Regenerative road cold filling material

A cold patching and road technology, applied in the field of road paving, can solve the problems that the cold patching material cannot quickly form strength, the joints of the pit interface fall off, and the cohesion of the cold patching material is poor, so as to improve the strength and shear resistance Strength, the effect of increasing the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

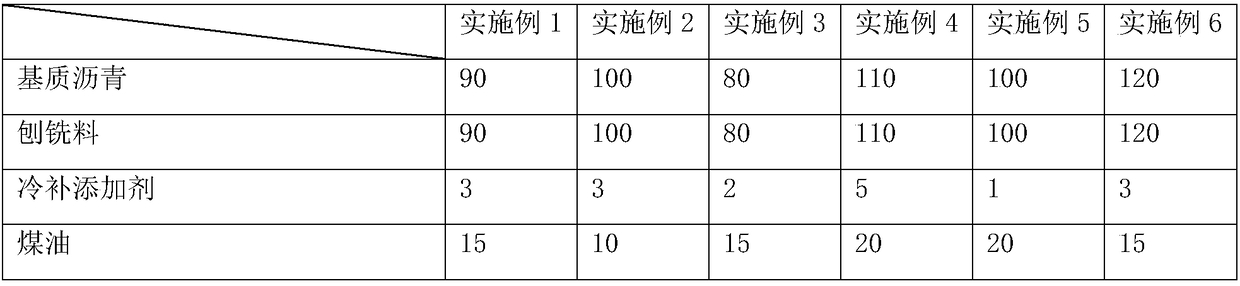

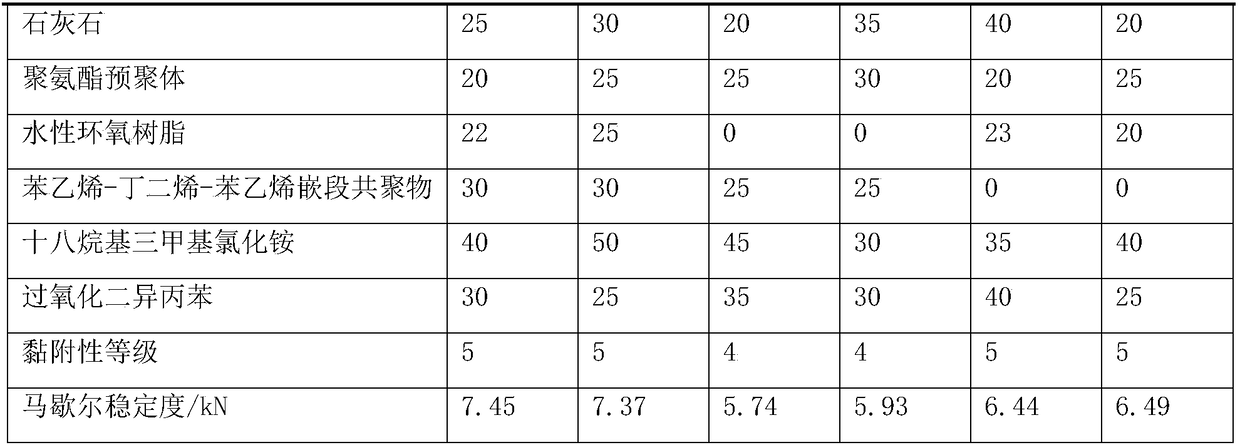

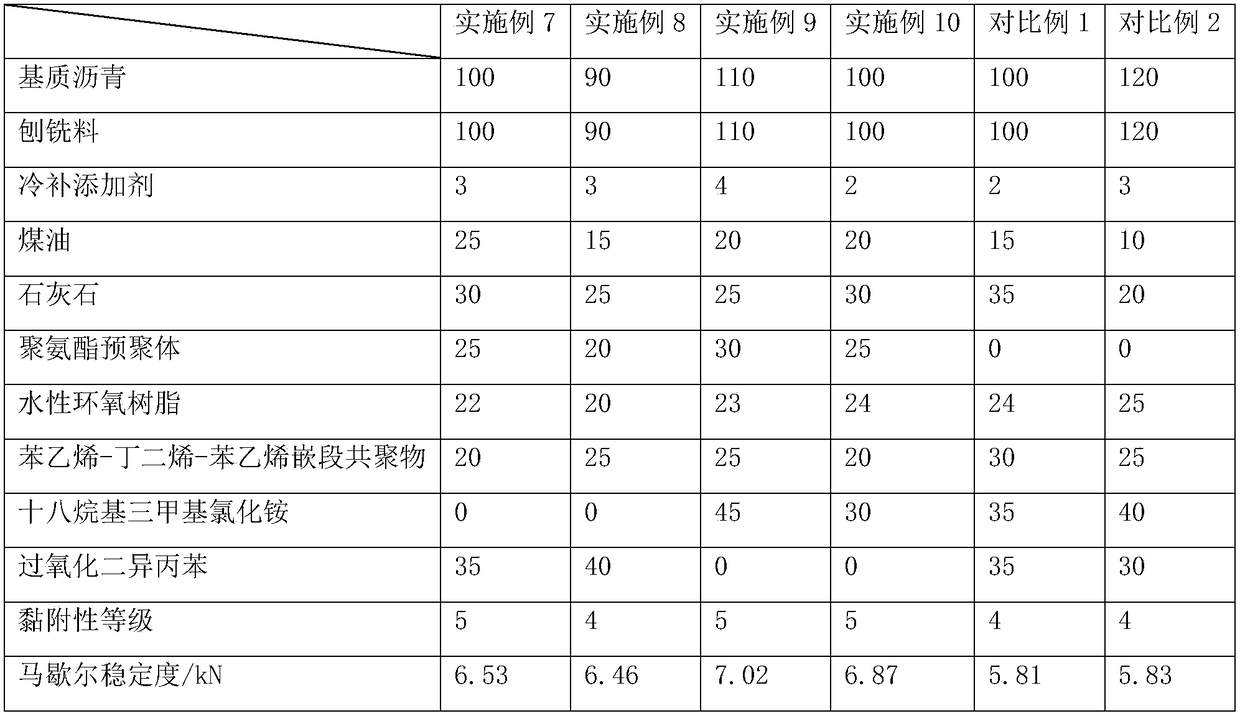

[0032] Example 1, a regenerative road cold patch material, the raw material components are shown in Table 1 in parts by weight. Wherein, the cold patch is prepared through the following steps:

[0033] Step 1: Heat base asphalt and planing and milling material to 120-140°C, add kerosene and stir for 20-30 minutes, then add cold patching additives and keep warm to 100°C to obtain diluted asphalt;

[0034] Step 2, the polyurethane prepolymer, water-based epoxy resin and octadecyltrimethylammonium chloride are dropped into the diluted asphalt and stirred evenly to obtain the mixture;

[0035] Step 3, putting styrene-butadiene-styrene block copolymer and dicumyl peroxide into the cold repair mixture and stirring evenly to obtain the modified mixture;

[0036] In step 4, limestone is put into the modified mixture for mixing and stirring to obtain cold patching material.

Embodiment 2

[0037] Embodiment 2 differs from Embodiment 1 in that, in parts by weight, the raw material components are as shown in Table 1.

Embodiment 3

[0038] Example 3, a regenerative road cold patch material, the raw material components are shown in Table 1 in parts by weight. Wherein, the cold patch is prepared through the following steps:

[0039]Step 1: Heat base asphalt and planing and milling material to 120-140°C, add kerosene and stir for 20-30 minutes, then add cold patching additives and keep warm to 100°C to obtain diluted asphalt;

[0040] Step 2, putting the polyurethane prepolymer and octadecyltrimethylammonium chloride into the diluted asphalt and stirring evenly to obtain the mixture;

[0041] Step 3, putting styrene-butadiene-styrene block copolymer and dicumyl peroxide into the cold repair mixture and stirring evenly to obtain the modified mixture;

[0042] In step 4, limestone is put into the modified mixture for mixing and stirring to obtain cold patching material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com