Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid technical risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

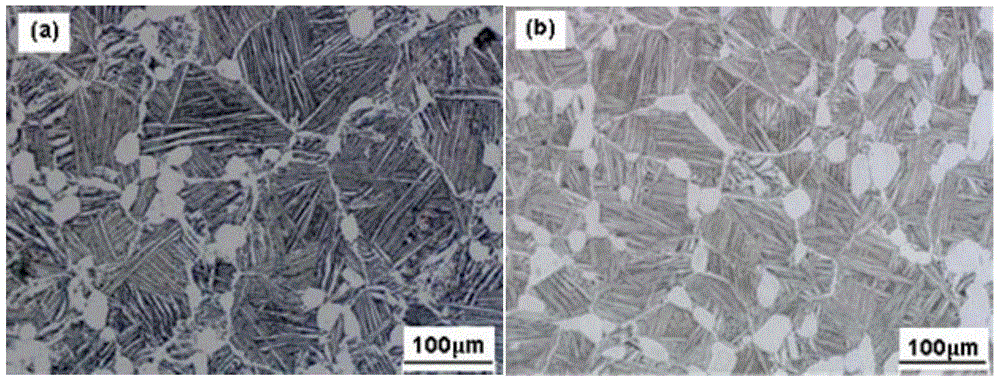

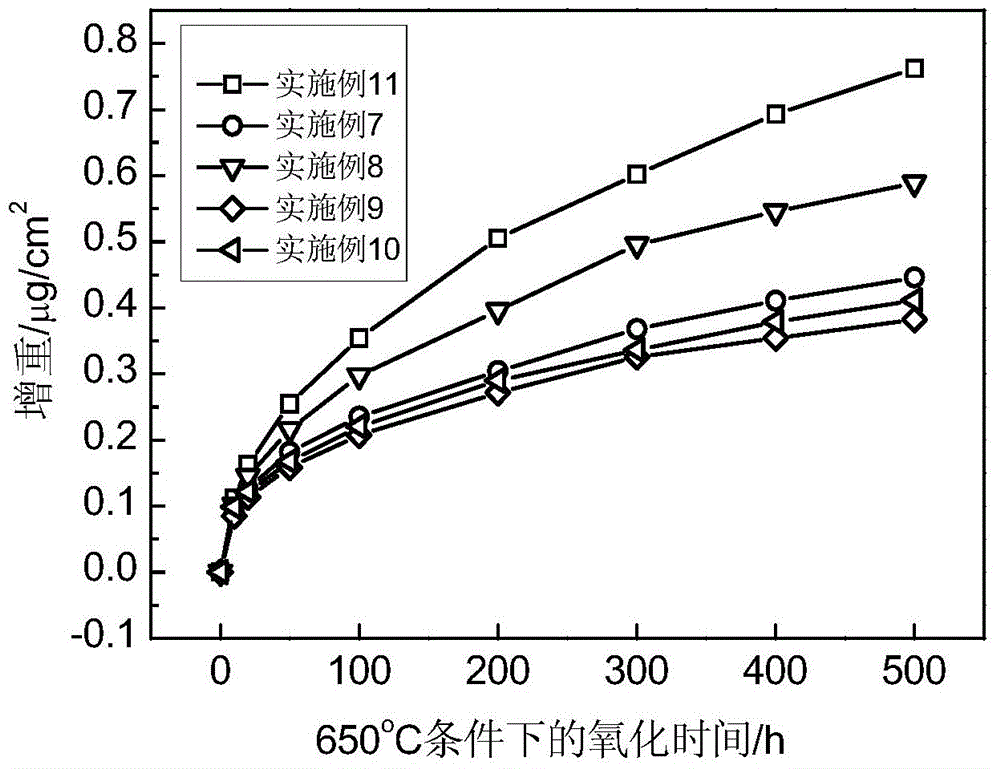

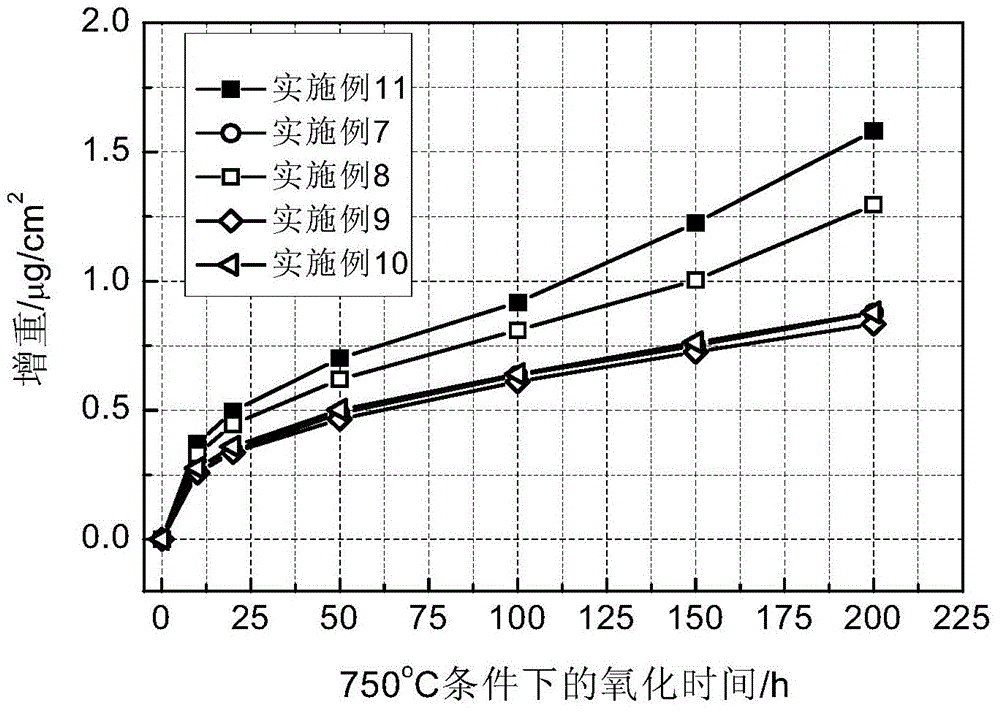

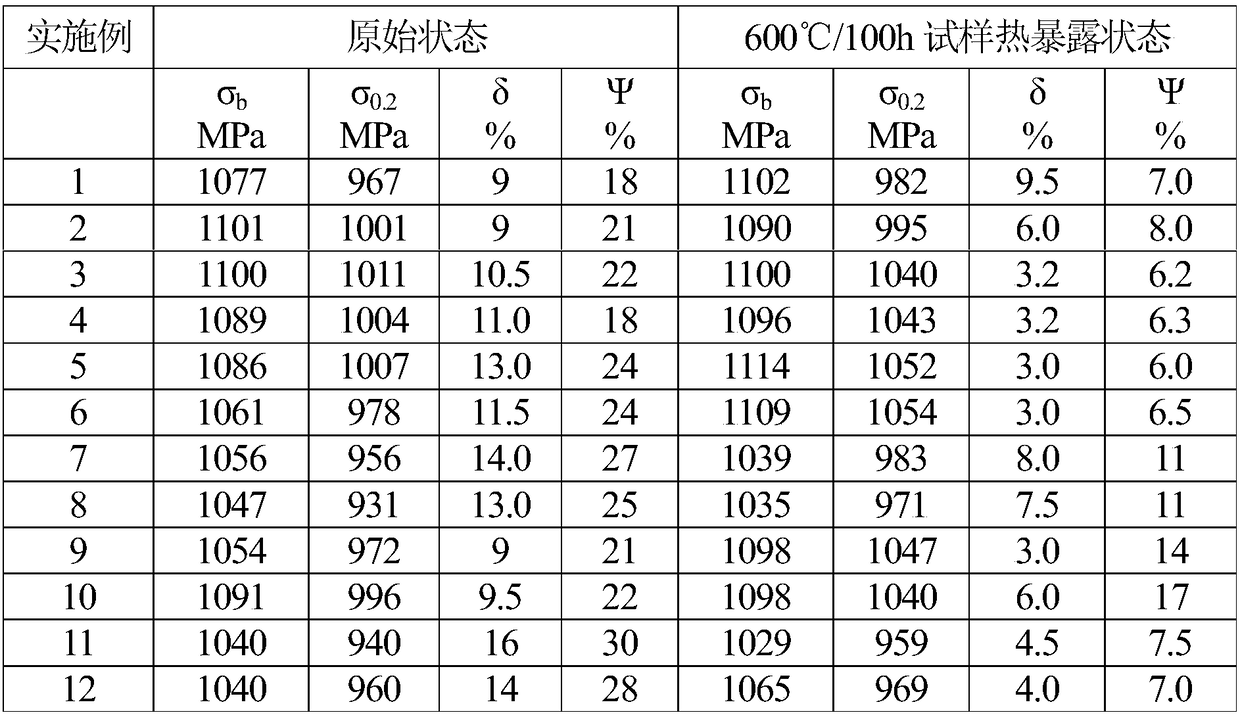

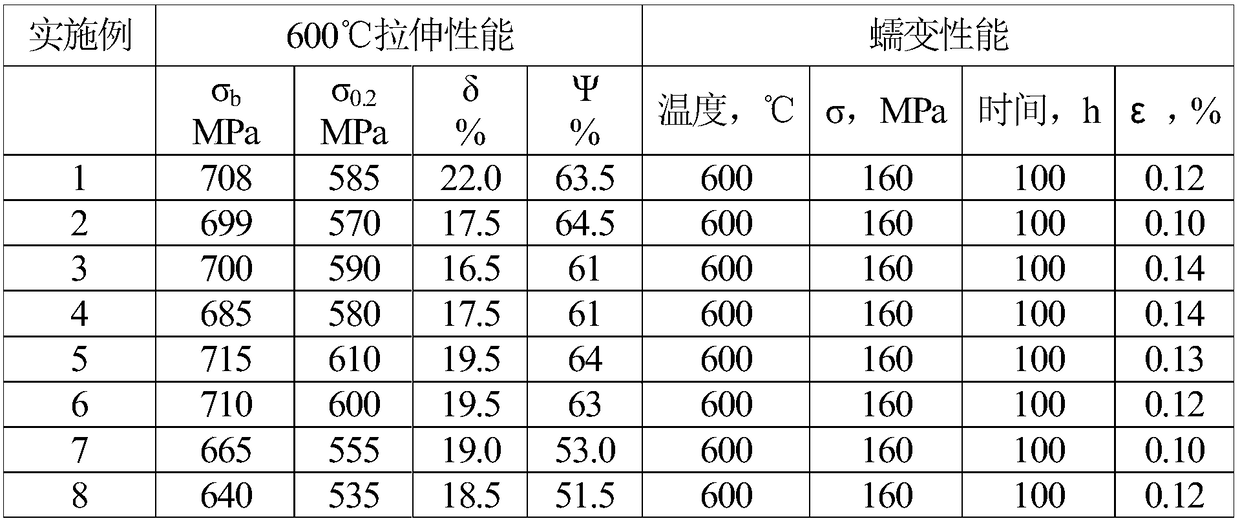

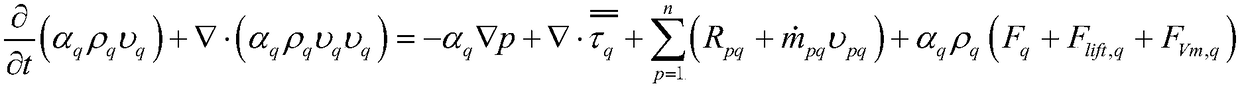

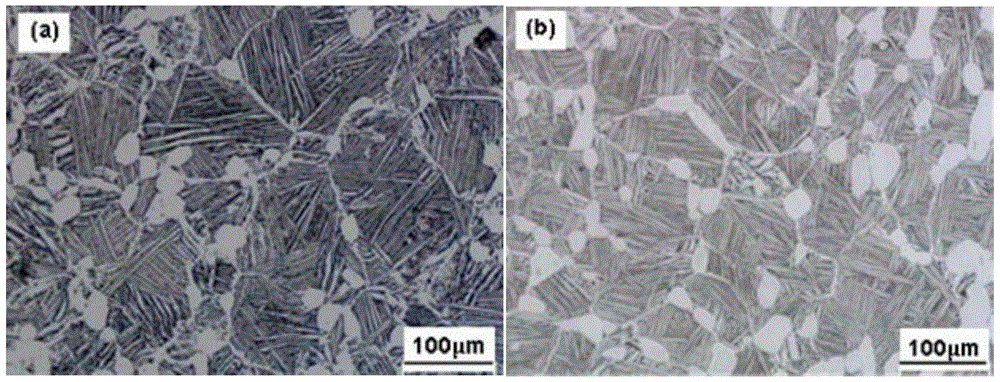

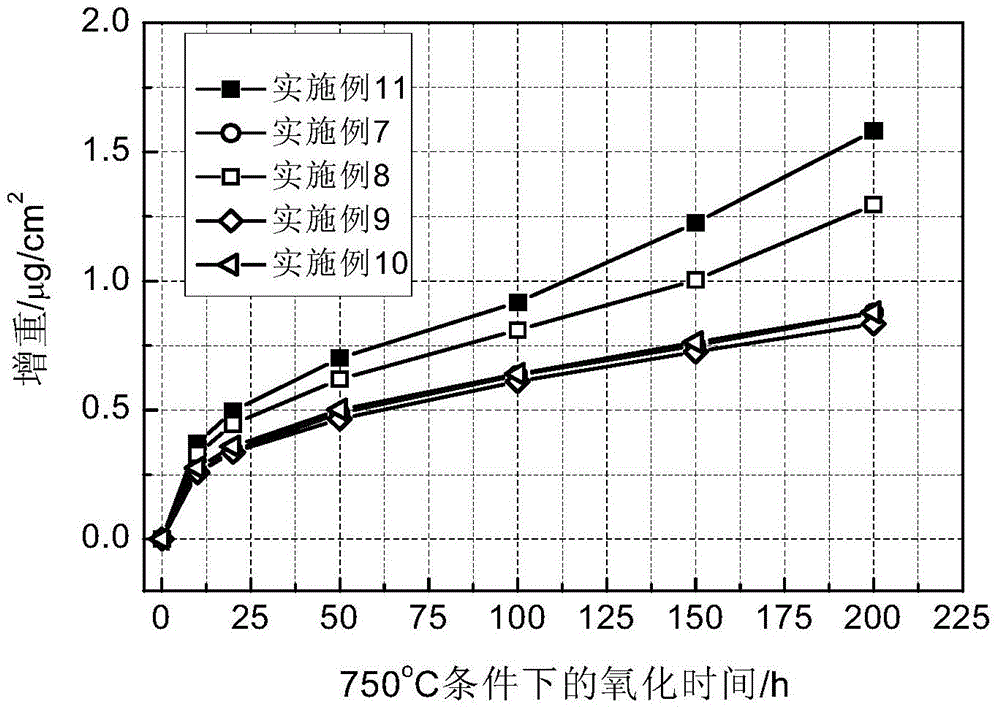

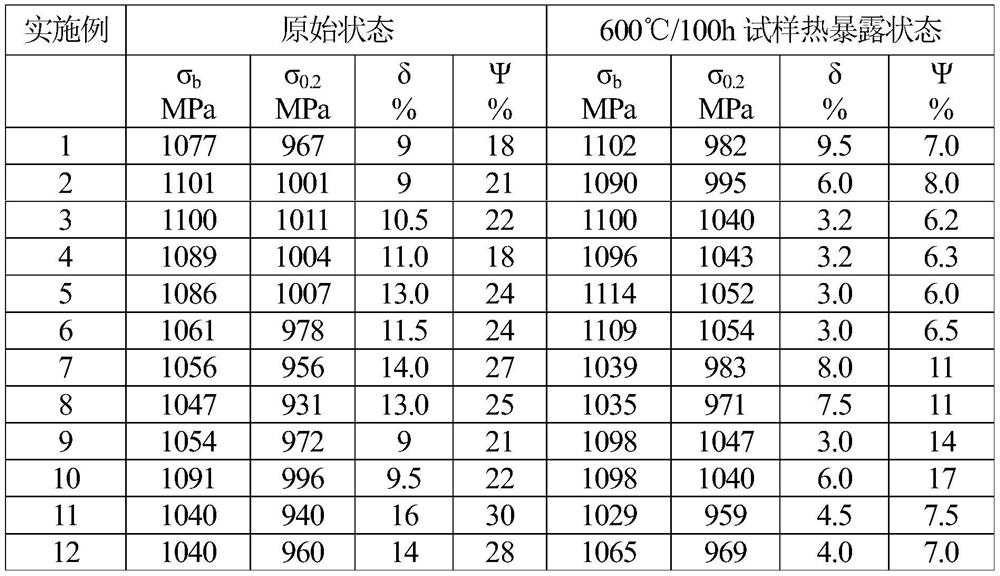

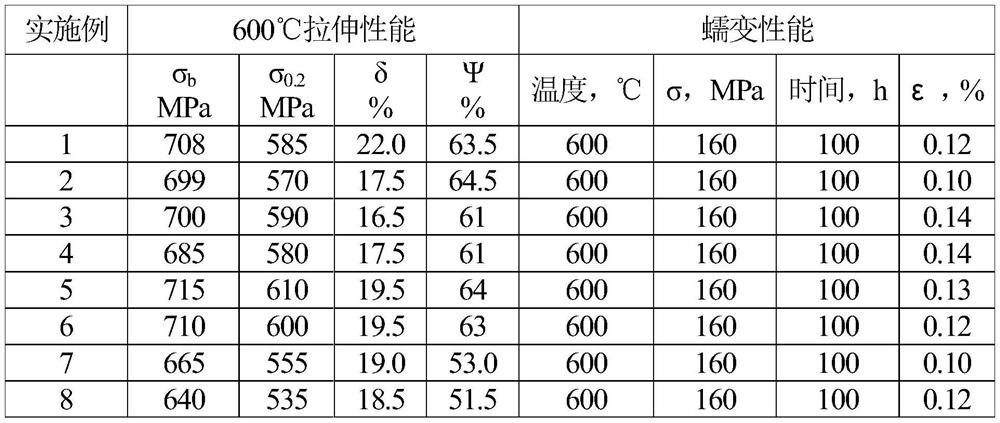

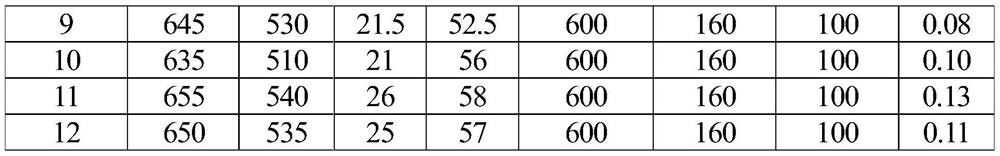

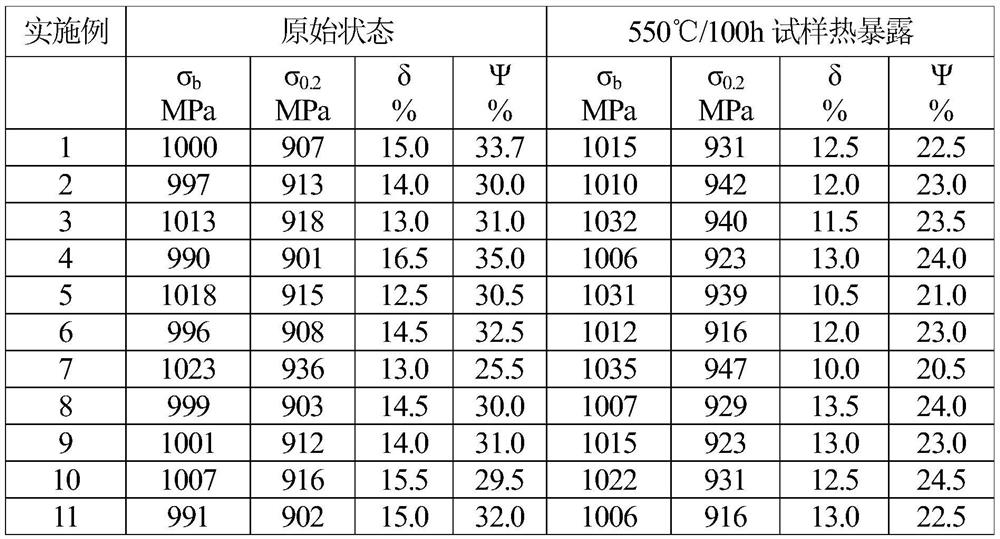

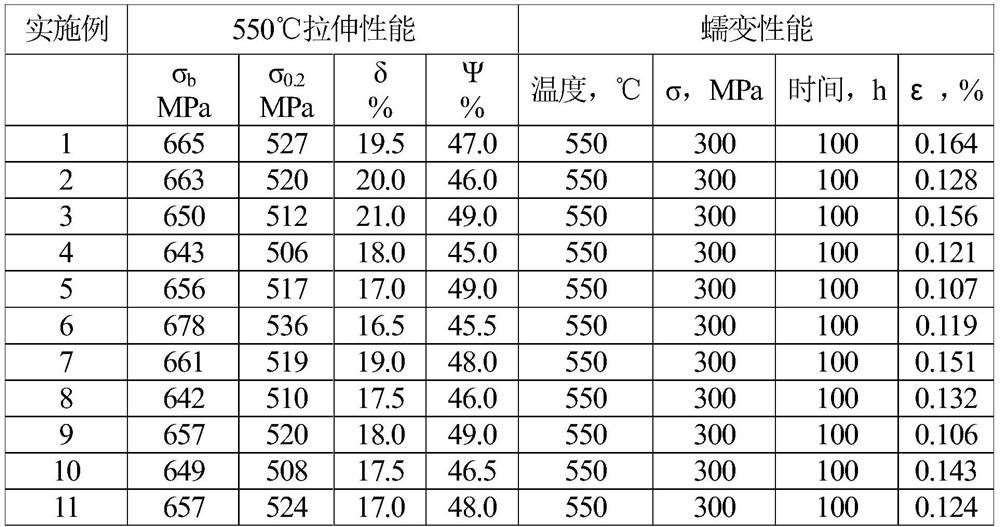

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

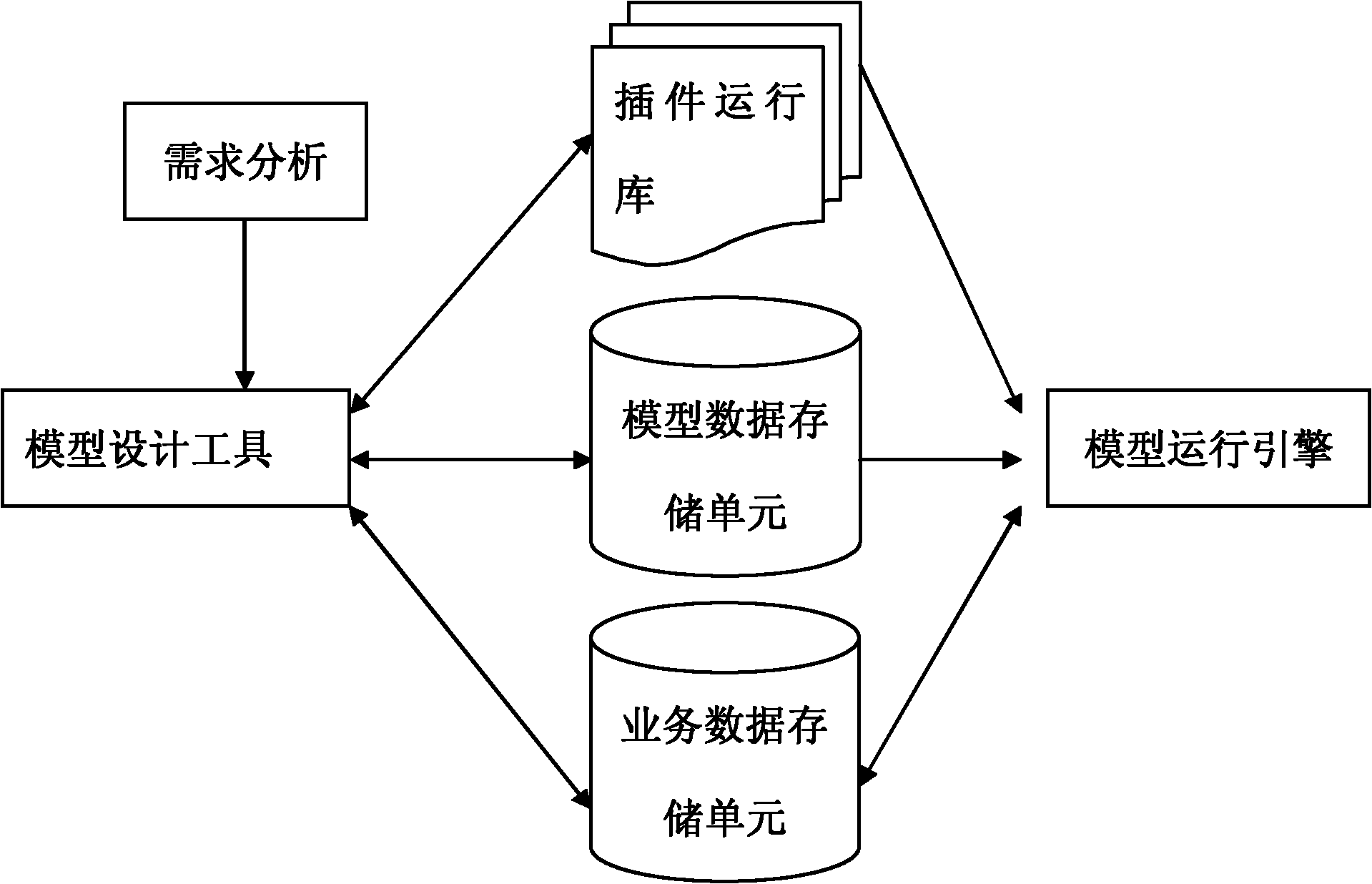

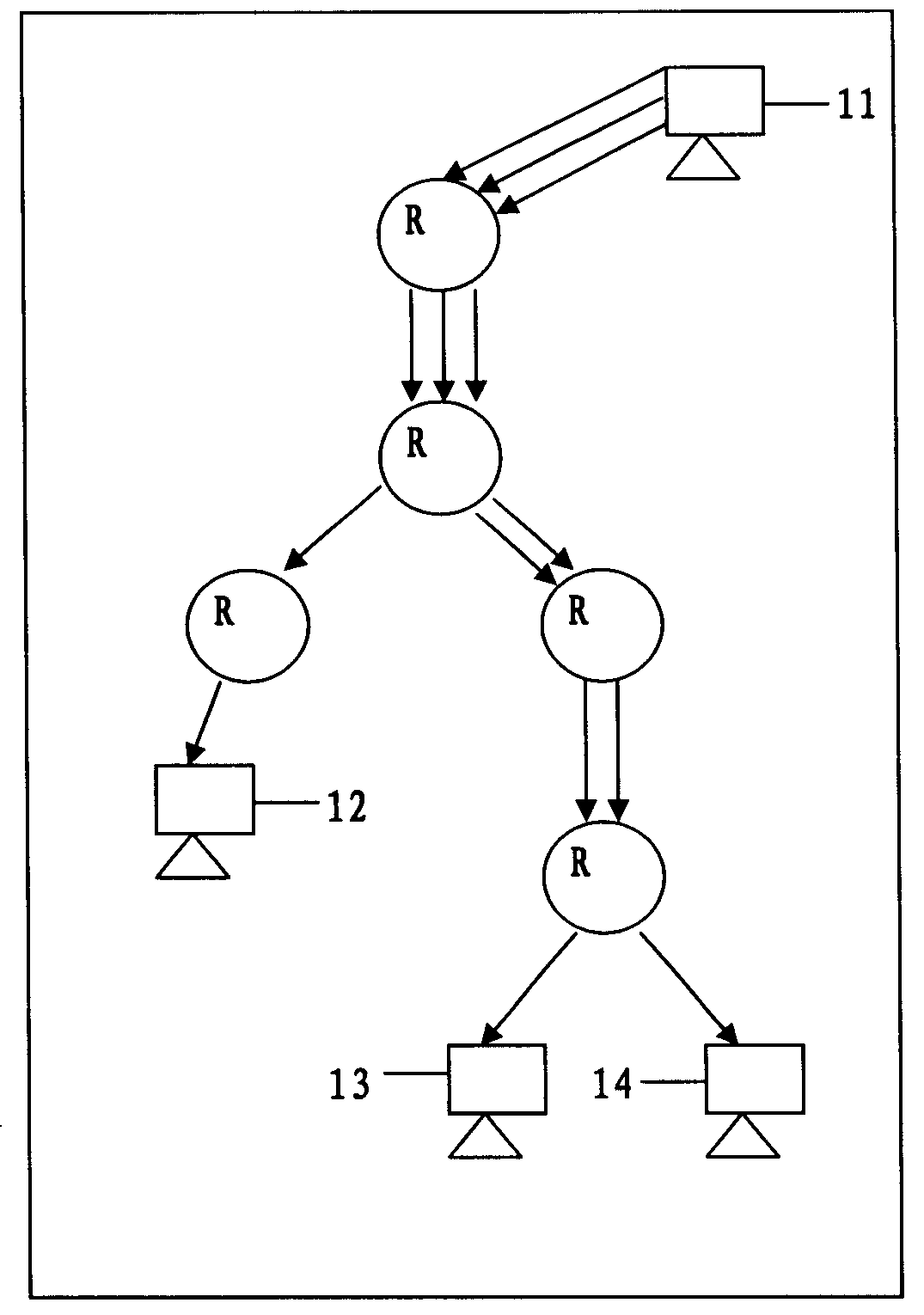

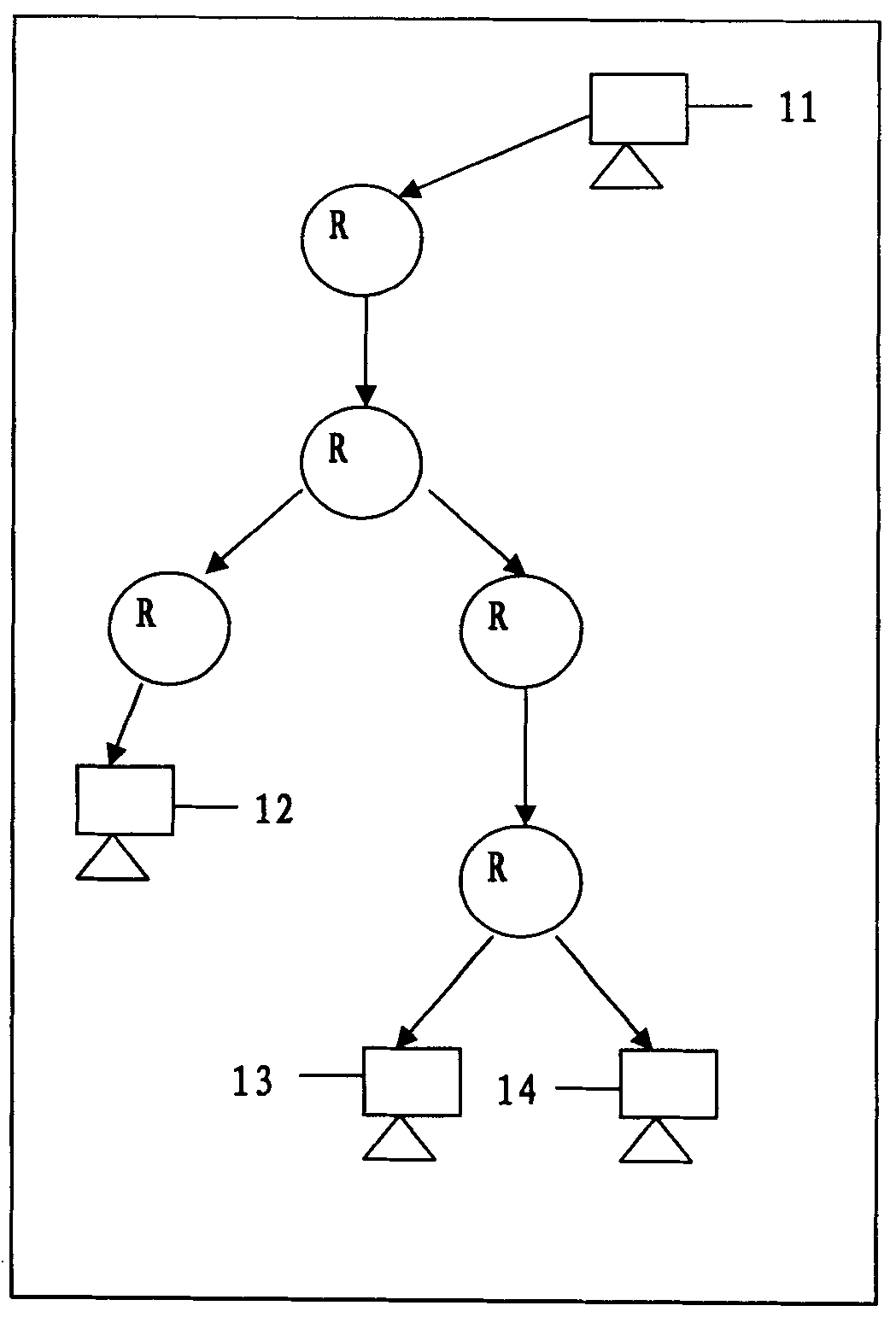

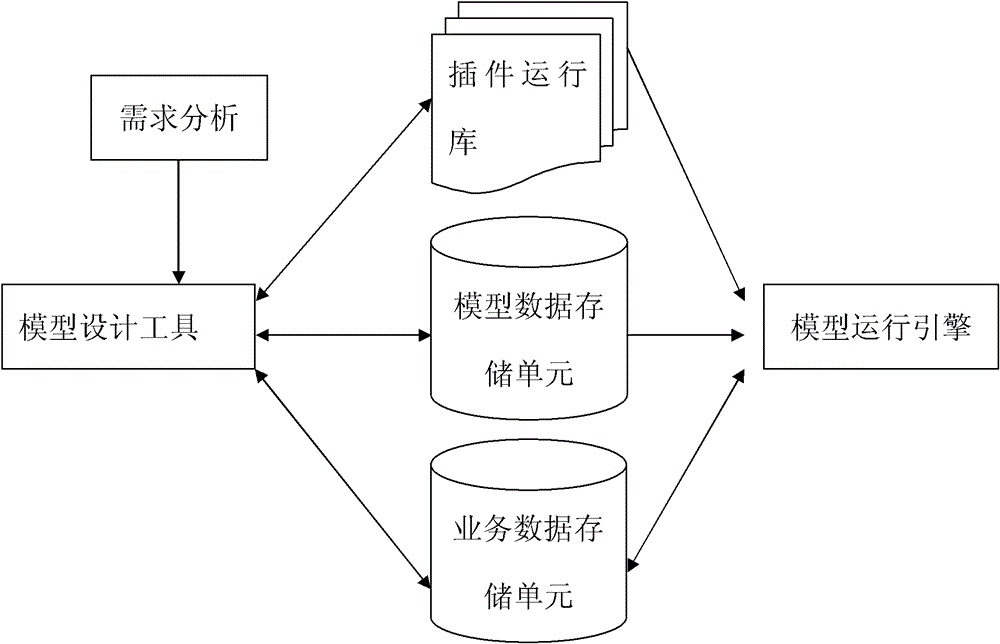

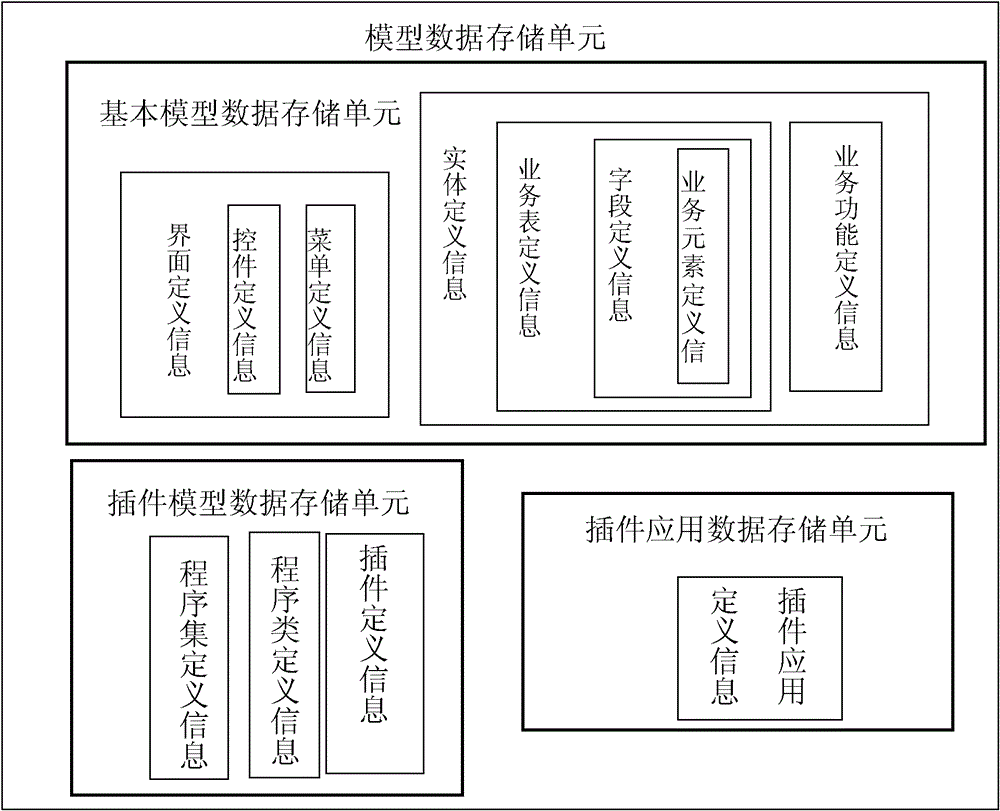

System and method for expanding model driving development capability by applying plug-in

ActiveCN102033743ASolve the problem of insufficient description abilityExpandable and flexibleSpecific program execution arrangementsModel descriptionStationary model

The invention relates to a system and method for expanding the model driving development capability by applying a plug-in. In the system and the method, a'model and plug-in' combined mode is provided to describe and establish a software system, firstly a model designing tool is used for establishing basic model description of the software system and then establishing a plurality of reusable plug-pin model for further describing a basic model object, the plug-in model can be expanded randomly on various basic model objects, and the plug-in can complete a software function with any complexity, therefore, the expansion of the model driving development capability is realized. By utilizing the invention, the technical problems of the existing model driving development method that because a fixed model is adopted, the describing capability of complex service system is poor, and the software system with the model driving development can not be established, expanded and maintained visually and dynamically under the operating state and the like are solved. The system developed by using the method has the advantages that the development complexity degree is low, the development speed is fast, the reusable degree of technology is high, the expansion is flexible, the maintenance is convenient and the reliability is high.

