of synergistically improving the strength and the water permeability of the sand-based water-permeable brick is achieved; for the treatment on the aggregate on the bottom layer, rollerrolling is adopted to reduce the influence on the quality performance of the material caused by physical friction, silt on the surfaces of the aggregates can be shaken off, crack-containing particlescan be completely eliminated, and the forming strength of the brick body can be enhanced; and the concrete water-permeable brick with high strength and excellent wear resistance can be prepared, sintering is avoided, and the use strength and high water permeability of the water-permeable brick can be guaranteed.

Owner:海南华舜泰环保科技有限公司

Laser processing method for semiconductor wafer

ActiveUS20100297831A1Improve die strengthHigh molding strengthSolid-state devicesSemiconductor/solid-state device manufacturingPeak valueEnergy density

Owner:DISCO CORP

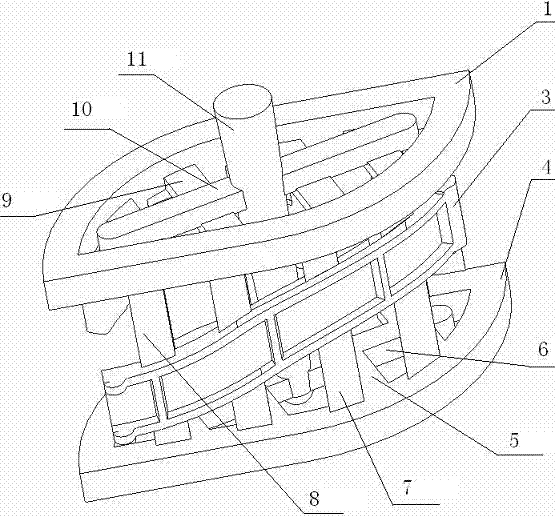

Space curve type casting anti-deformation box cage structure and machining method

InactiveCN105436419APrevent excessive deformationCounteract internal stressFoundry mouldsFoundry coresMachine buildingEngineering

The invention relates to a process method with the space curve type casting anti-deformation function, and belongs to the field of machine manufacturing. By means of a casting method for changing an upper guide rail casting and a lower guide rail casting, an upper annular cavity type tie bar, a lower annular cavity type tie bar, upper follow-up cavity type tie bars and lower follow-up cavity type tie bars are communicated with a straight sprue, transverse sprues and inner sprues to form a box cage structure. The number of times of deformation in the casting forming process is controlled, and the deformation is controlled within 0.5 mm. In the pouring and heat treatment process, under the alternating stress action of heating and cooling, the castings bear irresistible residual stress which cannot be fully offset in the shell expansion and casting shrinkage process, and irregular and disordered permanent plastic deformation is generated. For deformation, a one-mold two-piece process is adopted, the heads and tails are oppositely arranged, the box cage structure is designed, and the deformation of the castings is reduced. The residual stress of the castings is removed through subsequent heat treatment, and it is guaranteed that no excessive deformation is generated after casting cleaning.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Binder composition for casting mold formation and process for producing casting mold using the binder composition for casting mold formation

InactiveCN102105241AImprove mold strengthImprove initial strengthFoundry mouldsFoundry coresMetal chlorideAlkaline earth metal

A binder composition for casting mold formation which can give a casting mold having sufficient strength without complicating the production step; and a process for producing a casting mold using the binder composition for casting mold formation. The binder composition for casting mold formation is characterized by comprising an acid-curable resin, water, and the chloride of a metal. The composition is further characterized in that the acid-curable resin comprises furfuryl alcohol and one or more products of the condensation or co-condensation of one or more members selected from a group consisting of furfuryl alcohol, phenols, and urea with an aldehyde, and that the metal is an alkaline earth metal and / or a zinc-family element.

Owner:GUN EI CHEM IND

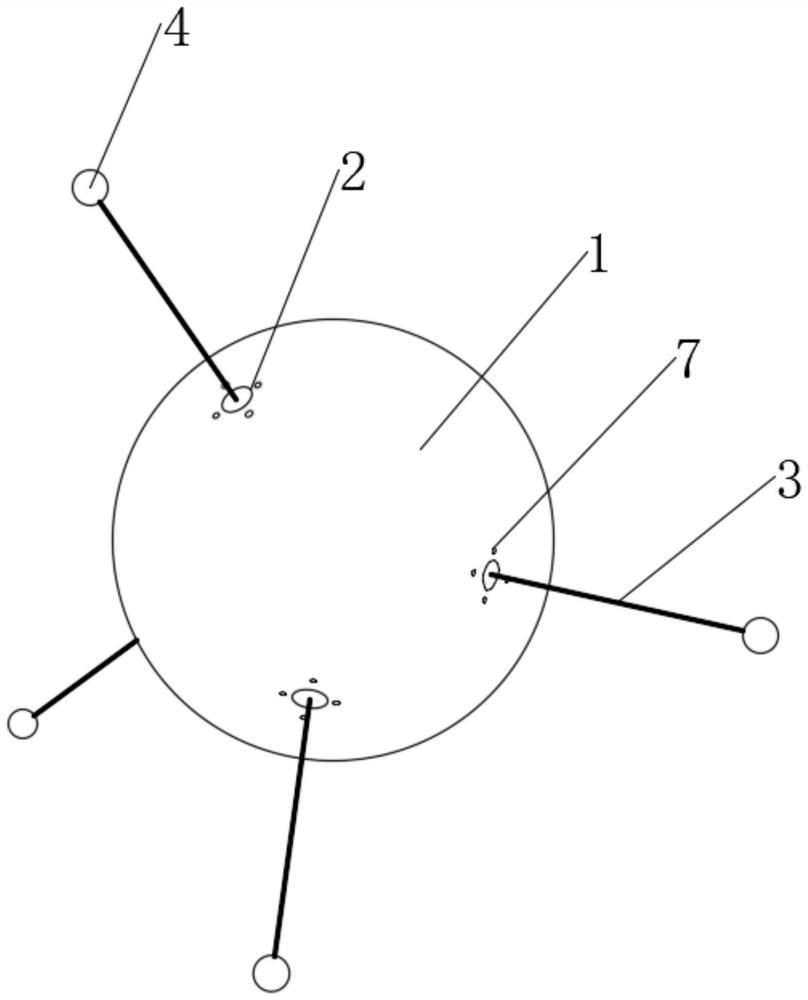

Self-netting type scattered-point internal vibration ball for concrete pouring

InactiveCN111809879AImprove liquidityHigh molding strengthBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a self-netting type scattered-point internal vibration ball for concrete pouring, and belongs to the field of construction technology. The self-netting type scattered-point internal vibration ball can be put in a concrete pouring process so as to replace the traditional concrete vibrator for concrete pouring without actual operation by technicians at a site. Compared with aconcrete vibrator, the self-netting type scattered-point internal vibration ball is in the concrete, and high-quality vibration is carried out to the concrete by moisture in the concrete and the high-frequency vibration caused by the decomposing reaction of a water disintegration vibration ball; meanwhile, a large number of tiny bubbles can be released during the disintegration, the tiny bubblescan be used as an air-entraining agent to improve the peaceability, water-retaining property and cohesiveness of a concrete mixture and improve the flowability of the concrete, and after the vibrationis finished, the tiny bubbles can extend in the concrete by a released self-hardening netting vibration transmission rod; and a high-strength adhesion is established by a double magnetic dot ball, areinforcing net is formed in the concrete, and the forming strength of the concrete is significantly improved through cooperating with an internal vibration sphere.

Owner:周德超

Forming method of wall-thickness-variable composite skirt

The invention discloses a molding method of a composite material skirt with variable wall thickness. The method comprises the following steps: attaching a component to be formed on the outer side of component one, and connecting component two end to end in a ring shape and attaching to the outer side of the component to be formed , set a vacuum bag on the outer side of the whole formed by the component to be formed and the second component and carry out vacuum treatment, put it into an autoclave for curing and molding, and after the forming of the component to be formed is completed, open the second component along the junction. , and then separate the component to be formed from the component 1 to complete the process of demolding, wherein the component 1 is an annular hard component, and the component 2 is a strip-shaped soft component. Compared with the prior art, the combination of the soft mold and the hard mold is beneficial to improve the quality of the surface forming. By disassembling the soft mold, rapid demoulding is realized without destroying the mold, and the mold can be reused, effectively saving the cost of the mold and reducing the manufacturing cost. .

