Flow and heat transfer process numerical simulation analysis method of hot air drum type phoenix single fir tea leaf fixation machine

A technology of numerical simulation and heat transfer process, applied in CAD numerical modeling, pre-extraction tea processing, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

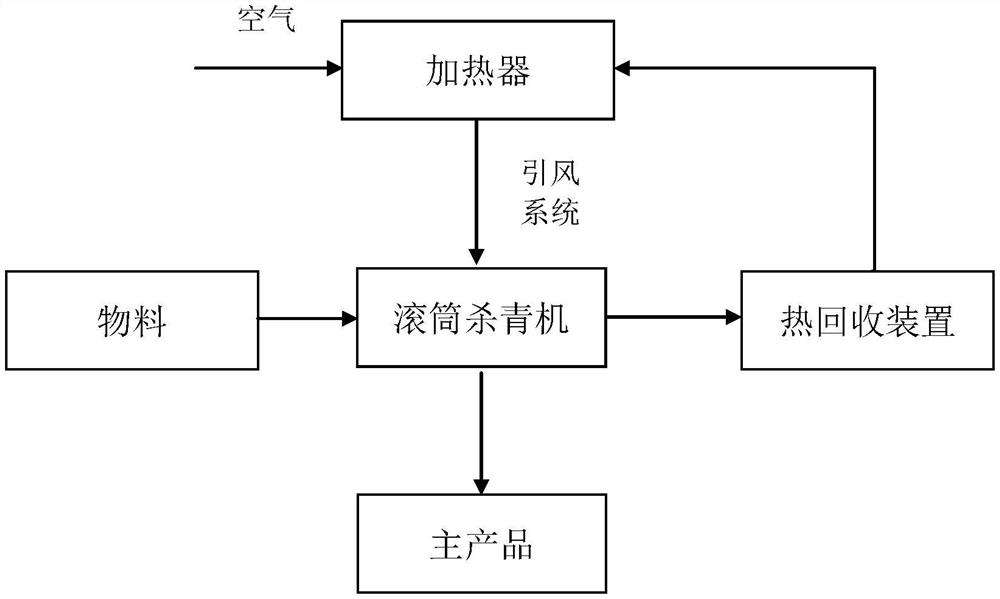

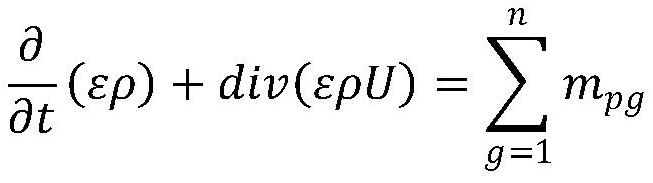

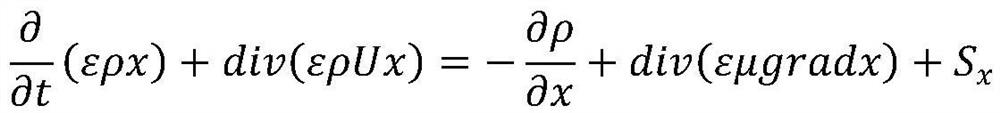

[0060] In this example, see figure 1 , the hot-air drum type Phoenix Dancong tea greening machine used in this embodiment mainly includes: a heating system, a greening drum, a draft system, a piping system, a feeding system, a heat recovery device and a discharging system. The heating system is The natural air is heated by the heating device, and then the hot air is introduced into the degreening machine by the air induction system to heat and deactivate the tea leaves in the drum; The air system is used to extract the drum; the heat recovery device collects the heat of the waste hot air extracted by the air induction system and reuses it, so as to improve the overall energy utilization rate of the tea greening machine system. The method for numerical simulation analysis of the flow and heat transfer process of the drum-type degreening machine in this embodiment is applicable to the numerical simulation calculation process of the hot-air drum-type Phoenix Dancong tea degreenin...

Embodiment 2

[0109] This embodiment is basically the same as Embodiment 1, especially in that:

[0110] In this embodiment, the hot air drum type Phoenix Dancong tea greening machine system mainly includes: a heating system, a greening drum, a blowing air system, a piping system, a feeding system, a heat recovery device, and a discharging system. This embodiment is a method for numerical simulation analysis of the flow and heat transfer process in the de-greening machine. The computational fluid dynamics software FLUENT is used to analyze the dehydration process of the tea leaves in the drum-type de-greening machine and the accompanying heat transfer with the hot fluid. Numerical calculations were carried out on the quality process, and the obtained results perfected the dehydration mechanism of degreening, which has significant value and important guiding significance for improving the high-efficiency tea degreening process, and to a certain extent, avoids high costs and technical risks ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com