Owner:广州翼风信息科技股份有限公司

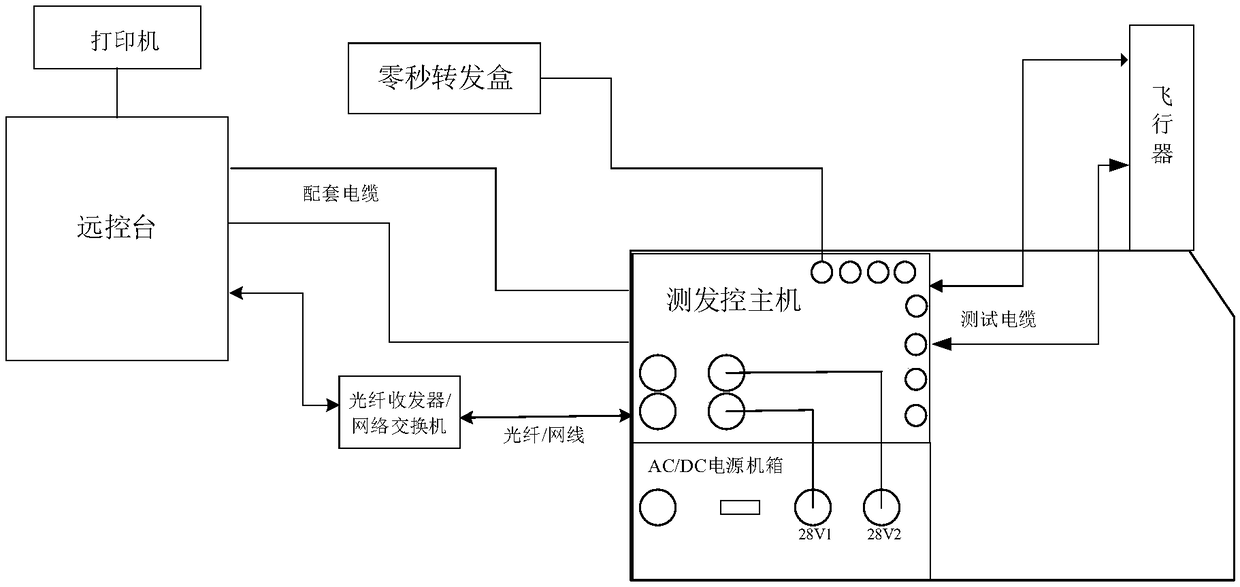

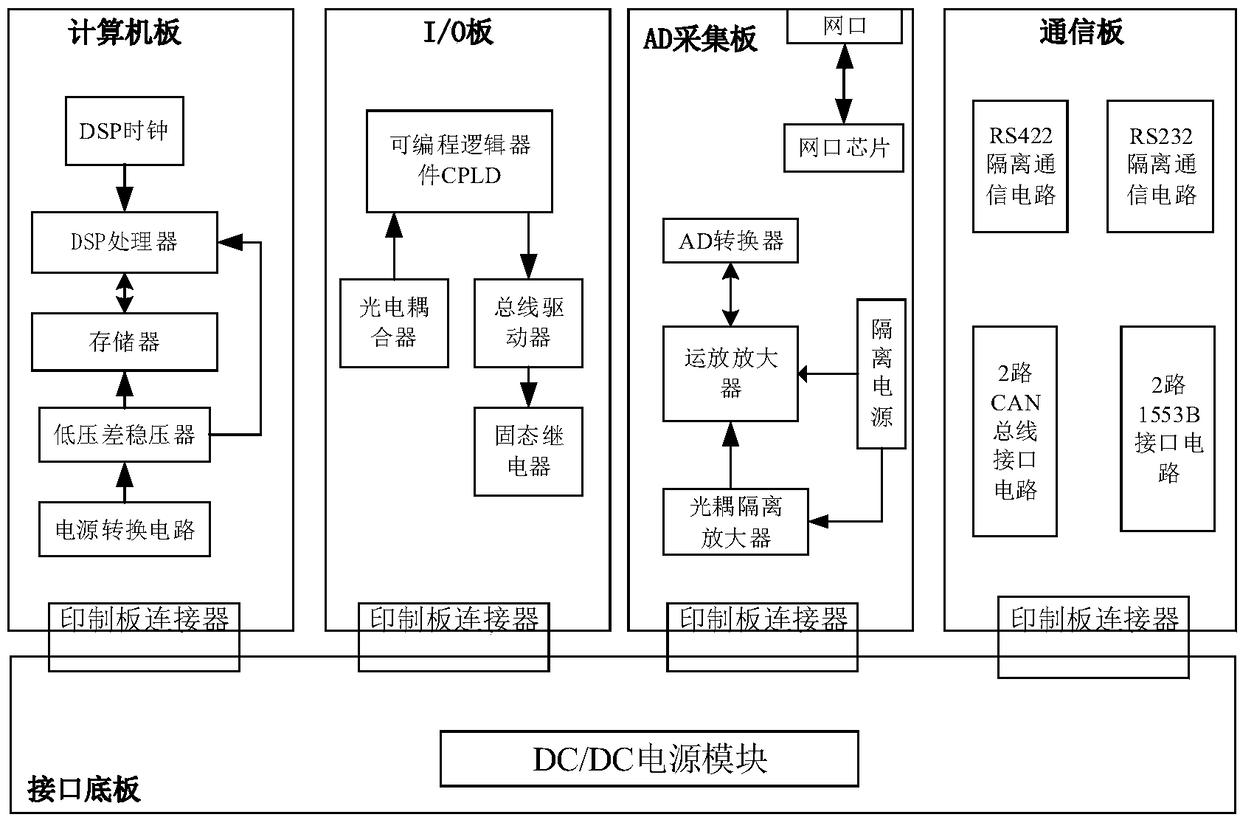

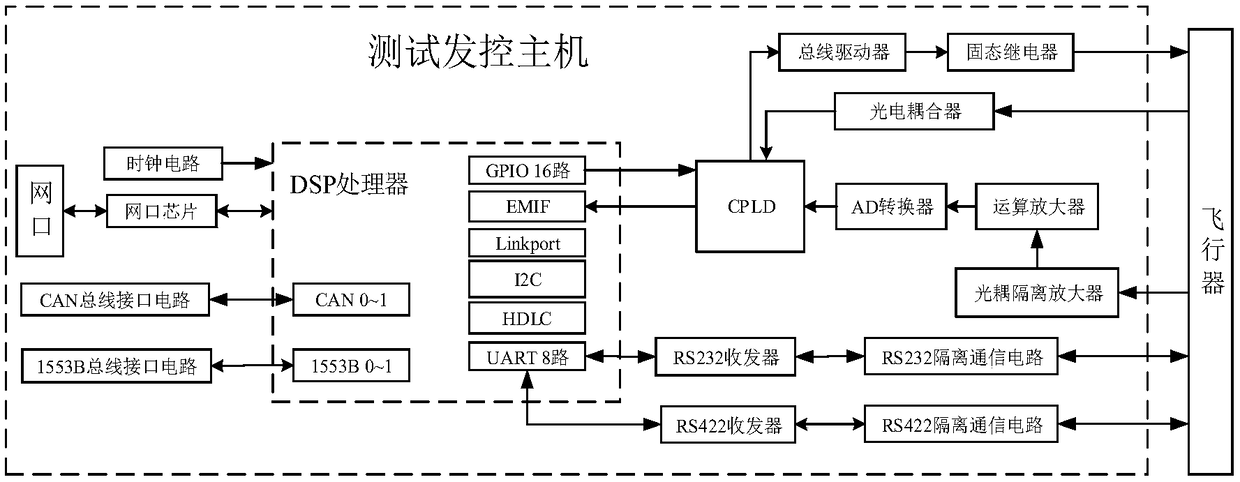

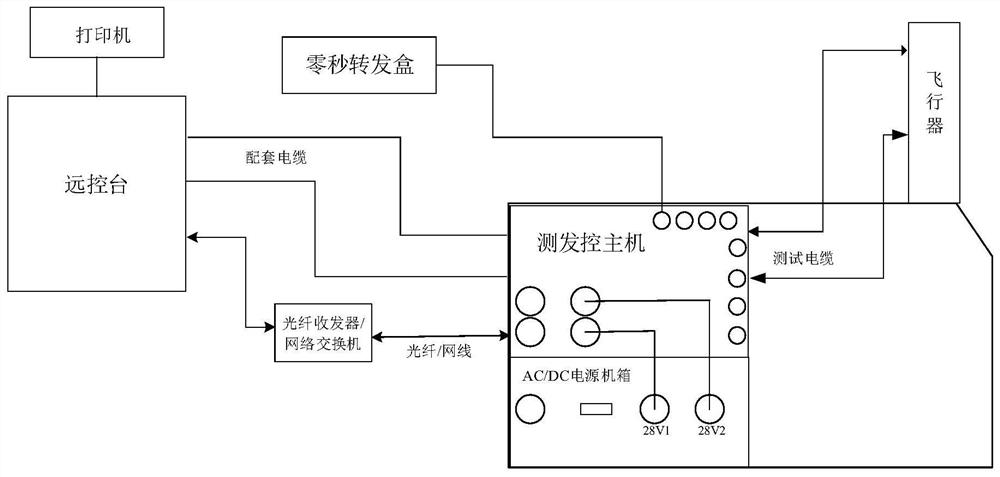

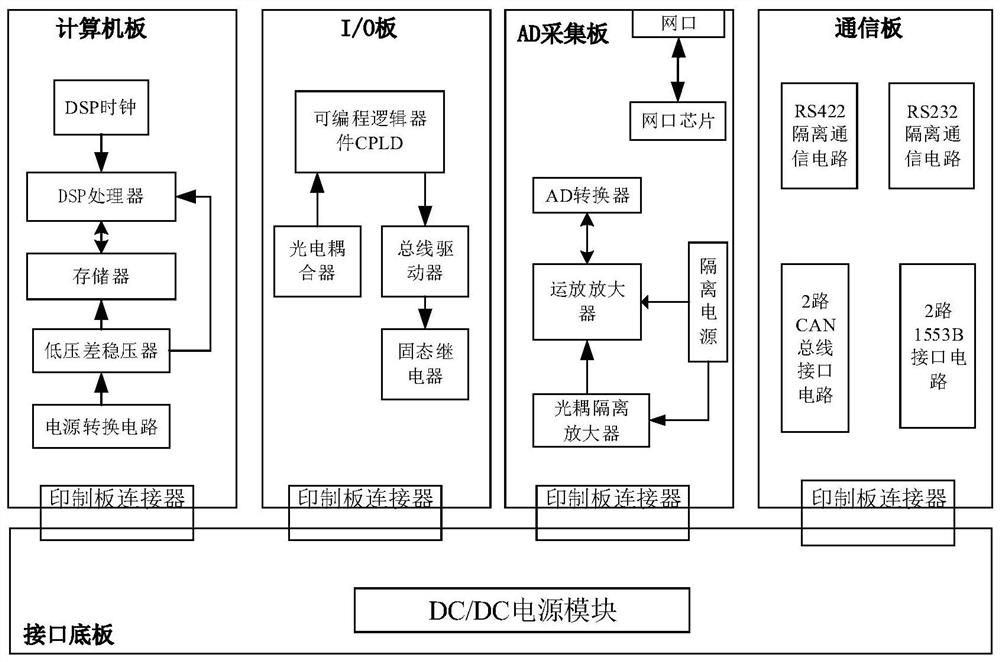

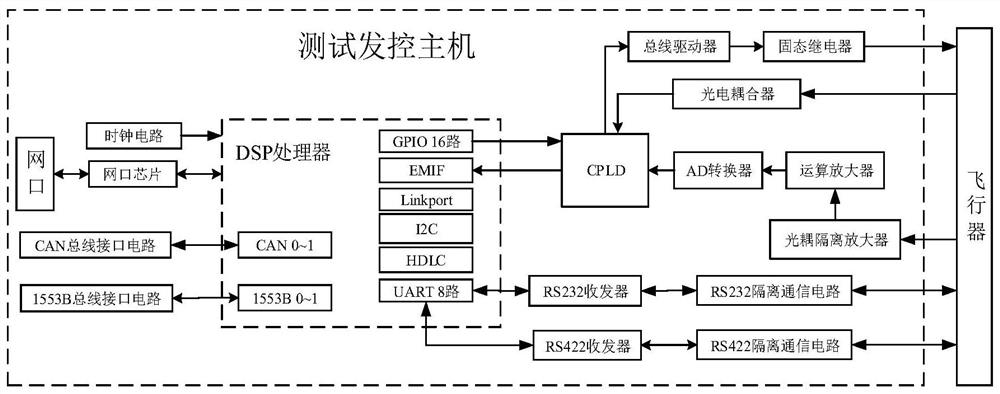

Automatic controllable general test launch and control system

ActiveCN108891622AImprove compatibilityImprove versatilityAircraft components testingTransceiverRemote control

The invention discloses an automatic controllable general test lunch and control system. The system comprises a remote control console, a test lunch and control host, a zero-second forwarding box andan AC / DC power supply case; the remote control console and the test lunch and control host are connected through a cable, and are in network communication through a fiber optical transceiver or a network switch; the test lunch and control host comprises a computer board, an I / O board, an AD acquisition board, a communication board and an interface backplane; the computer board, the I / O board, theAD acquisition board and the communication board are plugged in the interface backplane through printed board connectors; the computer board comprises a DSP, a clock circuit and a memory, wherein theclock circuit and the memory are connected with the DSP; the DSP is used for sending an on-off output signal to the I / O board, receiving on-off input data fed back by the I / O board and analog quantitydata fed back by the AD acquisition board and performing parsing to realize output control and condition monitoring of an aircraft. Through modular function board cards and standardized interfaces and buses between the board cards, the integration and generality of the system are improved, and the maintenance cost is saved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

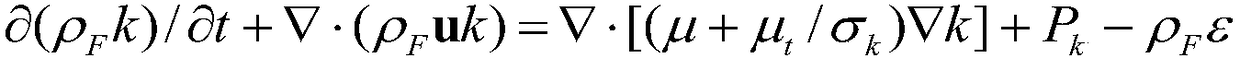

Preparation method of high-temperature titanium alloy bar

The invention belongs to the field of titanium-base alloys and particularly relates to a preparation method of a high-temperature titanium alloy bar. The preparation method comprises the following steps: heating a prepared Ti60 titanium alloy cast ingot to 1150-1200 DEG C, and carrying out blank-opening forging in a beta phase region by virtue of a rapid forging machine or a hydraulic press; heating to 1080-1150 DEG C, carrying out repeated upsetting and swaging forging by virtue of the rapid forging machine or the hydraulic press, heating the forged blank to Tbeta-120 DEG C to Tbeta-30 DEG C(Tbeta is a Ti60 titanium alloy alpha+beta / beta phase inversion temperature), and carrying out repeated upsetting and swaging forging by virtue of the rapid forging machine or the hydraulic press until the blank is in a required size, so as to obtain the titanium alloy bar, wherein the macrostructure of the titanium alloy bar is a fuzzy crystal, and the microstructure of the titanium alloy bar isuniform. After the prepared Ti60 titanium alloy bar is subjected to solid dissolving and ageing thermal treatment, the matching degree of the obdurability of the bar is relatively good, and the matching degrees of the durability, creeping strength and thermal stability are relatively good. The preparation method is convenient in operation and relatively strong in process controllability, and the batch stability of the prepared Ti60 titanium alloy bars is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +2

Preparation method of para-aramid and graphene oxide/graphene composite paper

ActiveCN110055807ASimple methodReduce manufacturing costSynthetic cellulose/non-cellulose material pulp/paperInorganic compound additionDispersityPapermaking

The invention relates to a preparation method of para-aramid and graphene oxide / graphene composite paper and belongs to the technical field of high molecular materials. The preparation method includes: utilizing a polymerization one-step process without a surfactant added to prepare para-aramid nanofiber water dispersion liquid, utilizing the characteristic that para aramid nanofiber and grapheneoxide have high dispersity in water to well mix two dispersion liquids proportionally, and utilizing a conventional papermaking method to prepare the para-aramid / graphene oxide composite paper; utilizing a wet process or a dry process to reduce graphene oxide to obtain the para-aramid / graphene composite paper. Compared with the prior art, the preparation method has the advantages that the para-aramid and graphene / graphene oxide composite paper can be produced continuously on a large scale, the obtained composite paper has excellent performance, and the preparation method is friendly in corresponding production environment, low in cost and simple in process..