Owner:成都联科航空技术有限公司

Regenerative road cold filling material

The invention discloses a regenerative road cold filling material, and relates to the technical field of road paving. The regenerative road cold filling material is prepared from, by weight, 80-120 parts of matrix asphalt, 80-120 parts of milling material, 1-5 parts of cold filling addictive, 10-25 parts of separant, 20-40 parts aggregate and 20-30 parts of polyurethane prepolymer. The milling material is a waste asphalt mixture, the cold filling material is prepared by using the milling material, and the milling material is fully recycled. The polyurethane prepolymer can improve the adhesiveaggregation performance of the cold filling material, so that the cold filling material and a pit slot interface can form a stronger bonding effect, thereby preventing the asphalt mixture from loosening too early or preventing an interface seam of the pit slot from being damaged the pit slot is filled, and then the durability of the cold filling material is improved. After the polyurethane prepolymer and liquid asphalt are fully mixed and solidified, the asphalt is evenly distributed in a spatial net-shaped structure formed by the polyurethane prepolymer, not only is the strength of the cold filling material improved, but also the cold filling material cannot become sticky and soft at a high temperature.

Owner:ZHEJIANG XIUSHAN GARDEN CONSTR CO LTD

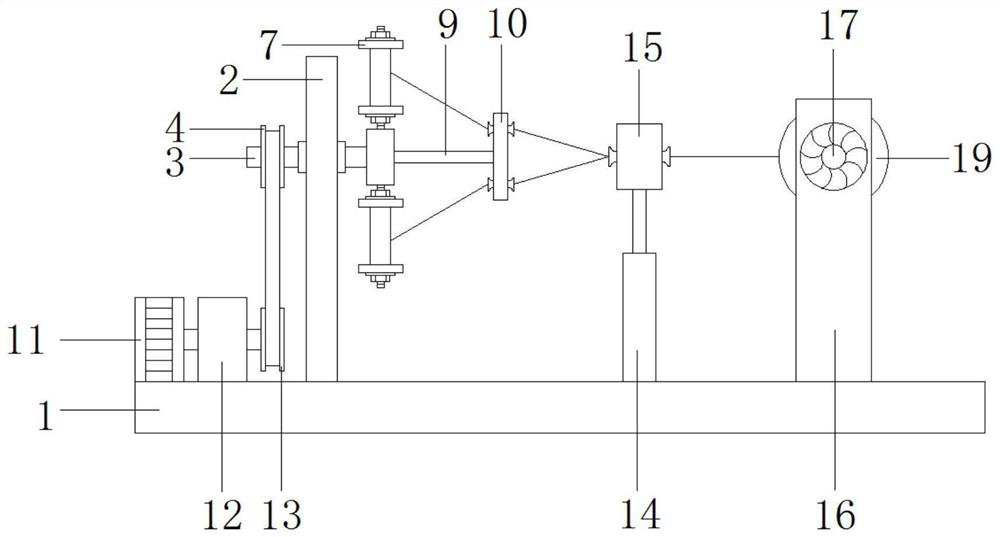

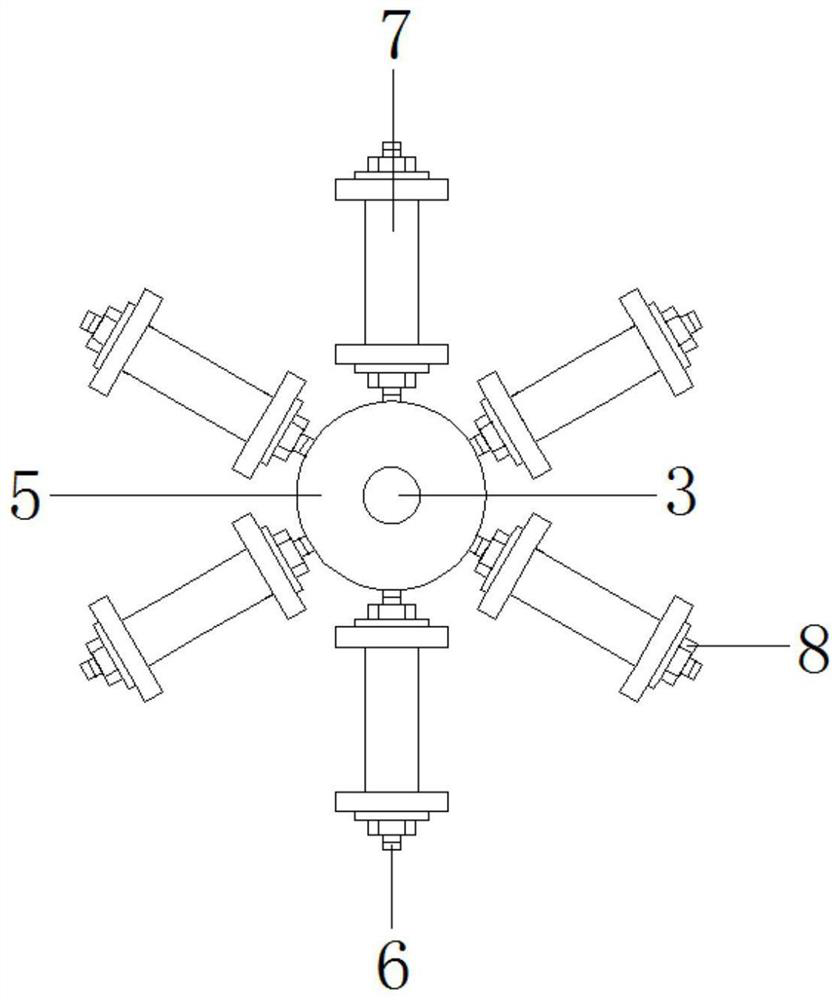

Stranding device for steel wire rope

InactiveCN111607996AHigh molding strengthImprove processing efficiencyRope making machinesDrive wheelElectric machinery

The invention relates to a stranding device for a steel wire rope. The stranding device comprises a pedestal, a top part of the pedestal is fixedly provided with a vertical plate, the vertical plate is rotationally provided with a support column through a rotating shaft, one end of the support column is externally and fixedly sleeved with a driven wheel while the other end thereof is fixedly provided with a turntable, a first driving motor is arranged, and through the driving wheel, the first driving motor can drive the driven wheel to rotate, the driven wheel can drive the turntable and a stranding disk to rotate synchronously through the support column, steel wires on a wire separating reel can be stranded into the steel wire rope, and by arrangement of a wire pressing device, the steelwire rope can be integrated, and molding strength of the steel wire rope can be improved; and by arrangement of a second driving motor, the second driving motor can drive a take-up reel to rotate, thetake-up reel can take up and collect the steel wire rope processed well, the wire separating reel and the take-up reel are respectively locked and fixed through a first lock nut and a second lock nut, thus, the wire separating reel and the take-up reel can be detached and changed conveniently, and processing efficiency of the steel wire rope can be improved.

