Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1060 results about "Function model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A function model or functional model in systems engineering and software engineering is a structured representation of the functions (activities, actions, processes, operations) within the modeled system or subject area.

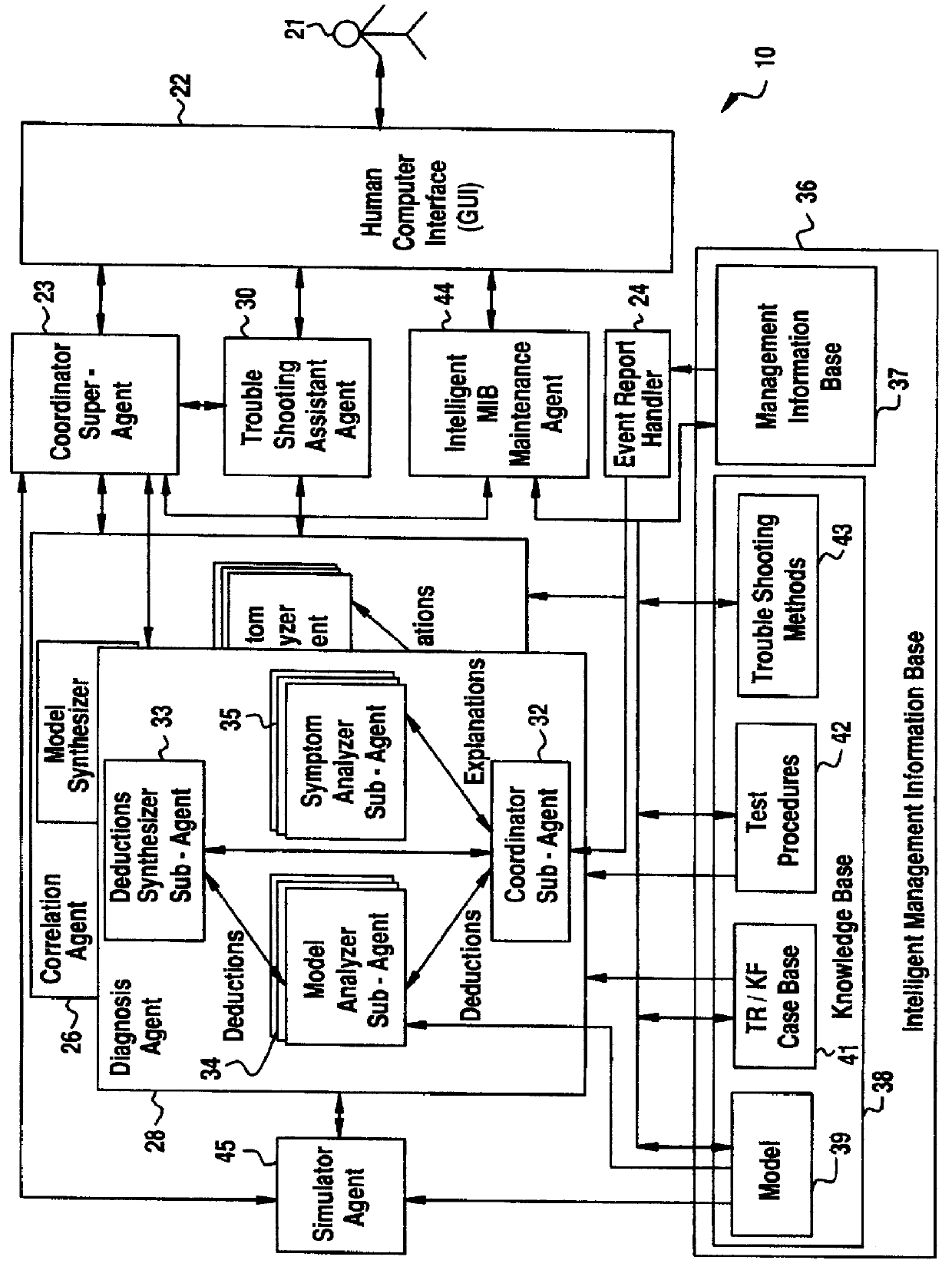

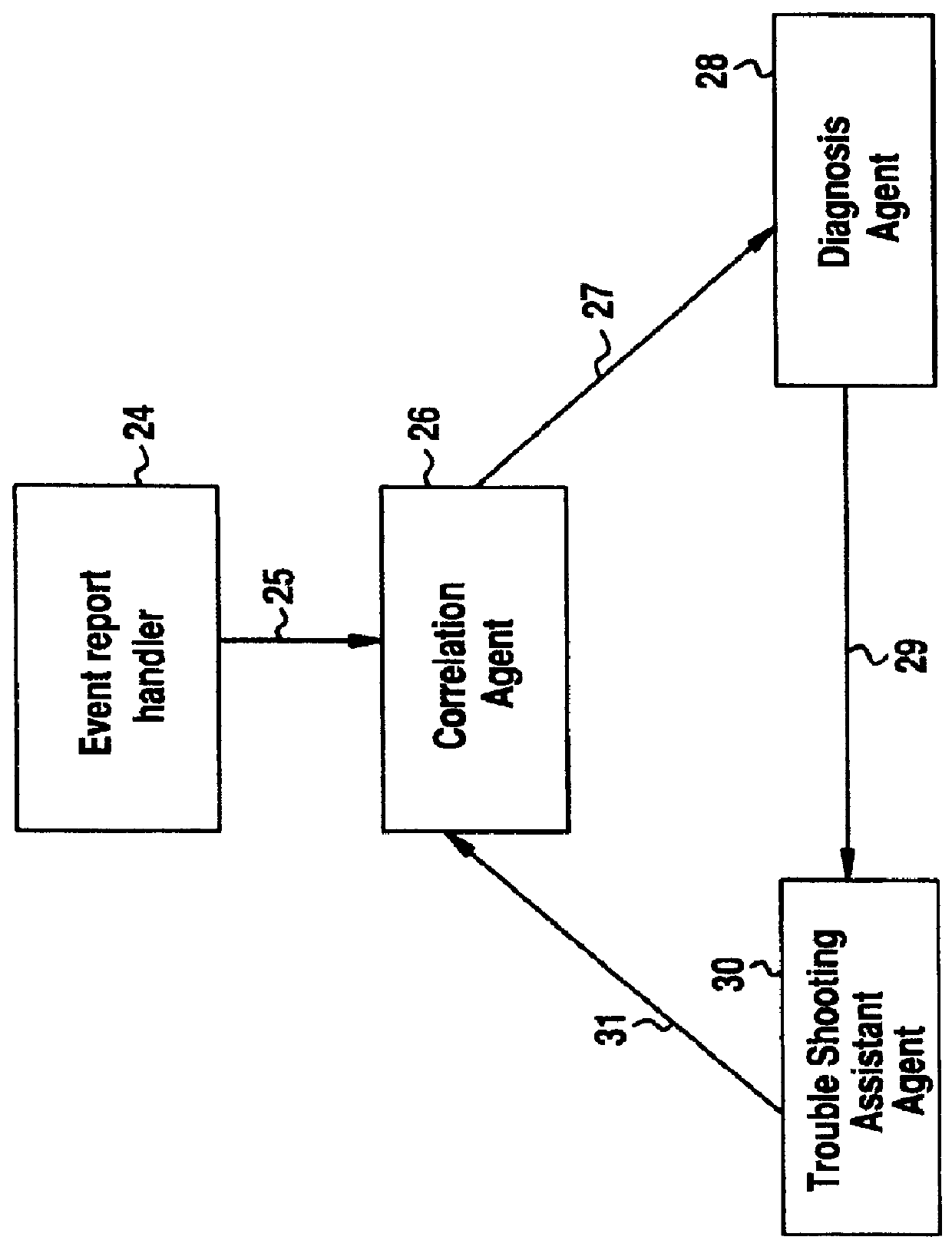

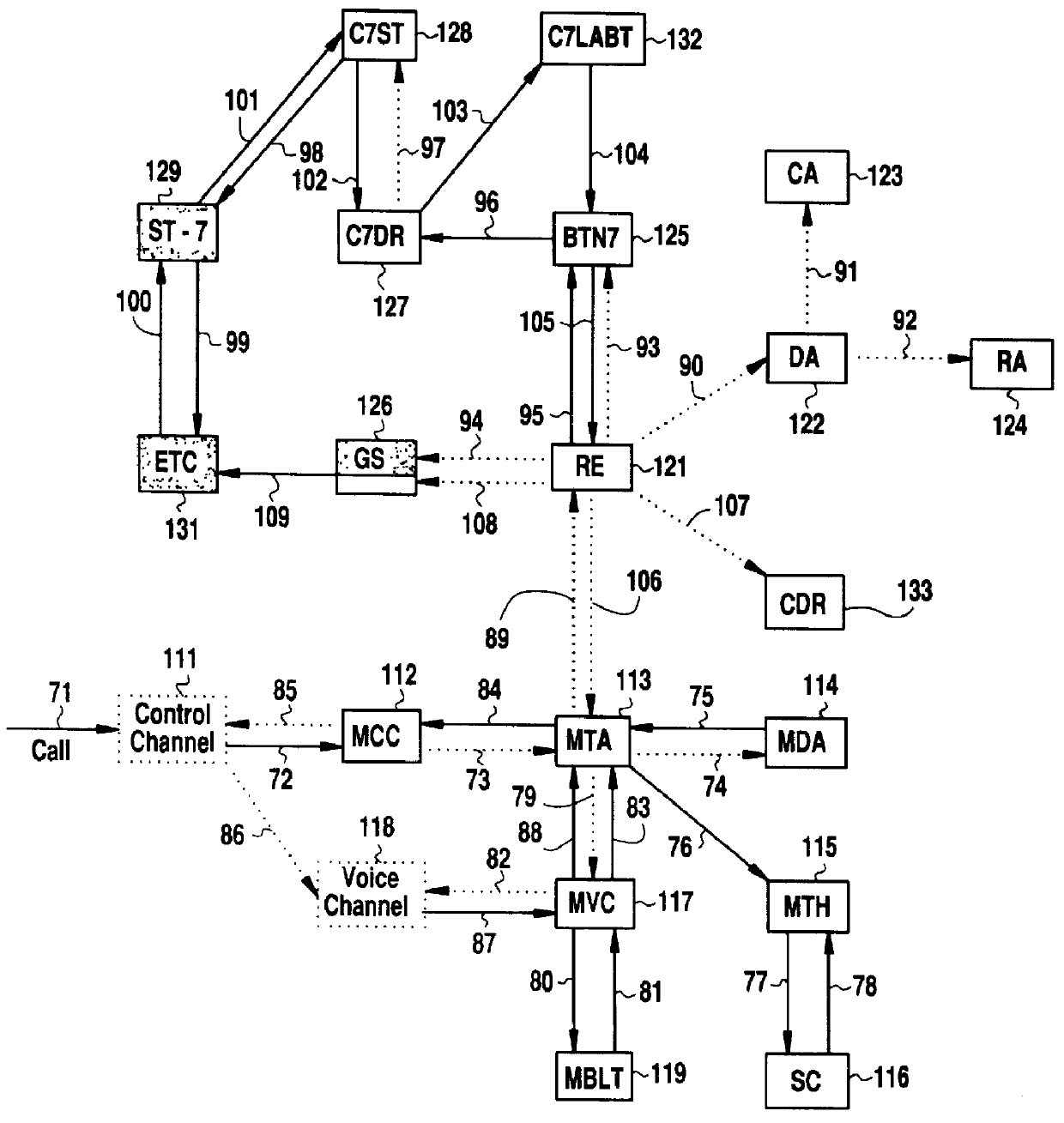

Software fault management system

InactiveUS6012152ASupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsInformation repositoryManagement information systems

A Software Fault Management (SFM) system for managing software faults in a managed mobile telecommunications network. The SFM system includes an Intelligent Management Information Base (I-MIB) comprising a Management Information Base (MIB) and a Knowledge Base (KB) having a functional model of the managed network and a trouble report / known faults (TR / KF) case base. The SFM system also includes an intelligent multi-agent portion having a plurality of agents which process the software faults utilizing the functional model from the I-MIB, case-based information, and other management information. The I-MIB and the intelligent multi-agent portion are compliant with Telecomunications Management Network (TMN) principles and framework. Fault management is both proactive and reactive. The SFM system is made independent of technology-specific implementations by representing the underlying switch design knowledge in a modular and changeable form which is then interpreted by the intelligent multi-agent portion. A clear separation is maintained between the generic procedural inference mechanisms and agents, and the specific and explicit models of the different network elements of a mobile telecommunications network.

Owner:TELEFON AB LM ERICSSON (PUBL)

