Plastic deformation magnesium alloy and preparation method thereof

A plastic deformation and magnesium alloy technology, which is applied in the field of metal materials and metal material processing, can solve the problems of high cost and complicated process, and achieve the effect of improving alloy texture, improving mechanical properties, and inhibiting the growth of recrystallized grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

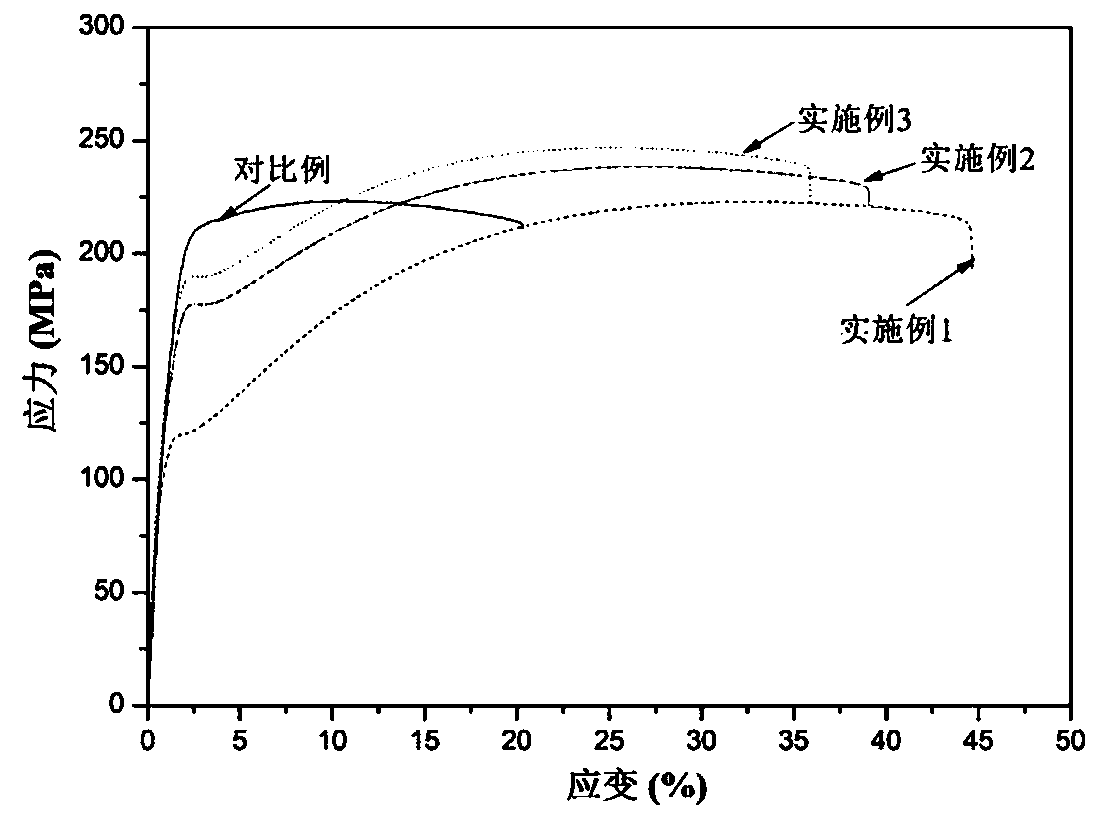

Embodiment 1

[0039] Embodiment 1: Select the Mg-3Al-3Bi-1Sn-0.04Ca-0.02Y (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method includes the following steps.

[0040] 1) Ingredients: Use pure Mg ingots, pure Al blocks, pure Bi blocks, pure Sn blocks, Mg-Ca master alloys and Mg-Y master alloys as raw materials, and make ingredients according to the above-mentioned target components.

[0041] 2) Melting: Put the pure Mg ingot into the crucible of the smelting furnace, set the furnace temperature to 720°C and keep it. 200°C pure Al block, Mg-20Ca master alloy and Mg-30Y master alloy are added to the magnesium melt; then the melting temperature is raised to 750°C and kept for 15 minutes, then stirred for 5 minutes, and high-purity Ar gas is introduced Carry out refining and degassing treatment, adjust and control the temperature at 720°C, keep warm for 8 minutes; the melting process is in CO 2 / SF 6 under the protection of mixed gas.

[0042] 3) Pouring: remove ...

Embodiment 2

[0047] Embodiment 2: Select the Mg-4Al-2Bi-1Sn-0.03Ca-0.03Y (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method includes the following steps.

[0048] 1) Ingredients: Use pure Mg ingots, pure Al blocks, pure Bi blocks, pure Sn blocks, Mg-Ca master alloys and Mg-Y master alloys as raw materials, and make ingredients according to the above-mentioned target components.

[0049] 2) Melting: Put the pure Mg ingot into the crucible of the smelting furnace, set the furnace temperature to 720°C and keep it. 200°C pure Al block, Mg-20Ca master alloy and Mg-30Y master alloy are added to the magnesium melt; then the melting temperature is raised to 750°C and kept for 15 minutes, then stirred for 5 minutes, and high-purity Ar gas is introduced Carry out refining and degassing treatment, adjust and control the temperature at 720°C, keep warm for 8 minutes; the melting process is in CO 2 / SF 6 under the protection of mixed gas.

[0050] 3) Pouring: remove ...

Embodiment 3

[0055] Embodiment 3: Select the Mg-6Al-3Bi-1Sn-0.03Ca-0.05Y (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method includes the following steps.

[0056] 1) Ingredients: Use pure Mg ingots, pure Al blocks, pure Bi blocks, pure Sn blocks, Mg-Ca master alloys and Mg-Y master alloys as raw materials, and make ingredients according to the above-mentioned target components.

[0057] 2) Melting: Put the pure Mg ingot into the crucible of the smelting furnace, set the furnace temperature to 720°C and keep it. 200°C pure Al block, Mg-20Ca master alloy and Mg-30Y master alloy are added to the magnesium melt; then the melting temperature is raised to 750°C and kept for 15 minutes, then stirred for 5 minutes, and high-purity Ar gas is introduced Carry out refining and degassing treatment, adjust and control the temperature at 720 ° C, keep warm for 8 minutes; the melting process is in CO 2 / SF 6 under the protection of mixed gas.

[0058] 3) Casting: remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com