Method for rapidly achieving solidification falling welding of satellite-borne software program at low risk

A software program and low-risk technology, applied in the aerospace field, can solve problems such as prolonging the development cycle, increasing development costs, and EEPROM can not be reused, so as to improve reliability and usability, avoid technical risks and hidden dangers, and shorten program curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

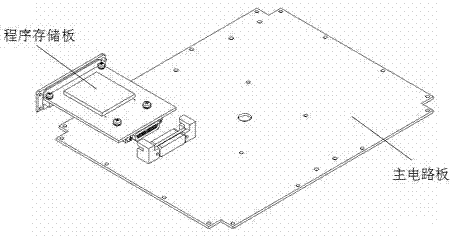

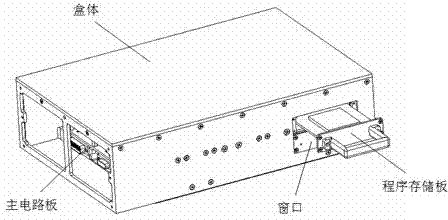

[0017] based on the following figure 1 and figure 2 , specifically explain the preferred embodiment of the present invention.

[0018] The present invention provides a low-risk method for fast realization of on-board software program solidification and soldering, the method includes the following steps:

[0019] Step 1. Independently design printed boards for EEPROM memory, PROM memory, application memory devices and other peripheral devices. The first two are program memory boards. The EEPROM memory board is EEPROM memory board, and the PROM memory is PROM memory board. The main circuit board, the application memory device and other peripheral devices, the program storage board and the main circuit board are equipped with pluggable interconnection plug-ins;

[0020] Step 2. In the program debugging stage, insert the EEPROM memory board into the main circuit board through a pluggable interconnection plug-in (such as figure 1 shown), EEPROM can be programmed multiple times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com