Owner:溧阳市华菱精工科技有限公司

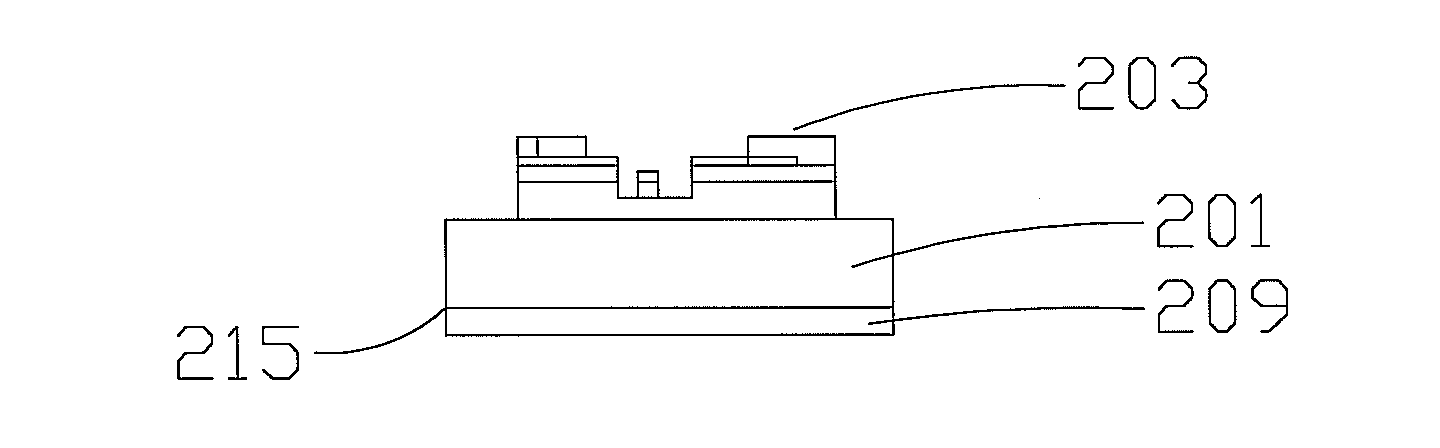

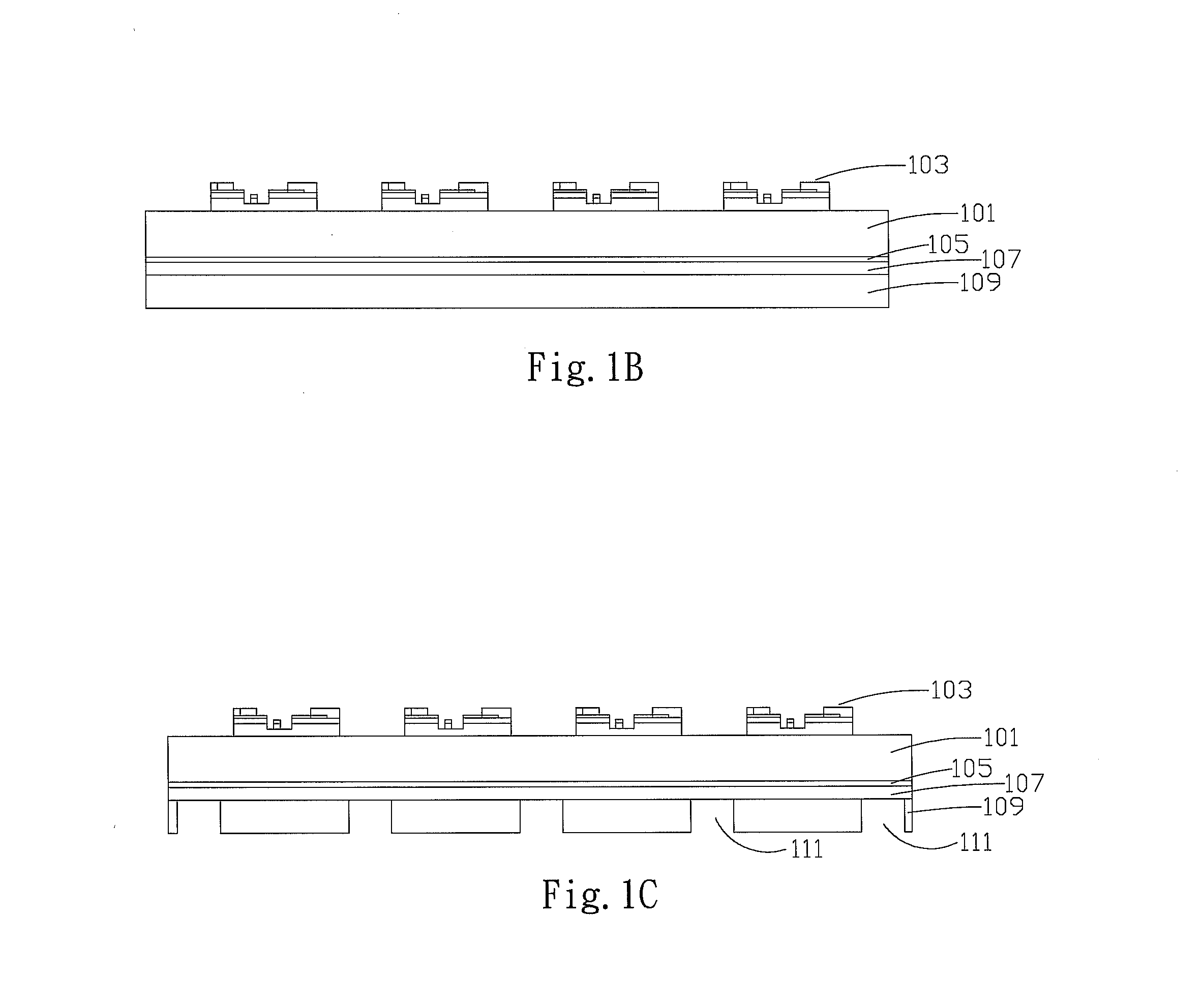

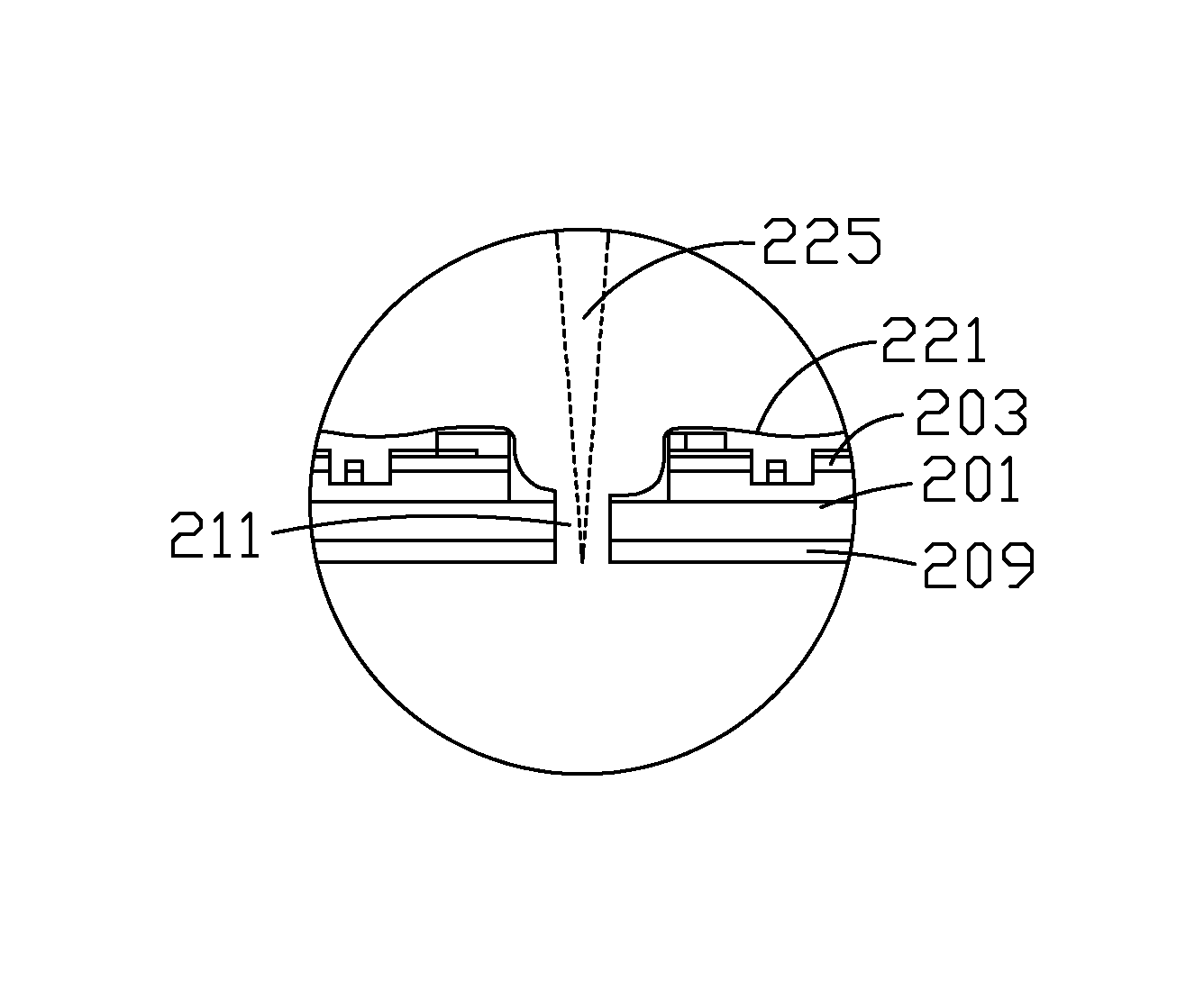

Structure of semiconductor chips with enhanced die strength and a fabrication method thereof

InactiveUS20130099250A1High molding strengthSimple structureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

An improved structure of semiconductor chips with enhanced die strength and a fabrication method thereof are disclosed. The improved structure comprises a substrate, an active layer, and a backside metal layer, in which the active layer is formed on the front side of the substrate and includes at least one integrated circuit; the backside metal layer is formed on the backside of the substrate, which fully covers the area corresponding to the area covered by the integrated circuits in the active layer. By using the specific dicing process of the present invention, the backside metal layer and the substrate can be diced tidily. Die cracking on the border between the substrate and the backside metal layer of the diced single chip can be prevented, and thereby the die strength can be significantly enhanced.

