Numerical Simulation Method for Atomization of Suspension Materials to Film Formation

A numerical simulation and suspension technology, applied in design optimization/simulation, special data processing applications, sustainable transportation, etc., can solve problems such as difficulty in measuring liquid film thickness and droplet diameter, and complex material and liquid atomization process. The effect of avoiding high costs and technical risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The numerical simulation method of this suspension material atomization film formation, the specific operation steps are as follows:

[0031] (1) Use the 3D drawing software to draw the 3D geometric model of the atomizing disc:

[0032] Modeling the 3D model of the atomizing disc by using the modeling module (Design Model) in ANSYS Workbench

[0033] (2) Establish the finite element model of the atomizing disc and solve it. The specific methods are as follows:

[0034] A. Set the assumptions of numerical simulation;

[0035] a) The heat transfer between gas and liquid is not considered;

[0036] b) the liquid is poured continuously along the central axis of the disc;

[0037] c) In order to reduce the amount of calculation, a limited part of the air near the atomizing disc is included;

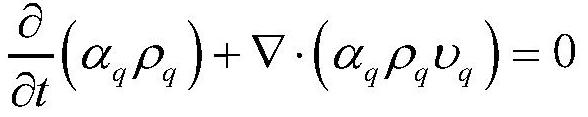

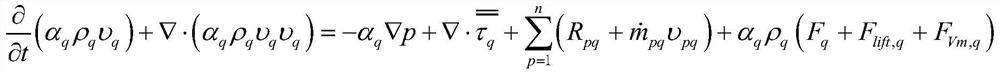

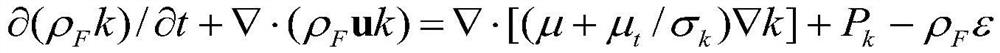

[0038] B. The Euler-Eulerian method is used for modeling, and both gas and liquid phases are treated as continuous phases. In order to describe the interpenetrating and continuous m...

Embodiment 2

[0051] This embodiment specifically introduces a numerical simulation method for the atomization process of molten metal to prepare steel shot, and the method at least includes the following steps:

[0052] First, use the modeling module (DM) in ANSYS Workbench to model the 3D model of the atomizing disc:

[0053] Diameter 75mm, rotating speed 1500rpm, material flow 2.5kg / min, density 2590kg / m 3 , viscosity 0.7Pa s. The fluid volume function model of the FLUENT software is used to capture the interface between the liquid phase and the gas phase. Create a new material in FLUENT and input relevant parameters according to the physical properties of the material, that is, to model the molten metal.

[0054] Secondly, the finite element model of the atomizing disc is established and solved. It should be noted that the present invention is a numerical simulation method based on FLUENT in ANSYS Workbench. Without further ado, the assumptions and theoretical basis of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com