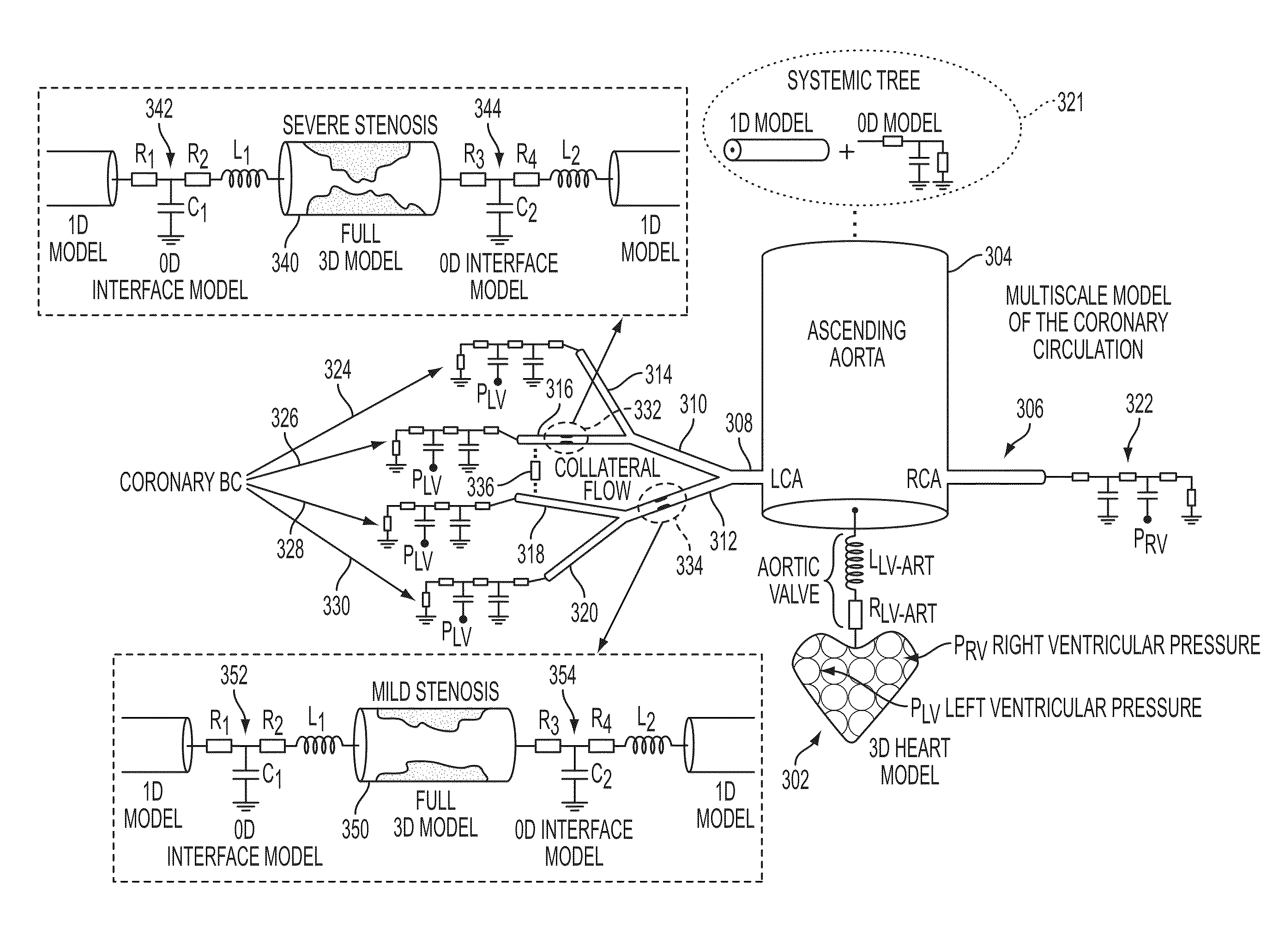

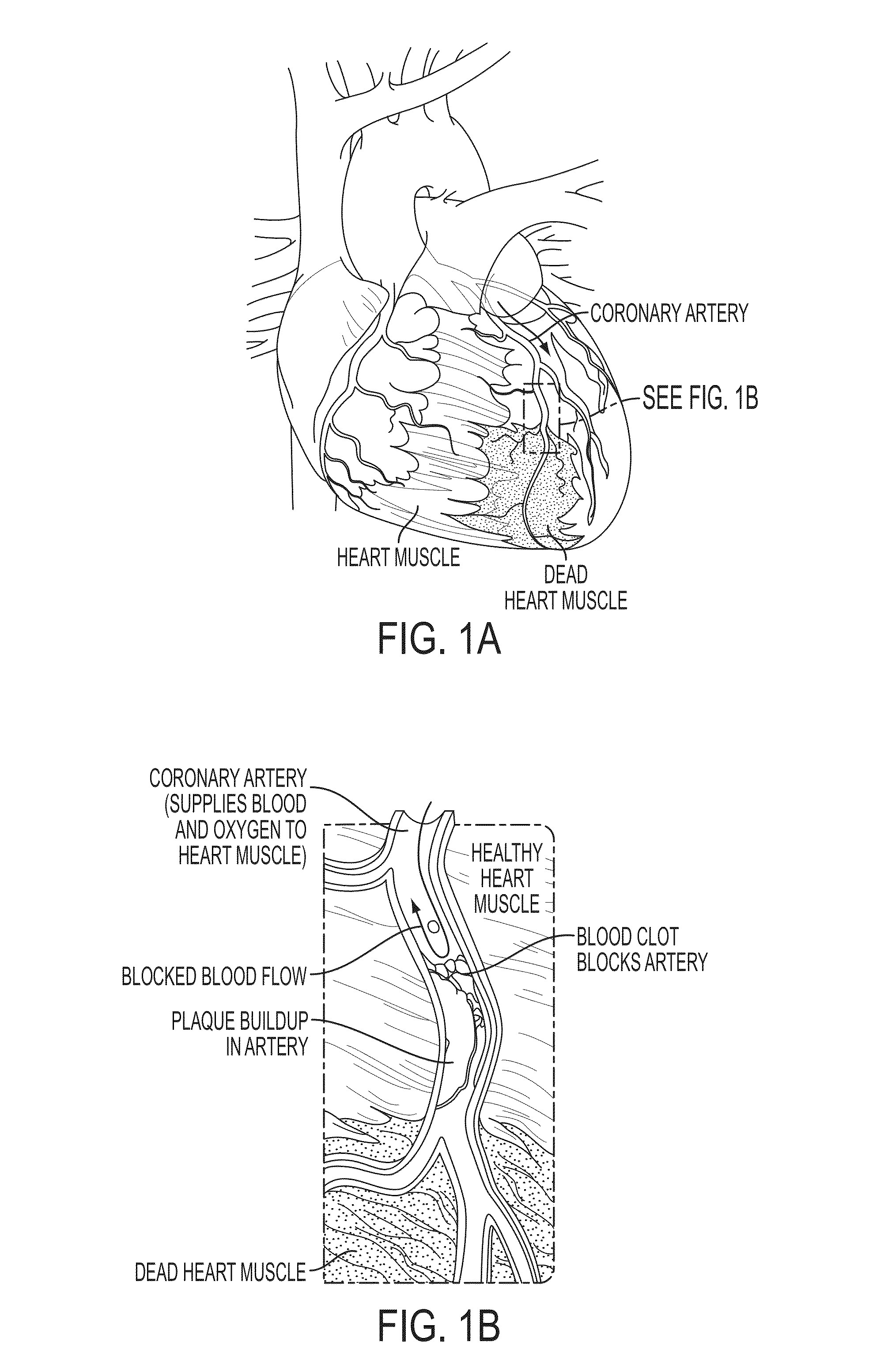

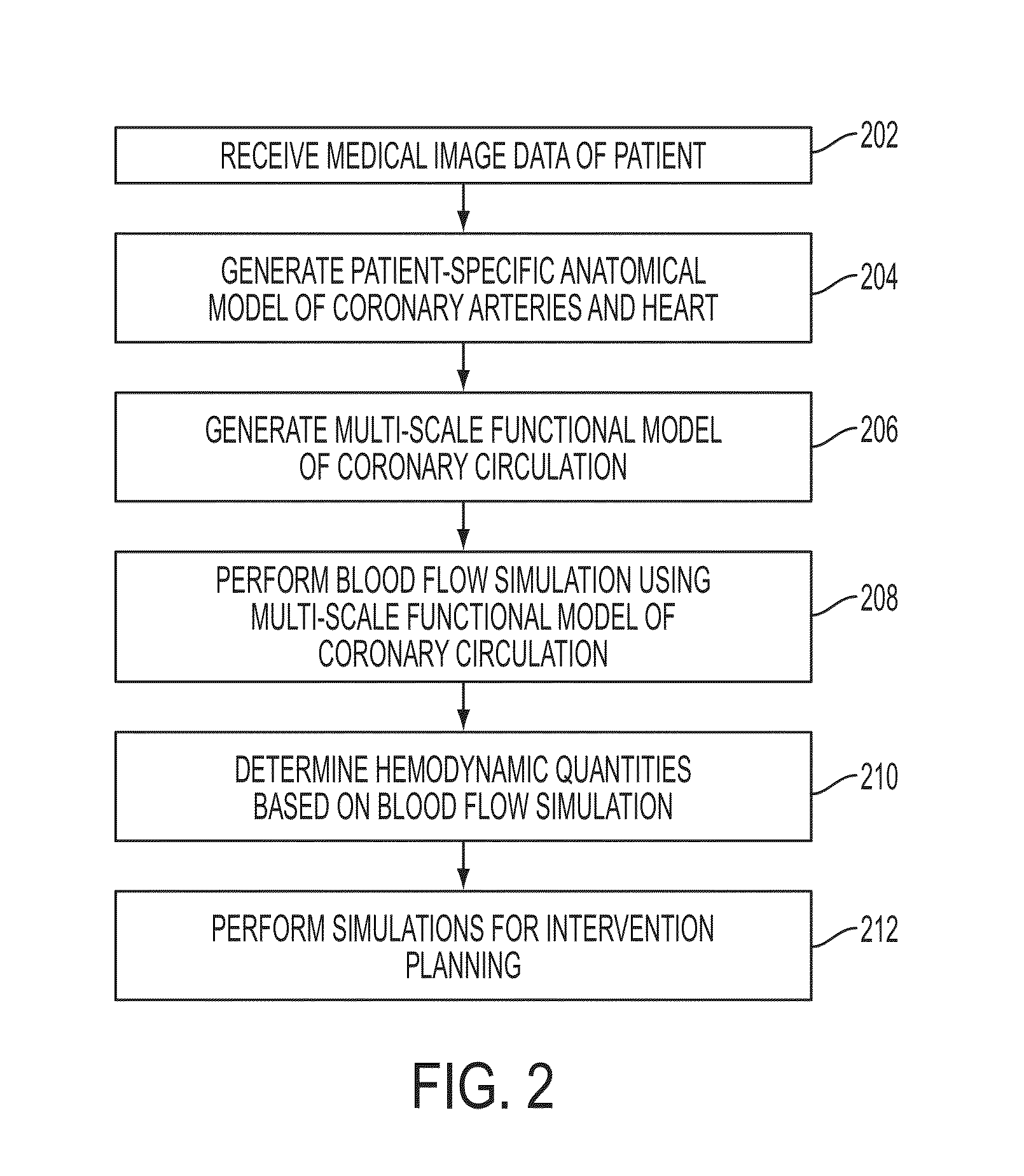

Method and System for Multi-Scale Anatomical and Functional Modeling of Coronary Circulation

ActiveUS20130132054A1Improve predictive performanceImprove clinical managementChemical property predictionChemical structure searchCoronary arteriesIntervention planning

A method and system for multi-scale anatomical and functional modeling of coronary circulation is disclosed. A patient-specific anatomical model of coronary arteries and the heart is generated from medical image data of a patient. A multi-scale functional model of coronary circulation is generated based on the patient-specific anatomical model. Blood flow is simulated in at least one stenosis region of at least one coronary artery using the multi-scale function model of coronary circulation. Hemodynamic quantities, such as fractional flow reserve (FFR), are computed to determine a functional assessment of the stenosis, and virtual intervention simulations are performed using the multi-scale function model of coronary circulation for decision support and intervention planning.

Owner:SIEMENS HEALTHCARE GMBH +1

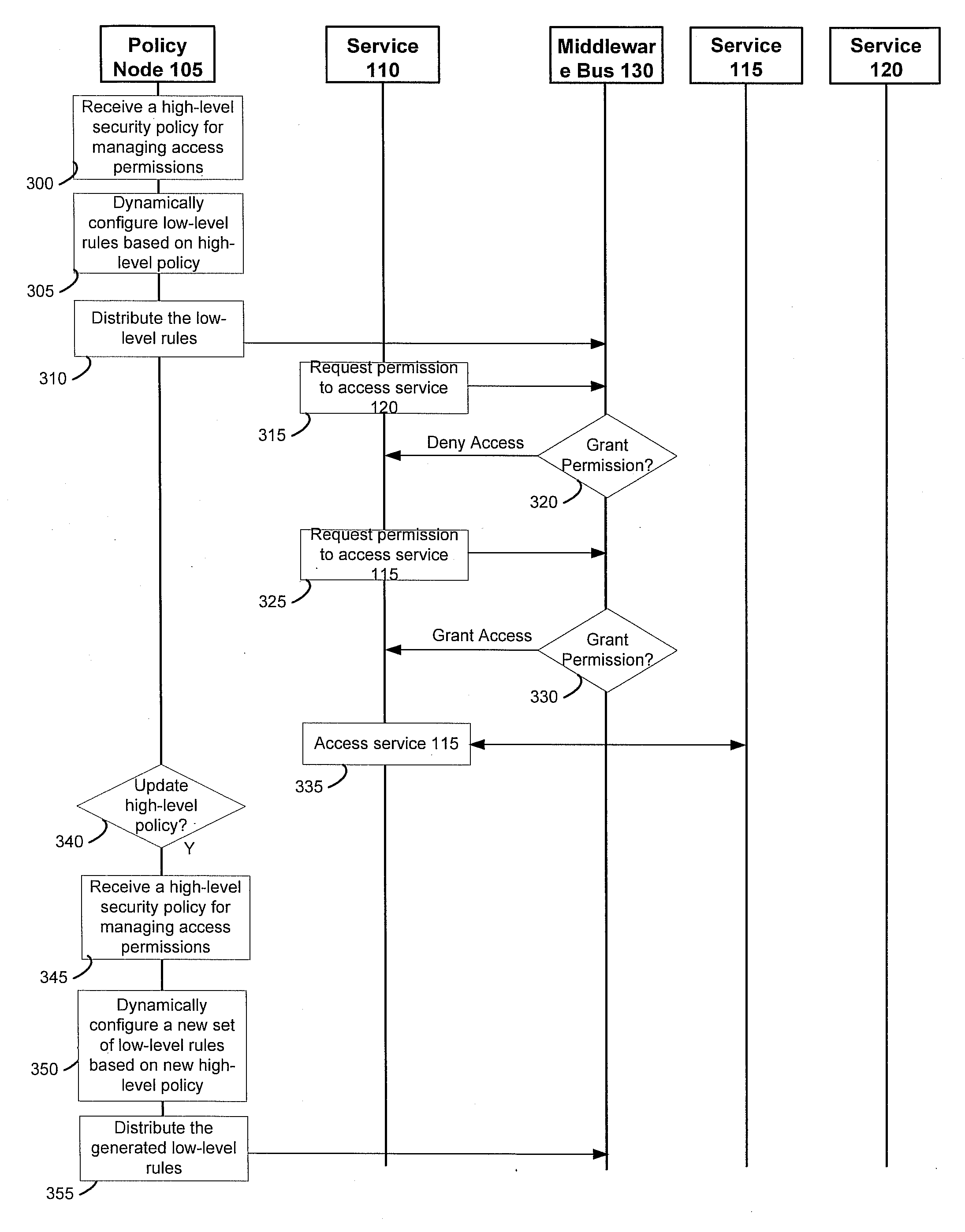

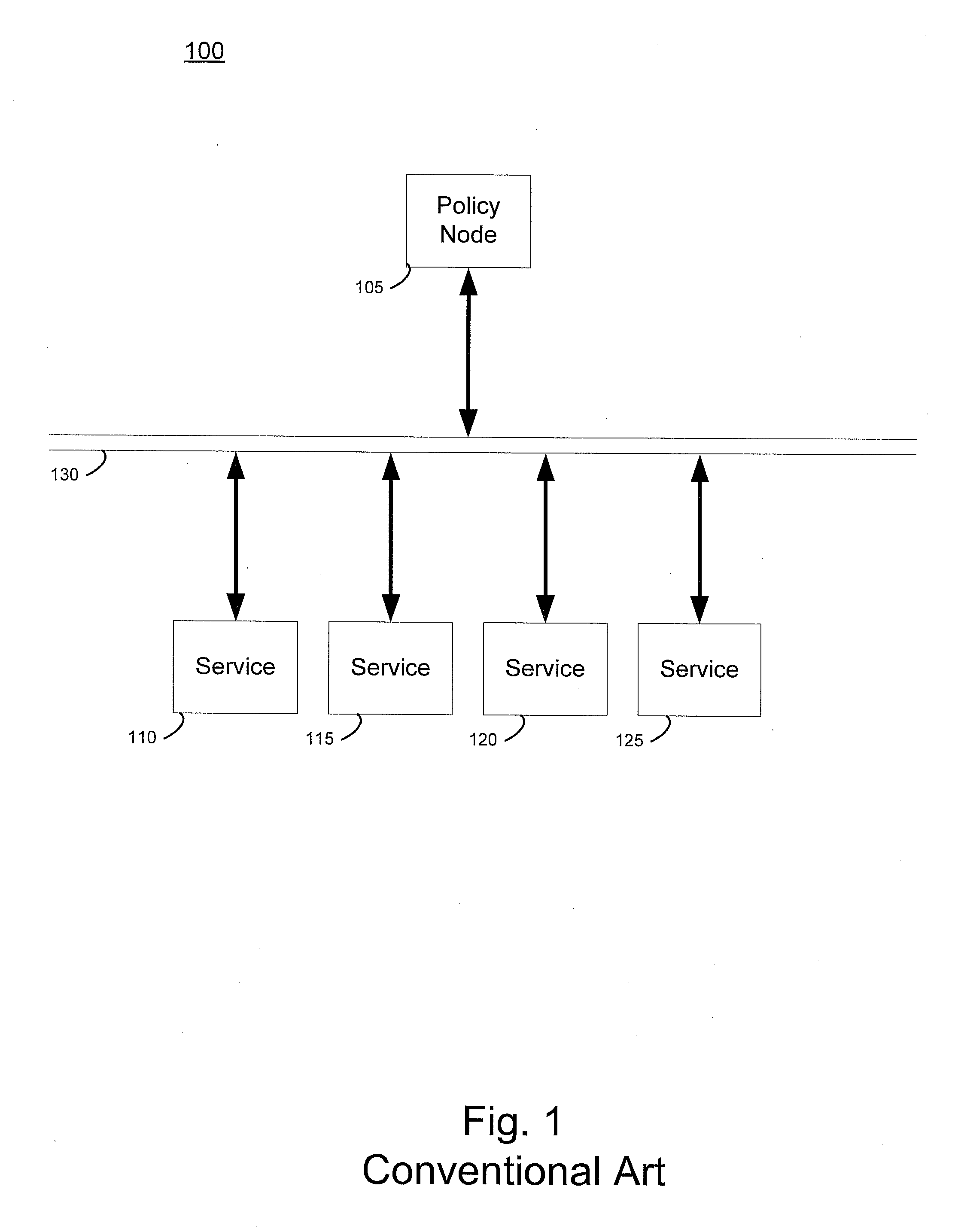

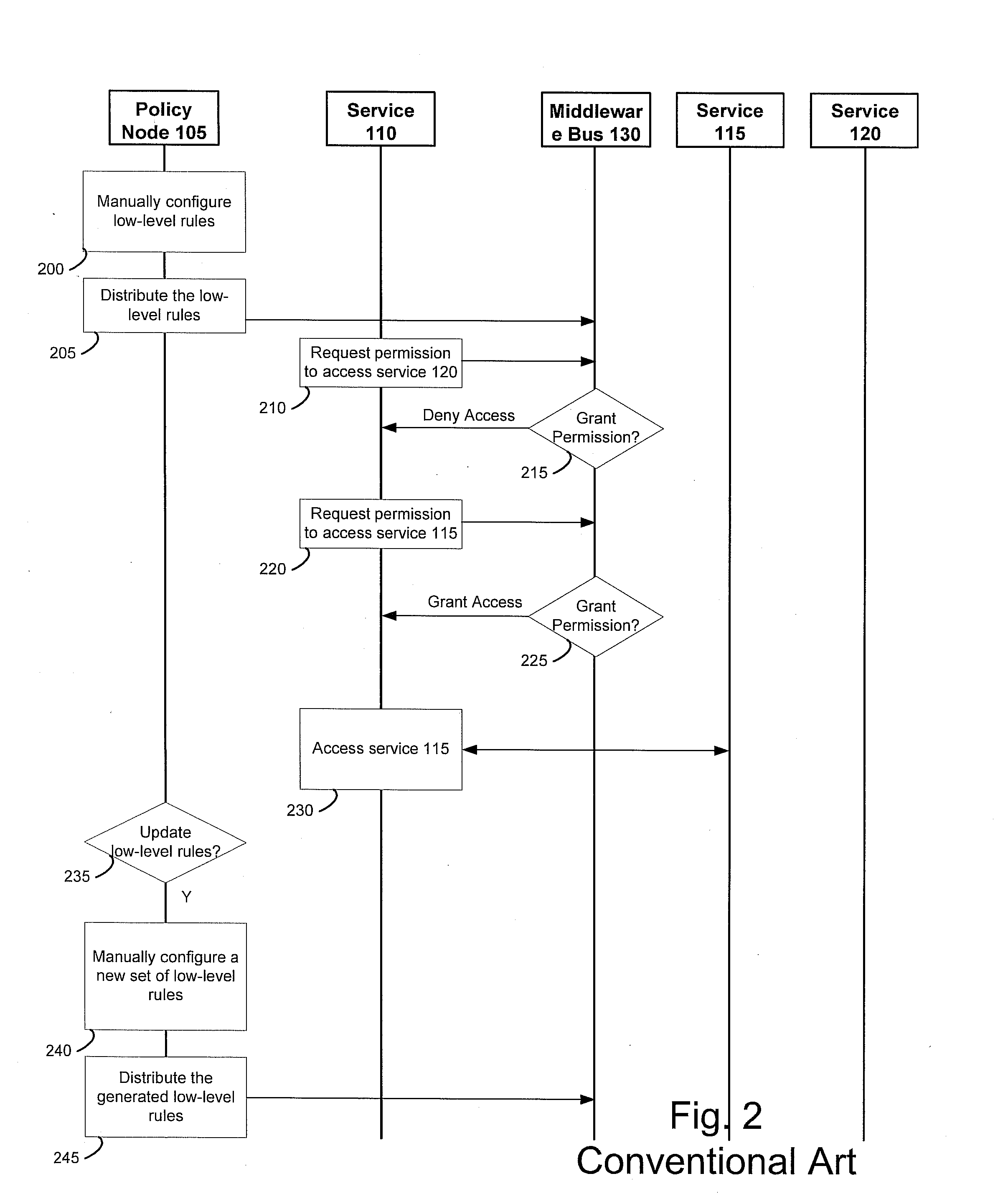

Method and system for managing security policies

ActiveUS20090077621A1Computer security arrangementsTransmissionSecurity policyReliability engineering

A system and method of managing security policies in an information technologies (IT) system are provided. In an example, the method includes receiving an input indicating a high-level security policy for the IT system, the received high-level security policy relating to non-functional system attributes for the IT system and received in a format that is not machine-enforceable at an enforcement entity of the IT system. A functional model for the IT system is determined, where the functional model indicates functional system attributes of the IT system. At least one pre-configured rule template is loaded, and at least one machine-enforceable rule is generated in a manner compliant with the received high-level security policy by iteratively filling the at least one pre-configured rule template with functional system attributes indicated by the functional model. After the generating step, the at least one machine-enforceable rule can be distributed (e.g., to an enforcement entity, an Intrusion Detection System (IDS), etc.). In another example, the receiving, determining, loading, generating and distributing steps can be performed at a policy node within an IT system.