Owner:WIN SEMICON

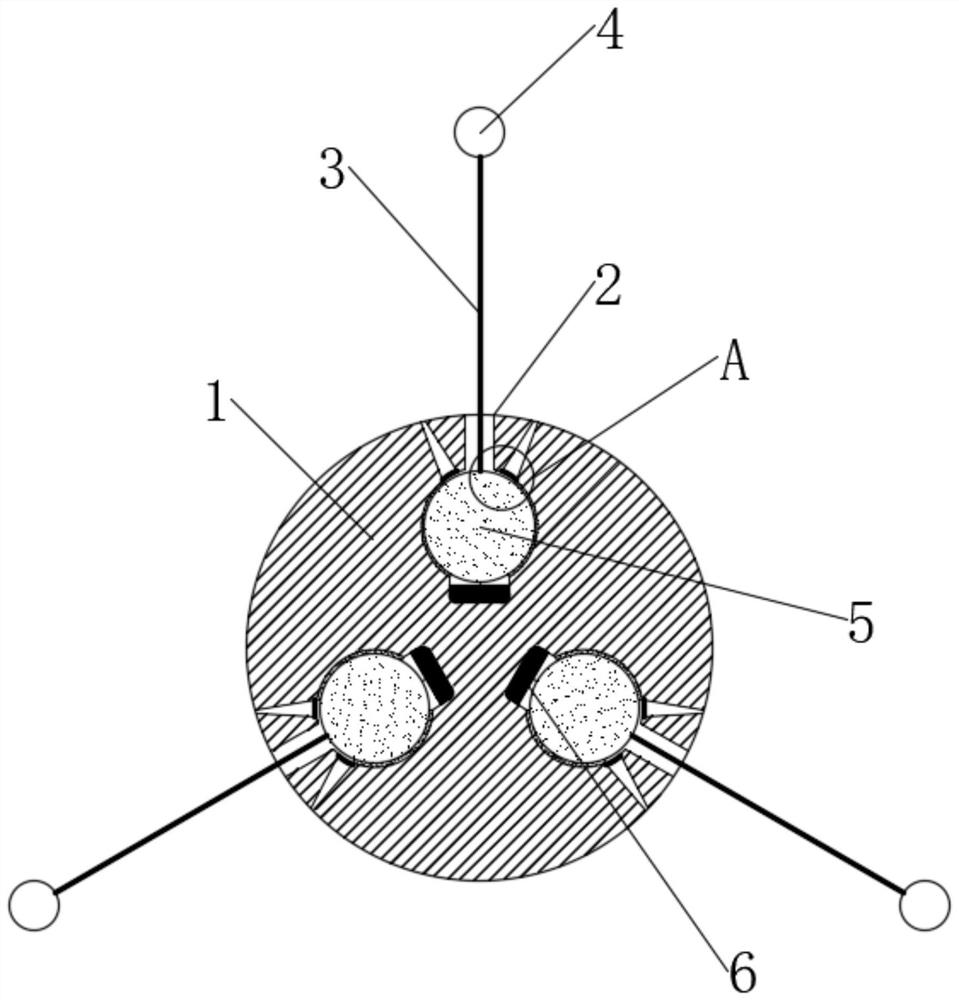

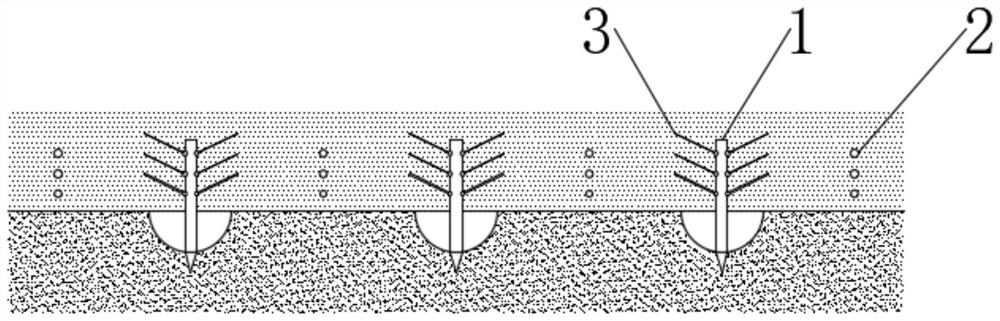

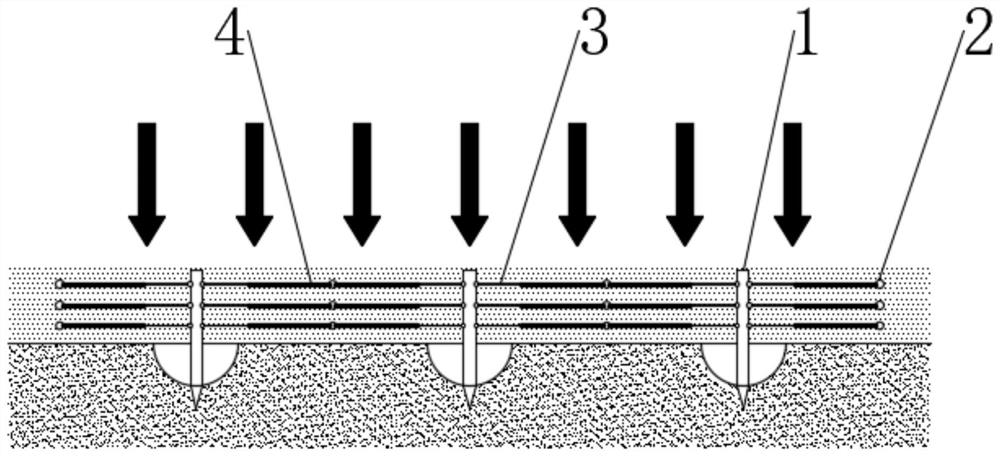

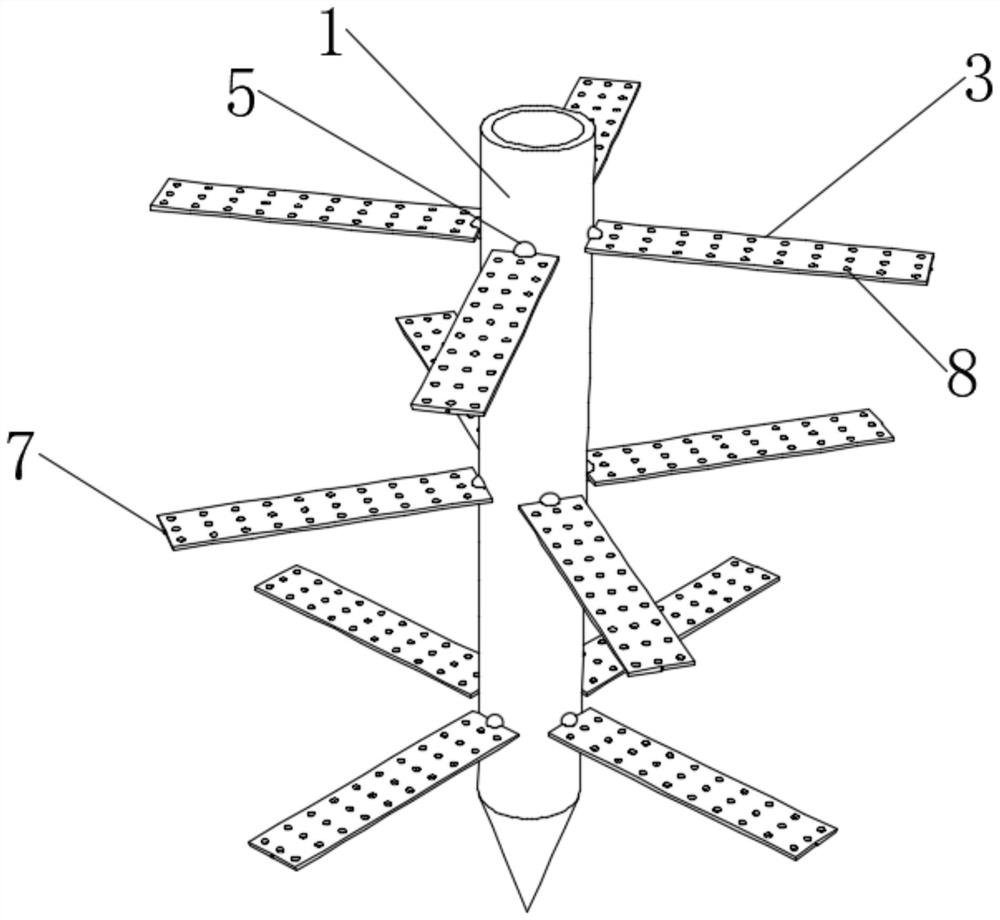

Novel netting type tamping method of filler for roadbed construction

ActiveCN111663388AAvoid drifting and sinkingFirmly connectedMagnetsRoads maintainenceAdhesiveArchitectural engineering

