Easy-to-fill precoated sand and preparation process thereof

A coated sand, filling technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the difficult to meet the shape wall thickness difference sand core production process, coated sand strength, stiffness, refractoriness, The amount of deformation and fluidity can not meet the needs and other problems, so as to achieve the effect of easy shaking and sand cleaning, small deformation, and improved high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

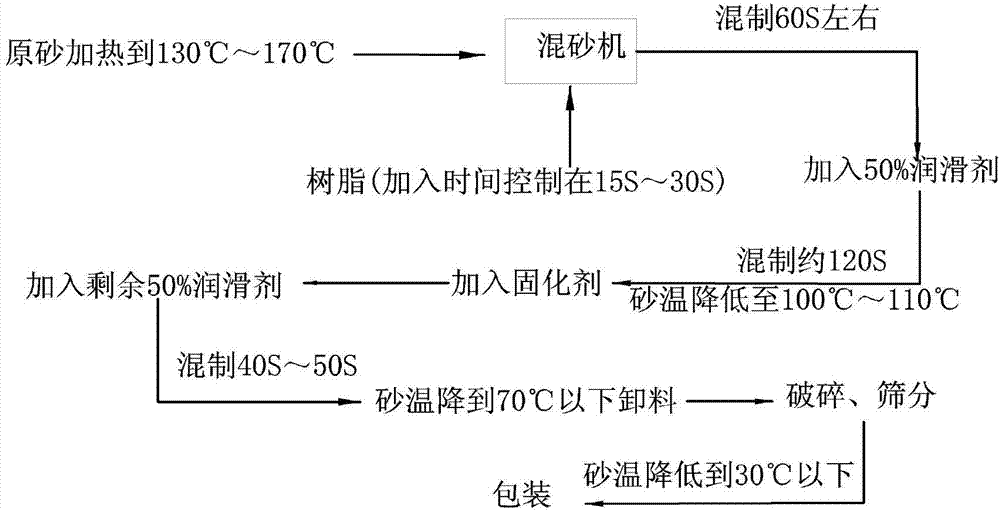

Method used

Image

Examples

Embodiment 1

[0031] An easy-to-fill coated sand, including raw sand, phenolic resin, curing agent, lubricant and additives, the raw sand is composed of 20% pearl sand and 80% scrubbing sand, and the amount of resin added is 1.2% of the weight of the raw sand , the amount of lubricant added is 0.05% of the original sand mass. The amount of curing agent added is 10% of the amount of resin added. Among them, the thermal expansion coefficient of pearl sand is small, and its performance is comparable to that of zircon sand. When it is used to prepare molding sand, castings will not produce expansion defects. The sand particles are spherical, with good fluidity, easy to pound, and good air permeability. The binder can be evenly covered. Pearl sand is a neutral material. Both acid and alkali binders can be used. It has good recycling performance, high cost performance, high refractoriness, easy to collapse, high thermal conductivity, and good stability. No cracking; scrubbing sand is made of nat...

Embodiment 2

[0034] An easy-to-fill coated sand, including raw sand, phenolic resin, curing agent, lubricant and additives, the raw sand is composed of 30% pearl sand and 70% scrubbing sand, and the amount of resin added is 1.6% of the weight of the raw sand , the amount of lubricant added is 0.2% of the original sand mass. The amount of curing agent added is 20% of the amount of resin added. Among them, the thermal expansion coefficient of pearl sand is small, and its performance is comparable to that of zircon sand. When it is used to prepare molding sand, castings will not produce expansion defects. The sand particles are spherical, with good fluidity, easy to pound, and good air permeability. The binder can be evenly covered. Pearl sand is a neutral material. Both acid and alkali binders can be used. It has good recycling performance, high cost performance, high refractoriness, easy to collapse, high thermal conductivity, and good stability. No cracking; scrubbing sand is made of natu...

Embodiment 3

[0037]An easy-to-fill coated sand, including raw sand, phenolic resin, curing agent, lubricant and additives, the raw sand is composed of 25% pearl sand and 75% scrubbing sand, and the amount of resin added is 1.4% of the weight of the raw sand , the amount of lubricant added is 0.1% of the mass of the original sand. The amount of curing agent added is 15% of the amount of resin added. Among them, the thermal expansion coefficient of pearl sand is small, and its performance is comparable to that of zircon sand. When it is used to prepare molding sand, castings will not produce expansion defects. The sand particles are spherical, with good fluidity, easy to pound, and good air permeability. The binder can be evenly covered. Pearl sand is a neutral material. Both acid and alkali binders can be used. It has good recycling performance, high cost performance, high refractoriness, easy to collapse, high thermal conductivity, and good stability. No cracking; scrubbing sand is made o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com