Owner:LANG ULRICH +1

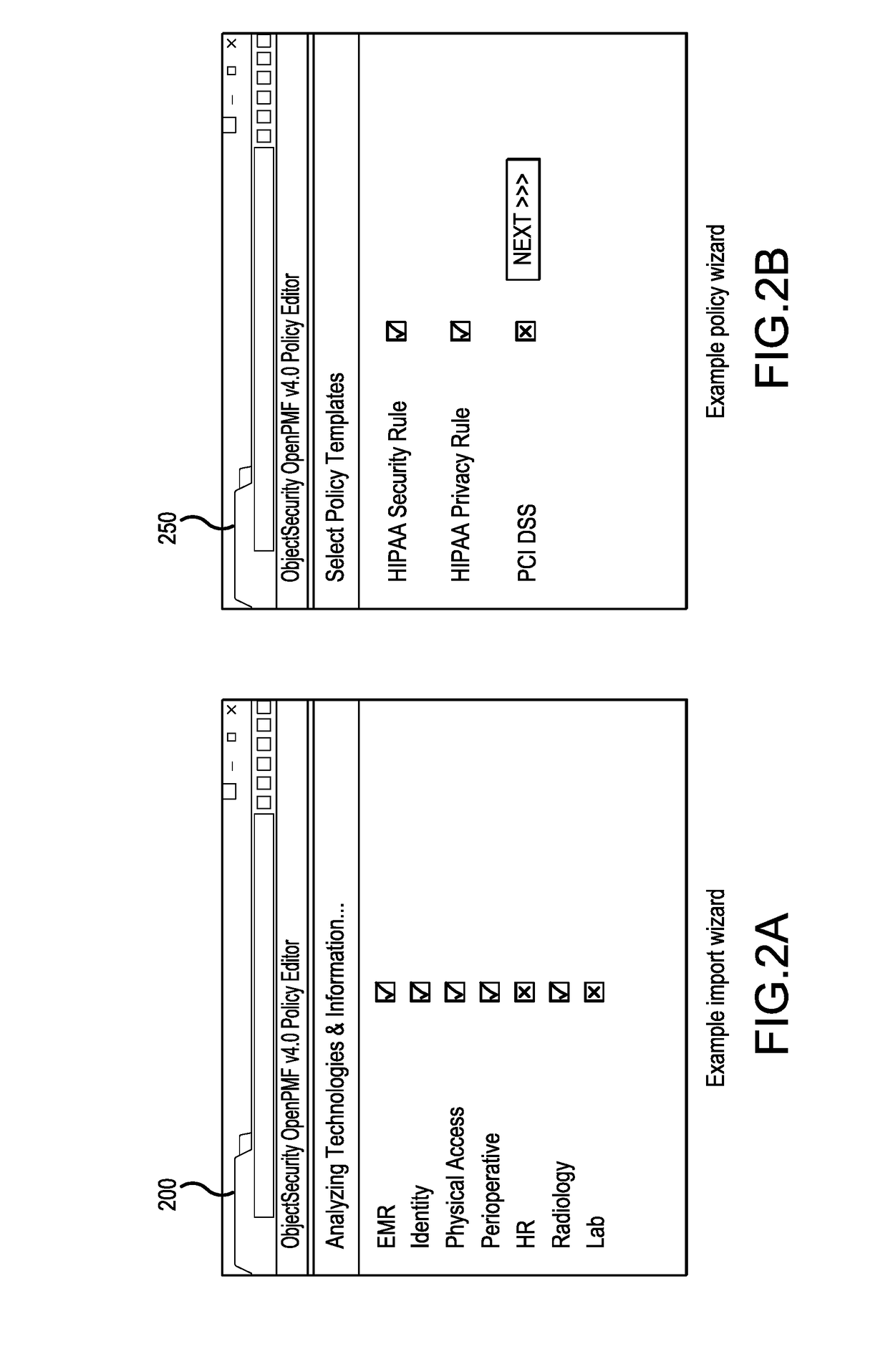

Method and system for policy management, testing, simulation, decentralization and analysis

ActiveUS20180069899A1Software engineeringNatural language data processingInternet privacyData memory

A policy management method and system, which determines at least one functional model for the IT system; loads at least one pre-configured policy selection template that indicates at least one policy aspect applicable to the at least one IT system; generates at least one policy user interface that gathers a policy input; receives a policy input loaded from a data storage or a memory or entered by a user via a user interface; loads at least one pre-configured policy generation template that indicates at least one technical rule or configuration aspect of the policy that the policy template pertains to; generates at least one machine-enforceable rule / configuration compliant with the received input policy; transmits the at least one machine-enforceable rule and / or configuration to at least one policy implementation entity; and executes the transmitted at least one machine-enforceable rule / configuration.

Owner:LANG ULRICH +1

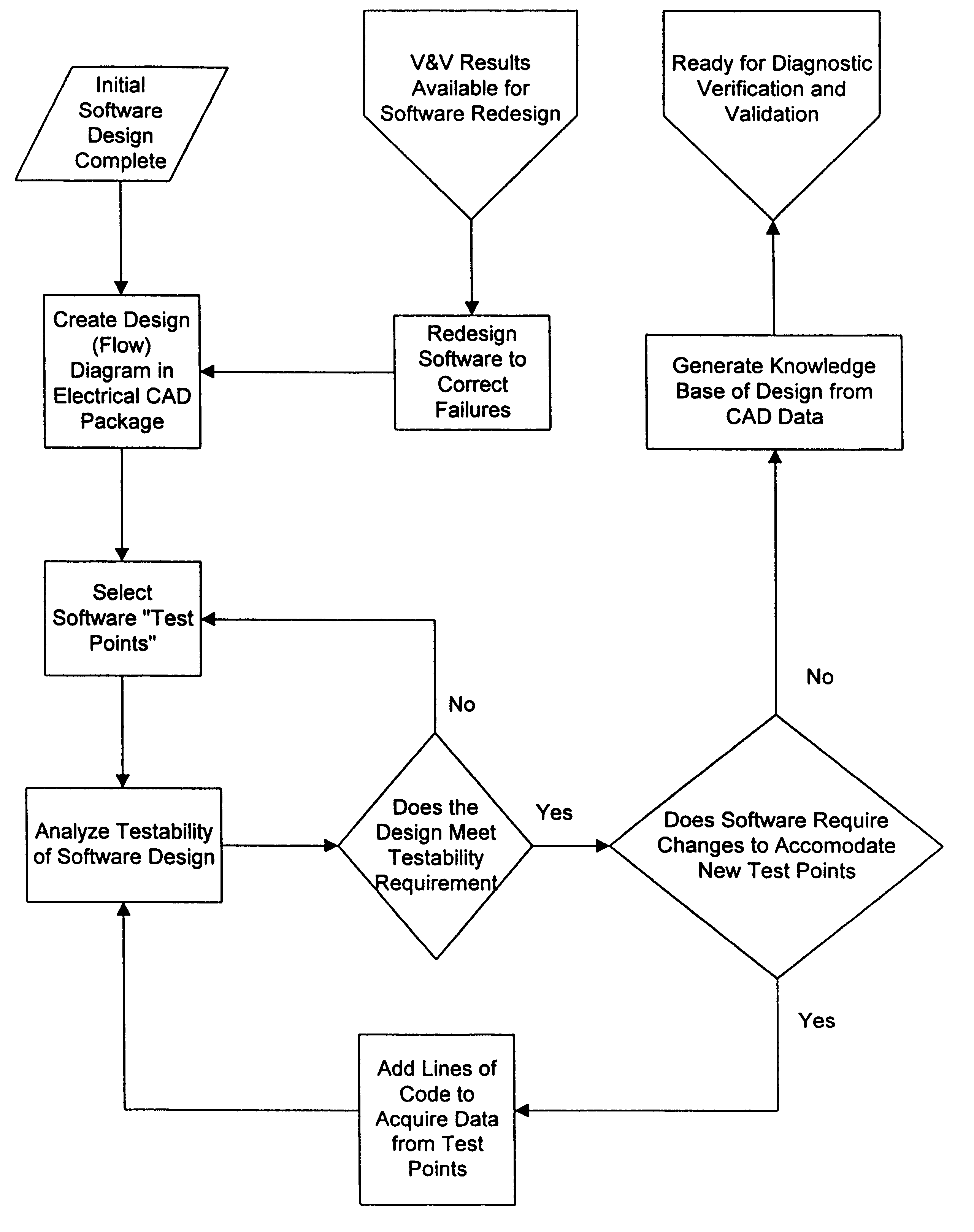

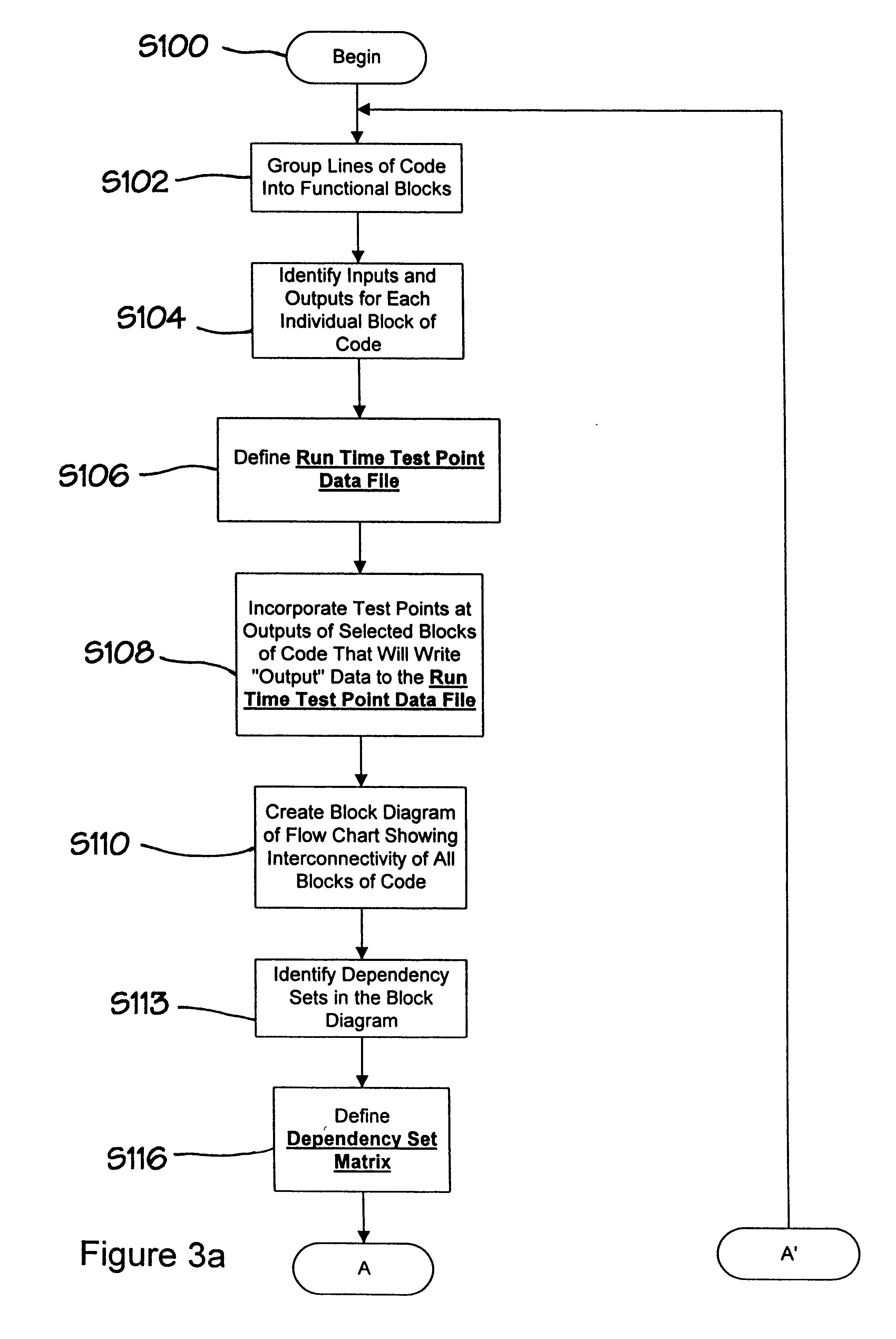

Method and apparatus for debugging, verifying and validating computer software

InactiveUS6173440B1Software testing/debuggingProgram loading/initiatingSoftware designVerification procedure

A new approach for software debugging, verification and validation is disclosed. The present invention utilizes a knowledge-based reasoning approach to build a functional model of the software code for identifying and isolating failures in the software code. The knowledge-based reasoning approach of the present invention uses the software design, which is preferably based upon a flow chart or block diagram representation of the software functionality, to build the functional model. The software block diagram contributes to the functional model by defining the inputs and outputs of the various blocks of code, as well as defining data interconnections between the various blocks of code. In accordance with a method of the present invention, test points are strategically inserted throughout the code, and each test point is associated with a corresponding block of code. Expected values of the test points for an expected proper-operation execution of the computer program are generated. The computer program is then executed on a computer, and the actual values of the test points from the program execution are compared with the expected values of the test points. Failed test points which do not agree with corresponding expected values are determined. The functional model, which includes information functionally relating the various test points to one another, is then used to isolate the failed test points to one or more sources of failure in the code.