Owner:TSINGHUA UNIV +2

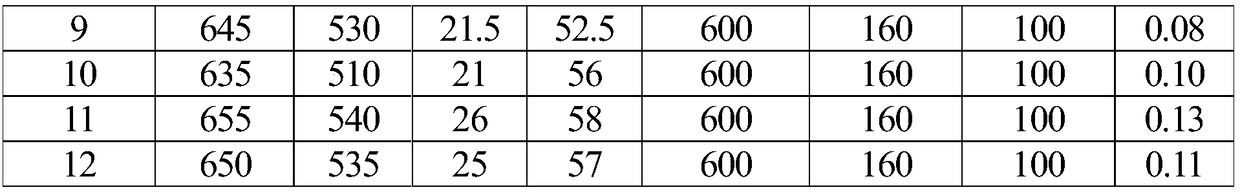

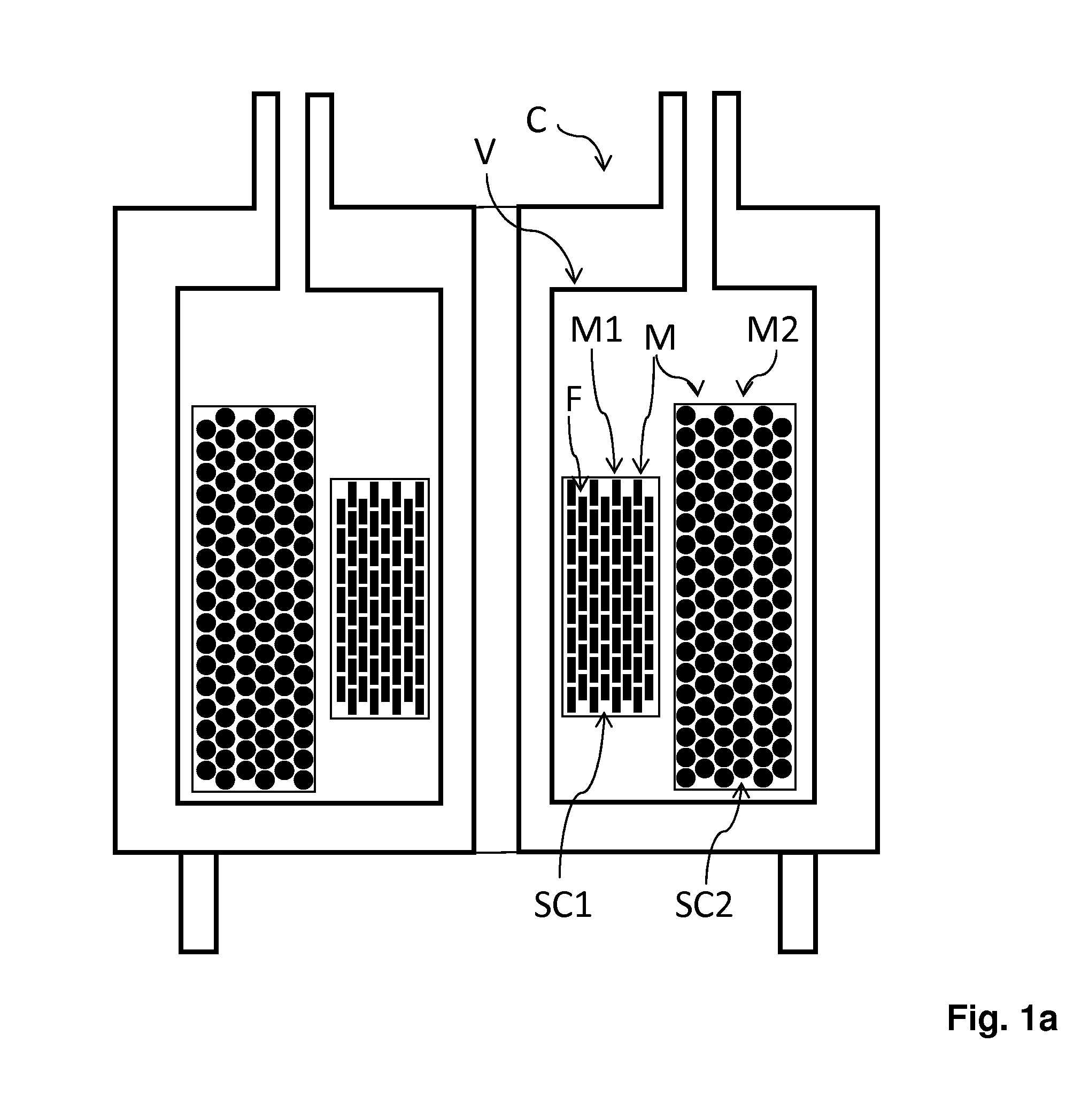

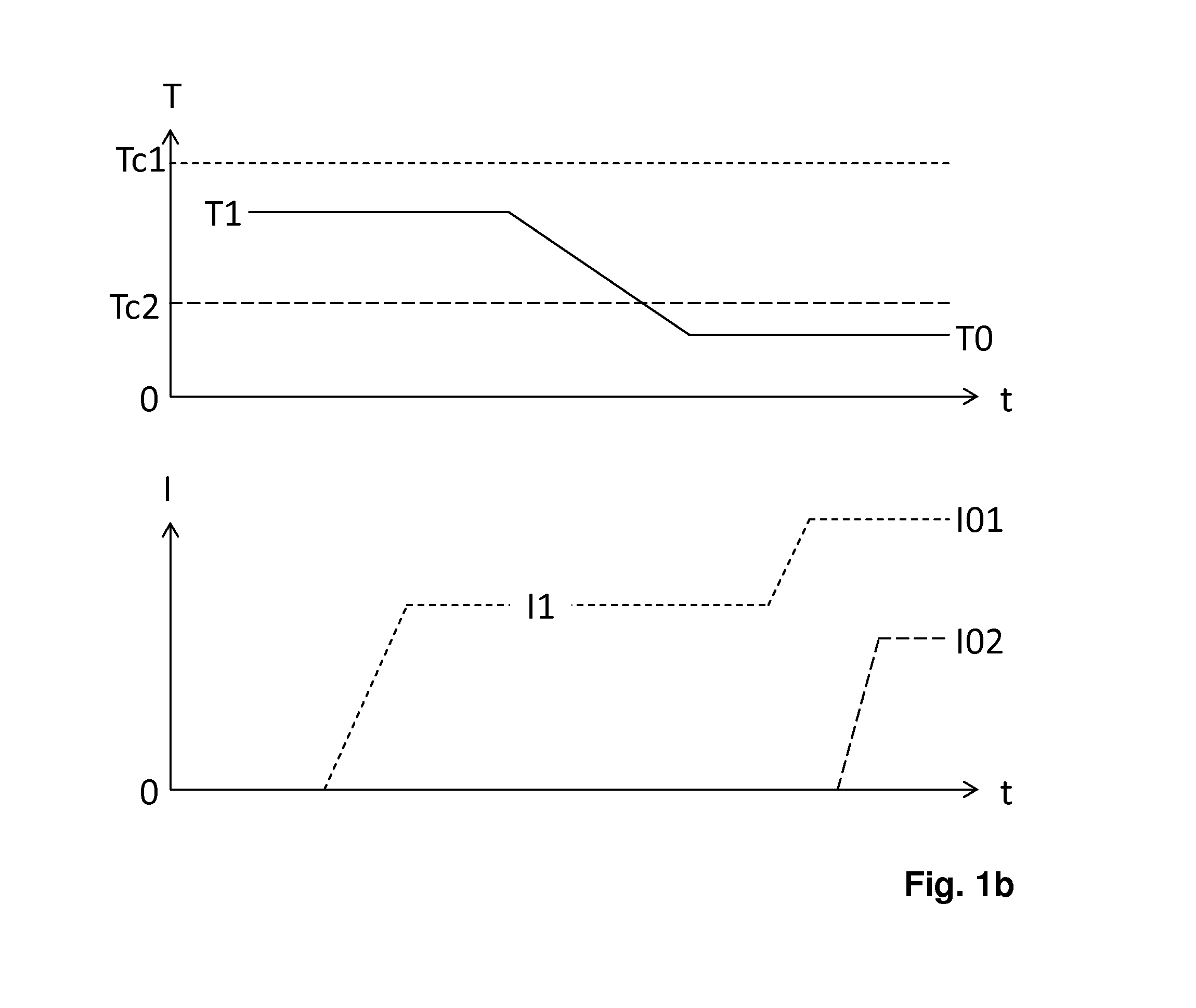

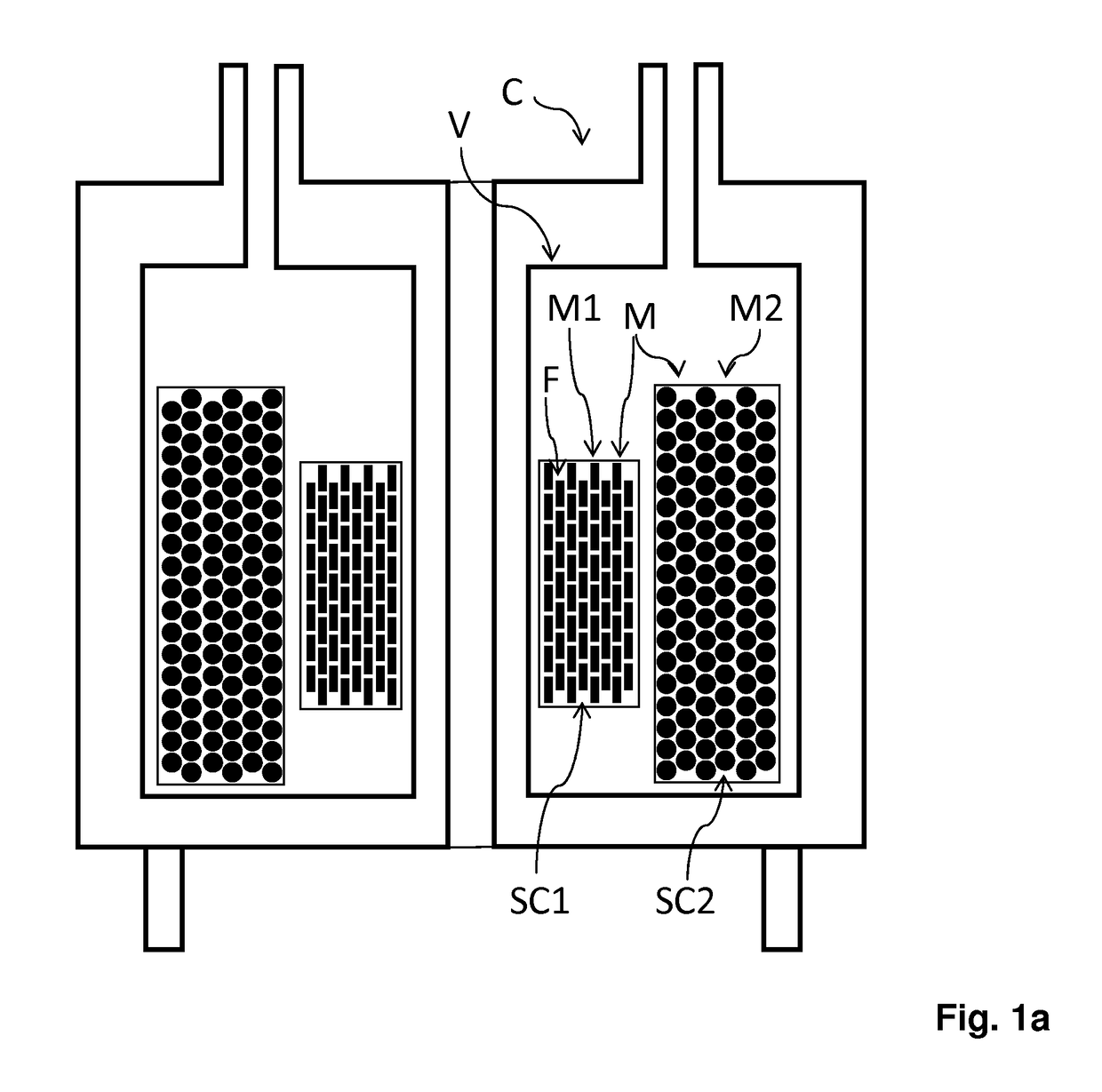

Method for energizing a superconducting magnet arrangement

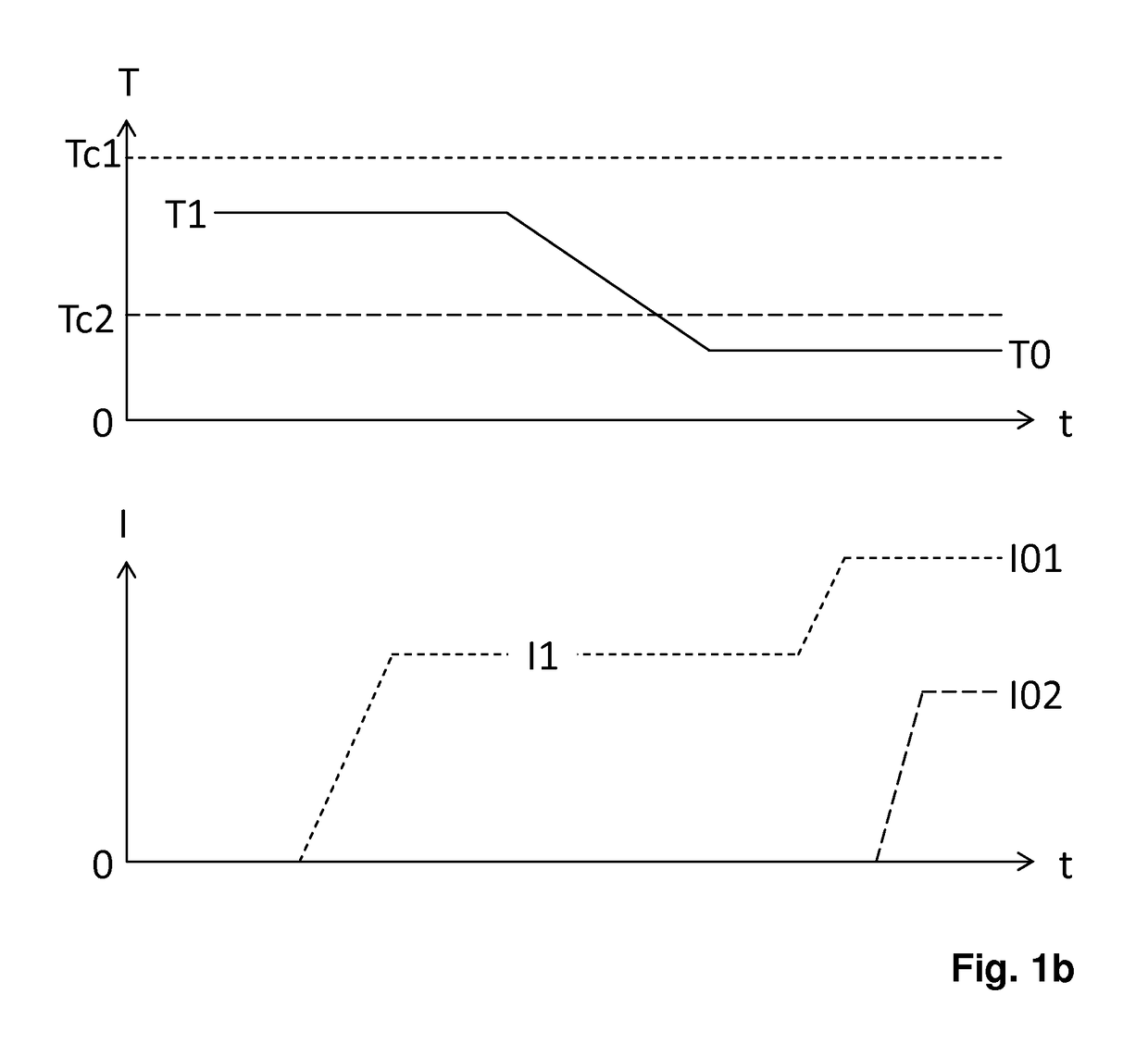

ActiveUS20160049228A1Reduced stabilityReduce expenditureSuperconductors/hyperconductorsMagnetic measurementsTemperature controlPower flow

A method for charging a magnet arrangement having a superconducting tape conductor with a first transition temperature in a cryostat device. The magnet arrangement is temperature-controlled to a first pre-operating temperature between the first transition temperature and the operating temperature, a first pre-operating current is excited, the magnet arrangement is cooled to operating temperature and a first operating current is excited. The magnet arrangement has a second magnet winding composed of a second superconductor material with a second transition temperature above the operating temperature and at least 15 K below the first transition temperature, wherein a second operating current in the second magnet winding is excited at the latest after cooling of the magnet arrangement to the operating temperature, and with the second operating current the second magnet winding generates a second operating magnetic field in the volume of the first magnet winding.

Owner:BRUKER SWITZERLAND AG

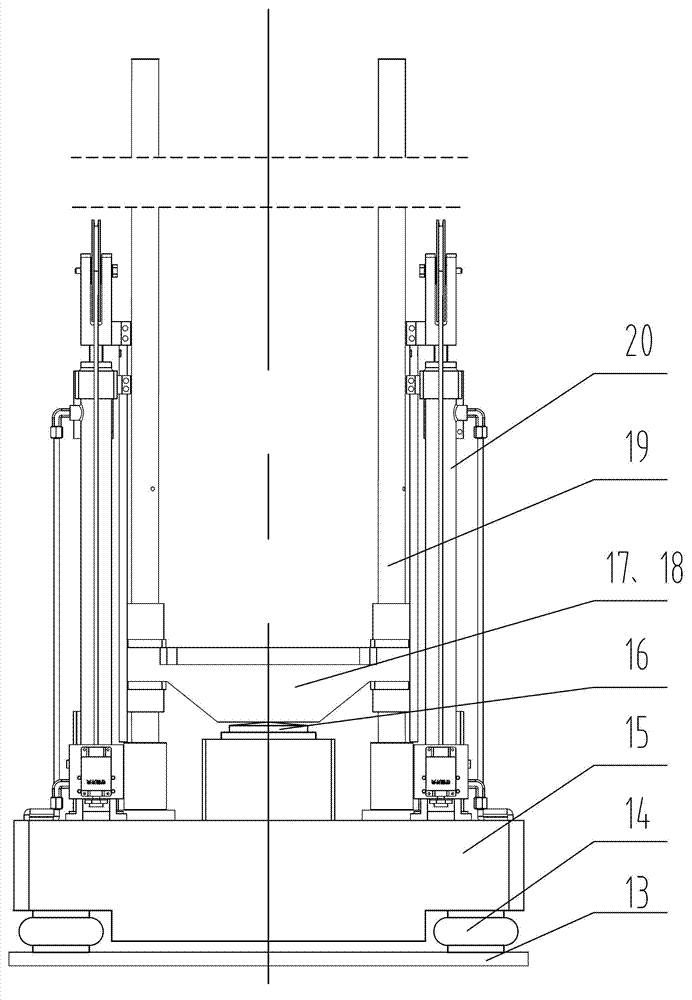

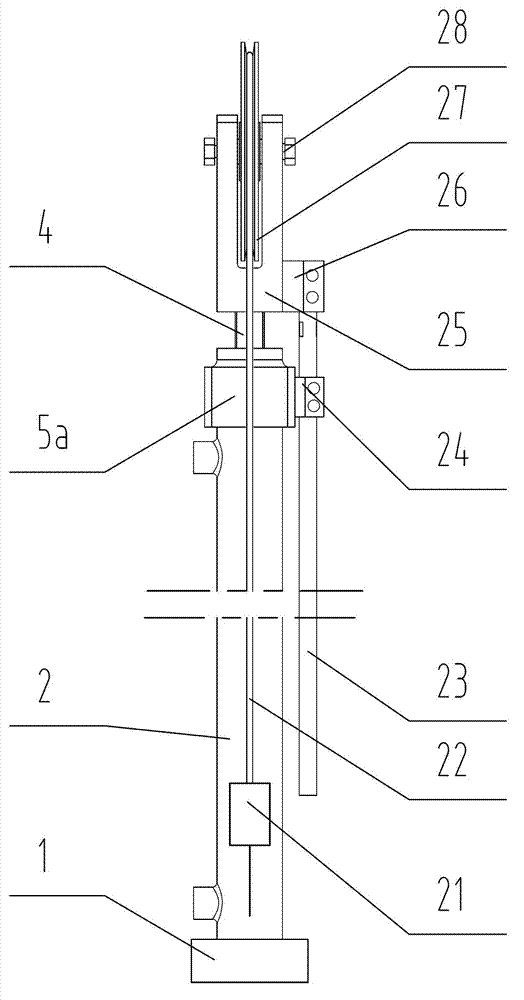

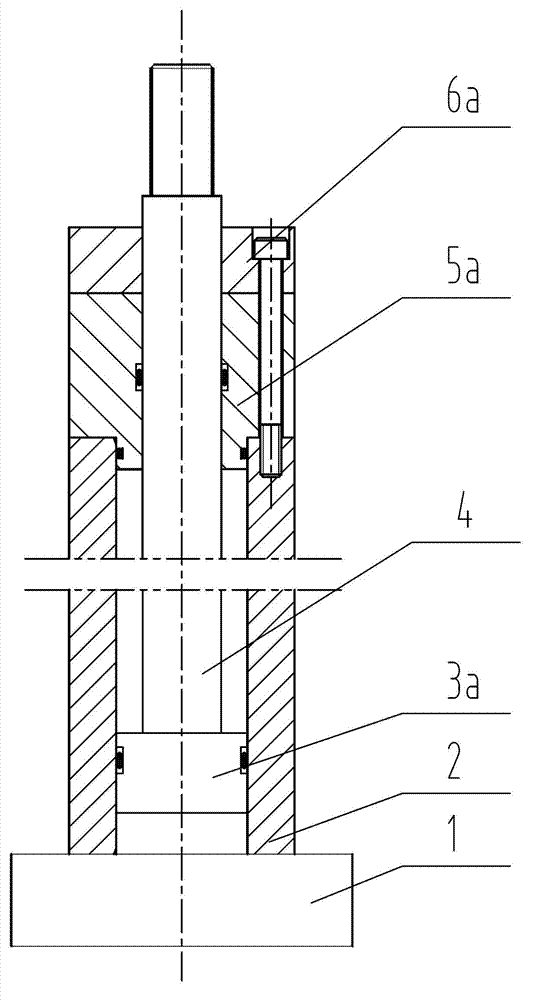

Anti-rotation structure and method for hydraulic cylinder

InactiveCN102966625AAvoid swingingSolve the defect of insufficient rigidityFluid-pressure actuatorsShock testingHydraulic cylinderRotation method

The invention discloses an anti-rotation structure and a method for a hydraulic cylinder. The anti-rotation structure for the hydraulic cylinder comprises a piston and a piston rod arranged in a main body of the closed hydraulic cylinder, one end of the piston rod is connected with the piston, and the other end of the piston rod penetrates out of the main body of the hydraulic cylinder. According to the method, one end of the piston rod is connected with a non-central part of the piston, and the axial lines of the piston rod and the piston are made in parallel. By improving the structure of the hydraulic cylinder, particularly adopting eccentric combination of the piston and the piston rod, the diameter of the tube of the hydraulic cylinder needs not to be increased to solve the problem of rotation of the traditional hydraulic cylinder in the piston rising process. Meanwhile, the problems of technical risks, significant cost increase and the like caused by adding a guide rod, changing the state of the piston rod, adopting a sleeve type cylinder and using other schemes can be avoided. Moreover, the device has the advantages of simple structure, convenience int operation, high reliability and low cost.

Owner:苏州世力源科技有限公司

Para-position nanometer aramid fiber and carbon nano-tube composite paper preparation method

PendingCN110846926AEvenly dispersedImprove conductivityCarbon compoundsPaper/cardboardPolymer chemistryOrganic chemistry

The invention discloses a para-position nanometer aramid fiber and carbon nano-tube composite paper preparation method, which comprises: obtaining a para-aramid fiber (short for ANF) aqueous dispersion liquid, obtaining a carbon nano-tube (short for CNT) aqueous dispersion liquid, and mixing the two aqueous dispersion liquids to prepare the para-aramid fiber / carbon nano-tube (ANF / CNT) composite paper. According to the method of the invention, carbon nano-tubes are adopted, the advantages of high conductivity and high radiation of the carbon nano-tubes are utilized, and a specific dispersing agent capable of opening the agglomeration among the carbon nano-tubes is added, so that the carbon nano-tubes are uniformly dispersed, and then the carbon nano-tubes are mixed with a para-aramid fiberaqueous dispersion liquid to prepare the nanometer para-aramid / carbon nano-tube composite paper; and by adding the specific dispersing agent, the carbon nano-tubes can be uniformly dispersed, so thatthe conductivity of the nanometer para-aramid / carbon nano-tube composite paper can be greatly improved while the infrared emissivity is more than 90%.