The invention discloses a novel netting type tamping method of a filler for roadbed construction, and belongs to the technical field of building construction. A mode of half pre-buried a tamping-assisting pre-buried rod on a lower side foundation can be realized; the filler matched with an auxiliary tamping plate is laid and filled in a layered manner, and netting node magnetic balls are placed; then, during overall tamping, the auxiliary tamping plate is forced to rotate to assist tamping; meanwhile, a heat release ball is extruded to release heat to trigger netting action after being broken;a migration netting bundle in the auxiliary tamping plate and the netting node magnetic balls are promoted to actively approach and establish connection due to a relationship of a magnetic attractionforce; then, local tamping is carried out on the tamping-assisting pre-buried rod to extrude the migration netting bundle extending into the filler so that a fracturing compaction promoting ball on asurface is forced to break locally; and a self-extending gap opening rod is used as a guide to form a material conveying hole in the filler, a water-based adhesive in the fracturing compaction promoting ball moves and spreads in the filler along the material conveying hole, and a binding force and compactness between the fillers are remarkably improved after curing.

Owner:安徽重标建筑工程有限公司

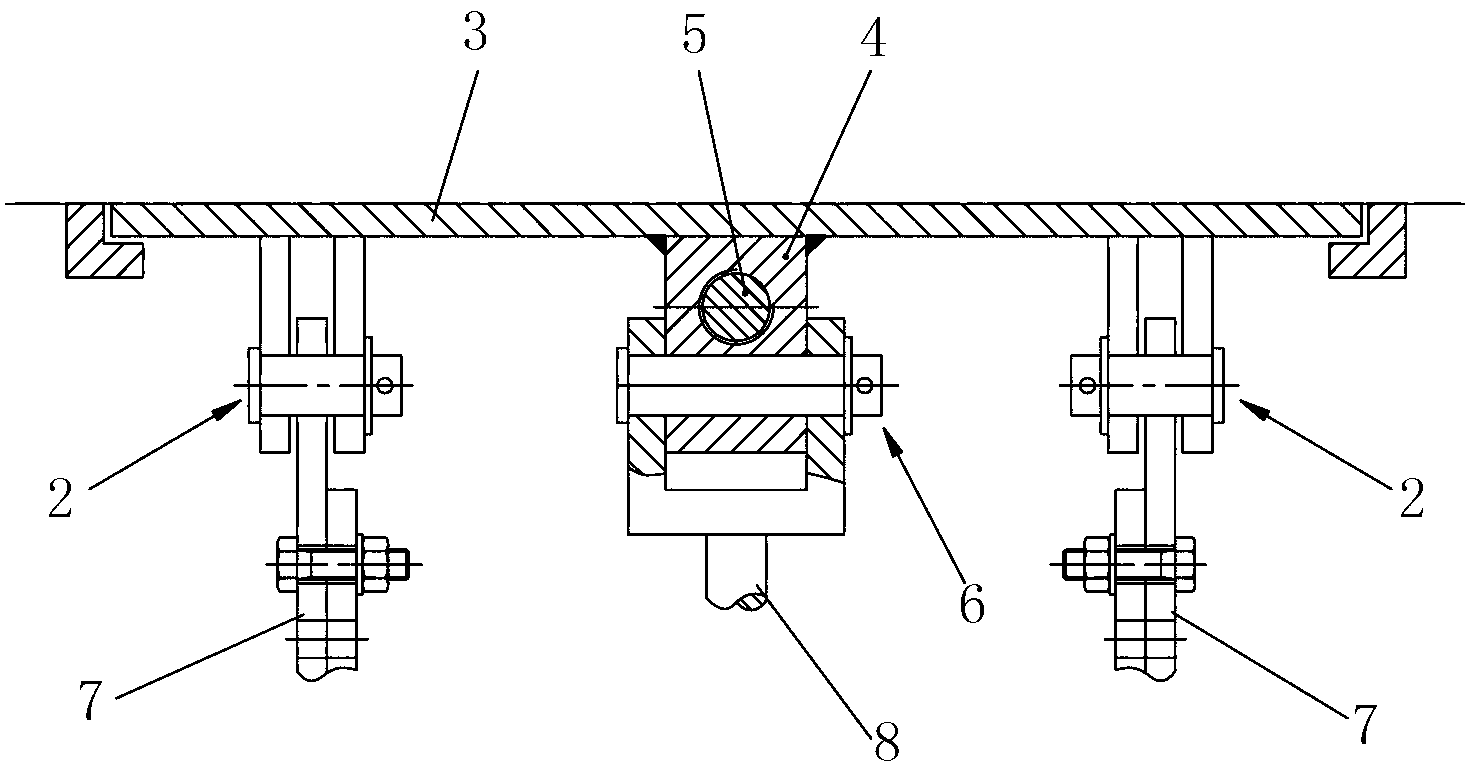

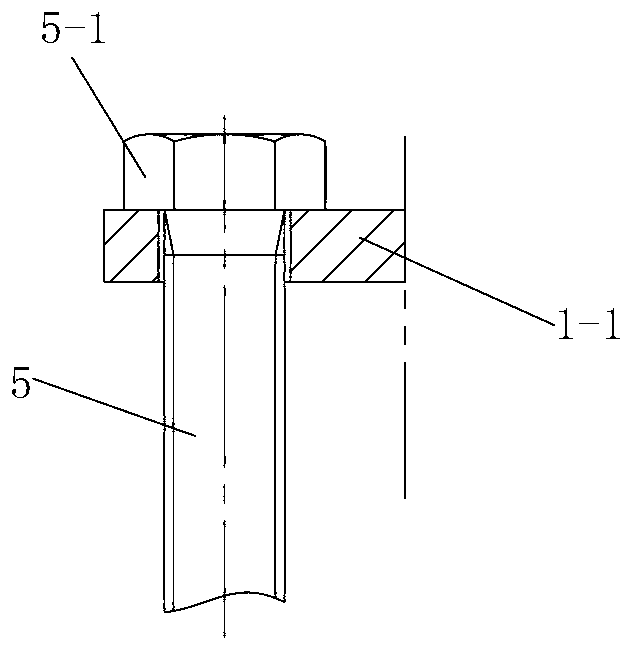

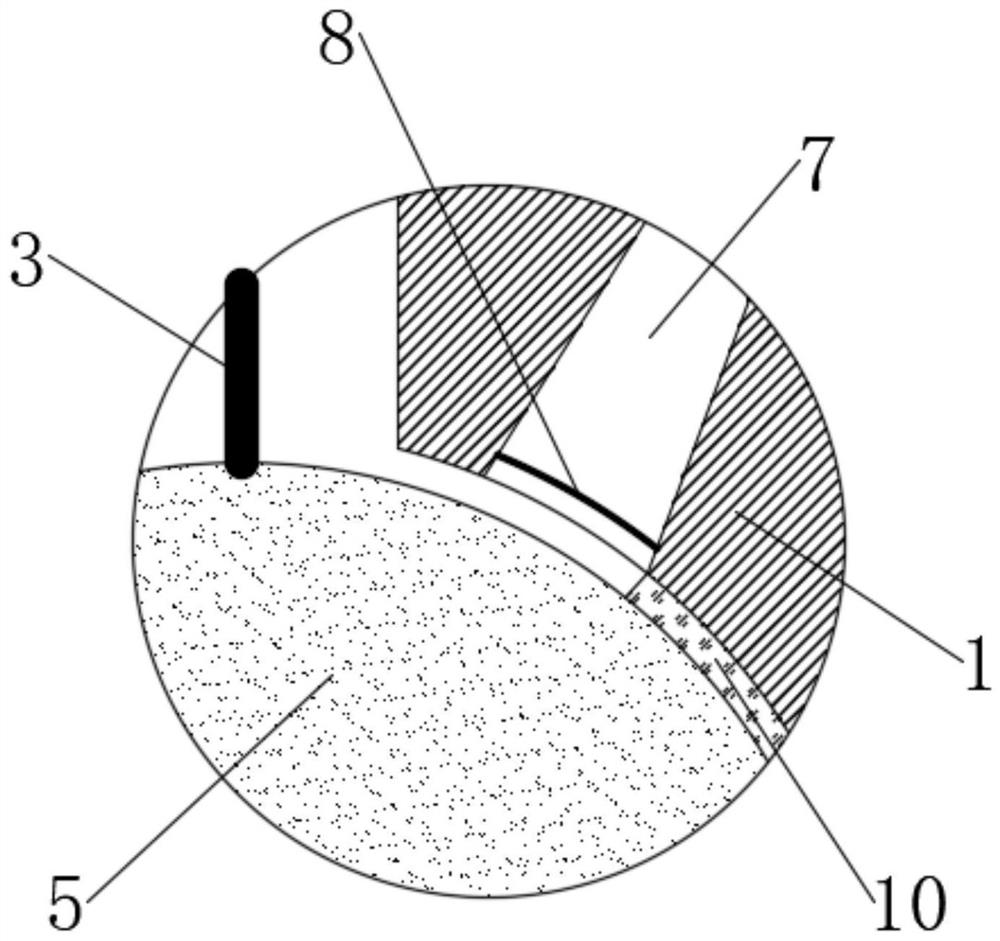

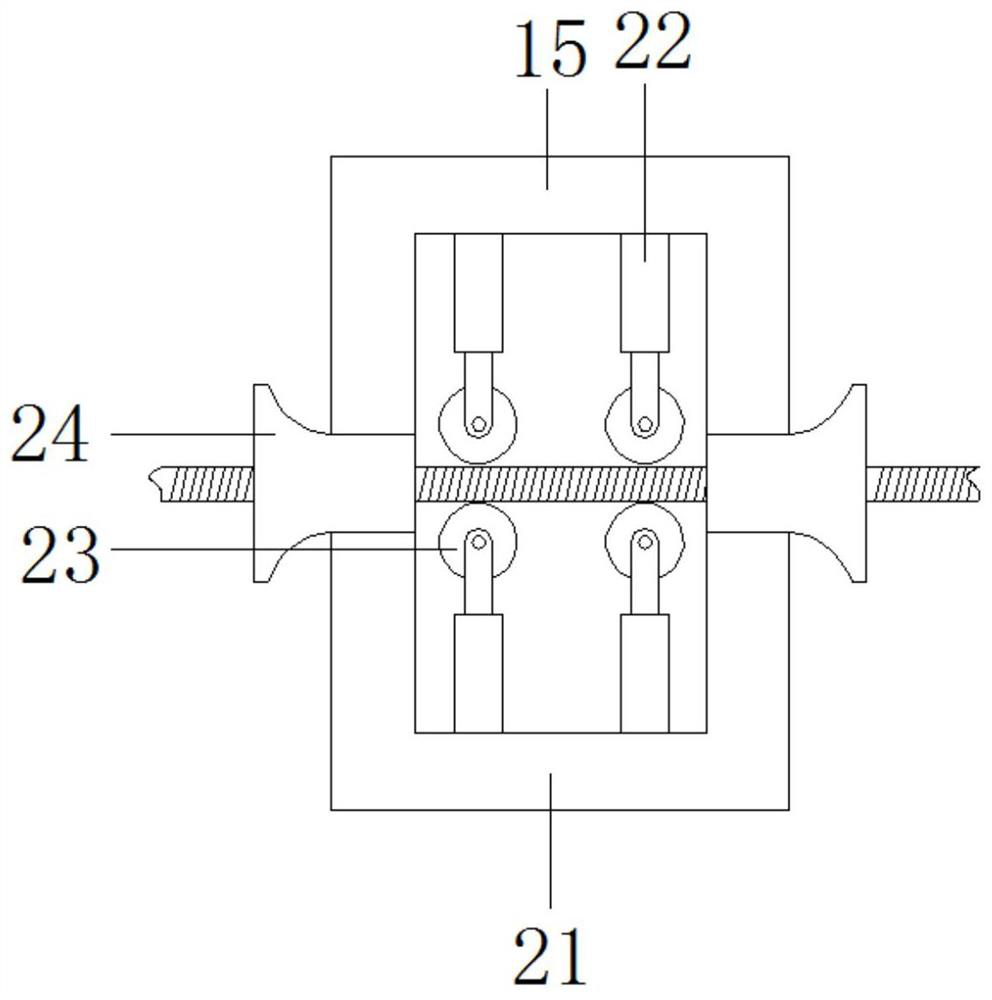

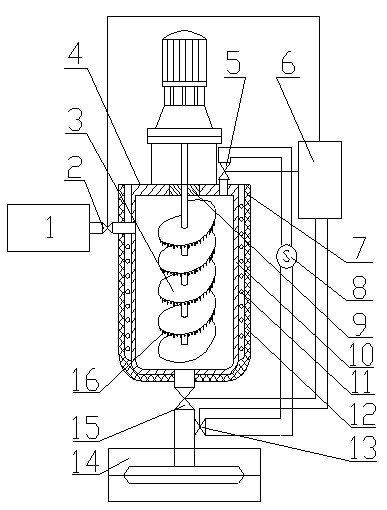

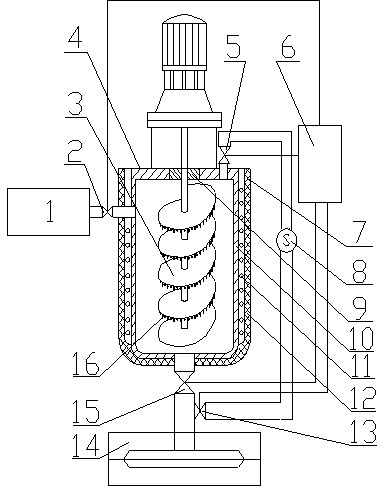

Vacuum mixing injection molding system and method for membrane filter plate of filter press