Owner:MCDONNELL DOUGLAS

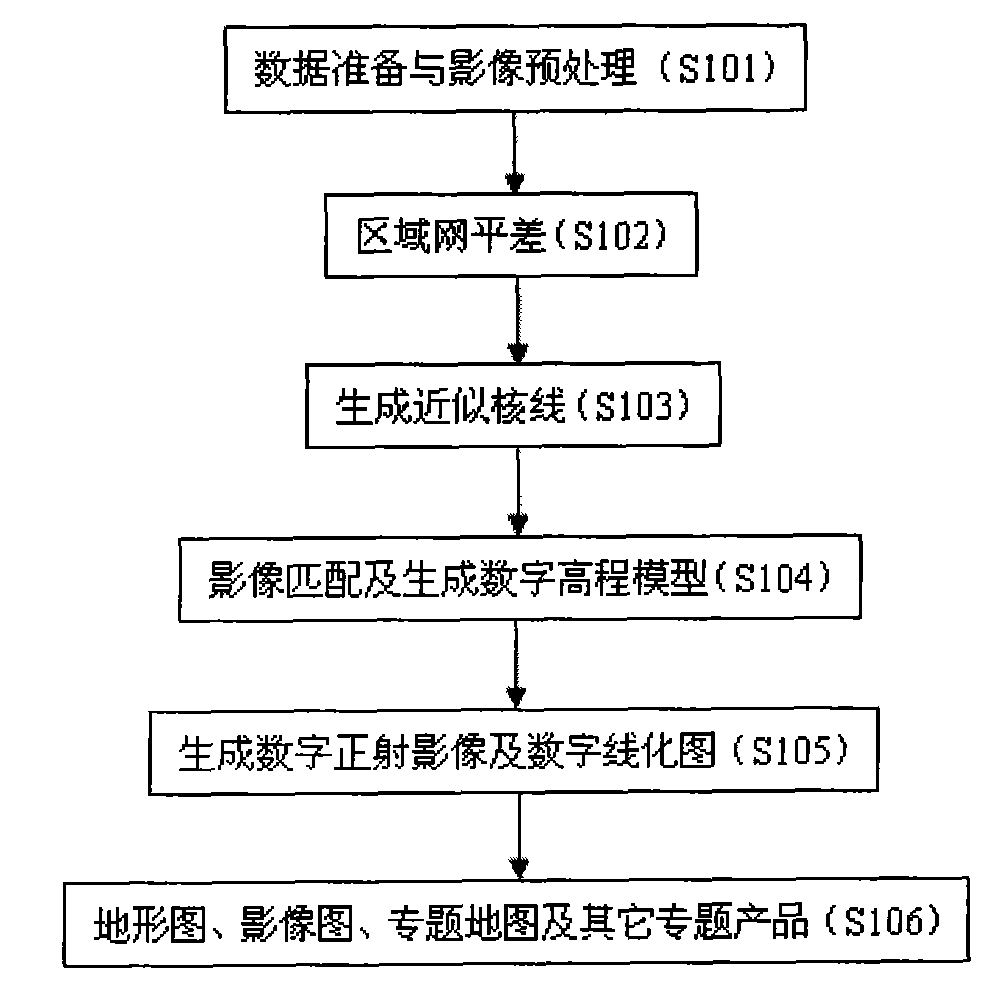

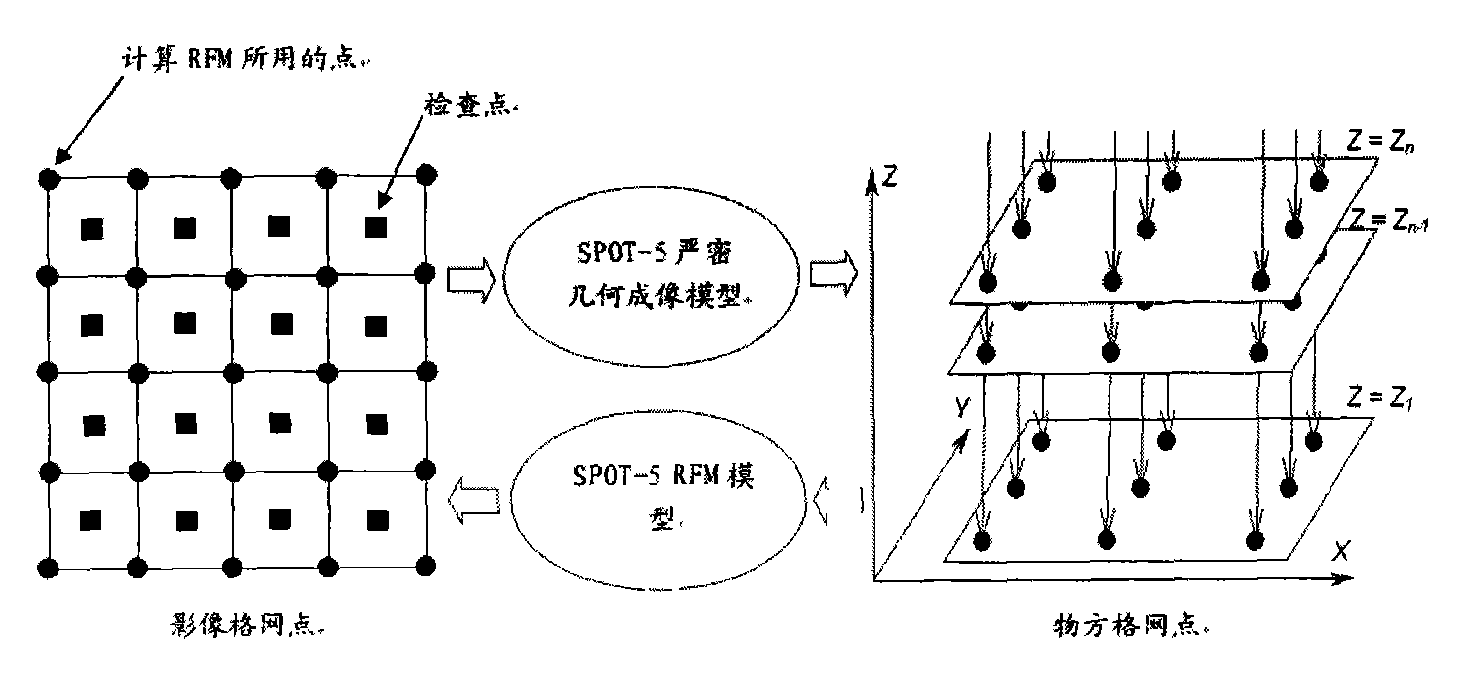

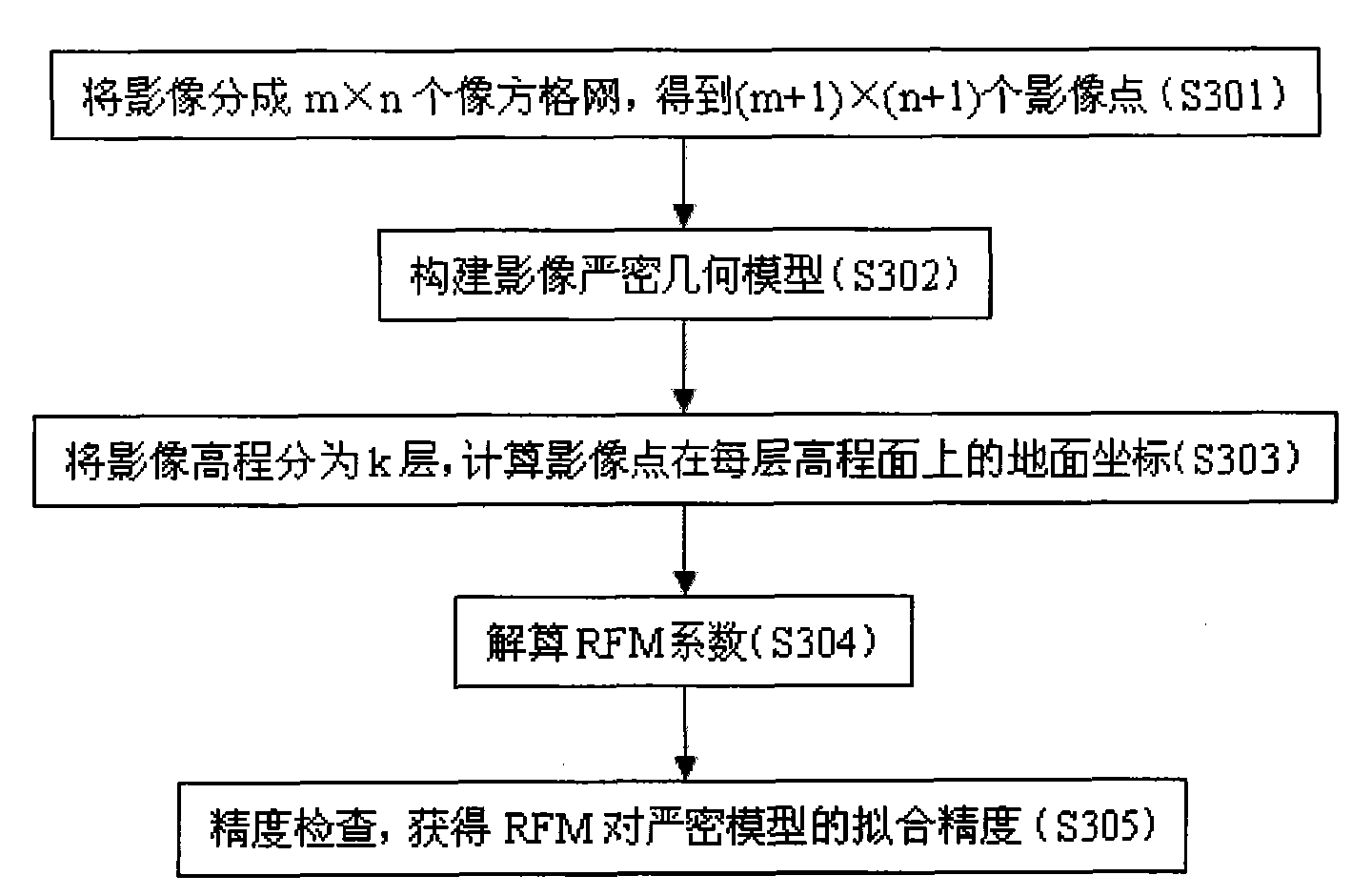

Method and system for processing high-definition remote sensing image data

InactiveCN101604018AImplement photogrammetry processingAchieve production tasksWave based measurement systemsArea networkData treatment

The invention provides a method and a system for processing high-definition remote sensing image data by applying a rational function model, a satellite image block adjustment and auto-match and distributed parallel processing technology. The method comprises the following steps: analyzing and processing input primary image data and computing parameters of the corresponding rational function model so as to obtain a stereo image pair by applying the computed rational function model; performing measurement and singlechip orientation of a control point and a connecting point on the primary image data, and performing block adjustment processing on an error between stereo image pixel data and the primary image data so as to improve the fit precision between the stereo image pixel data and the primary image data; generating an image similar to an epipolar ray, defining a matching template, measuring matched seed points and lines, performing automatic image matching and generating a digital elevation model; and respectively generating a digital orthophoto map and a digital line graph, and finishing manufacturing a product by applying the obtained data.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

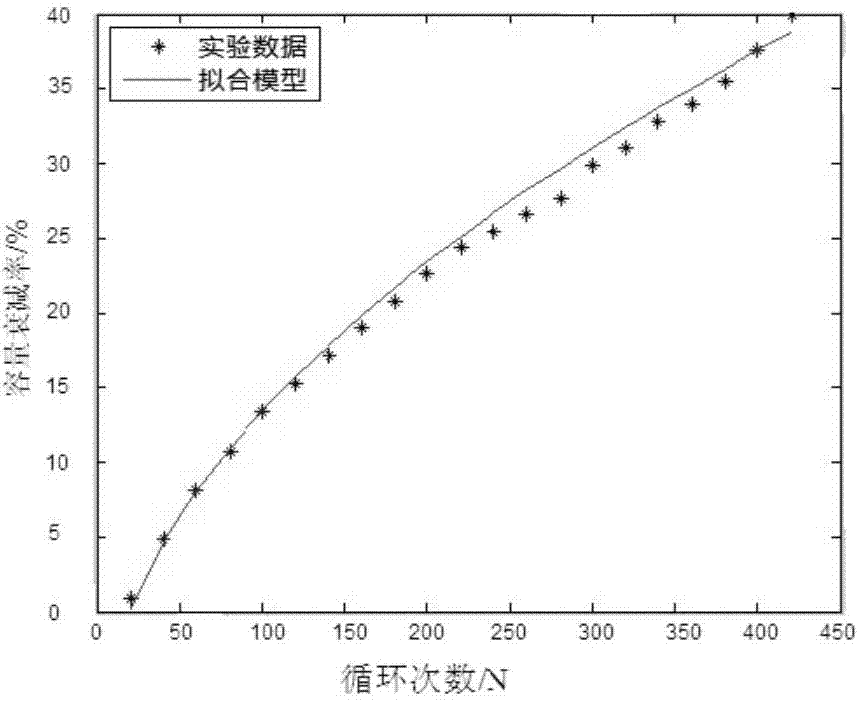

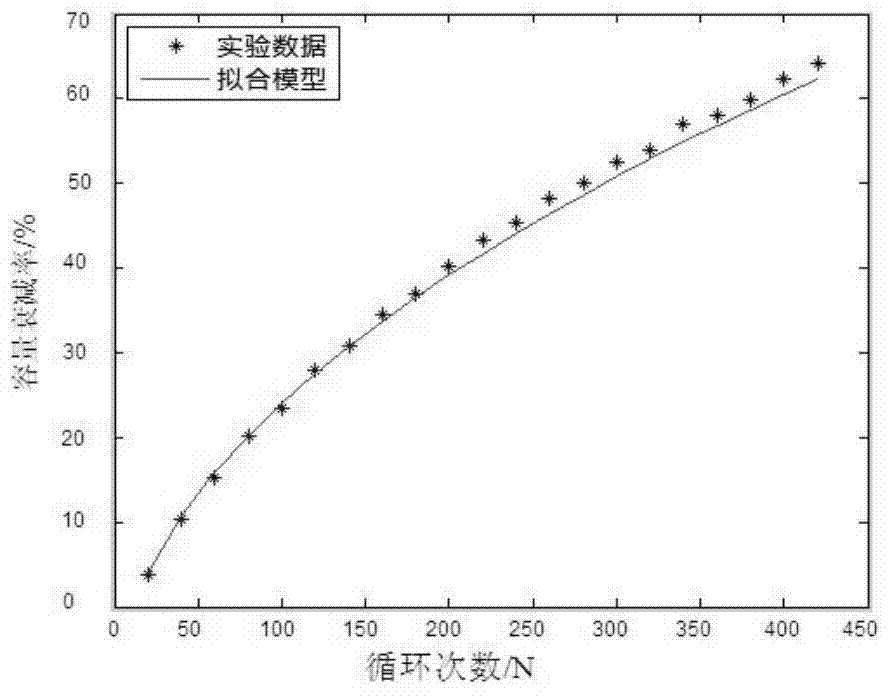

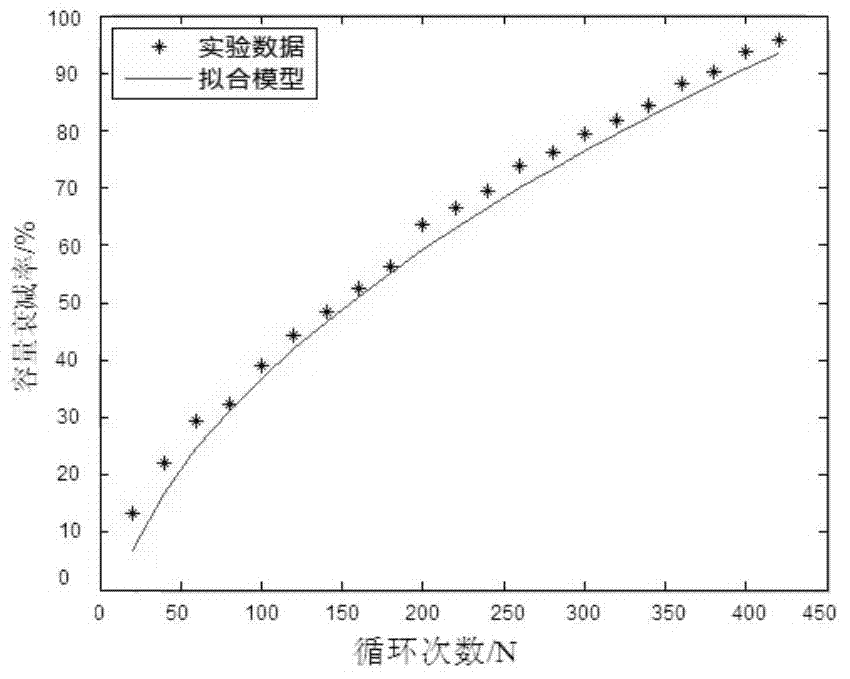

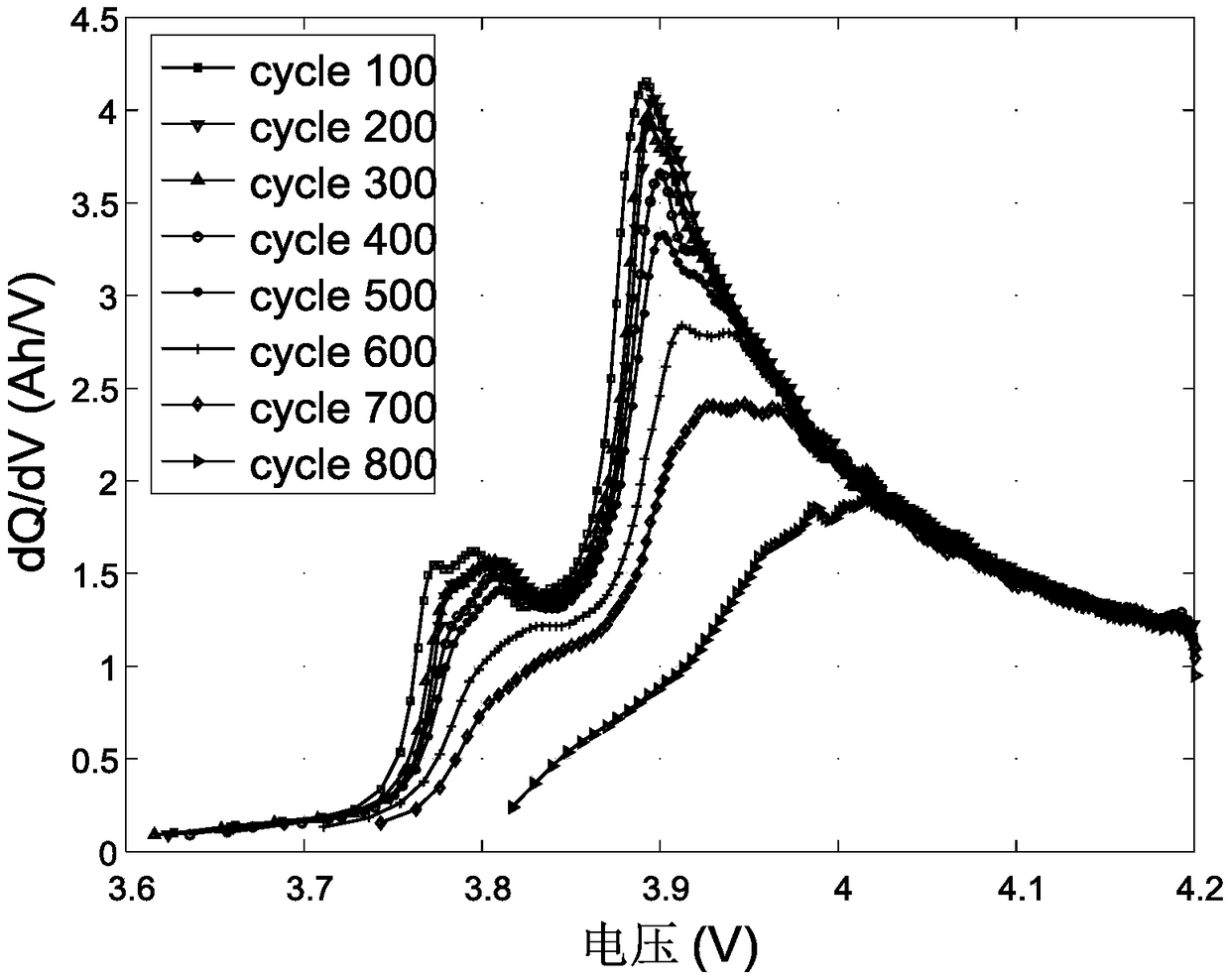

Prediction method for life cycle of battery

InactiveCN103698710AExtend your lifeGood for determining performanceElectrical testingCyclic testTested time

The invention discloses a prediction method for a life cycle of a battery. The prediction method comprises the following steps: drawing a curve of the number of discharge and capacity fading rate; determining a function model of the capacity fading rate Qloss of the battery and the number of discharge N of the battery; substituting data of a certain impact factor impacting the life of the battery into the function model, wherein Qloss is 50-80 percent of the nominal capacity of the battery; calculating to obtain the expected cycle period N of the battery. According to the prediction method disclosed by the invention, as long as little cyclic test is performed on the battery, the residual life of the battery can be judged, and therefore, the test time is greatly shortened and the test cost is greatly reduced; the objective condition of capacity fading during the actual use process of the battery can be truly and comprehensively described, the life and the residual life of the battery can be obtained, the performance of the battery can be helped to be determined, and the life of the battery is prolonged. As the established model is universal, the prediction method disclosed by the invention is suitable for establishing life fading models of various storage batteries.