Owner:乐烯恒业(北京)科技有限公司

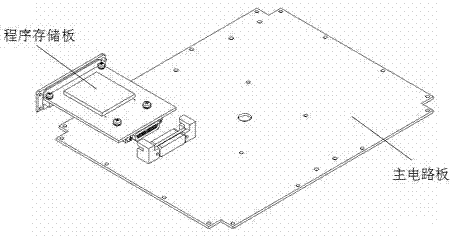

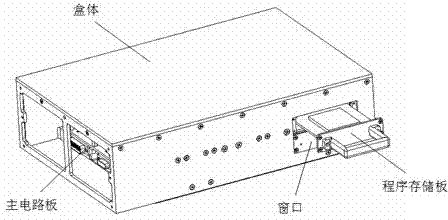

Method for rapidly achieving solidification falling welding of satellite-borne software program at low risk

InactiveCN103488566AReduce development costsAvoid disassemblySoftware testing/debuggingProgrammable read-only memoryInterconnection

A method for rapidly achieving solidification falling welding of a satellite-borne software program at a low risk comprises the steps of respectively independently designing printed boards for an electrically-erasable programmable read-only memory (EEPROM), a programmable read-only memory (PROM), an application memory and other peripheral devices, and inserting an EEPROM memory board in a main circuit board through a pluggable interconnection plug-in at a program debugging stage; when the program debugging is finished and the program needs to undergo solidification falling welding, enabling finally solidified software to be burned in the PROM, enabling the well burned PROM to be welded to a PROM memory board, pulling out the EEPROM memory board on the main circuit board, enabling the PROM memory board to be plugged in the main circuit board through a pluggable interconnection plug-in, and finally enabling the main circuit board with the program having undergone solidification falling welding to enter the space to be used. According to the method, the development cost is reduced, system dismantling and installing operation during software program solidification is omitted, the technical risk and hidden danger are avoided, system reliability is improved, program solidification time is shorted, the development cycle is shorted, the program solidification risk is reduced, and system reliability and availability are improved.

Owner:SHANGHAI RADIO EQUIP RES INST

Method for energizing a superconducting magnet arrangement

ActiveUS9715958B2Reduced stabilityReduce expenditureMagnetic measurementsMagnetic materialsTemperature controlSuperconducting Coils

A method for charging a magnet arrangement having a superconducting tape conductor with a first transition temperature in a cryostat device. The magnet arrangement is temperature-controlled to a first pre-operating temperature between the first transition temperature and the operating temperature, a first pre-operating current is excited, the magnet arrangement is cooled to operating temperature and a first operating current is excited. The magnet arrangement has a second magnet winding composed of a second superconductor material with a second transition temperature above the operating temperature and at least 15 K below the first transition temperature, wherein a second operating current in the second magnet winding is excited at the latest after cooling of the magnet arrangement to the operating temperature, and with the second operating current the second magnet winding generates a second operating magnetic field in the volume of the first magnet winding.

Owner:BRUKER SWITZERLAND AG

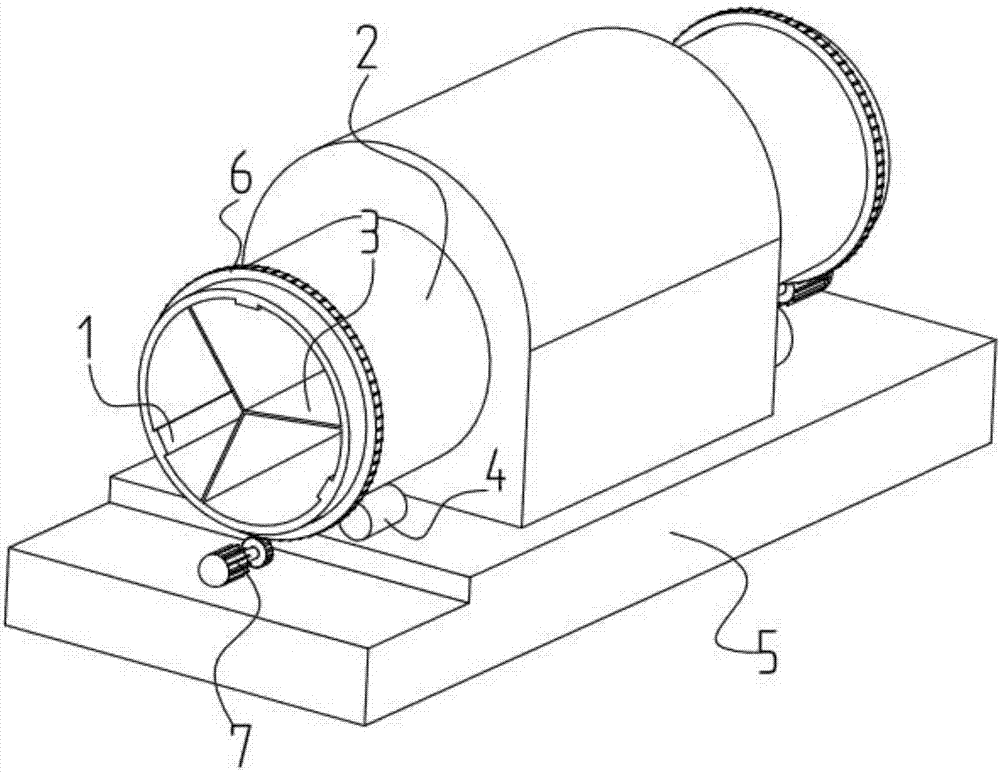

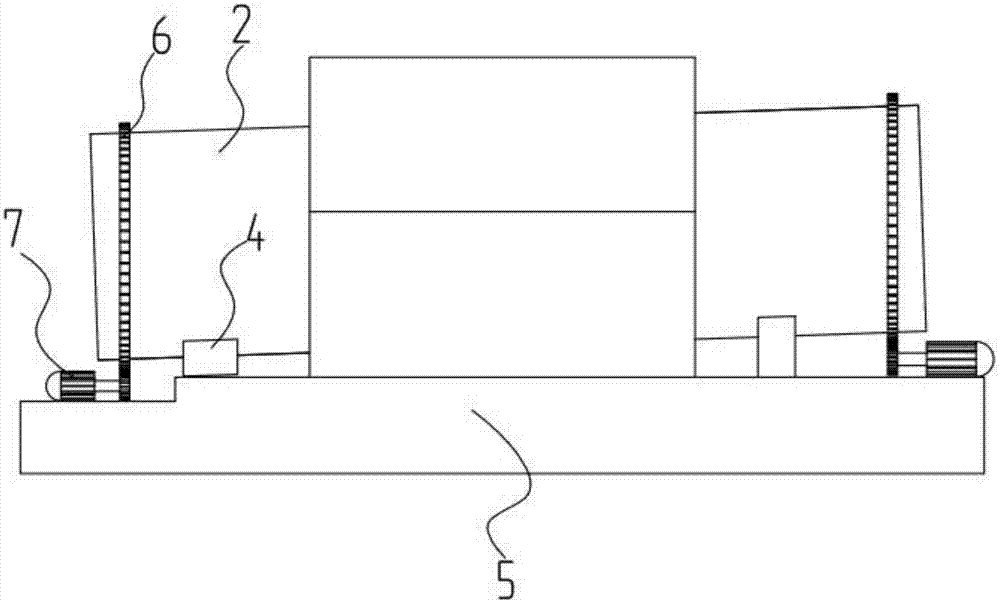

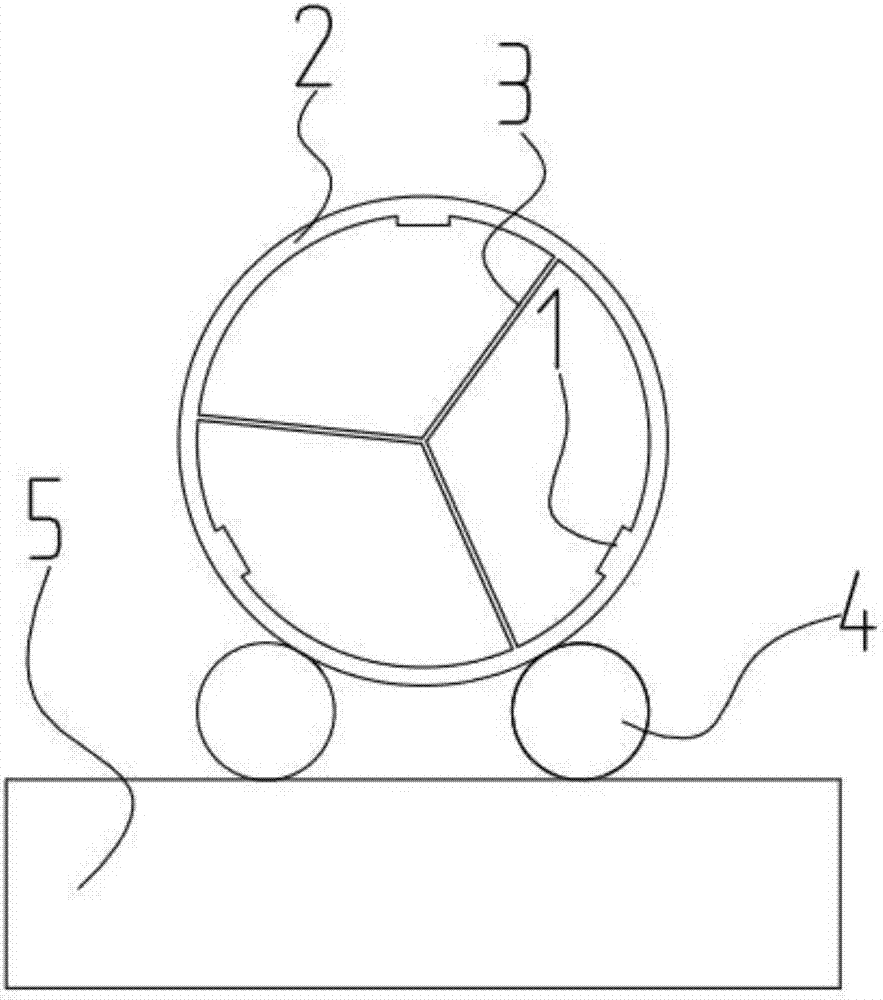

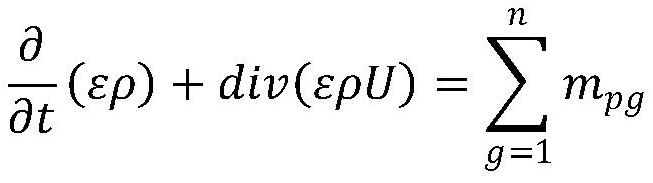

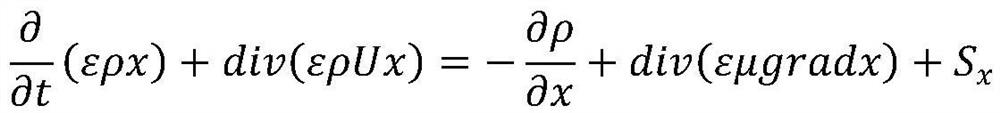

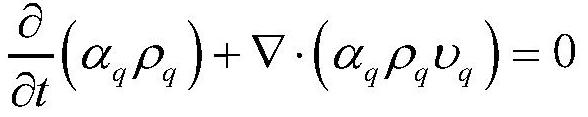

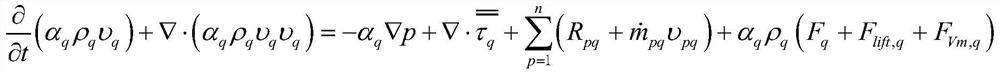

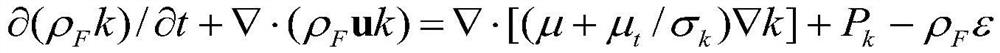

Multi-chamber rotary furnace and numerical simulation method for performing catalyst particle heating

InactiveCN107038284AScientific and reasonable structure designIncrease contact areaDesign optimisation/simulationSpecial data processing applicationsProcess engineeringOperant conditioning

The invention discloses a multi-chamber rotary furnace, which is scientific and reasonable in structure, good in drying effect, low in energy consumption, low in cost, high in efficiency and easy to realize. On this basis, the invention provides a numerical simulation method for performing catalyst particle heating by utilizing the multi-chamber rotary furnace. Computational fluid dynamics software CFX is adopted to perform numerical computation on a heating process of catalyst materials in the gas multi-chamber rotary furnace and an accompanying heat transfer process, so that high cost and technical risks caused by experiments or blind design are avoided to a certain extent; and the method is of a certain guiding significance for actual operation conditions of the multi-cavity rotary furnace.

Owner:SHANGHAI UNIV

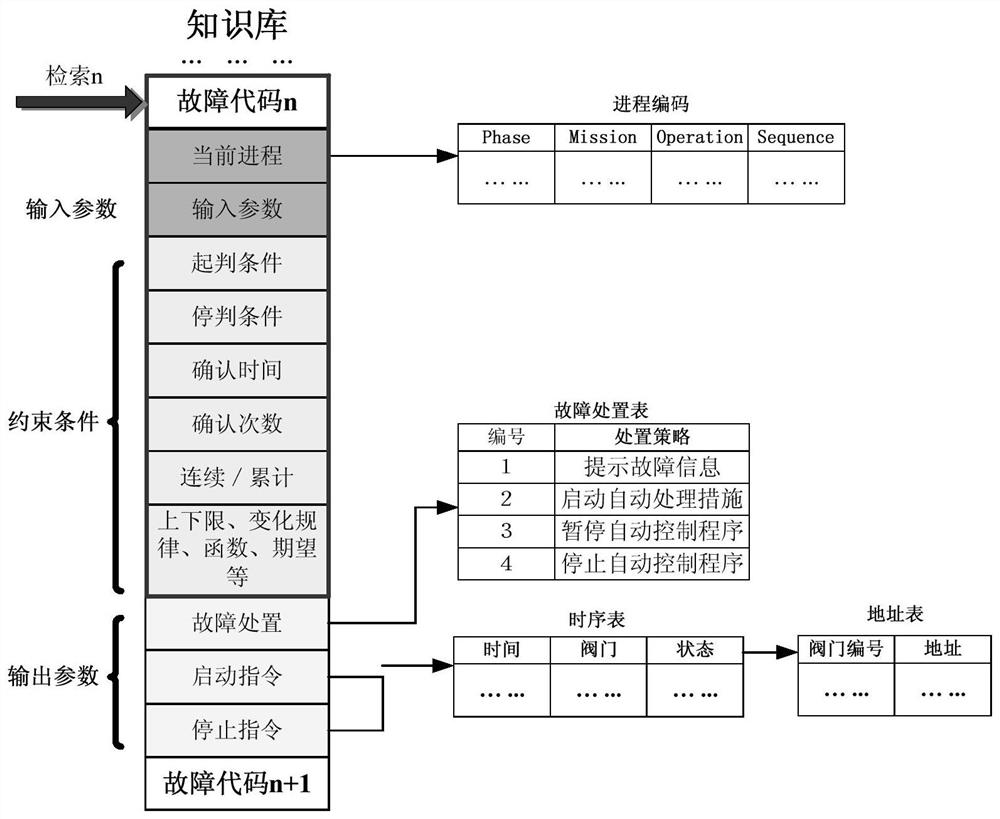

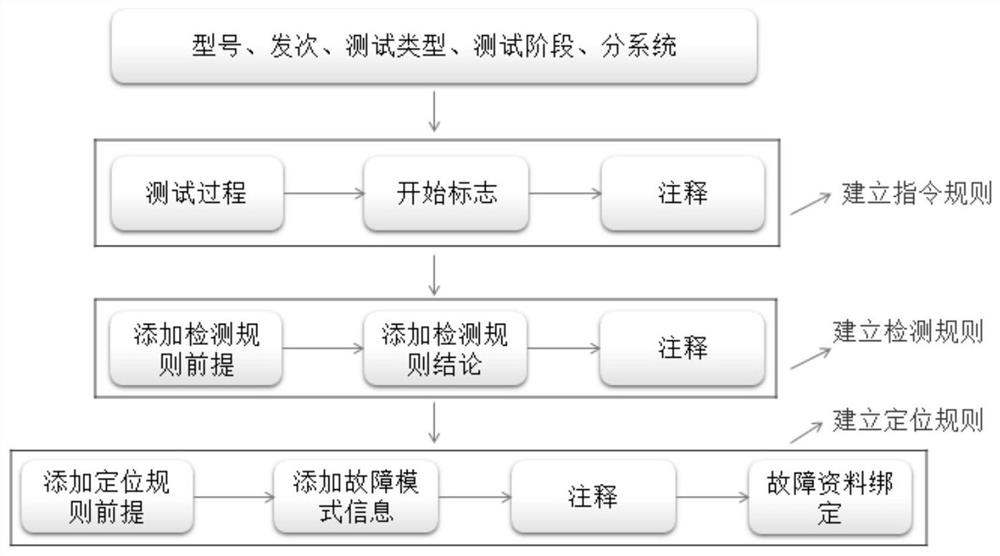

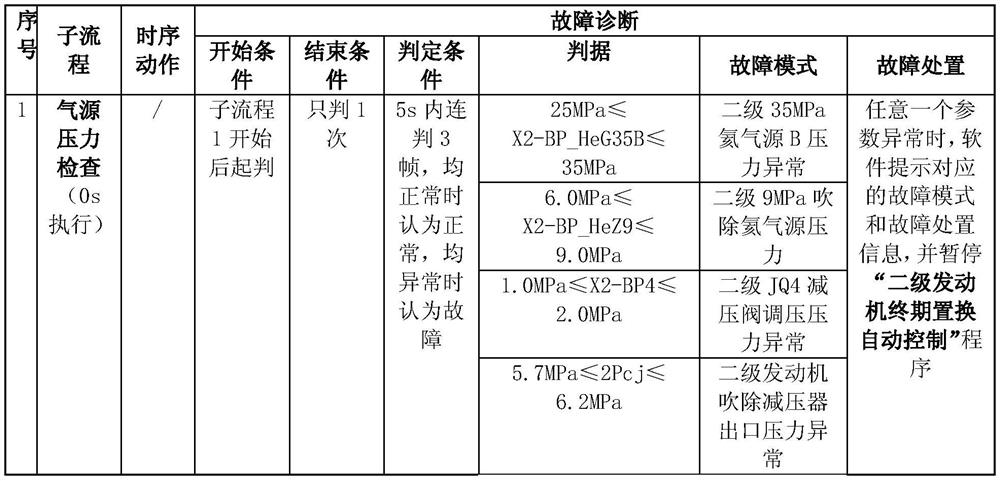

Automatic launch control method for carrier rocket low-temperature power system

ActiveCN112539678AHigh security riskAvoid difficultiesRocket launchersAmmunition testingAutomatic controlLaunch control

The invention discloses an automatic launch control method for a carrier rocket low-temperature power system. According to the method, the whole launch process is subjected to stage planning accordingto the characteristics of different time period processes of a launch day; each stage is divided into a plurality of items of work according to the independent degree of the work content, and each item of work is controlled and executed by an independent automatic control program; and due to the fact that the interpretation data is more, the algorithm is complex, the fault detection and positioning difficulty is high, and the processing requirement is high, a data processing knowledge base for fault diagnosis is constructed while the automatic launch control is executed, the important data inthe flow is interpreted, the rapid fault positioning is realized, and the fault processing is automatically executed.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

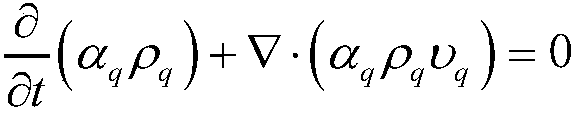

Numerical simulation method of atomized film formation of suspension liquid material

ActiveCN108804744ALow costAvoid technical risksSustainable transportationDesign optimisation/simulationLiquid jetJet flow

The invention provides a numerical simulation method of atomized film formation of suspension liquid material, and obtains the relationships among thickness of liquid film and each parameter through dimensional analysis and the linear least square regression analysis method. The liquid jet continuously impacts on an atomizing disk, and the liquid jet expands on the surface of the atomizing disk toform a film; and the liquid film leaves the atomizing disk along the tangent direction and breaks up to form ligaments or droplets. The computational fluid dynamics software FLUENT is used to performnumerical calculation on the process, therefore, the high cost and waste of raw materials caused by experiment or blind design are avoided, which has certain guiding significance for the atomizationmechanism of feed liquid.