The invention relates to a vacuum mixing injection molding system and a vacuum mixing injection molding method for a membrane filter plate of a filter press, which can fundamentally eliminate air pockets in membranes and filter plates in an injection molding process of the membranes or the filter plates. A discharge port of an injection mold machine is communicated with a barrel body of a vacuum mixer through a feeding solenoid valve, and a control end of the feeding solenoid valve is connected with a signal output end of a controller; a spiral propelling mixer is positioned in the barrel body of the vacuum mixer, and is driven by a motor reducer positioned at the upper part the barrel body of the vacuum mixer to rotate, and a vacuum suction nozzle is communicated with a vacuum air extractor through an air path solenoid valve and an air pipe, and a control end of the air path solenoid valve is connected with the signal output end of the controller; a discharge port of the barrel body of the vacuum mixer is communicated with one end of a through way of a tee joint through the discharge solenoid valve, and the other end of the through way of the tee joint is communicated with a feed port of an injection mold in a butt joint way; and a middle way of the tee joint is communicated with the vacuum air extractor through the air path solenoid valve. The system and the method have the advantages that: the molding strength of the membranes or the filter plates is improved, and the rupture phenomenon does not occur when the membranes bulge and the filter plates are pressed.

Owner:杭州兴源环保设备有限公司

Wafer processing method

ActiveUS20190027408A1WidthReduce in quantitySemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesSplit linesEngineering

A method of processing a wafer includes a laser beam applying step of applying a laser beam to the wafer to form modified layers in the inside of the wafer along division lines and to extend device layer splitting cracks from the modified layers to the front surface of the wafer. After the laser beam applying step is performed, a cutting step of cutting the wafer is performed by a cutting blade from the back surface side to form cut grooves and to remove the modified layers. Therefore, the modified layers are not left on chips, and the die strength of the chips is enhanced.