Owner:CENT SOUTH UNIV +2

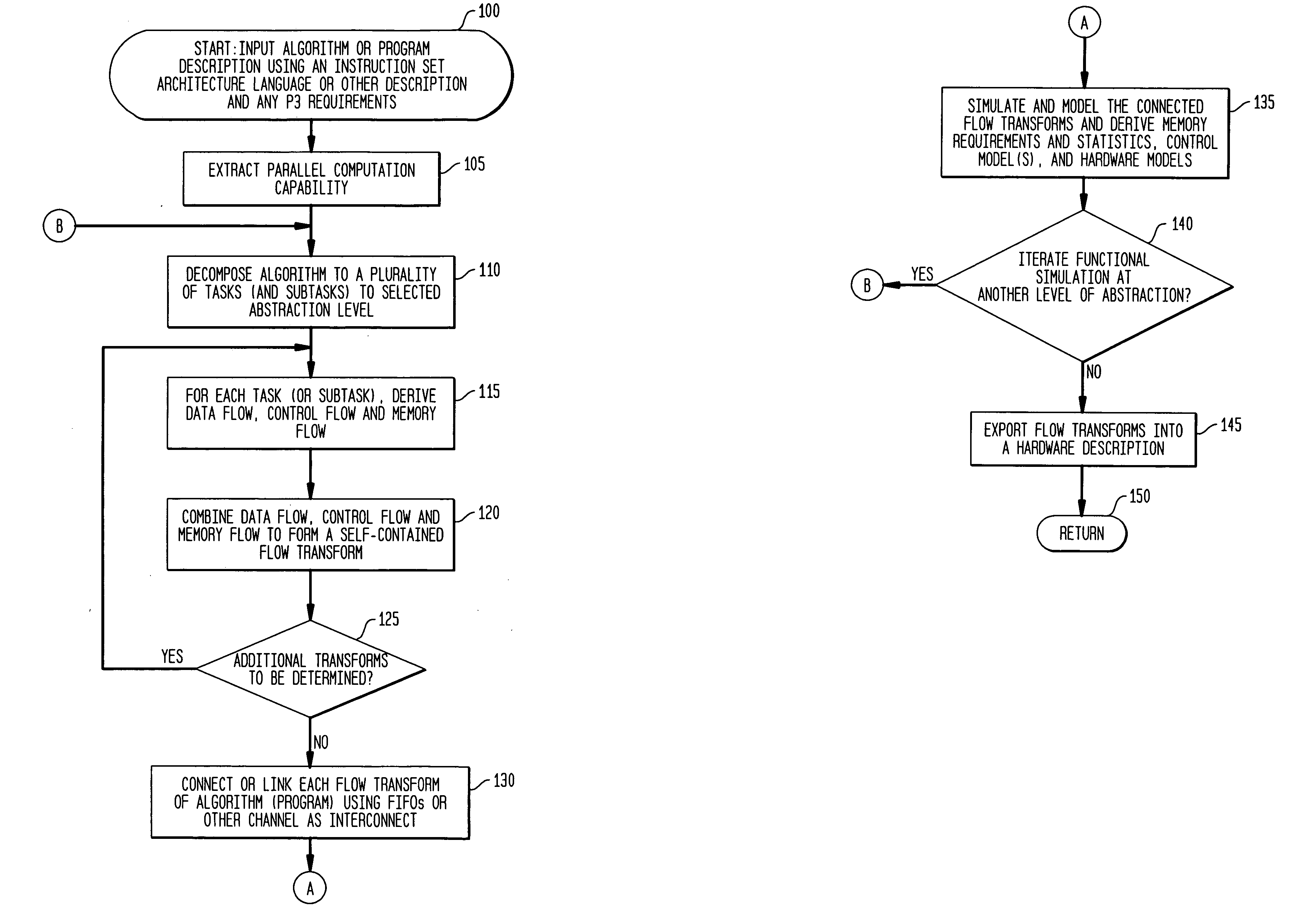

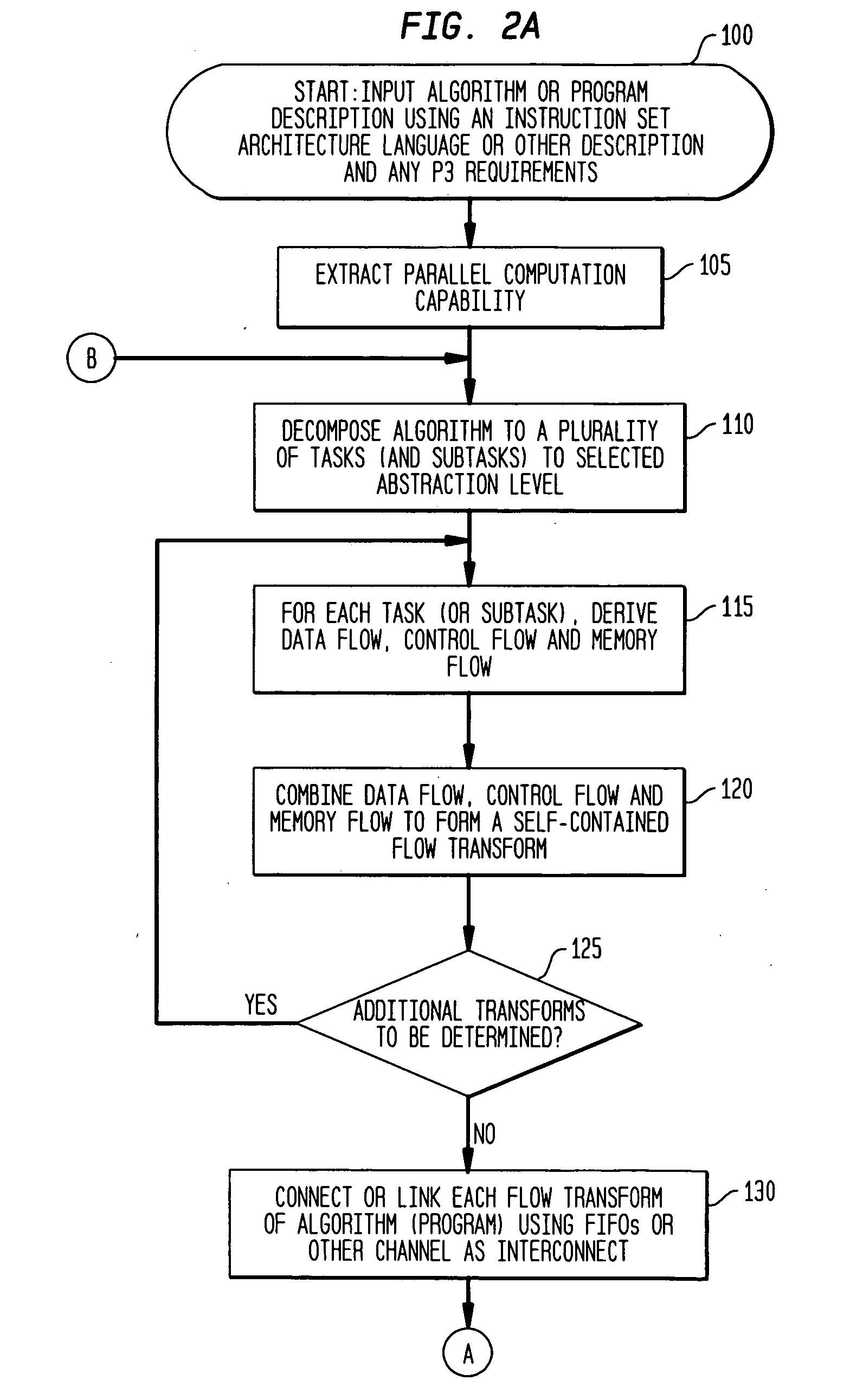

Algorithmic electronic system level design platform

InactiveUS20070162268A1CAD circuit designSpecial data processing applicationsElement modelComputer architecture

A computing system and method are provided for algorithmic electronic system level design. An exemplary system comprises a plurality of databases for storing a plurality of functional models, a plurality of computational element models, and a plurality of hardware definition representations. An application design processor is adapted to perform a first functional simulation of an algorithm using a plurality of computational element architecture definitions to generate a first selection of a plurality of computational elements and corresponding control code for an implementation of the algorithm. A control and memory modeling processor is adapted to generate a plurality of flow transforms from the algorithm and to convert the plurality of flow transforms into the plurality of plurality of computational element models. A system simulation processor is adapted to convert the plurality of computational element models into the plurality of hardware definition representations and to perform a second functional simulation of the algorithm using the plurality of computational element models corresponding to the first selection and the corresponding control code.

Owner:KOTA BHASKAR +3

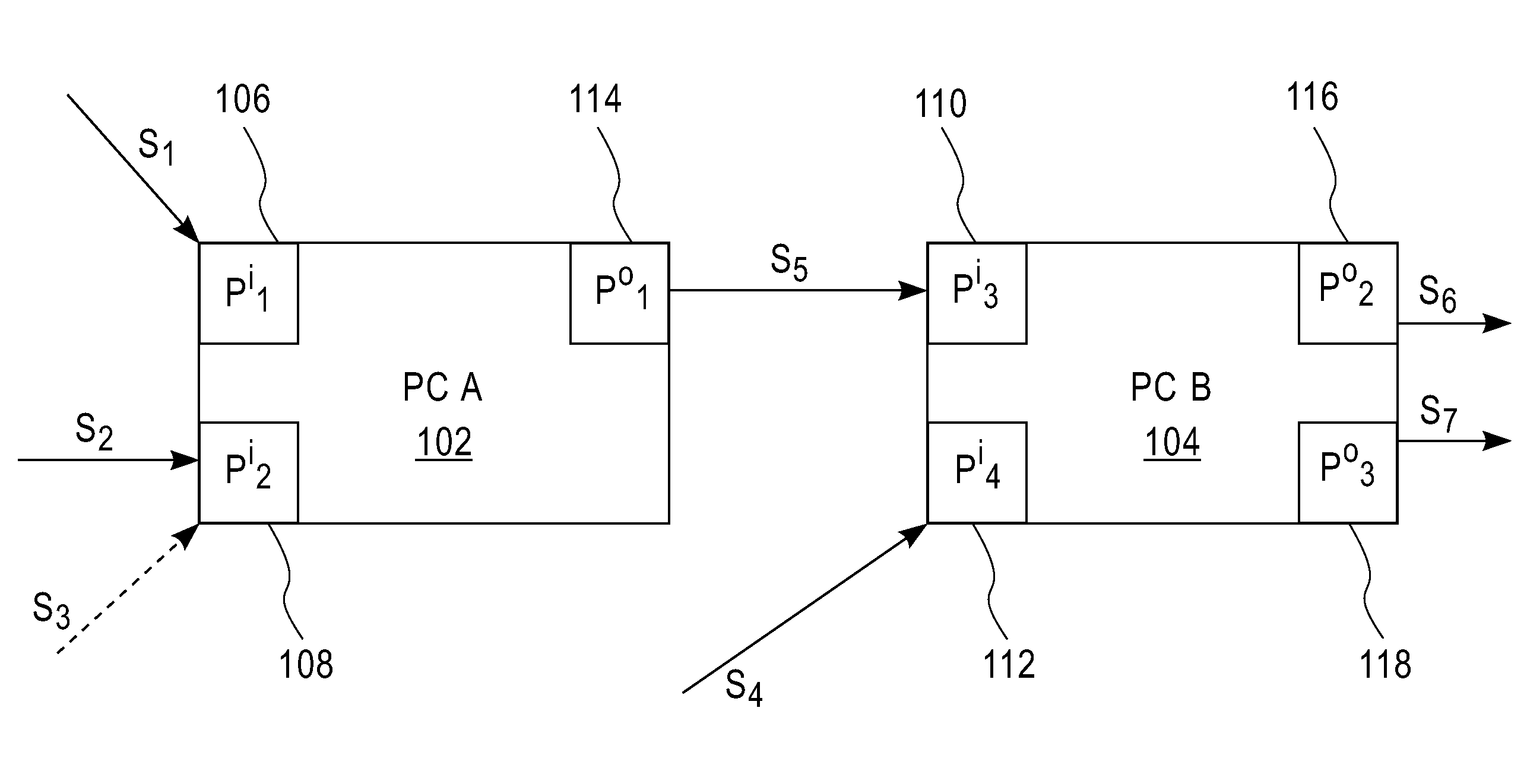

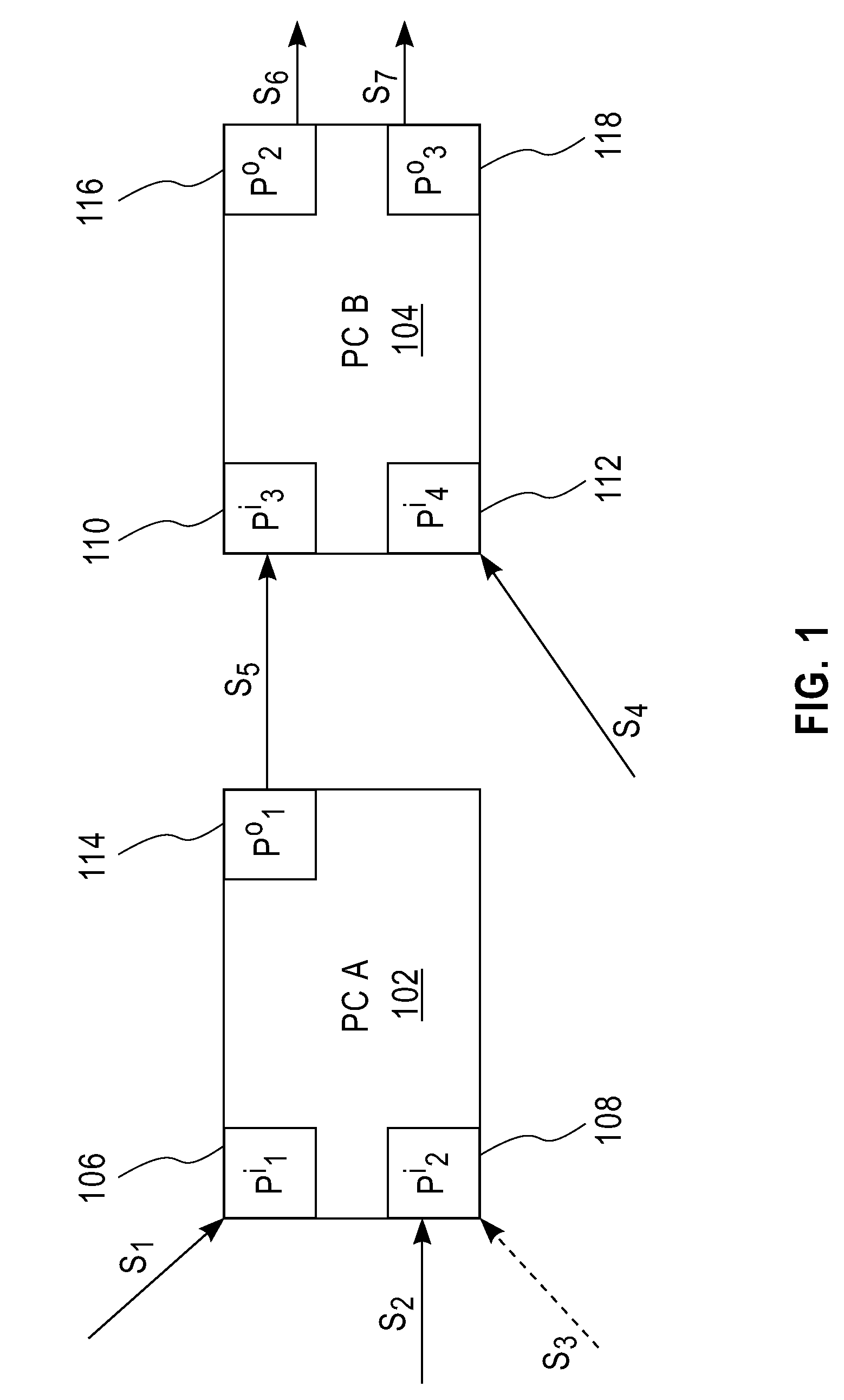

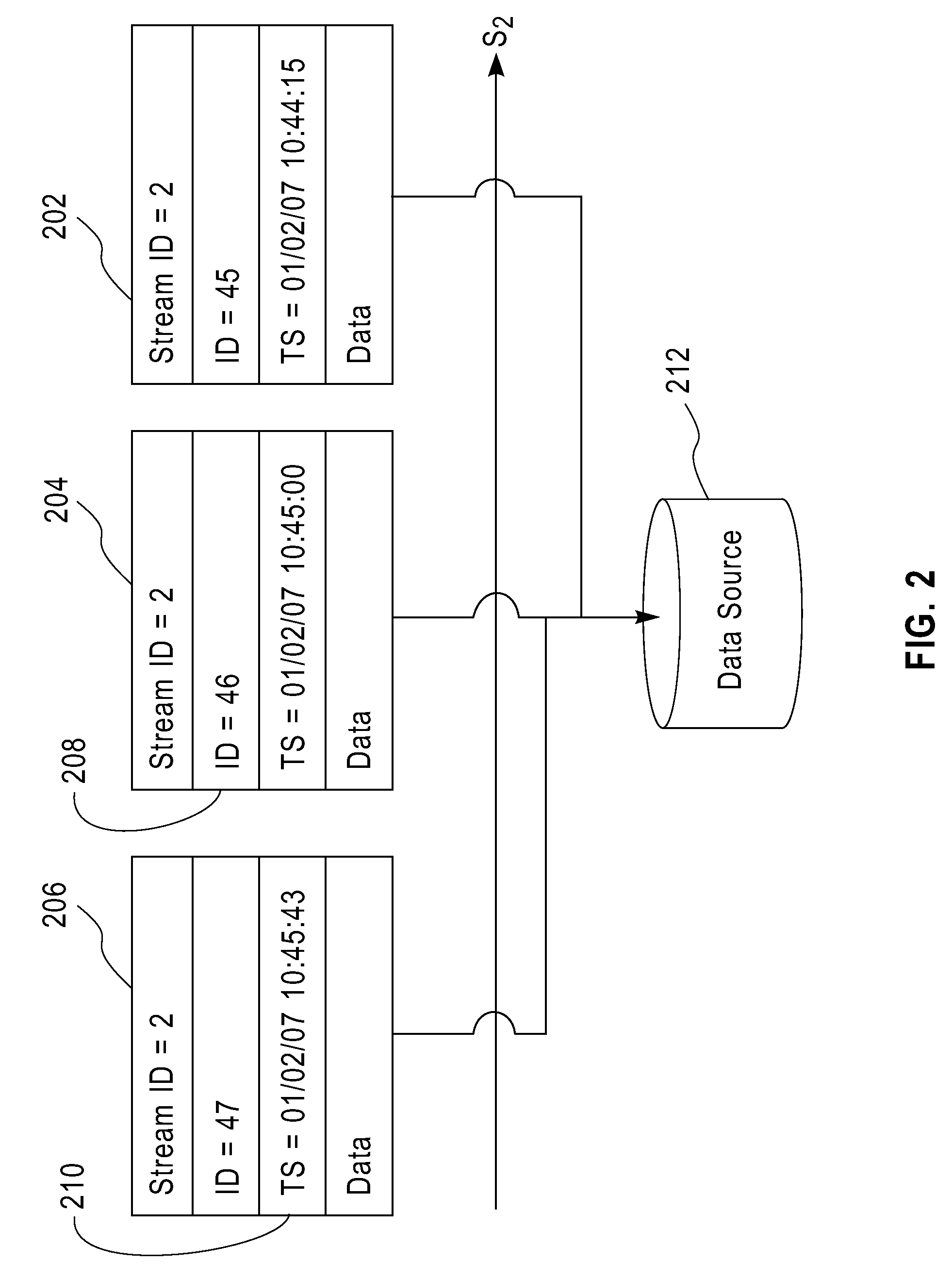

Methods and Apparatus for Functional Model-Based Data Provenance in Stream Processing Environments

InactiveUS20080307104A1Ability to useDigital data information retrievalMultiple digital computer combinationsData sourceTheoretical computer science

Techniques for deriving a provenance of one or more of a plurality of output data elements generated from a given output port of a PC are provided. At least one dependency function is created that relates the one or more output data elements to a set of one or more input ports of the PC and a corresponding plurality of input data elements. The dependency function comprises an encoding of at least one of one or more temporal filters and one or more sequence filters relating to the plurality of input data elements. The at least one dependency function is stored. A history of stream-level bindings of one or more input streams to one or more input ports of the processing component and one or more output streams from one or more output ports of the processing component is stored. The plurality of input data elements belonging to the one or more input streams and the plurality of output data elements belonging to the one or more output streams are stored. The set of one or more input data elements from the plurality of input data elements are determined that relate to the one or more output data elements in accordance with at least one dependency function and the history of stream-level bindings.