Owner:SHANGHAI UNIV

A heat-resistant titanium alloy and its processing and manufacturing method and application

The invention belongs to the field of titanium-based alloys, and specifically relates to a novel heat-resistant titanium alloy and its processing and manufacturing method and application, including components such as alloy composition, smelting, thermal processing and heat treatment. The composition (weight percentage) of said alloy is Al: 5.4%~6.3%; Sn: 3.0%~5.0%; Zr: 2.5%~6.4%, Mo: 0.0~0.96%, Si: 0.25%~0.5%, Nb : 0.2%~0.5%, Ta: 0.3%~3.4%, W: 0.2%~1.6%, C: 0.0~0.07%, O≤0.17%, Fe≤0.03%, the balance is Ti and unavoidable impurity elements . The alloy of the present invention can obtain different matchings of tensile strength and plasticity, durability and creep strength and thermal stability through different thermal processing and heat treatment process combinations, and can be used to make blades, discs and other parts of high-temperature parts of advanced aero-engines, It can be used for a long time in the range of 600-650°C; it can also be used to make high-temperature resistant structural parts such as aerospace vehicle skins, and it can be used for a short time at about 700°C; it can also be used as a material for high-temperature and corrosion-resistant valves for automobiles and boilers.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of preparation method of high temperature titanium alloy bar

The invention belongs to the field of titanium-base alloys and particularly relates to a preparation method of a high-temperature titanium alloy bar. The preparation method comprises the following steps: heating a prepared Ti60 titanium alloy cast ingot to 1150-1200 DEG C, and carrying out blank-opening forging in a beta phase region by virtue of a rapid forging machine or a hydraulic press; heating to 1080-1150 DEG C, carrying out repeated upsetting and swaging forging by virtue of the rapid forging machine or the hydraulic press, heating the forged blank to Tbeta-120 DEG C to Tbeta-30 DEG C(Tbeta is a Ti60 titanium alloy alpha+beta / beta phase inversion temperature), and carrying out repeated upsetting and swaging forging by virtue of the rapid forging machine or the hydraulic press until the blank is in a required size, so as to obtain the titanium alloy bar, wherein the macrostructure of the titanium alloy bar is a fuzzy crystal, and the microstructure of the titanium alloy bar isuniform. After the prepared Ti60 titanium alloy bar is subjected to solid dissolving and ageing thermal treatment, the matching degree of the obdurability of the bar is relatively good, and the matching degrees of the durability, creeping strength and thermal stability are relatively good. The preparation method is convenient in operation and relatively strong in process controllability, and the batch stability of the prepared Ti60 titanium alloy bars is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +2

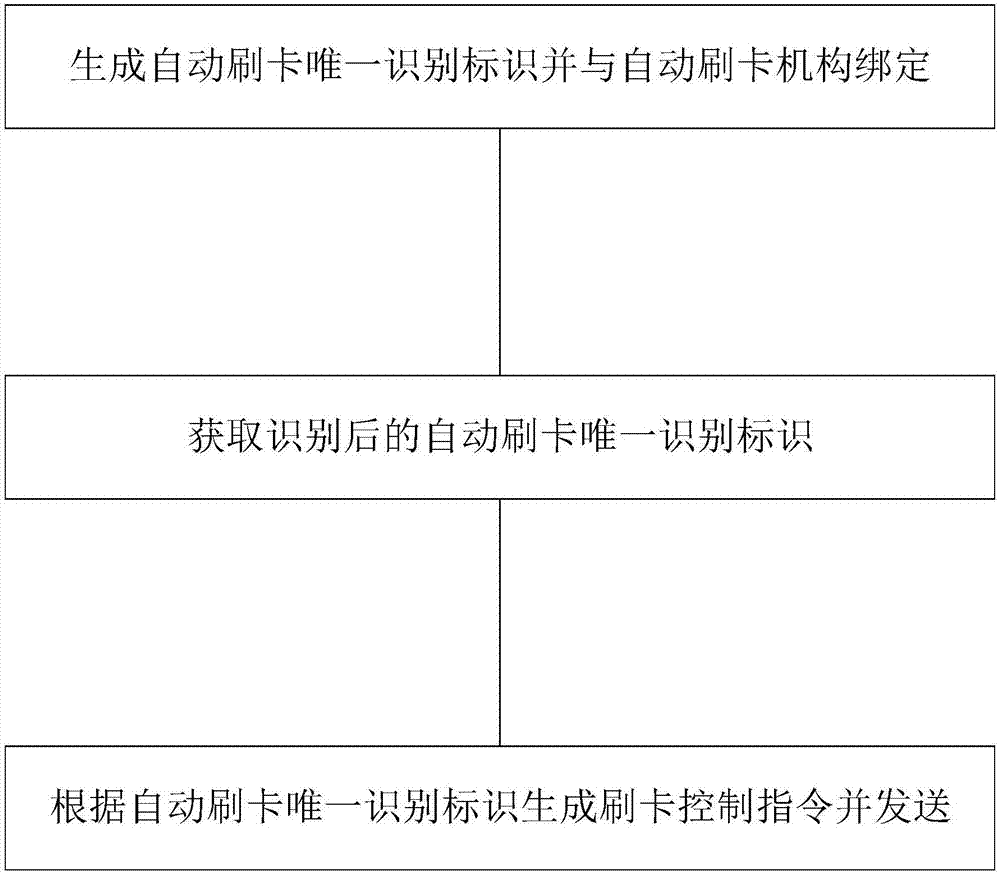

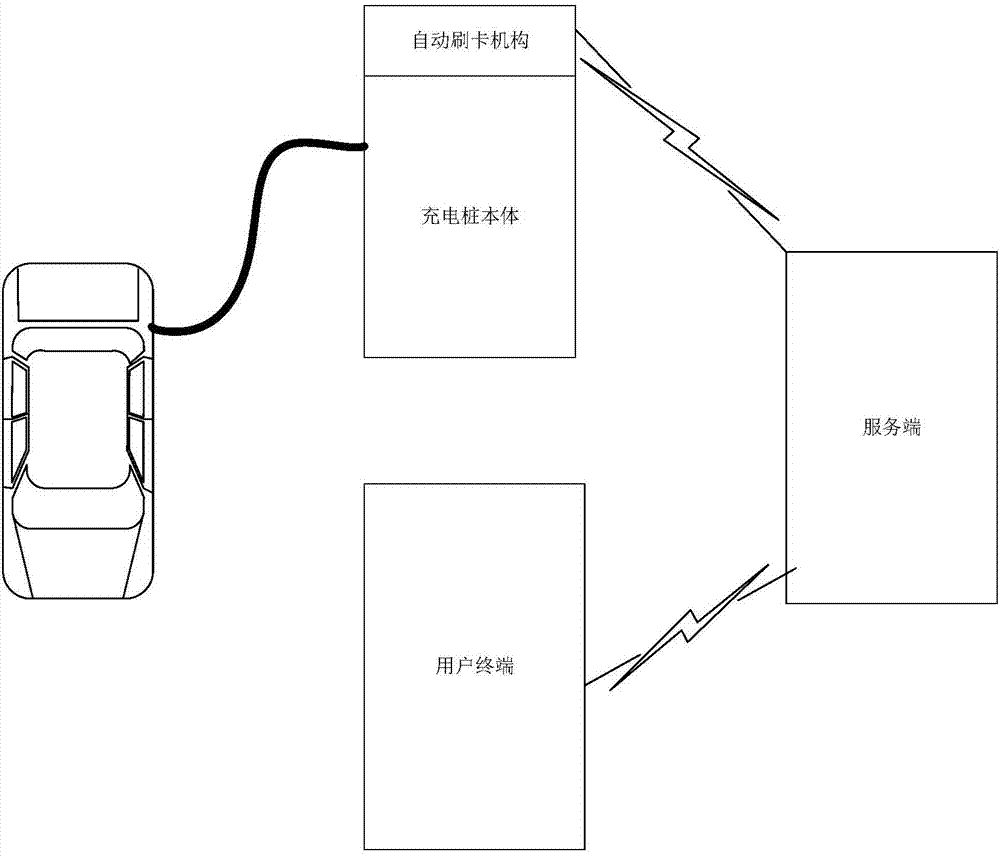

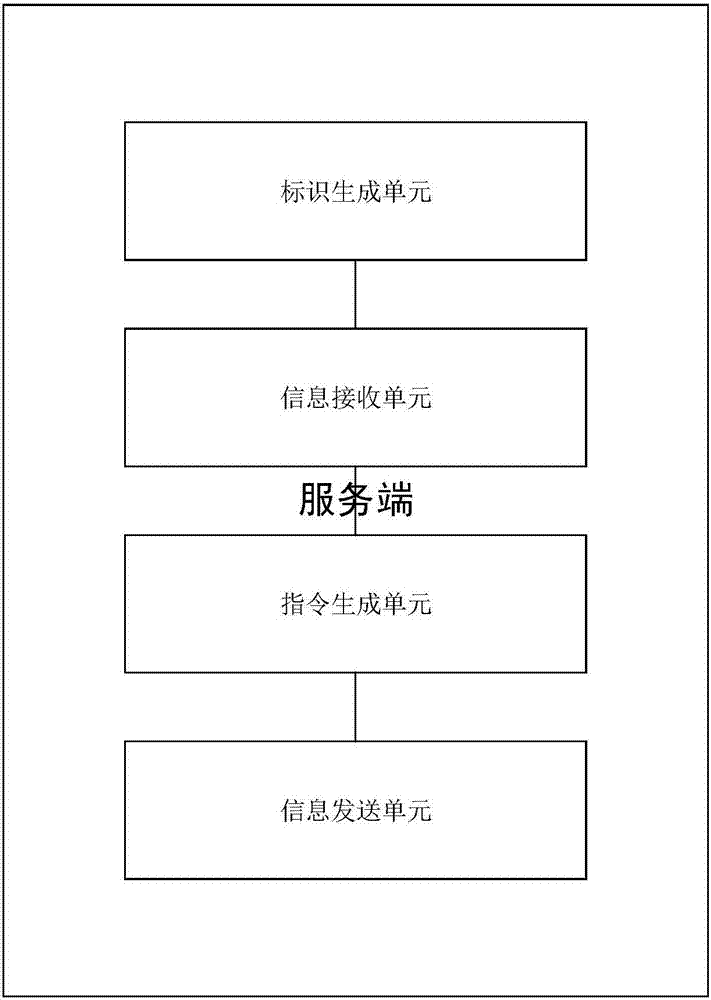

Charging method, charging pile, user terminal and server

InactiveCN107170125AAvoid technical risksEasy to modifyCharging stationsElectric vehicle charging technologyUtilization rateTechnical risk

One embodiment of the invention relates to a charging method, a charging pile, a user terminal and a server. The charging method comprises following steps: generating automatic card-swipe unique identification and binding to an automatic card-swipe mechanism, wherein the automatic card-swipe mechanisms and charging piles are corresponding one for one and bond; obtaining the identified automatic card-swipe unique identification, wherein the automatic card-swipe unique identification is identified and sent by a user terminal; generating and sending a card-swipe control instruction according to the automatic card-swipe unique identification; the automatic card-swipe mechanism performs card-swipe operation according to the card-swipe control instruction; the charging pile starts operation according to the card-swipe operation results. According to the embodiment of the invention, sharing by multiple people can be realized by the automatic card-swipe mechanism so as to avoid technical risk due to inner structure change; data of original charging piles will not be affected, which is convenient for refitting and sharing and therefore further increases the utilization rate of idle charging piles.

Owner:北京迅联游科技发展有限责任公司

A kind of preparation method of high temperature, high thermal stability, high creep resistance titanium alloy bar

The invention belongs to the field of titanium-based alloy and particularly relates to a preparation method for a high-temperature titanium alloy bar. The preparation method comprises the steps that aprepared Ti55 titanium alloy cast ingot is heated to 1150 DEG C-1200 DEG C, and then cogging forging is conducted in a beta phase region through a fast forging machine or a hydraulic press; and thenthe Ti55 titanium alloy cast ingot is heated to 1050 DEG C-1100 DEG C, upsetting and drawing-out forging are conducted repeatedly through the fast forging machine or the hydraulic press, then the forged blank is heated to Tbeta-100 DEG C-Tbeta-20 DEG C (Tbeta is Ti55 titanium alloy alpha+beta / beta phase transformation temperature), upsetting and drawing-out forging are conducted repeatedly throughthe fast forging machine or the hydraulic press till the needed size is obtained, and the titanium alloy bar of which the macrostructure is fuzzy crystals and the microstructure is uniform is obtained. After subjected to solution+aging heat treatment, the Ti55 titanium alloy bar prepared through the preparation method is good in strength and toughness match, good in endurance and creep strength and heat stability match, and high in fracture toughness. Operation is convenient, process controllability is high, and the prepared Ti55 titanium alloy bar is good in batch stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +2

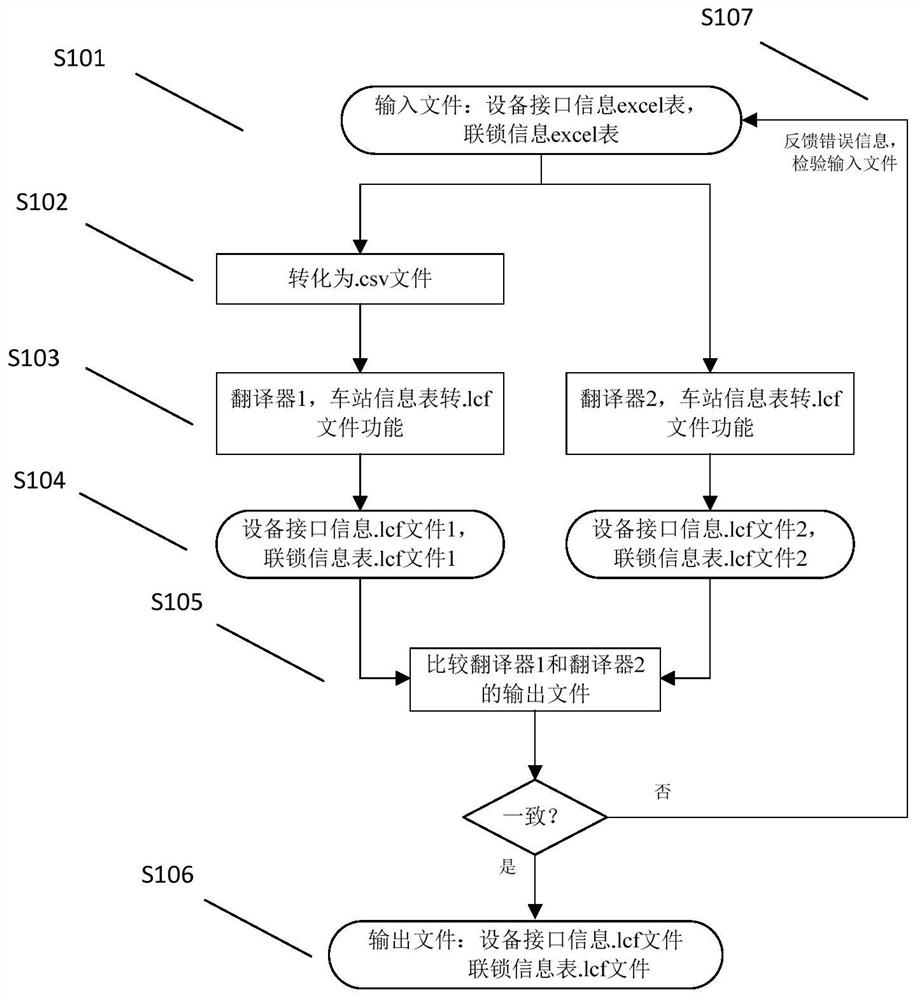

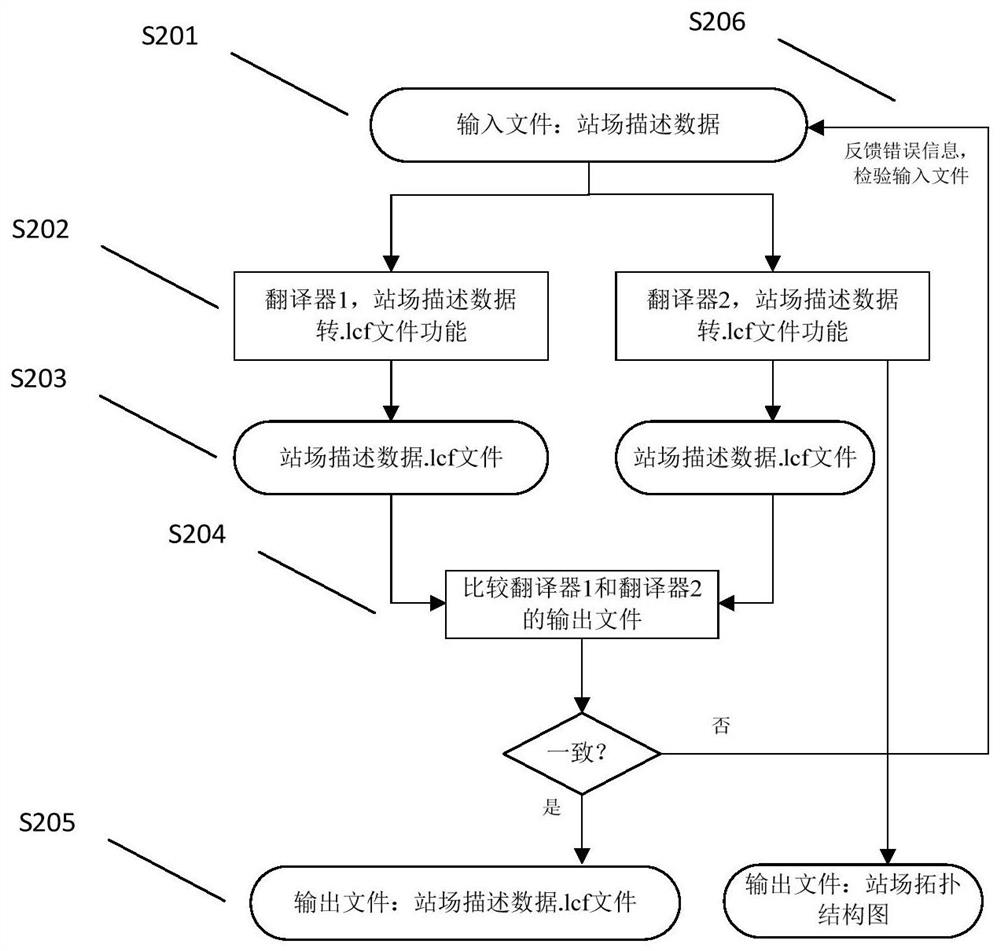

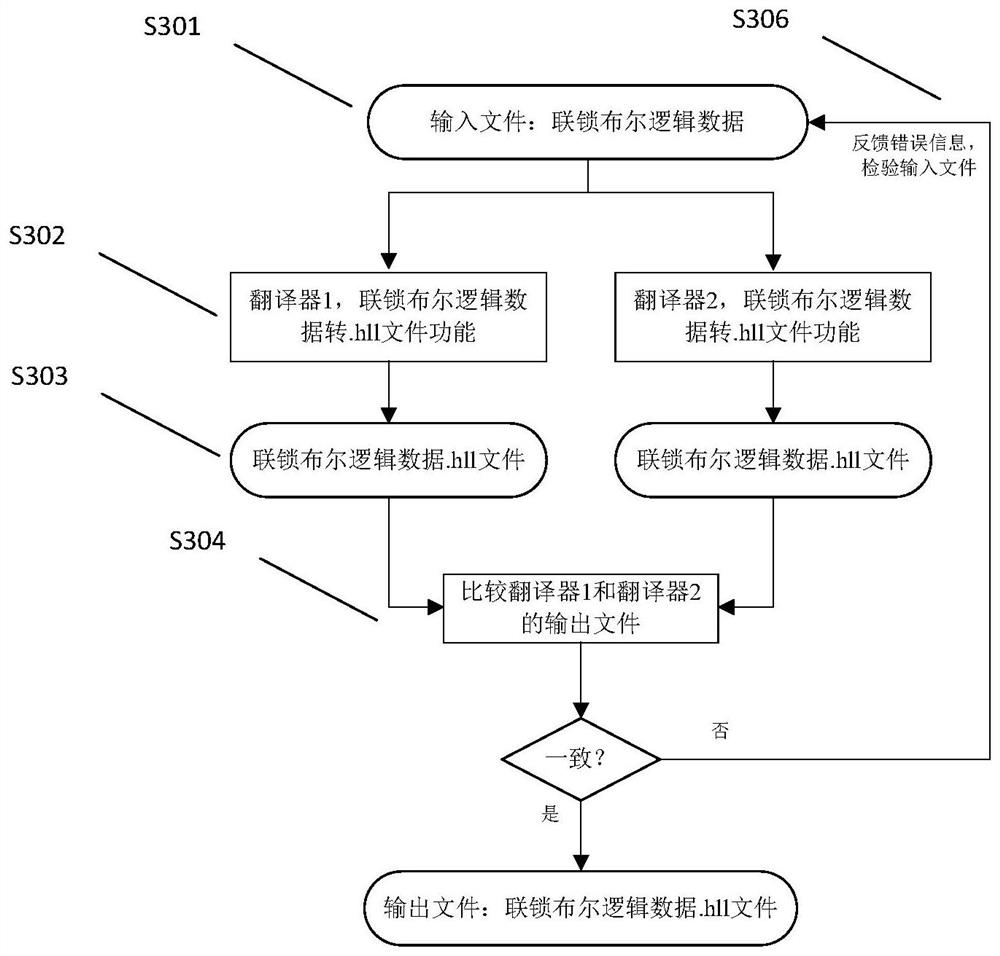

A method and translator for interlocking data security conversion for formal verification

ActiveCN113031934BImplement formal verificationImprove general performanceError detection/correctionRailway traffic control systemsFormal developmentStation

A safety conversion method and translator for interlocking data for formal verification, two translators with the same function are developed by using different programming methods and programming languages, and the input file of the translator at least contains: The interlocking information table, equipment interface information table, station description data and interlocking Boolean logic data are compared, and the consistency of the output files of the two translators is compared to realize the detection of process failure, thereby ensuring the safe conversion of data. The invention does not need special formal development for each station, reduces technical cost and design risk, has high safety, good compatibility, strong versatility and wide application range.