Owner:DISCO CORP

Cold patch material for disease repair of asphalt road pavements and preparation method thereof

InactiveCN108640565AExtended service lifeExtend service life and have broad application prospectsDiseaseCrushed stone

The invention relates to a cold patch material for disease repair of asphalt road pavements. The cold patch material is prepared from aggregate, asphalt and a cold patch agent, wherein the aggregate is prepared from crushed stone, machine-made sand and ore powder; the particle size of the crushed stone is 5mm to 16mm; the ratio of oil to stone is 4 to 6%; the amount of cold patch agent in the coldpatch material is 1.0 to 1.5%. The asphalt cold patch material has the characteristics that the defects of easiness in caking, poor durability and poor peaceability in the traditional cold patch asphalt mixture are overcome; the repair can be performed at any time, the peaceability is good, the temperature stability is good, the forming strength is high, the water stability is excellent, the durability is good, the storage is easy and the like; the service life of the cold patch material is effectively prolonged; the application prospect is broad.

Owner:重庆通力高速公路养护工程有限公司

Wafer processing method including a filament forming step and an etching step

ActiveUS9349646B2Effective divisionAvoid quality lossSemiconductor/solid-state device manufacturingLaser beam welding apparatusLength wavePulsed laser beam

A wafer processing method for dividing a wafer along a plurality of division lines to obtain a plurality of individual chips. The wafer processing method includes a filament forming step of applying a pulsed laser beam having a transmission wavelength to the wafer along each division line in the condition where the focal point of the pulsed laser beam is set inside the wafer in a subject area to be divided, thereby forming a plurality of amorphous filaments inside the wafer along each division line, and an etching step of etching the amorphous filaments formed inside the wafer along each division line by using an etching agent to thereby divide the wafer into the individual chips along the division lines.

Owner:DISCO CORP

Method of wafer dicing and die

ActiveUS10685883B1Removes complex test structureImprove stressSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsWaferingWafer dicing

A method of wafer dicing and a die are provided. The method includes the following processes. A wafer is provided, the wafer includes a plurality of die regions and a scribe region between the die regions. The scribe region includes a substrate, and a dielectric layer and a test structure on the substrate, the test structure is disposed in the dielectric layer. A first removal process is performed to remove the test structure and the dielectric layer around the test structure, so as to expose the substrate. The first removal process includes performing a plurality of etching cycles, and each etching cycle includes performing a first etching process to remove a portion of the test structure and performing a second etching process to remove a portion of the dielectric layer. A second removal process is performed to remove the substrate in the scribe region, so as to form a plurality of dies separated from each other.

Owner:WINBOND ELECTRONICS CORP

Fabrication method for producing semiconductor chips with enhanced die strength

ActiveUS8835283B2High molding strengthImprove yieldSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A fabrication method for producing semiconductor chips with enhanced die strength comprises following steps: forming a semiconductor wafer with enhanced die strength by comprising the substrate, the active layer on the front side of the substrate and the backside metal layer on the backside of the substrate, wherein at least one integrated circuit forms in the active layer; forming a protection layer on a front side of the semiconductor wafer; dicing the semiconductor wafer by at least one laser dicing process and removing the laser dicing residues and removing said protection layer by at least one etching process, whereby plural semiconductor chips with enhanced die strength are produced, and wherein the backside metal layer of said semiconductor chip fully covers the backside of said semiconductor chip after dicing.