Owner:IBM CORP

Online estimation method of health state of lithium ion battery

ActiveCN109031153AGet flexible and easySmall amount of calculationElectrical testingLithium-ion batteryFeature parameter

The invention belongs to the field of lithium ion batteries, and discloses an online SOH estimation method of a lithium ion battery for solving the problems that characteristic parameters are difficult to be obtained online, the dependency of a model on training data is high, the required data size is large, the complex function relationship between the battery capacity and the characteristic parameters is difficult to be described by simple linear regression, and the estimation accuracy is difficult to be guaranteed in an implementation process of the existing SOH estimation technology. According to the online SOH estimation method disclosed by the invention, the characteristic parameters are obtained from a capacity increment curve by using a capacity increment method. The method does not require the battery to undergo a complete charging and discharging process, the feature parameter extraction is simpler, and the application of the method in the BMS is facilitated. The establishment of a characteristic parameter and SOH function model is completed by using a multi-output Gaussian process regression model method, the potential correlation between different outputs is better used, and the estimation accuracy of SOH is improved. Meanwhile, the dependency of the method on the training data is small, and the online SOH estimation method has very good adaptability on different types of lithium ion batteries.

Owner:徐州普瑞赛思物联网科技有限公司

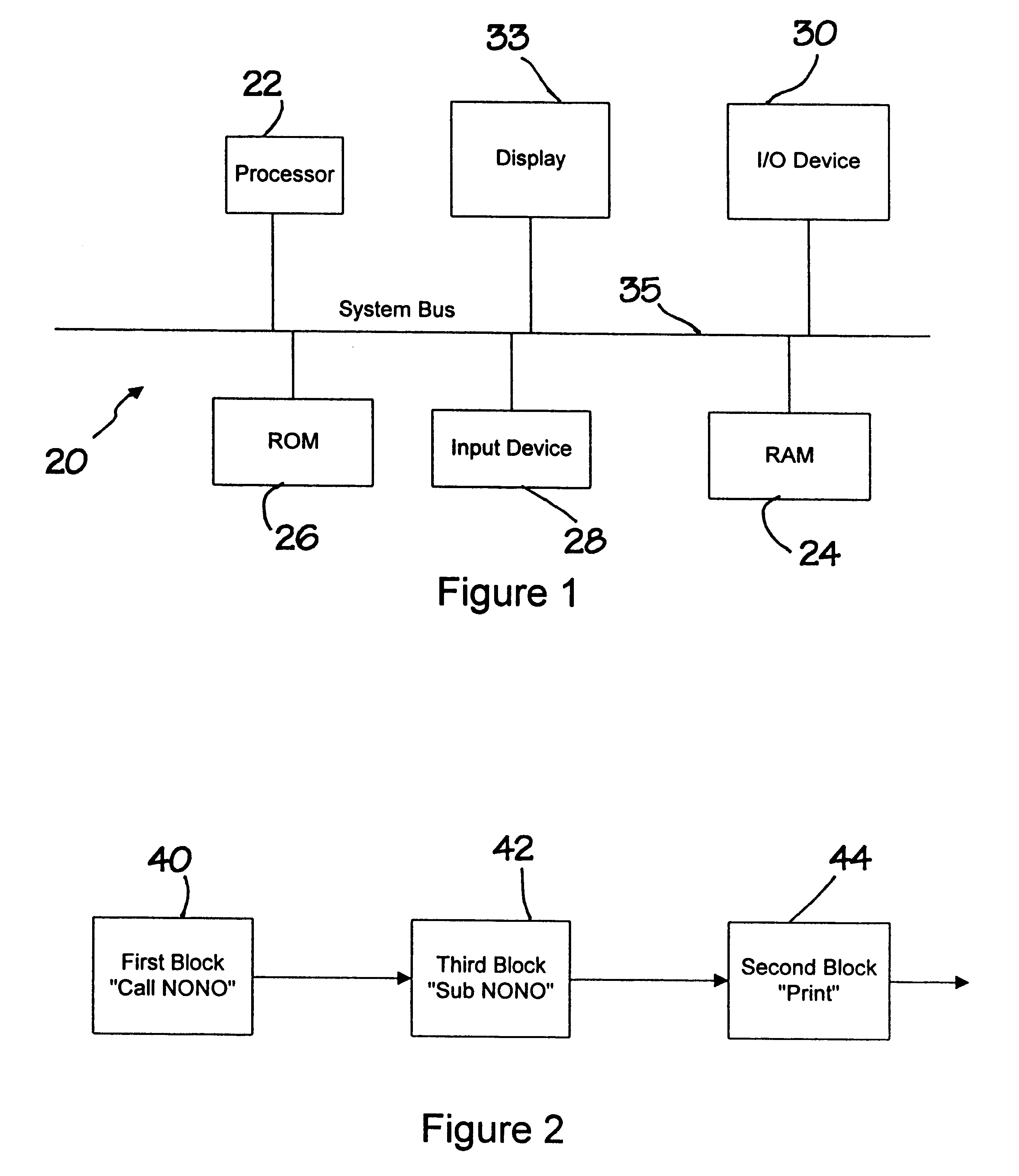

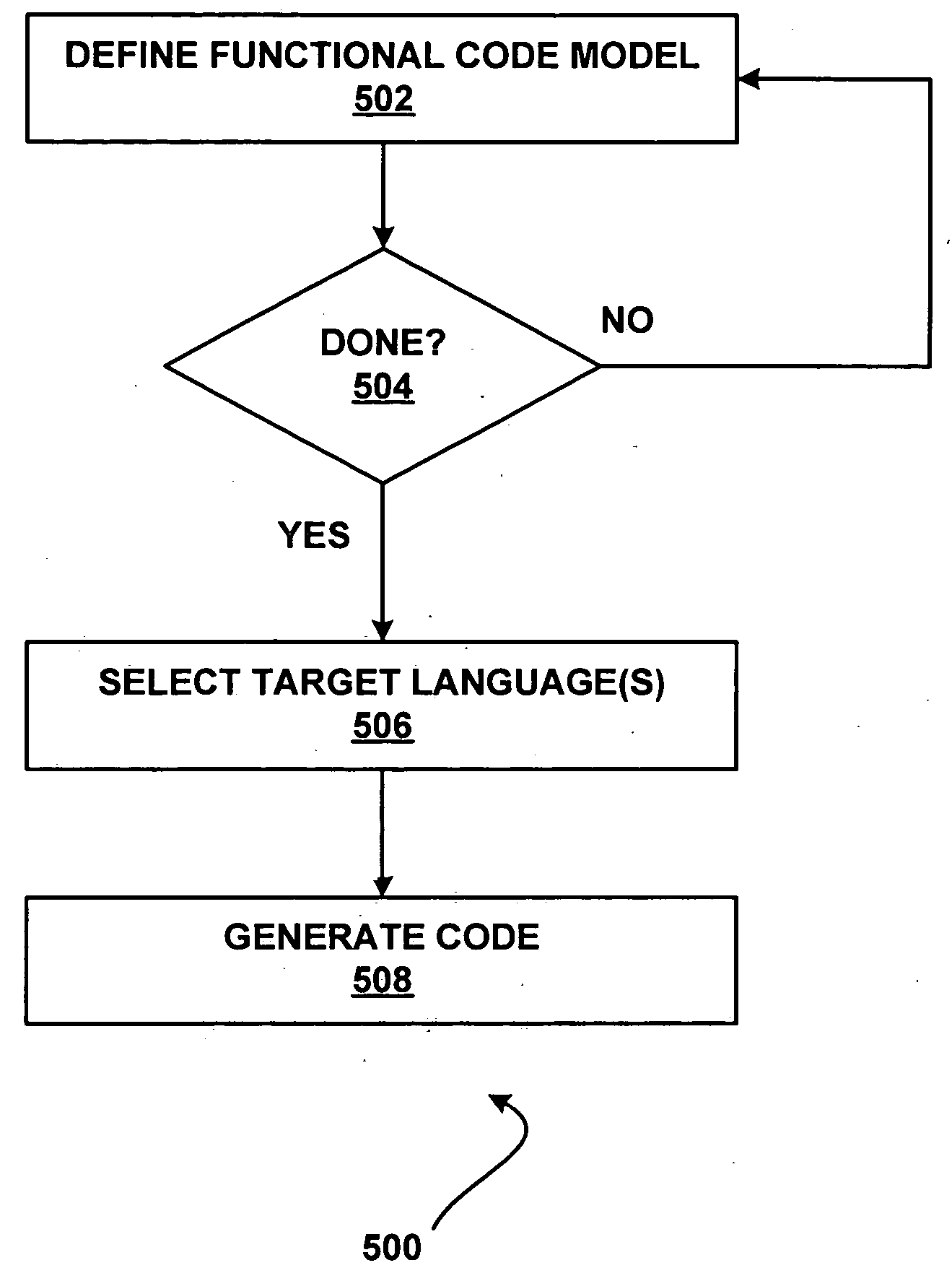

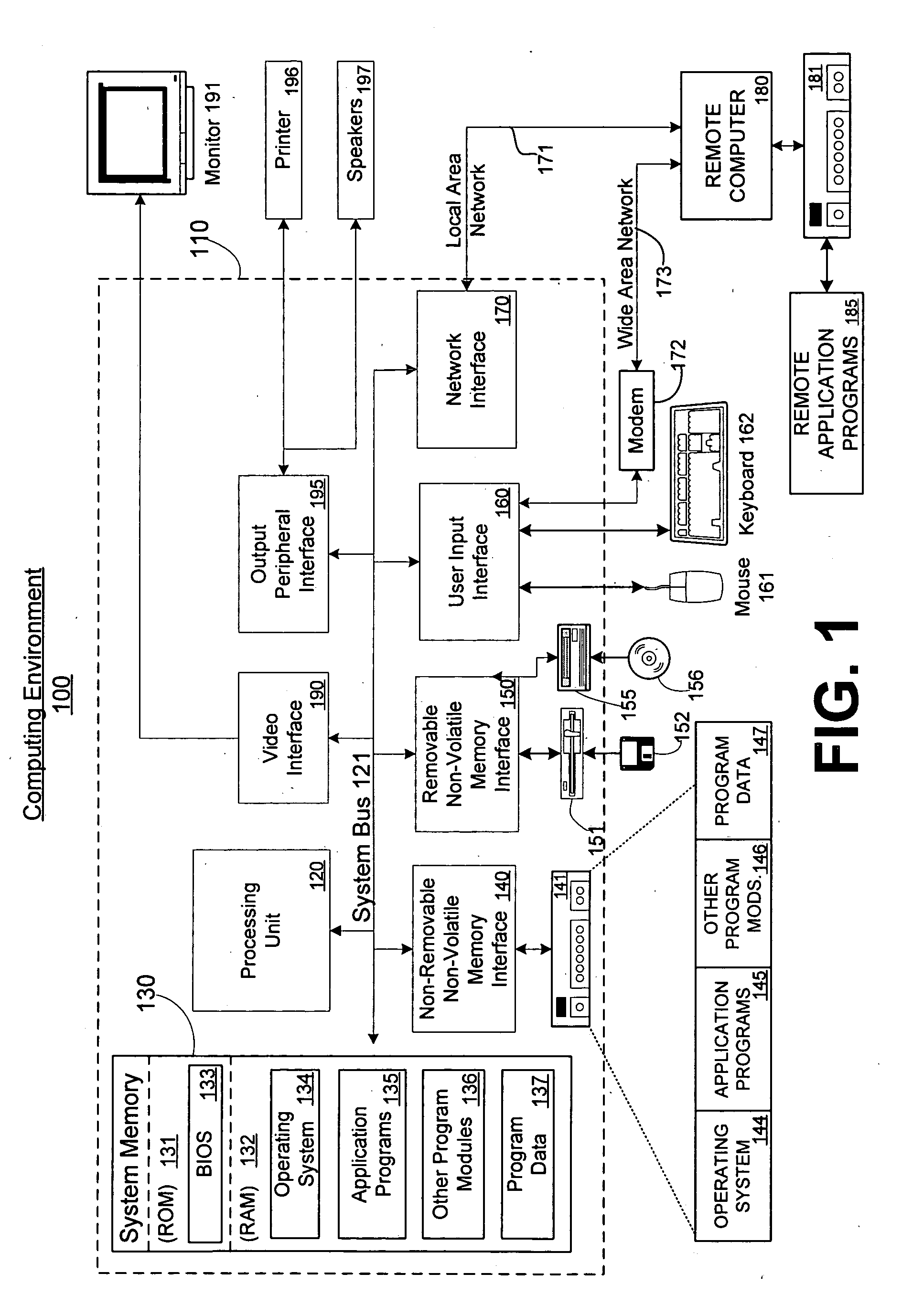

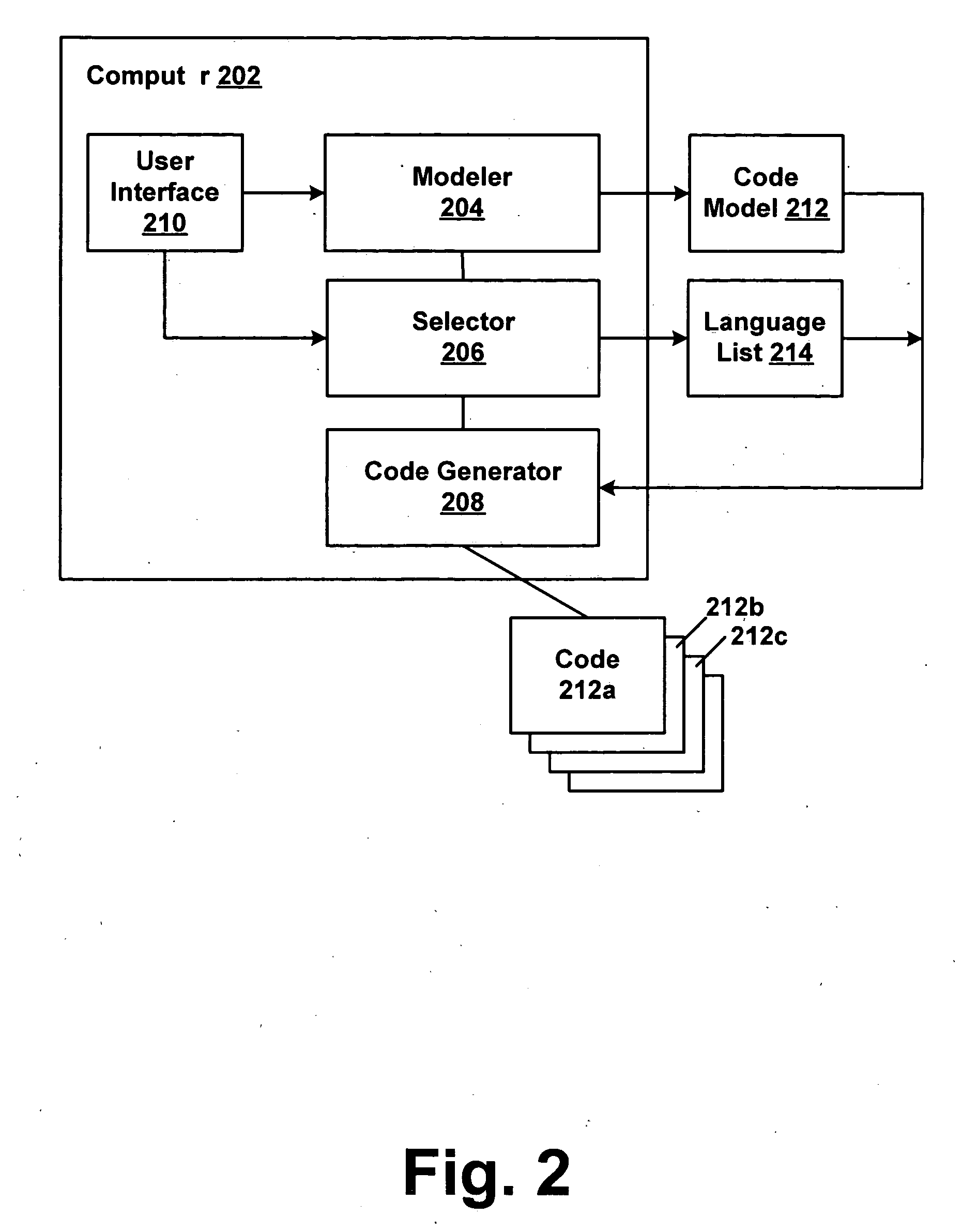

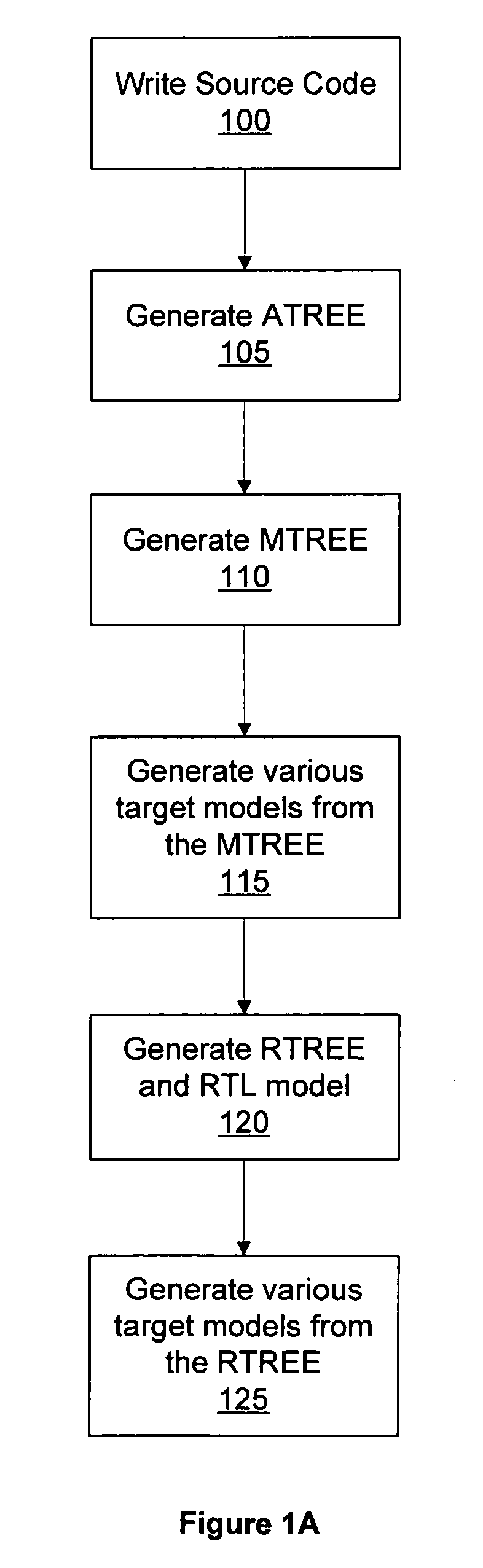

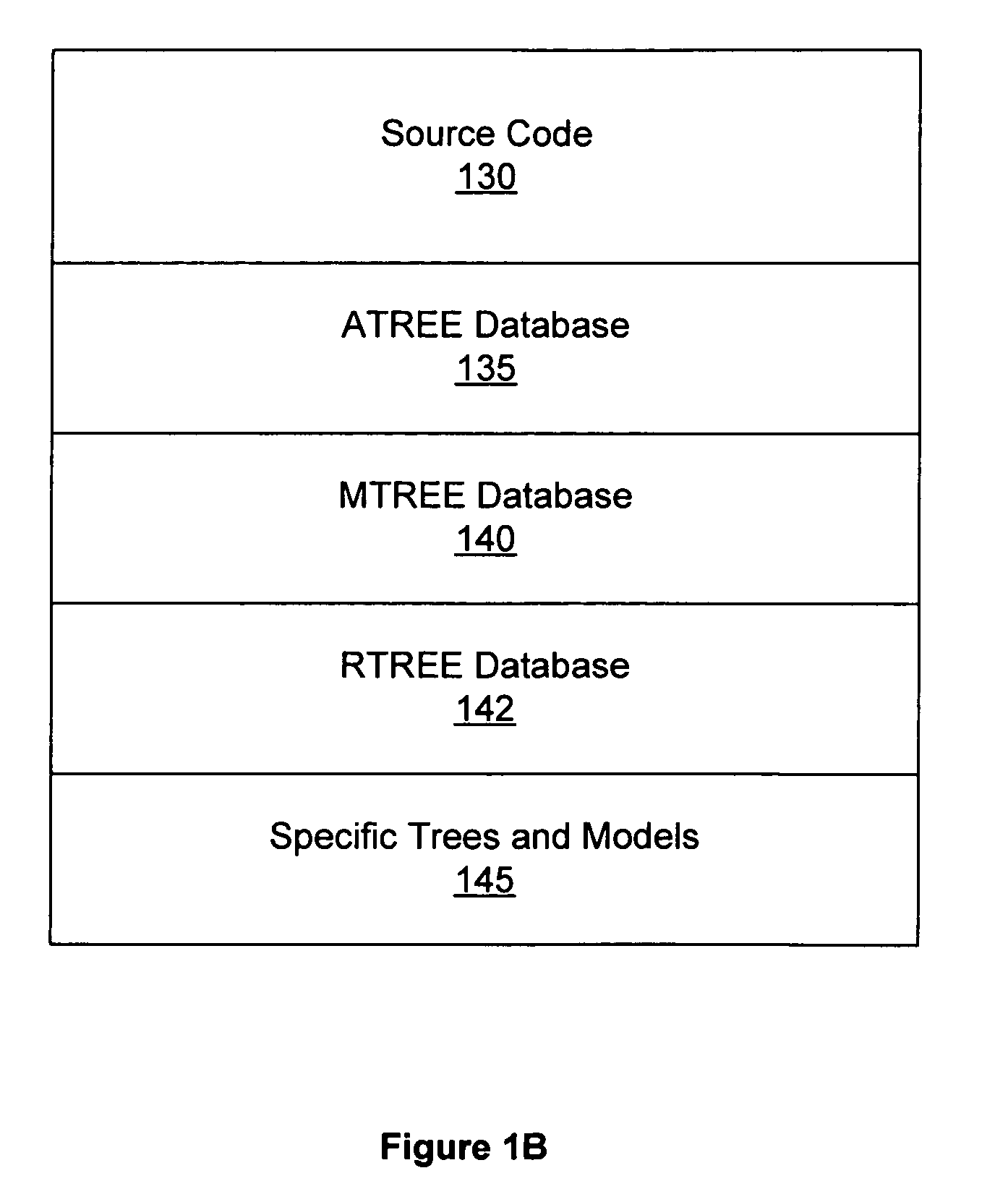

Automatically generating program code from a functional model of software

InactiveUS20050114832A1Rapid visualizationCode structure and flowVisual/graphical programmingSpecific program execution arrangementsProgramming languageCoded element

Modeling of the code elements and structure of a block of programming code enables code structure and flow to be visualized, eliminating language-specific aspects. One or more programming languages for which code is to be generated are selected. Code in the selected language(s) is generated from the functional model.

Owner:MICROSOFT TECH LICENSING LLC

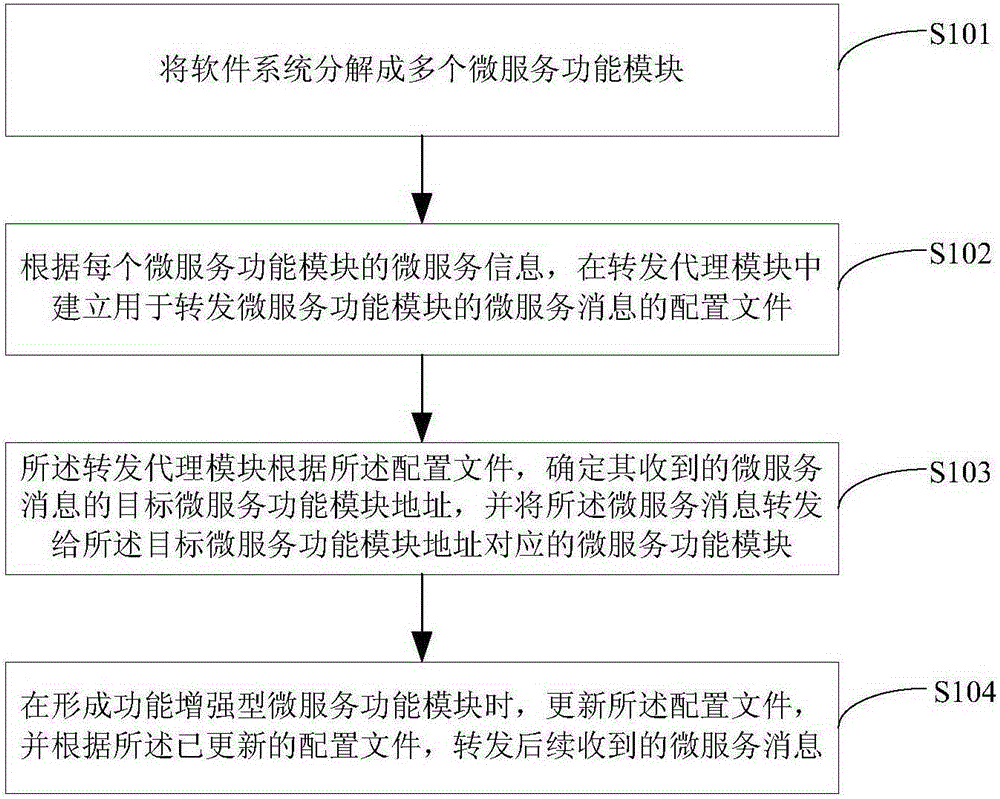

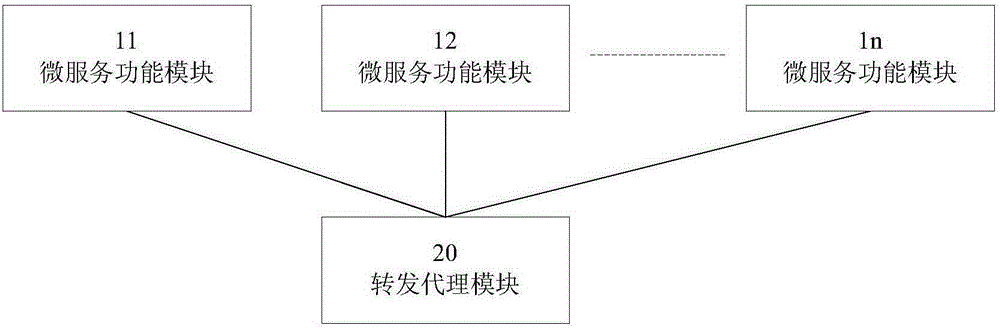

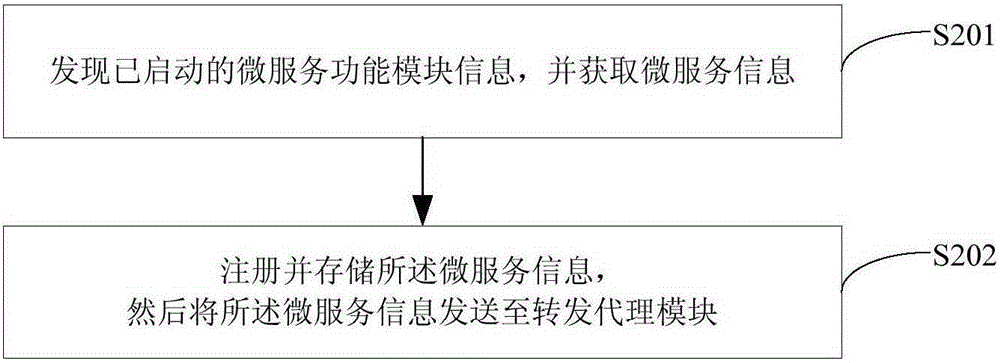

Method and device for extending software function based on micro service architecture

