Method for preparing zirconium-base amorphous alloy with plasticity at room temperature

A zirconium-based amorphous alloy and plasticity technology, which is applied in the field of preparation of amorphous alloys, can solve the problems of poor room temperature plasticity of amorphous alloys, and achieve the effect of improving room temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

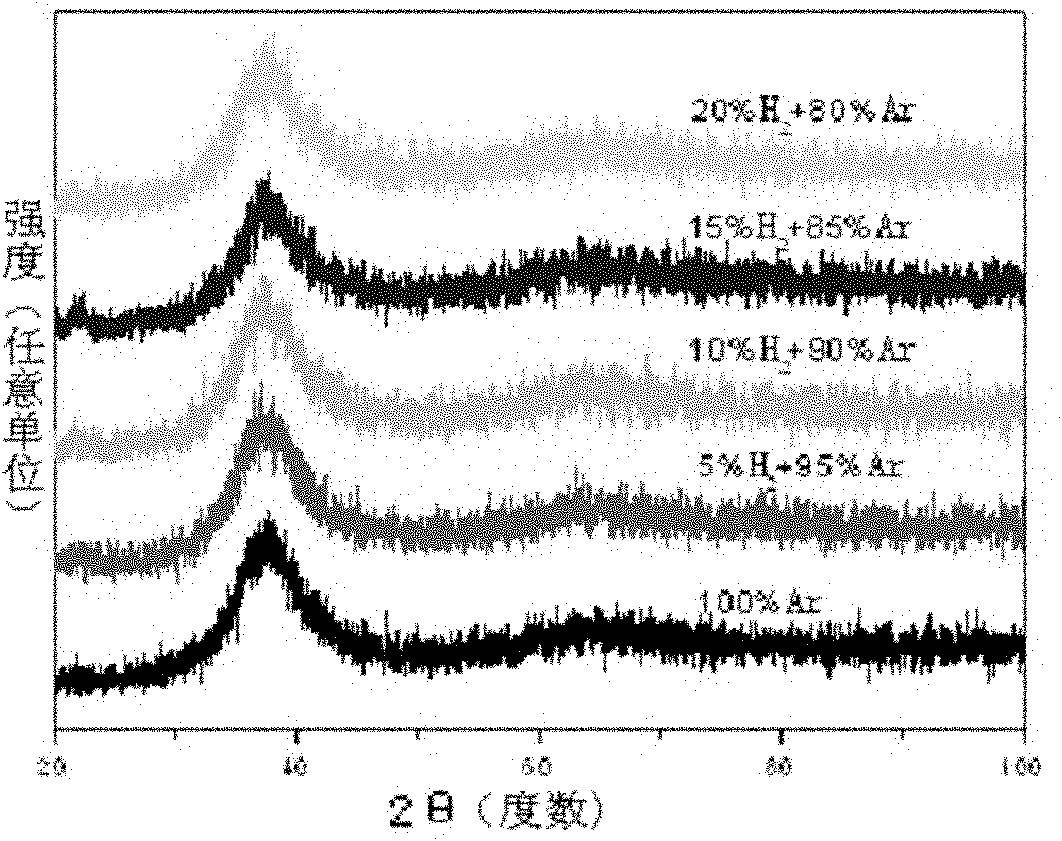

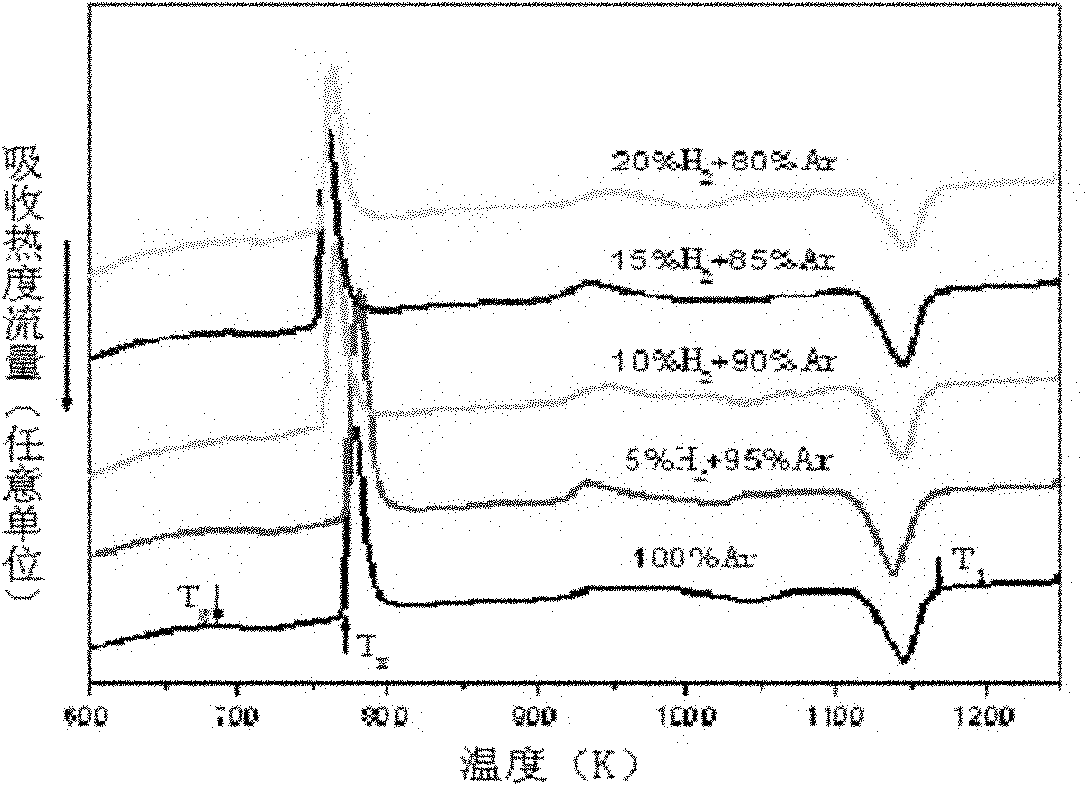

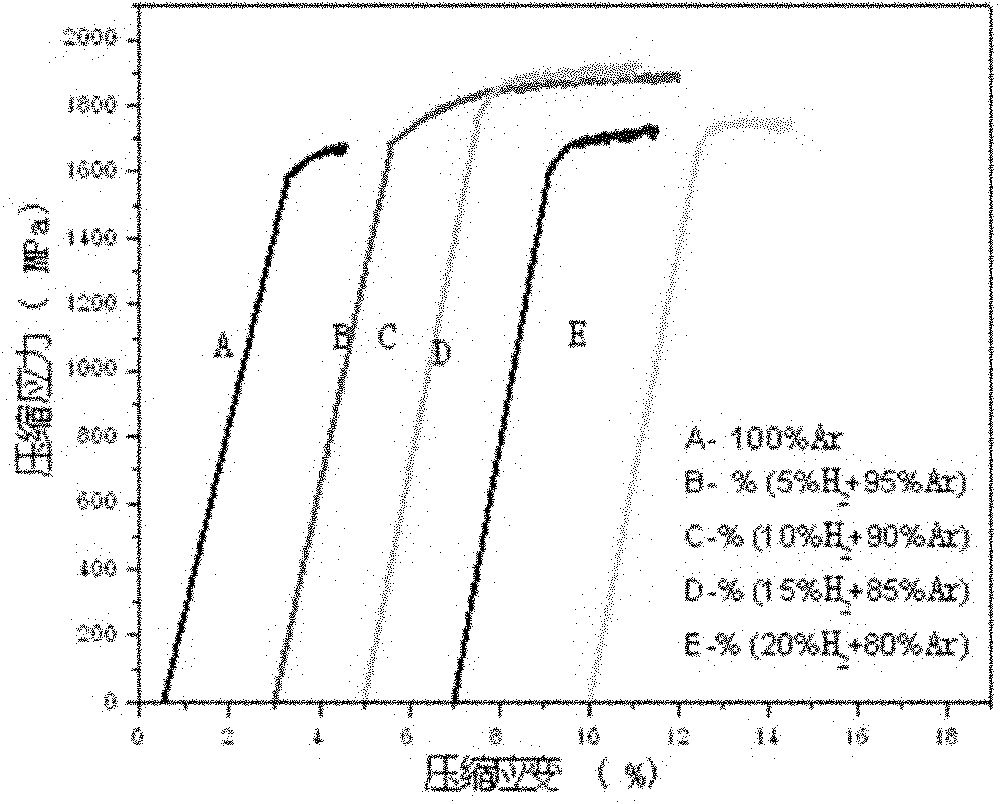

[0011] Specific Embodiment 1: In this embodiment, a method for preparing a zirconium-based amorphous alloy with room temperature plasticity is realized according to the following steps: 1. Weigh the raw material, which includes 10% to 30% Cu, 5% ~15% Ni, 6%~20% Al and Zr in the balance; 2. Put the raw materials into the water-cooled copper crucible of the electric arc furnace, and evacuate the melting chamber to 5~6×10 -3 Pa, the hydrogen and argon with a purity of 99.999% are introduced into the melting chamber, and the volume ratio of hydrogen and argon is 0 to 1:1; 3. The raw materials are smelted 3 to 6 times, each time for 1 to 3 minutes, and the current A zirconium-based amorphous alloy with room temperature plasticity is prepared by a copper mold suction casting method; the purity of each element constituting the raw material in step 1 is 99.0%-99.9%.

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the raw material in step 1 also includes 1%-10% Ti by atomic percentage. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment is different from Embodiment 1 in that the raw material in step 1 also includes 1%-10% Nb by atomic percentage. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com