Owner:WIN SEMICON

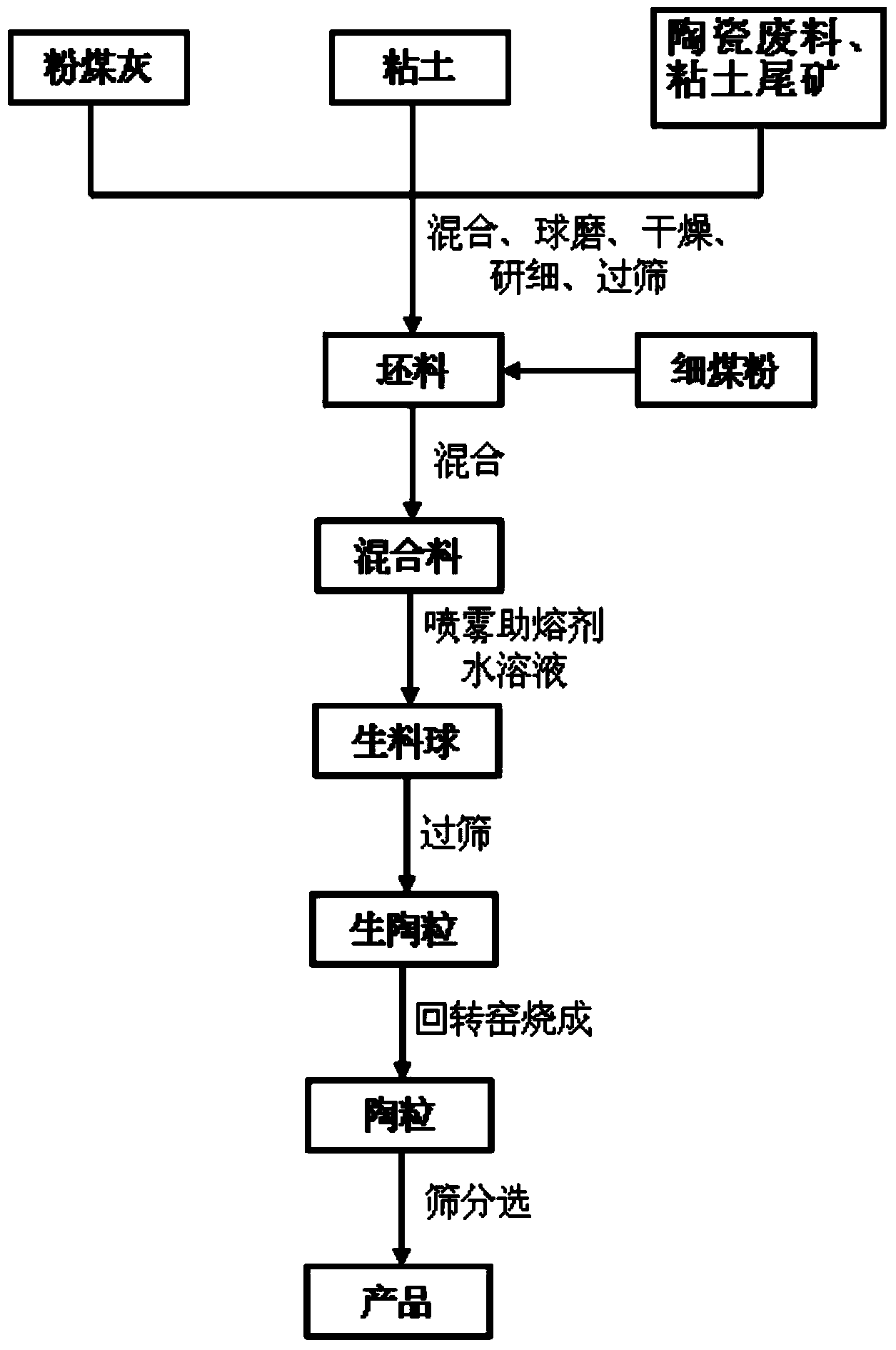

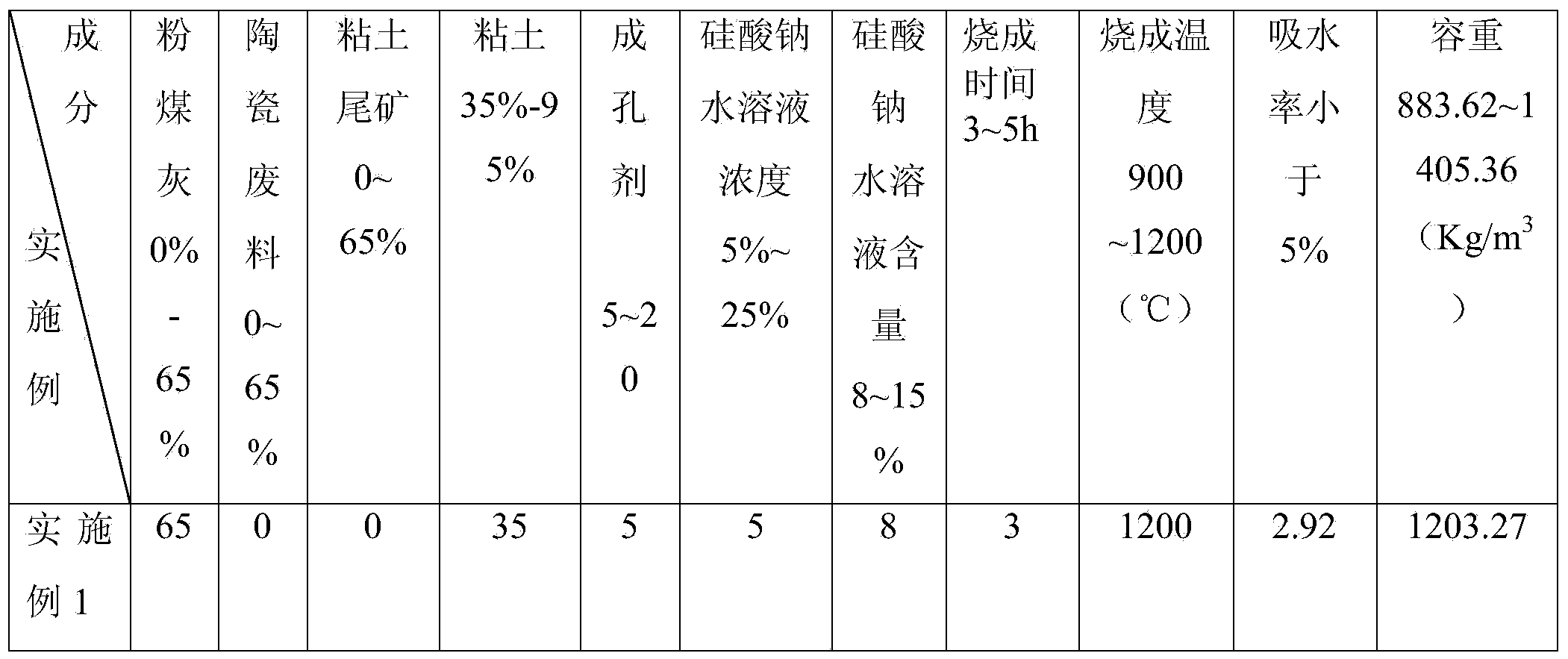

Sodium silicate surface co-sintered light ceramsite and preparation method thereof

ActiveCN104291786ALow costSimple processCeramic materials productionCeramicwareSurface layerHigh volume manufacturing

The invention relates to sodium silicate surface co-sintered light ceramsite and a preparation method thereof. The light ceramsite and the preparation method have the beneficial effects that by spraying a 5-25% sodium silicate solution step by step, during drying, sodium ions dissolved in water diffuse toward the surfaces along with the moisture and gather on the shells of surfaces of raw meal nodules, the sodium ions on the surface layers react with other matters in the sintering process to form fusible matters, thus playing a role of co-sintering agents, and the content of the sodium ions in the co-sintering agents below the surface layers of the raw meal nodules is very low; the ceramsite sintered at a surface layer sintering temperature has relatively low water absorption but the unsintered density of core regions below the surface layers is lower, so that the light ceramsite with low water absorption and low overall density is finally obtained; the problems that the ceramsite not only requires low water absorption and high strength but also requires light volume weight are solved; the preparation method of the sodium silicate surface co-sintered light ceramsite is simple in process and safe to operate, can be used for volume production and is low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

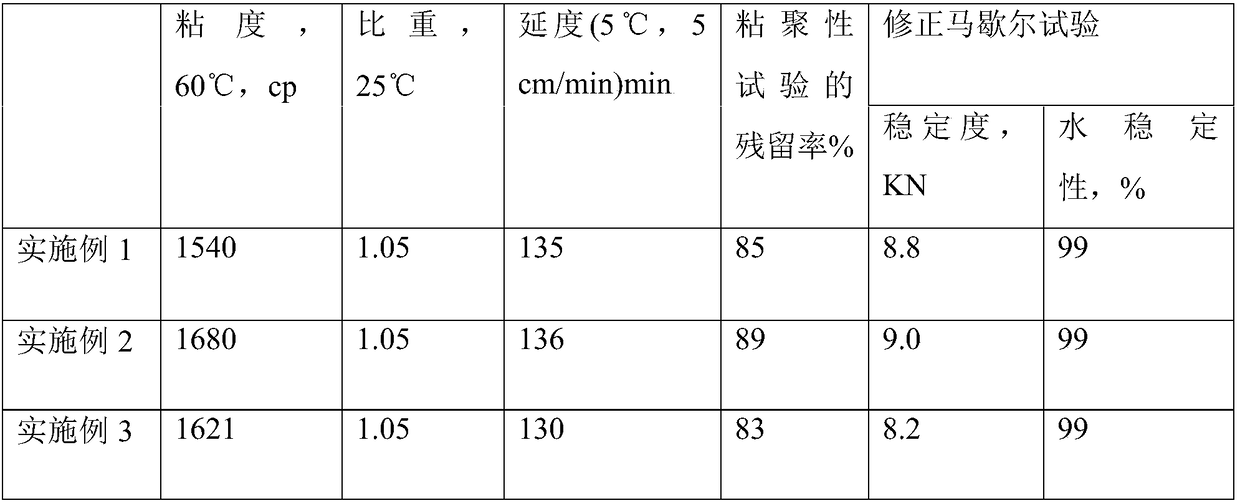

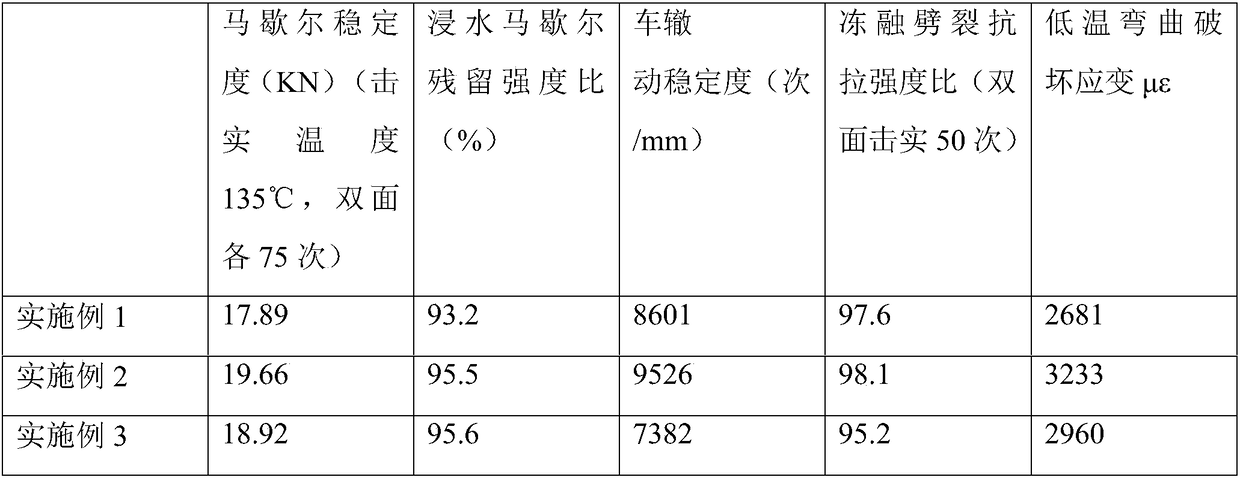

Super-viscous wear-resistant composite modified emulsified asphalt thin overlay material and preparation method thereof

The invention discloses a super-viscous wear-resistant composite modified emulsified asphalt thin overlay material and a preparation method thereof. The super-viscous wear-resistant composite modifiedemulsified asphalt thin overlay material is prepared from emulsified asphalt, basalt fiber, rubber powder, cement, aggregate and mineral powder. The modified emulsified asphalt is prepared from the following components in parts by mass: 6 to 8 parts of modified emulsified asphalt, 0.06 to 0.16 part of basalt fibers, 0.3 to 1.2 parts of rubber powder, 1 to 3.5 parts of cement, 100 parts of aggregate and 2 to 4 parts of mineral powder. The prepared composite modified emulsified asphalt thin overlay material has the characteristics of high adhesion, high wear resistance, easiness in constructionand the like.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com