InactiveCN106612188AImprove acceleration performanceImprove usabilityProgram loading/initiatingData switching networksSoftware systemBusiness function

The invention discloses a method and a device for extending a software function based on a micro service architecture. The method comprises steps: a software system is decomposed into multiple micro service function modules; according to the micro service information of each micro service function module, a configuration file for forwarding the micro service information of the micro service function module is built in a forwarding agent module; according to the configuration file, the forwarding agent module determines a target micro service function module address of the received micro service information, and the micro service information is forwarded to the micro service function module corresponding to the target micro service function module address; and when a function enhancement-type micro service function model is formed in the software system according to service function requirements, the forwarding agent module updates the configuration file according to the micro service information of the function enhancement-type micro service function model, and according to the already-updated configuration file, subsequently-received micro service information is forwarded. Thus, the software function can be dynamically extended.

Owner:ZTE CORP

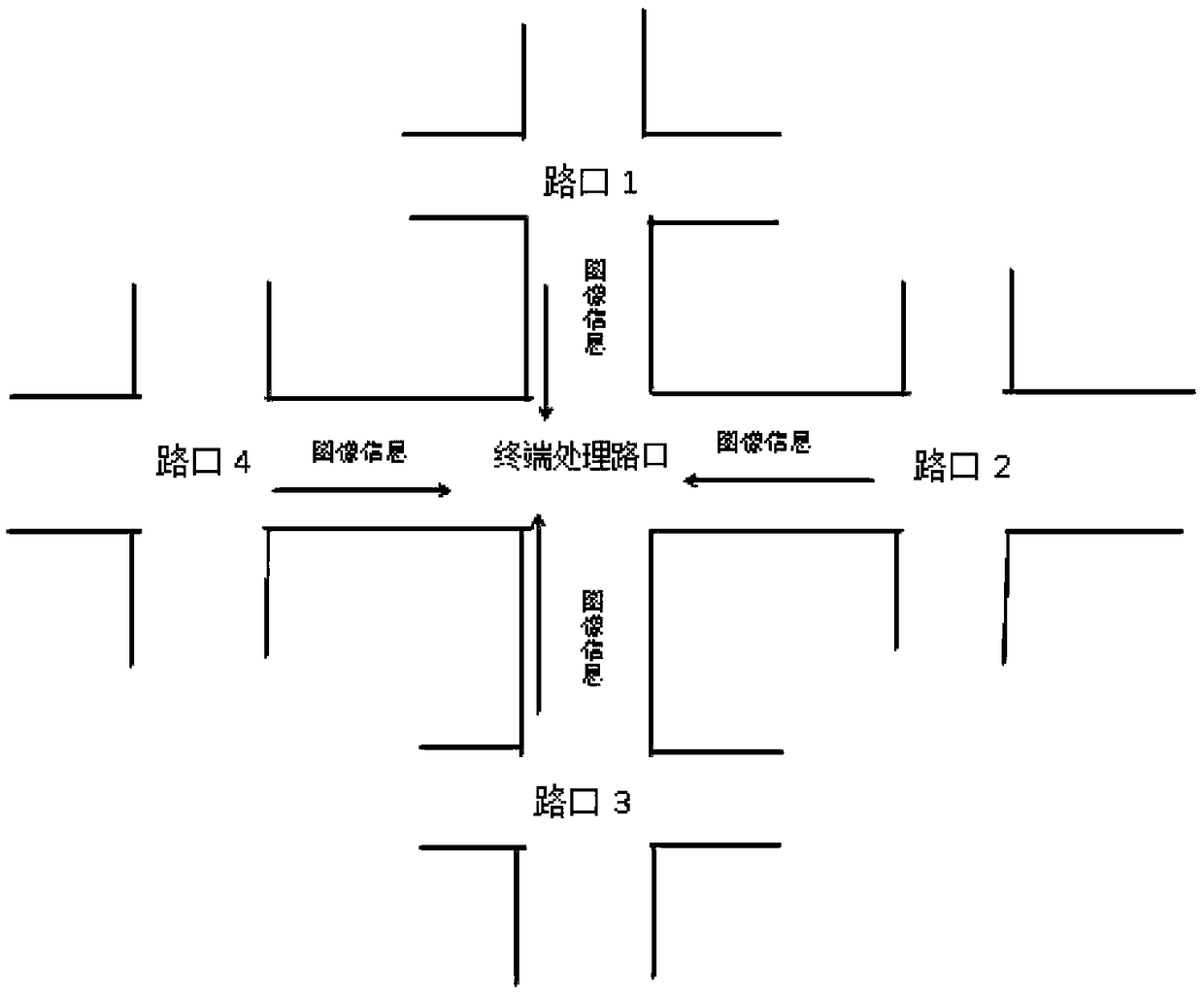

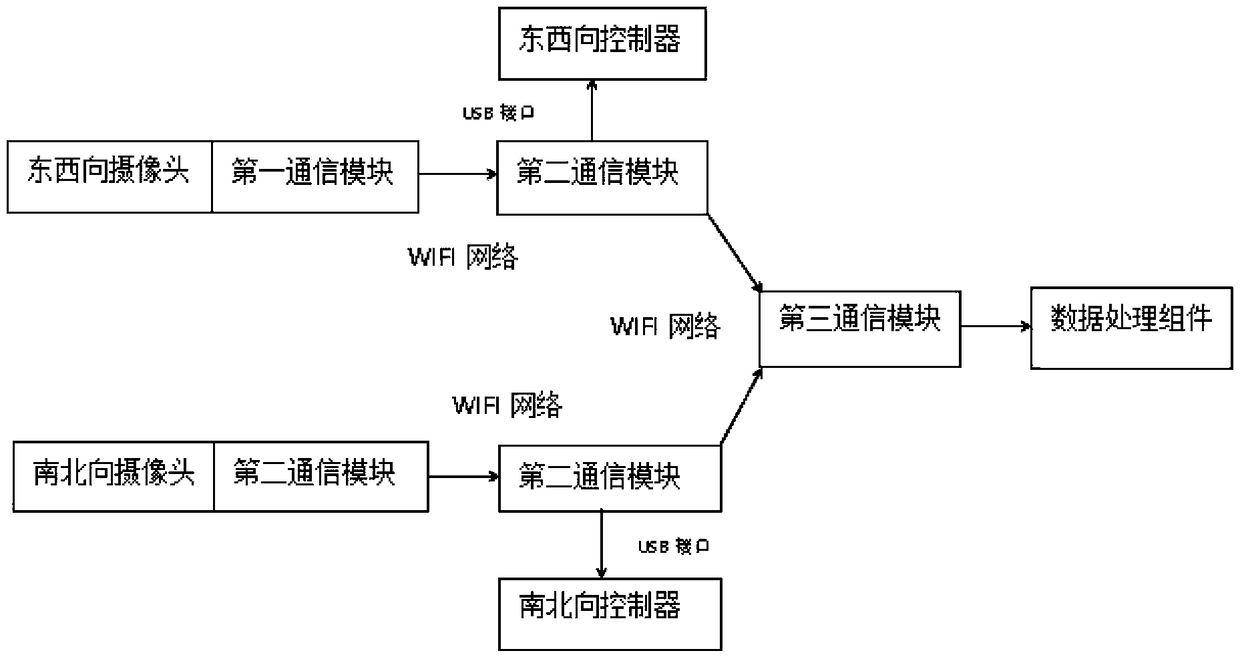

Signal lamp control method and system based on deep intensive learning and storage medium

The invention relates to an intelligent traffic lamp control method based on deep intensive learning. The method comprises the steps of selecting a center intersection, wherein multiple peripheral intersections communicated with the center intersection are arranged at the periphery of the center intersection; obtaining road condition information and signal lamp information of each intersection; building an intersection congestion and unblocking state model; modelling a traffic signal lamp control problem into a Markov decision-making process, and defining the state, motion and an immediate awarding function in the process; building a return value function model, utilizing a DQN deep intensive learning algorithm for solving an optimum strategy, and utilizing the optimum strategy for controlling traffic lights of all the intersections. By means of the method, a control strategy of the traffic lights can be self-adaptively and dynamically adjusted according to the real-time road conditioninformation. In the meanwhile, multiple intersections are synchronously adjusted, and full play can be given to the traffic capability of all the intersections.