Owner:CASCO SIGNAL

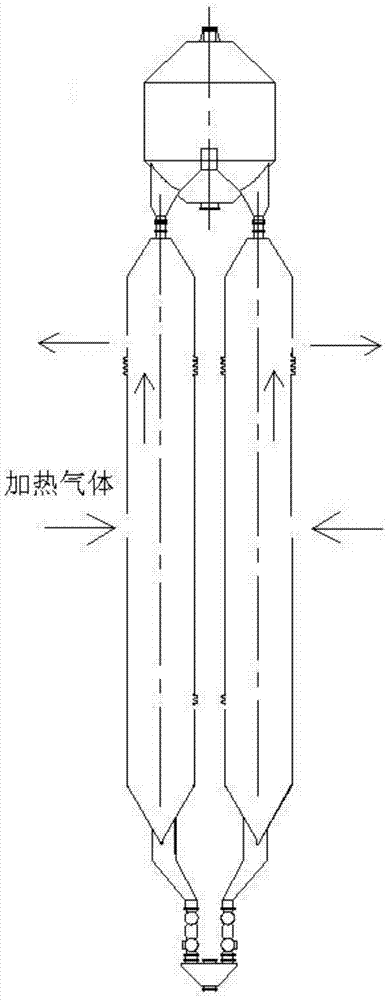

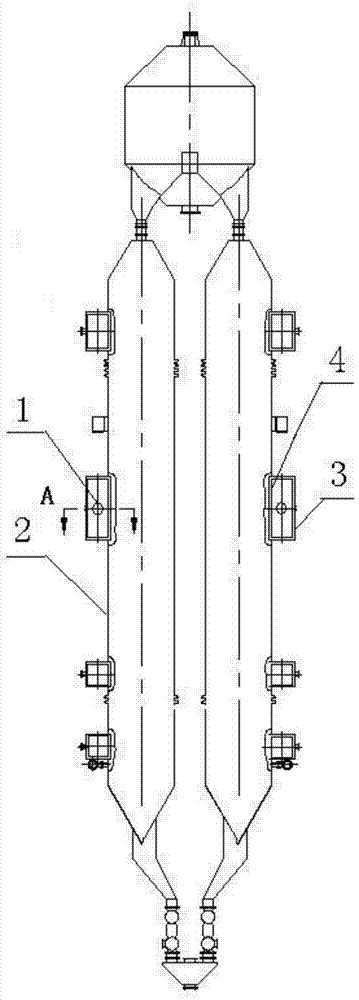

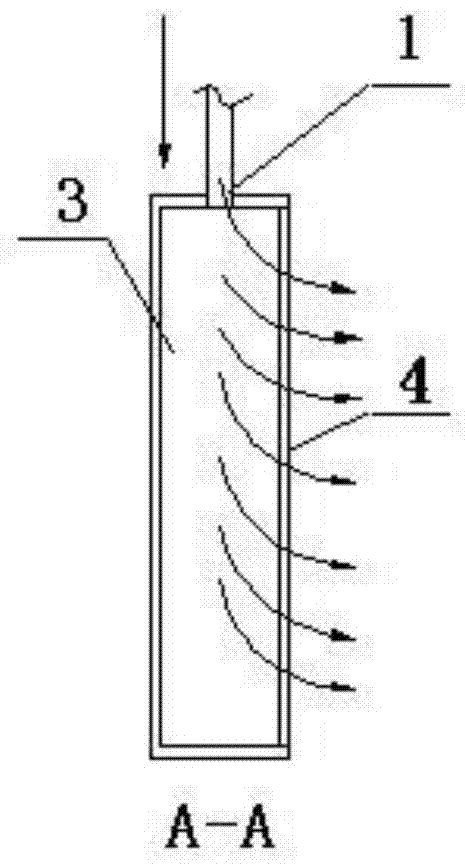

A desorption tower and its heating gas inlet channel

ActiveCN104667698BAvoid the problem of uneven flow rateAvoid technical risksDispersed particle separationActivated carbonEngineering

The invention relates to the technical field of activated carbon desulfurization and denitrification, and provides a desorption tower and its heating gas inlet passage, including an inlet buffer chamber arranged between the inlet pipe and the tower wall; the inlet of the inlet buffer chamber Located on the outer wall directly connected to the tower wall of the air inlet buffer chamber; the air inlet buffer chamber is connected with the tower wall of the desorption tower through an equalizing plate, and the equalizing plate is on the air inlet direction of the air inlet The circulation capacity gradually increases from the center to both ends. Compared with the prior art, firstly, it avoids the problem of uneven flow rate caused by the sudden enlargement of the space when the heating gas directly enters the desorption tower from the intake pipe. Second, break the limitations of pipeline layout, reduce technical risks and technical costs. Further, the flow capacity of the equalizer plate in the air inlet direction increases gradually from the center to both ends, so as to avoid the adverse effects caused by the decreasing trend of the flow velocity of the heated gas in the direction of diffusion from the center to the outer ends.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

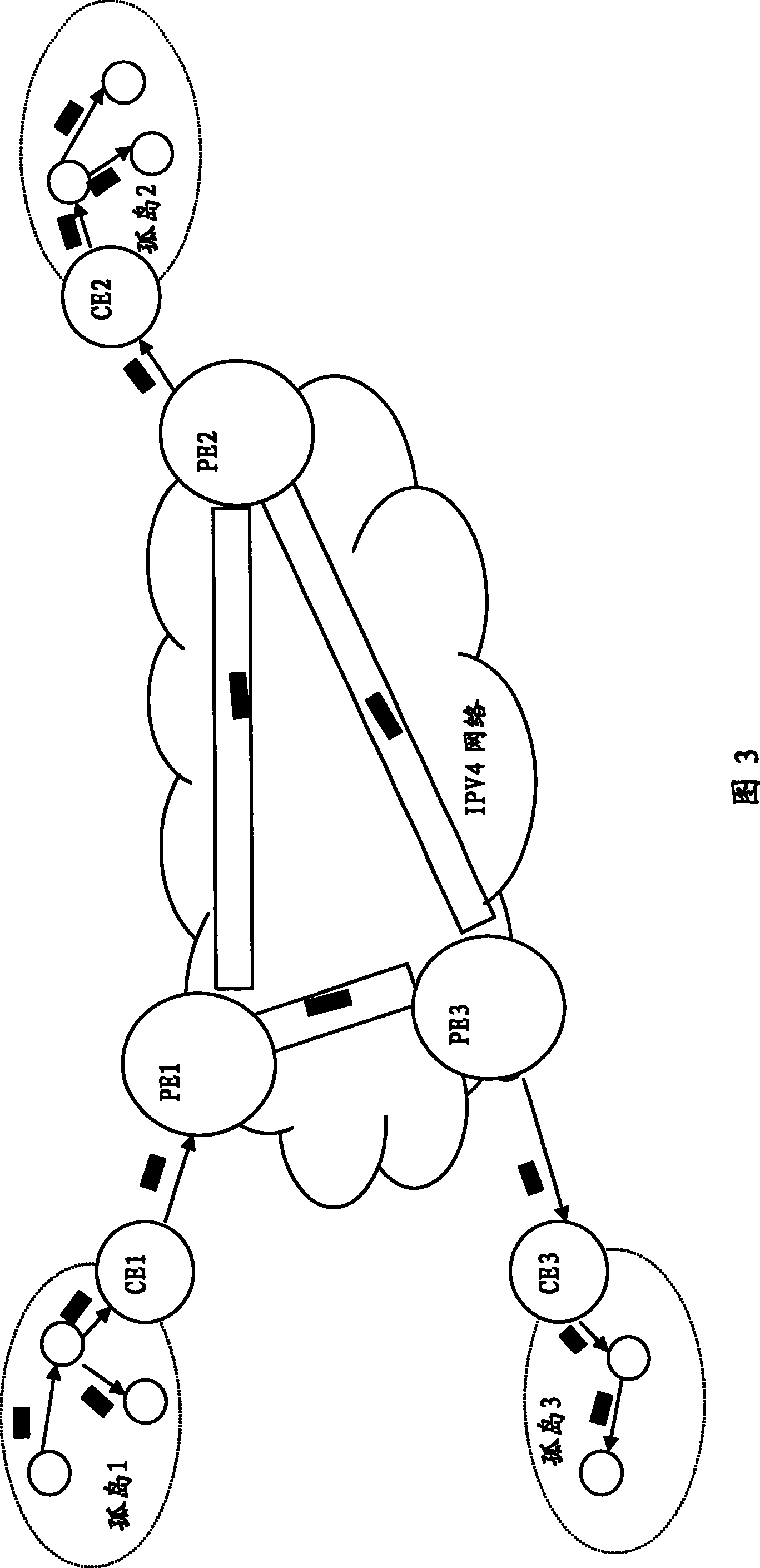

Group broadcast desposition method between IPv6 islet and its equipment

InactiveCN101001193BRealize multicast communicationSave money on upgradesNetworks interconnectionExtensibilityIt equipment

This invention discloses a multicast disposing method among IPv6 isolated islands and ISP internet border devices for realizing it, in which, multicast parameters are transmitted in IPv4 and negotiated, and a multicast service tunnel is set up in the IPv4 based on the negotiation result to realize multicast communication in the IPv4 network. This invention also provides an ISP internet border device including a multicast parameter setting module, a transfer module, a negotiation module, a multicast service tunnel set-up module and a multicast neighbour relation module, in which, the new IPv6 device can be connected to the current IPv4 network at any time without updating the current IPv4 core network.

Owner:HUAWEI TECH CO LTD

System and method for expanding model driving development capability by applying plug-in

ActiveCN102033743BSolve the problem of insufficient description abilityExpandable and flexibleSpecific program execution arrangementsModel descriptionStationary model

Owner:广州翼风信息科技股份有限公司

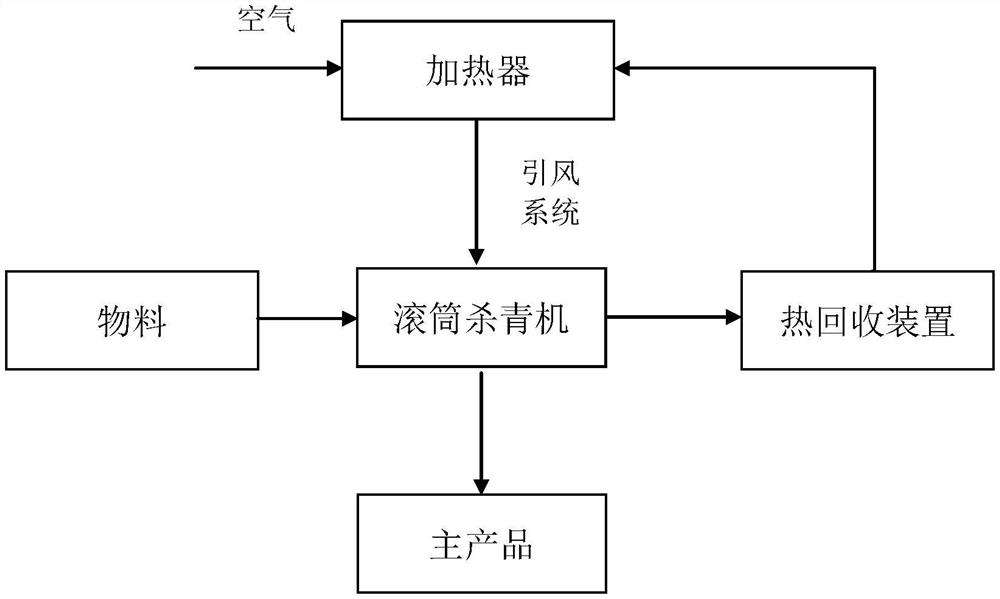

Flow and heat transfer process numerical simulation analysis method of hot air drum type phoenix single fir tea leaf fixation machine

InactiveCN112329169AScientific and reasonable structureImprove finishing effectGeometric CADPre-extraction tea treatmentProcess engineeringTea leaf

The invention discloses a flow and heat transfer process numerical simulation method of a hot air drum type phoenix single fir tea leaf fixation machine, and uses the hot air drum type phoenix singlefir tea leaf fixation machine which is scientific and reasonable in structure, good in fixation effect, high in efficiency, low in cost and easy to realize. According to the numerical simulation analysis method for the flow and heat transfer process in the fixation machine, calculation fluid dynamics software FLUENT is adopted for carrying out numerical calculation on the dehydration process of tea leaves in the drum-type fixation machine and the accompanying heat exchange and mass transfer process between the tea leaves and hot fluid, high cost and raw material waste caused by experiments orblind design are avoided, and the method has certain guiding significance for improving the fixation quality of the tea. High cost and technical risks caused by tests or blind design are avoided to acertain extent; programs of the numerical simulation analysis process are easy to implement, and the method has remarkable value in application of the efficient tea leaf fixation process.

Owner:SOUTH CHINA AGRI UNIV

Numerical Simulation Method for Atomization of Suspension Materials to Film Formation

ActiveCN108804744BLow costAvoid technical risksSustainable transportationDesign optimisation/simulationLiquid jetRegression analysis

The invention provides a numerical simulation method for the atomization of a suspension material to form a film, and obtains the relationship between the thickness of the liquid film and each parameter by means of dimension analysis and linear least square regression analysis. The liquid jet continuously impinges on the atomizing disk, the liquid jet spreads on the surface of the atomizing disk to form a film, the liquid film leaves the atomizing disk in a tangential direction, and breaks up to form ligaments or droplets. The computational fluid dynamics software FLUENT is used to numerically calculate the process, which avoids the high cost and waste of raw materials caused by experiments or blind design, and has certain guiding significance for the atomization mechanism of the feed liquid.

Owner:SHANGHAI UNIV

An autonomous and controllable universal test launch and control system

ActiveCN108891622BImprove compatibilityImprove versatilityAircraft components testingTransceiverControl system

The invention discloses an automatic controllable general test lunch and control system. The system comprises a remote control console, a test lunch and control host, a zero-second forwarding box andan AC / DC power supply case; the remote control console and the test lunch and control host are connected through a cable, and are in network communication through a fiber optical transceiver or a network switch; the test lunch and control host comprises a computer board, an I / O board, an AD acquisition board, a communication board and an interface backplane; the computer board, the I / O board, theAD acquisition board and the communication board are plugged in the interface backplane through printed board connectors; the computer board comprises a DSP, a clock circuit and a memory, wherein theclock circuit and the memory are connected with the DSP; the DSP is used for sending an on-off output signal to the I / O board, receiving on-off input data fed back by the I / O board and analog quantitydata fed back by the AD acquisition board and performing parsing to realize output control and condition monitoring of an aircraft. Through modular function board cards and standardized interfaces and buses between the board cards, the integration and generality of the system are improved, and the maintenance cost is saved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

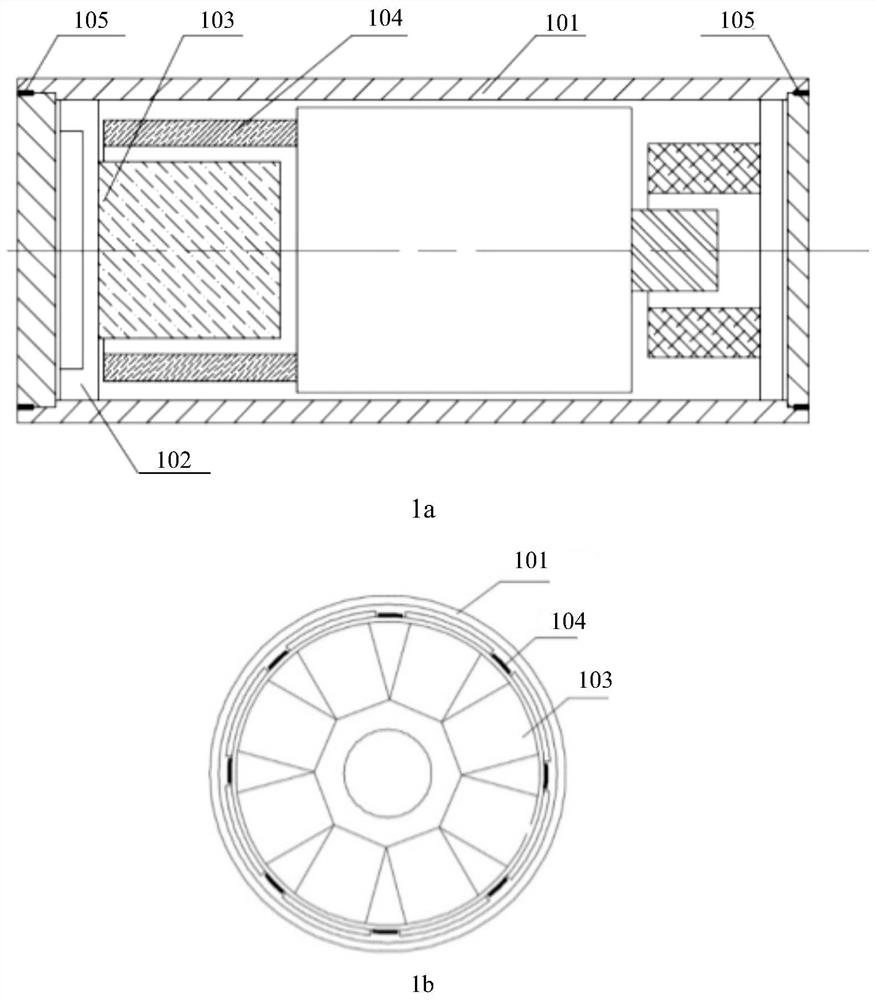

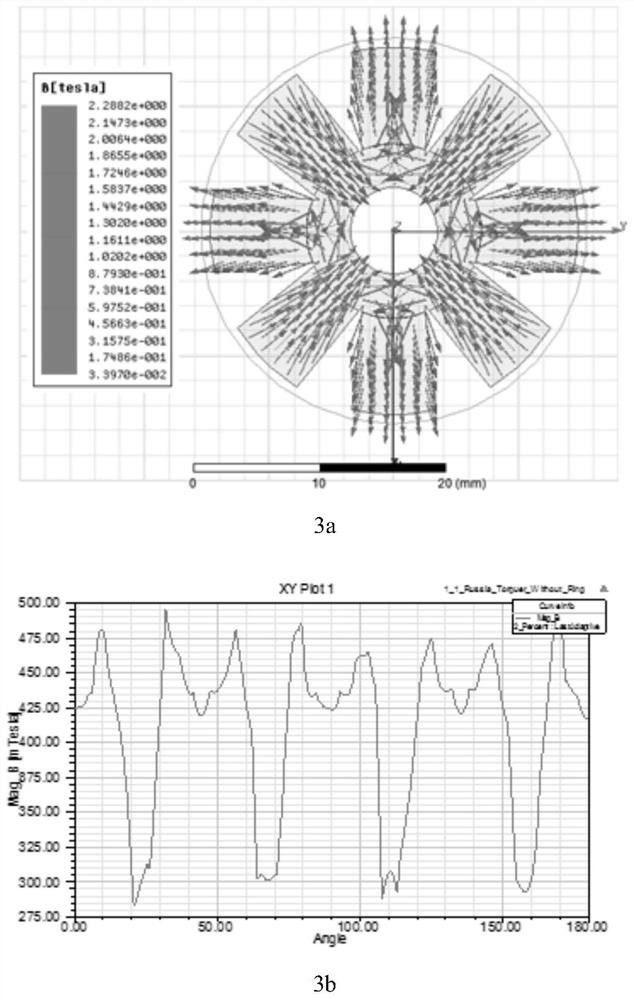

A method for maintenance and disassembly of liquid floating gyro

ActiveCN112188768BGuaranteed success rateIt is inconvenient to ensure the magnetic induction intensity BδCasings/cabinets/drawers detailsPrinted circuit board receptaclesGyroscopeClassical mechanics

The invention relates to a dismantling method applied to the maintenance of a liquid floating gyroscope, which uses an extension sleeve and an outwardly moving guide. Mechanically disassemble the welding seam; 2. Coaxially and fixedly connect the stator seat connection end of the outward movement guide with the outer end of the torquer stator seat; 3. Insert the end of the gyro shell into the positioning hole section of the extension sleeve. 4. Hold the hand-held operating end of the outward movement guide and pull the outward movement guide outward. The outward movement guide drives the torquer stator seat and the torquer stator to move out of the gyro housing and move into the extension sleeve to realize the disassembly of the torque stator. The method of the invention has the advantages of easy implementation, simple operation and low implementation cost, and ensures that the scale of the gyroscope will not go out of tolerance, thereby ensuring the success rate of gyroscope maintenance.

