Preparing method of TiAl inter-metallic compound containing rare earth element Er

An intermetallic compound and rare earth element technology, which is applied in the field of preparation of TiAl intermetallic compounds, can solve the problems of reducing the room temperature plasticity of directionally solidified TiAl-based alloys and the room temperature plasticity of directionally solidified TiAl-based alloys, and achieves the effect of improving room temperature plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

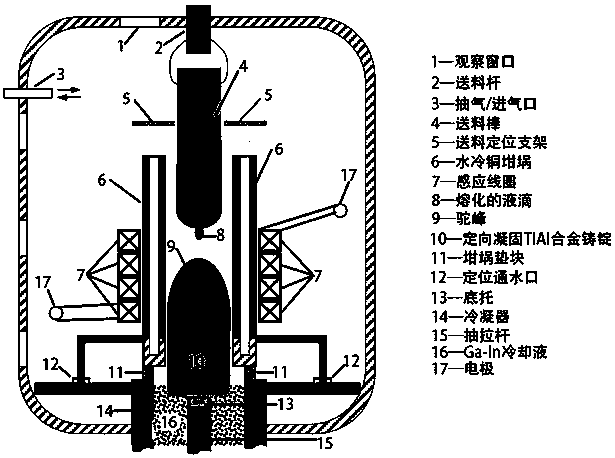

[0023] Specific Embodiment 1: This embodiment provides a method for preparing TiAl intermetallic compounds containing rare earth element Er. The method is carried out on a multi-functional cold crucible electromagnetically confined precise forming directional solidification equipment, and simultaneously realizes purification and refinement orientation Solidified TiAl-based alloy structure. Specific steps are as follows:

[0024] Step 1: Prepare a Ti-47Al-2Nb-2Cr-0.2Er alloy ingot with a rare earth element Er content of 0.2 at.% by vacuum induction melting. The specific operation is as follows: (1) Weigh titanium sponge, aluminum block, aluminum Niobium master alloy, chromium sheet and aluminum erbium master alloy, of which Ti-48.8 at.%, Al-47 at.%, Nb-2 at.%, Cr-2 at.%, Er-0.2 at.%; (2 ) Put the weighed raw materials into the crucible of the vacuum induction melting furnace in the order from bottom to top: titanium sponge layer, aluminum block layer, aluminum-niobium master a...

specific Embodiment approach 2

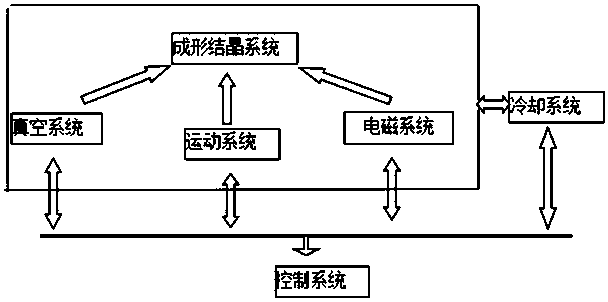

[0027] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is that, as figure 1 As shown, the multi-functional cold crucible electromagnetically constrained precise forming directional solidification equipment is composed of a forming crystallization system, a vacuum system, a motion system, an electromagnetic system, a control system and a cooling system. The forming crystallization system and the electromagnetic system are the core systems, wherein:

[0028] The control system is used to control the vacuum system, motion system, electromagnetic system and cooling system;

[0029] The cooling system is used to cool the vacuum system, motion system, electromagnetic system, and forming crystallization system;

[0030] The vacuum system, motion system, and electromagnetic system all serve the forming crystallization system, and provide the forming crystallization system with the reaction conditions required for p...

specific Embodiment approach 3

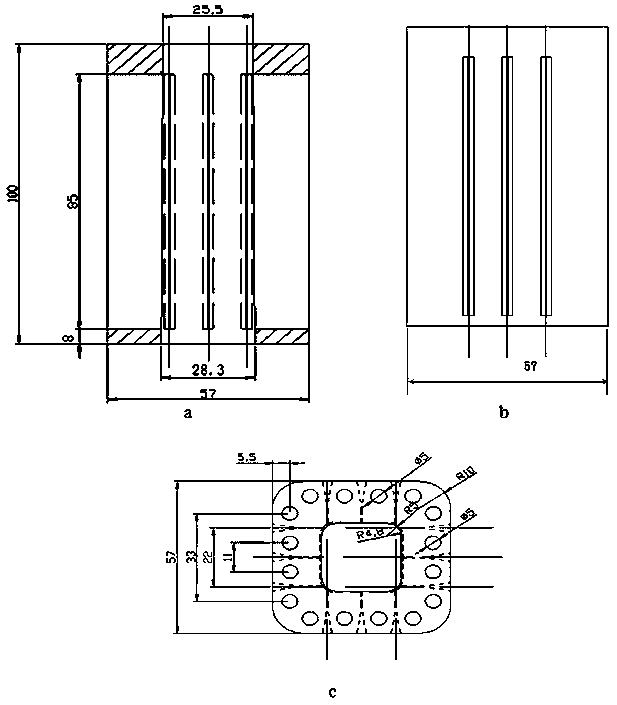

[0031] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the forming crystallization system contains a water-cooled copper crucible, such as figure 2 As shown, the material of the water-cooled copper crucible is copper, the height is 100mm, and the cross-section of the inner cavity is a rectangle of 25.5mm×25.5mm. The lower end of the crucible is connected, and 12 slits divide the entire crucible into 12 sub-section structures. The sections are filled with insulating materials, and cooling water is passed through each section.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com