Owner:TIANJIN NAVIGATION INSTR RES INST

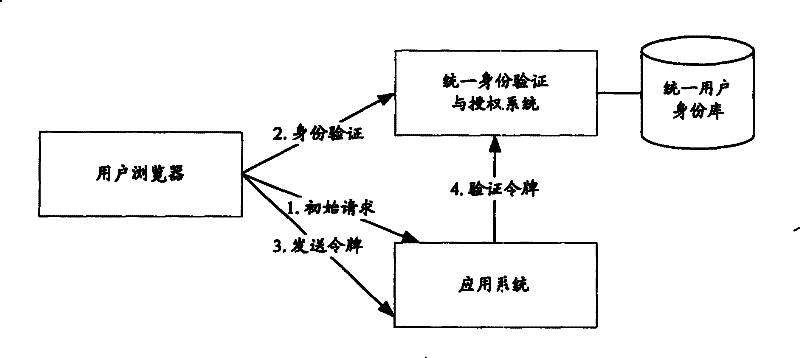

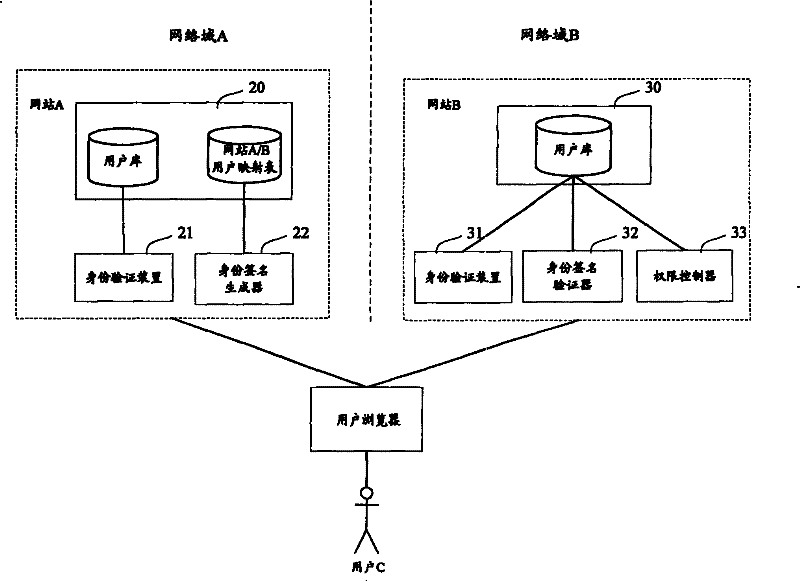

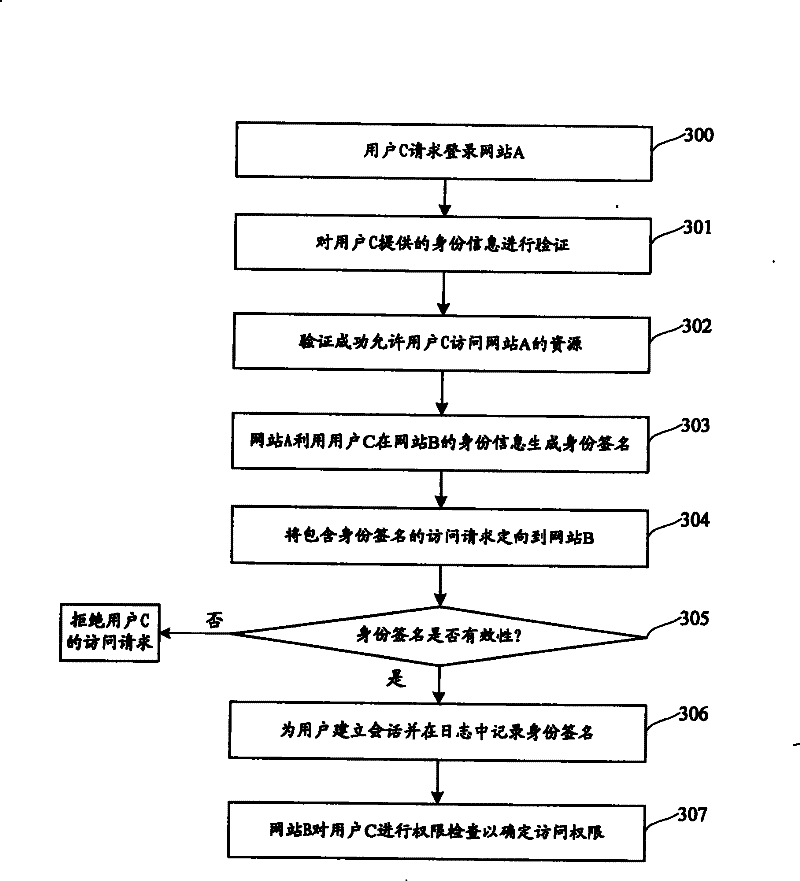

Method of realizing single time accession between websites and website thereof

ActiveCN1835438BEasy to implementSimple maintenance and managementUser identity/authority verificationWeb siteEngineering

The invention discloses a method for realizing intersystem Single Sign-On to solve the big difficulties of the realization technology and the difficult management existed in the intersystem Single Sign-On in the prior art. The method includes: a first website system preserving a user ID mapping relation in the first website system and a second website system, the second website system preserving the user ID mapping relation in the second website system and the first website system; for the first and the second website systems, any one website system obtaining ID information of the system user logged in the website in another website system and generating identity based signature according to the user ID mapping relation preserved in the website system, and carrying the identity based signature in the request message of the user which requests to log in another website system, and another website system verifying the user according to the identity based signature. The invention also discloses a verification system.

Owner:ADVANCED NEW TECH CO LTD

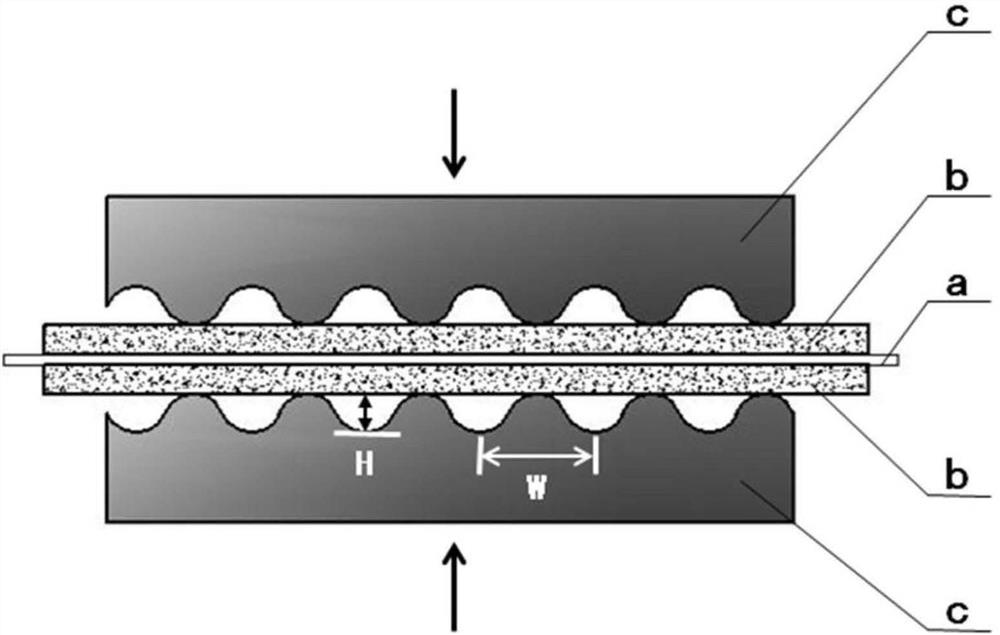

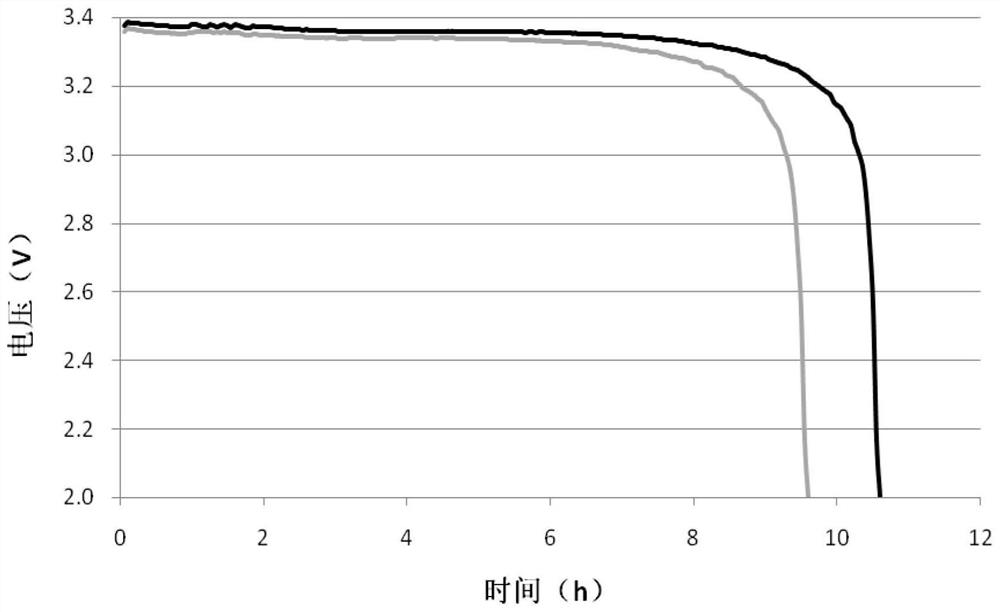

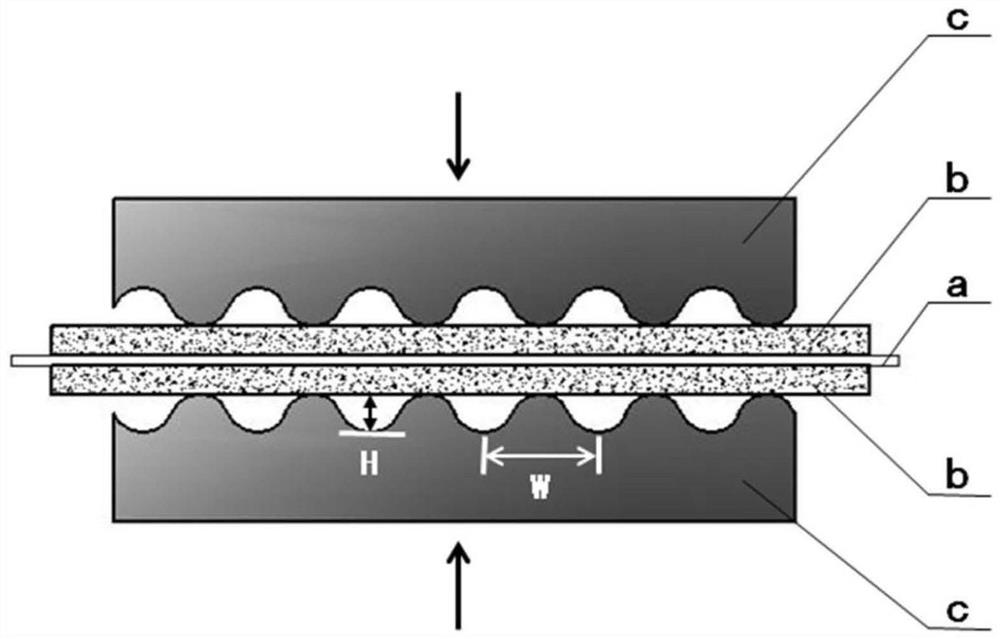

Preparation method of positive electrode of power type lithium thionyl chloride battery

ActiveCN111740073BAchieve staggered stretchAvoid technical risksElectrode rolling/calenderingElectrode thermal treatmentFiberElectrical battery

The invention discloses a method for preparing a positive electrode of a power type lithium thionyl chloride battery, which comprises the following steps: 1) mixing materials, 2) surfing the net, 3) fiberizing treatment, 4) stretching fibers interlacedly, 5) cutting and leaving blank , wherein, in the fiber interlaced stretching step, a pair of briquetting blocks or rollers with symmetrical fine wavy patterns on the surface are used to press or roll multiple times in different directions and different positions on both sides of the positive nickel expanded mesh, so that the positive nickel expanded mesh can be filled The adhesive inside the cladding material forms the overall fiber chain network adhesion; and then the positive nickel expanded mesh is rolled and leveled with a smooth pressure roller. The invention does not require secondary pasting, and can solve the problems of powder dropping, shedding, flanging and the like of the positive electrode, and simultaneously improves the capacity and discharge voltage platform of the battery.

Owner:武汉中原长江科技发展有限公司

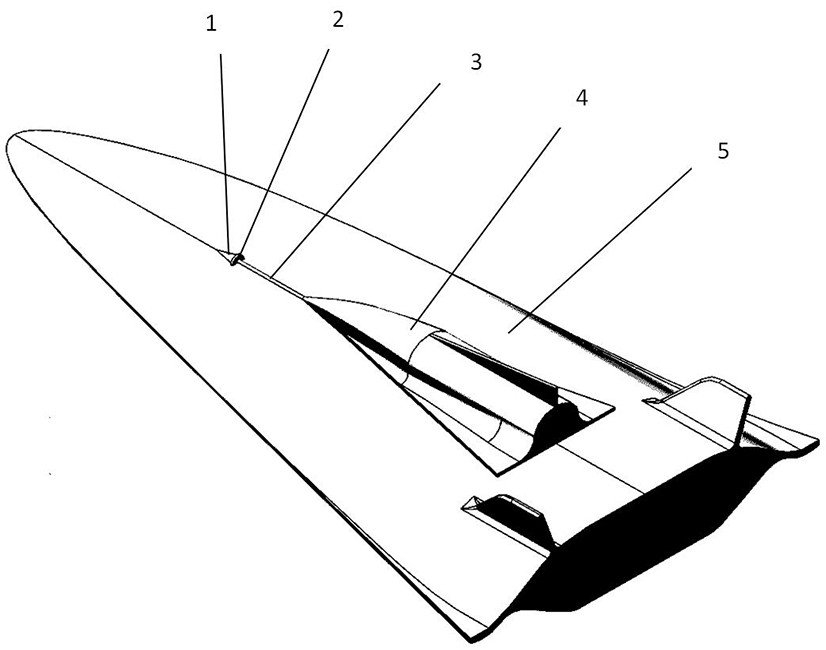

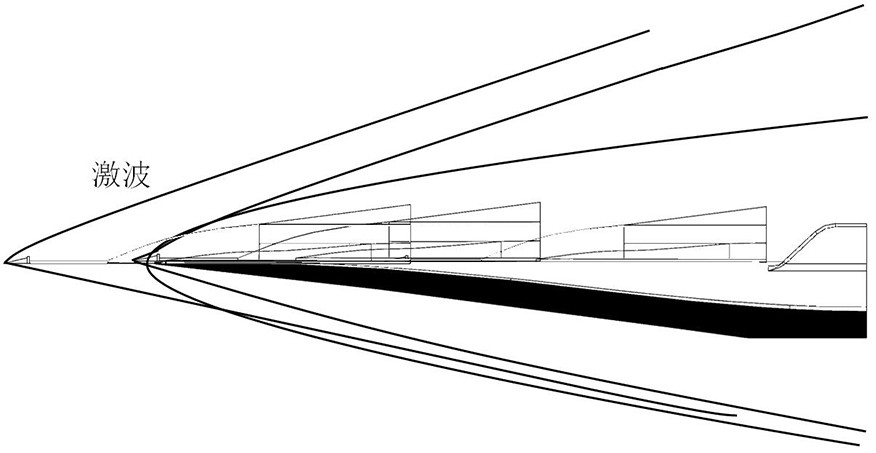

An aircraft with two-stage orbital separation and horizontal inter-stage separation and its anti-shock wave shock method

ActiveCN114148549BAvoid technical risksCosmonautic vehiclesCosmonautic component separationLeading edgeShock wave

The invention discloses a two-stage orbit-entry horizontally separated aircraft, comprising a booster-level aircraft and an orbital-level aircraft, the orbital-level aircraft is attached to the upper surface of the booster-level aircraft; the anti-shock wave impact method includes An anti-shock device is installed at the end of the aircraft; when the orbital-level aircraft and the booster-level aircraft are in a two-stage horizontal separation environment, the orbital-level aircraft accelerates and separates along the surface of the booster-level aircraft under the thrust of its own engine; the anti-shock device is in orbit In the process of the horizontal separation of the booster-stage aircraft and the booster-stage aircraft, the leading-edge bow shock wave formed by the leading edge end of the orbital-stage aircraft first passes through, and the leading-edge bow-shaped shock wave is gradually transformed into an anti-shock The conical shock wave formed by the device is then transformed into a curved shock wave when the anti-shock device fully protrudes from the leading edge end of the booster-stage vehicle until the orbital-stage vehicle and the booster-stage vehicle are completely horizontal separation.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

A kind of preparation method of para-aramid fiber and graphene oxide/graphene composite paper

ActiveCN110055807BSimple methodReduce manufacturing costSynthetic cellulose/non-cellulose material pulp/paperInorganic compound additionPolymer scienceOxide composite

The invention relates to a preparation method of para-aramid and graphene oxide / graphene composite paper and belongs to the technical field of high molecular materials. The preparation method includes: utilizing a polymerization one-step process without a surfactant added to prepare para-aramid nanofiber water dispersion liquid, utilizing the characteristic that para aramid nanofiber and grapheneoxide have high dispersity in water to well mix two dispersion liquids proportionally, and utilizing a conventional papermaking method to prepare the para-aramid / graphene oxide composite paper; utilizing a wet process or a dry process to reduce graphene oxide to obtain the para-aramid / graphene composite paper. Compared with the prior art, the preparation method has the advantages that the para-aramid and graphene / graphene oxide composite paper can be produced continuously on a large scale, the obtained composite paper has excellent performance, and the preparation method is friendly in corresponding production environment, low in cost and simple in process..

Owner:TSINGHUA UNIV +2

Preparation method of power type lithium thionyl chloride battery positive electrode

ActiveCN111740073AIncrease contentIncrease capacityElectrode rolling/calenderingElectrode thermal treatmentFiberAdhesive

The invention discloses a preparation method of a power type lithium thionyl chloride battery positive electrode. The method comprises the following steps of 1) mixing materials, 2) putting on a net,3) carrying out fibration treatment, 4) carrying out staggered stretching on fibers and 5) cutting and white space leaving. In the fiber staggered stretching step, a pair of pressing blocks or pressing rollers of which the surfaces are provided with symmetrical fine raised grains are used for pressing or rolling the two surfaces of the positive electrode nickel pull net for multiple times in different directions and at different positions, so that the positive electrode nickel pull net is filled with an adhesive in a material to form integral fiber chain network adhesion; and then rolling andleveling of the positive electrode nickel pull net by using a smooth pressing roller are carried out. Secondary adhesion is not needed, the problems of powder falling, falling, flanging and the like of the positive electrode can be solved, and meanwhile, the capacity and the discharge voltage platform of the battery are also improved.

Owner:武汉中原长江科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com