Owner:SUZHOU UNIV OF SCI & TECH

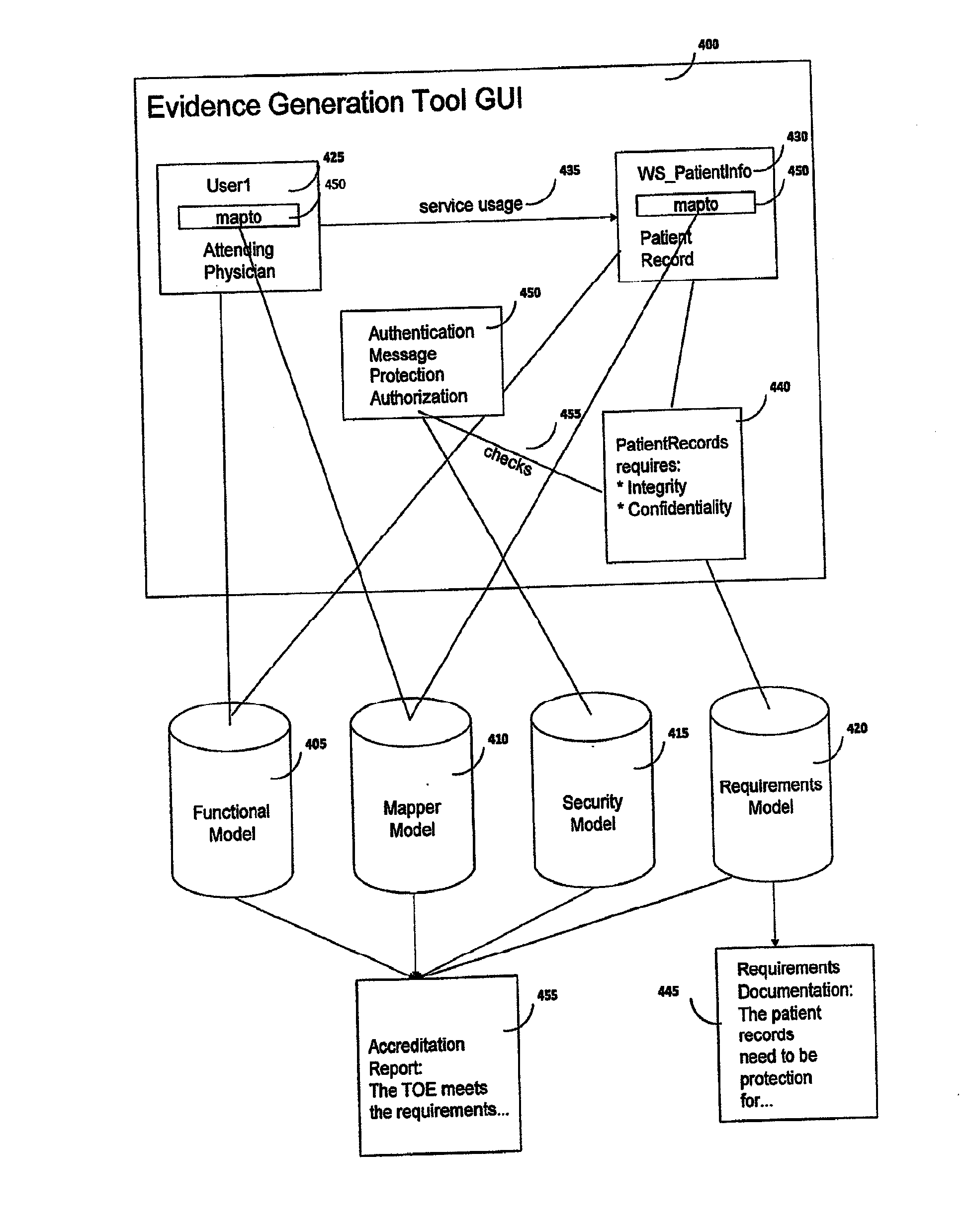

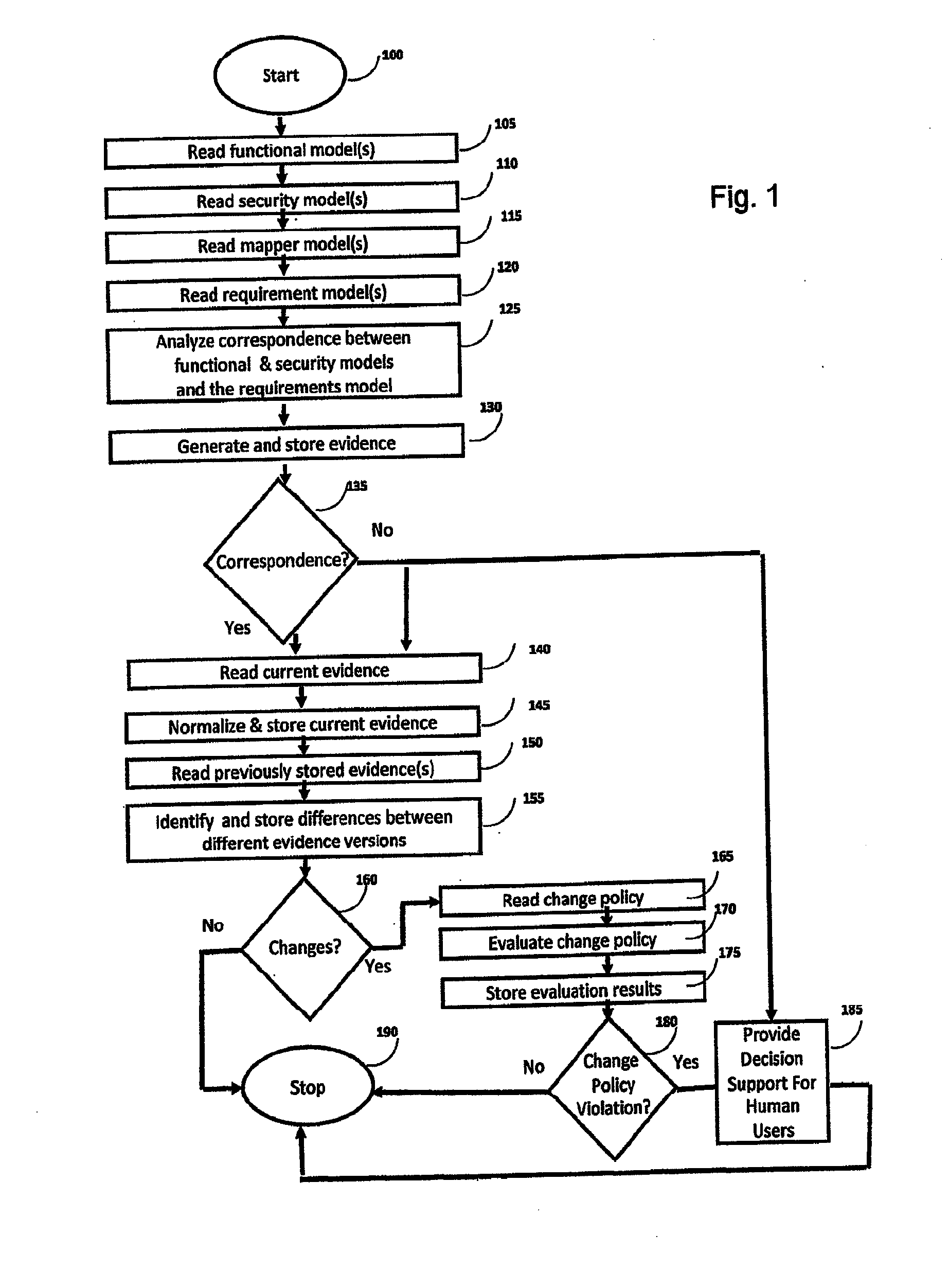

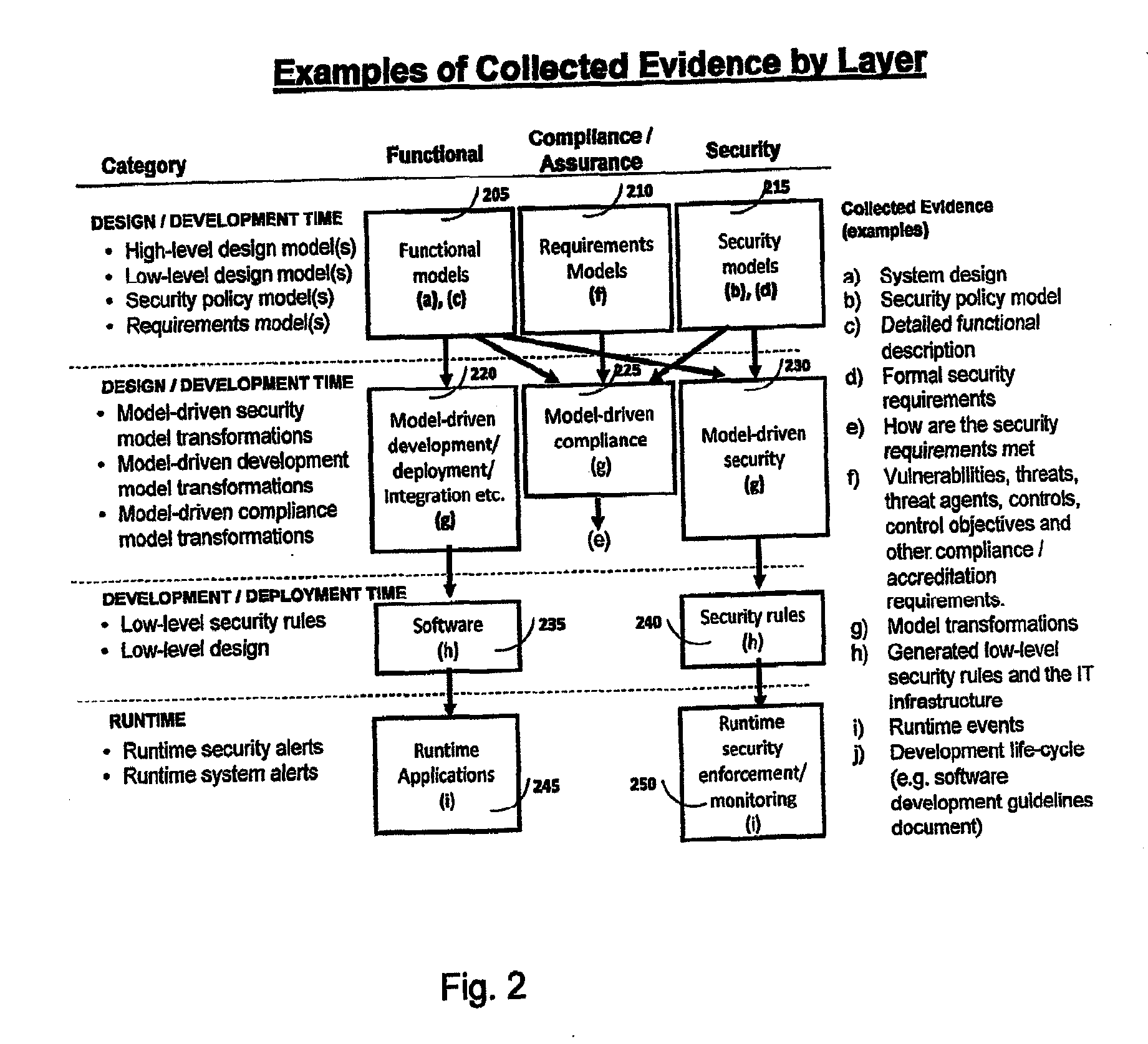

Method and system for rapid accreditation/re-accreditation of agile it environments, for example service oriented architecture (SOA)

A system and method for managing and analyzing security requirements in reusable models. At least one functional model, at least one security implementation model, at least one requirement model, and meta models of the models are read by a reader. A correspondence between the functional model, security implementation model, and the requirements model is analyzed, whereby the correspondence indicates that compliance / security / accreditation requirements defined in the requirement model match with security objectives implemented by controls defined by the security implementation model. Next, it is determined whether correspondence is or is not given based on the analysis of the correspondence and then evidence is generated based on the analysis of the correspondence and the determination and the impact of changes is analyzed.

Owner:OBJECTSECURITY

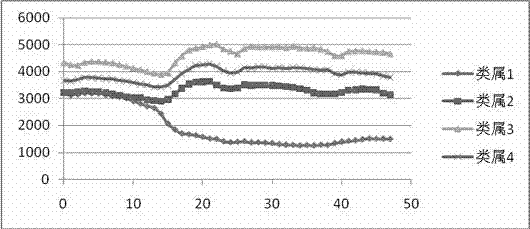

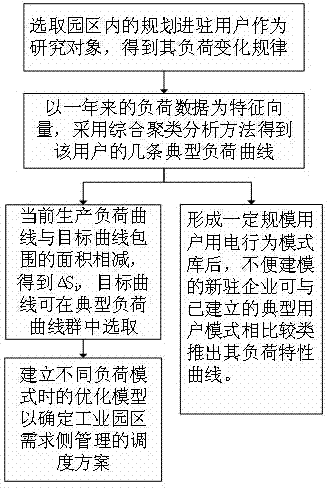

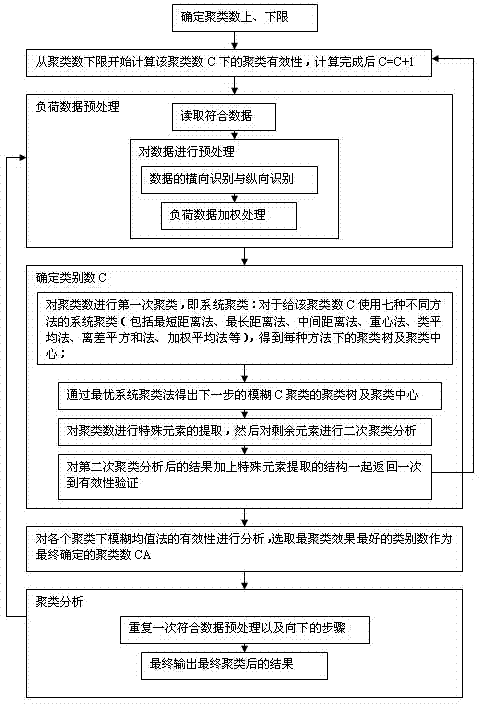

Power utilization mode classification and control method based on user behavior characteristics

ActiveCN104200275AImprove planning efficiencyReduce lossesForecastingElectricity pricingFeature vector

The invention discloses power utilization mode classification and control method based on user behavior characteristics. With an improved secondary clustering model built by use of a secondary clustering method, the load point of each day of the same user in one year in an industrial park is taken as a characteristic vector, the daily power utilization characteristics of the user can be concluded from a clustering result, and a plurality of typical power utilization modes of the enterprise user can be provided, and therefore, basis can be provided for load prediction, fault diagnosis, electricity pricing and the like in the industrial park; furthermore, the optimal plane power utilization mode in demand side management can be selected by virtue of optimization function modeling on load data; the model is advantageous for a power supply company to reduce the loss of electricity selling profit as much as possible under the premise of guaranteeing power supply; at last, a user power utilization behavior mode library in the industrial park built on the basis is capable of comparing a new settling enterprise inconvenient to model with the modelled typical user mode and obtaining the load characteristics of the new settling enterprise by virtue of analogizing, and therefore, the planning efficiency of the park can be improved.

Owner:STATE GRID CORP OF CHINA +3

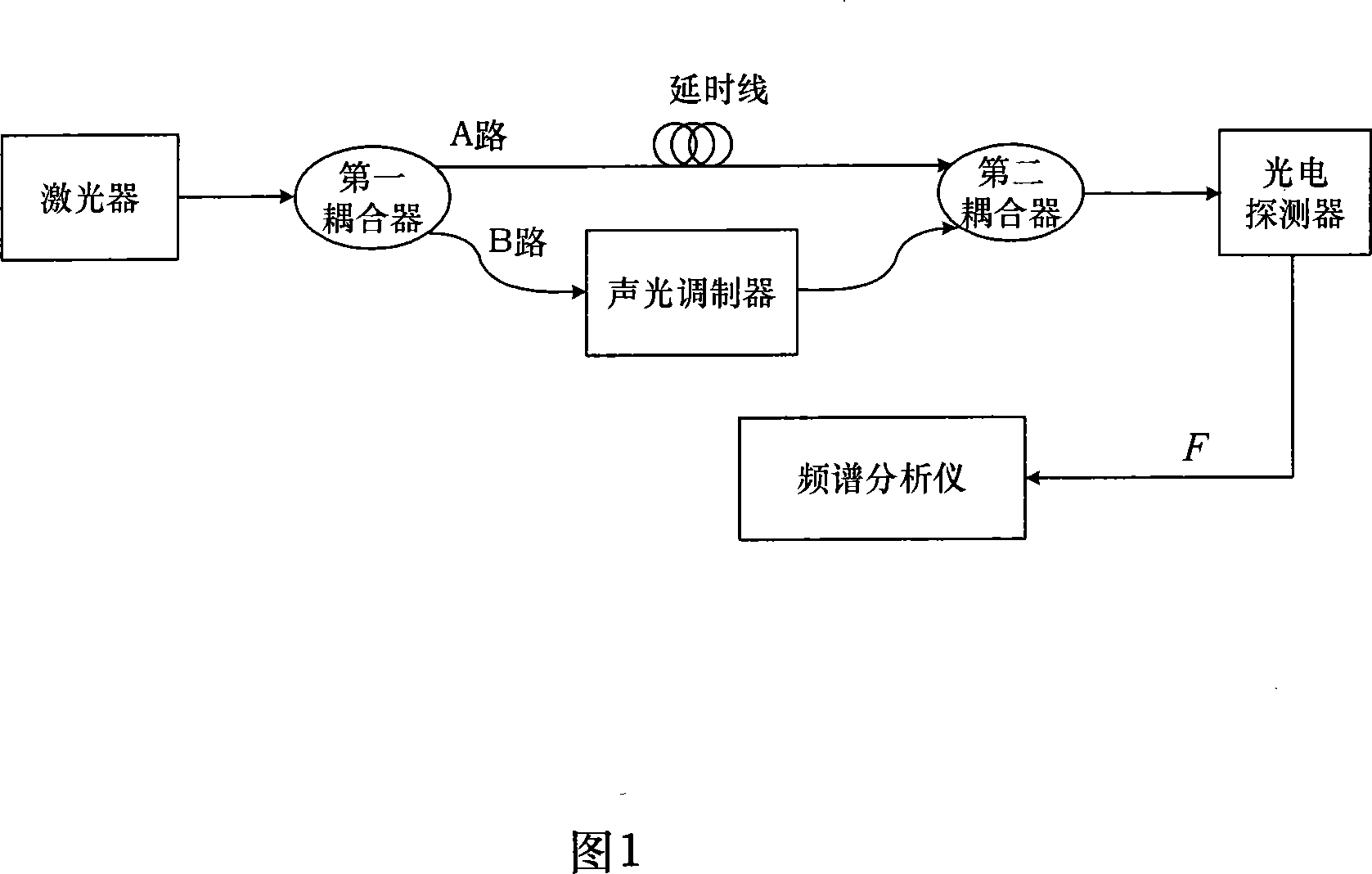

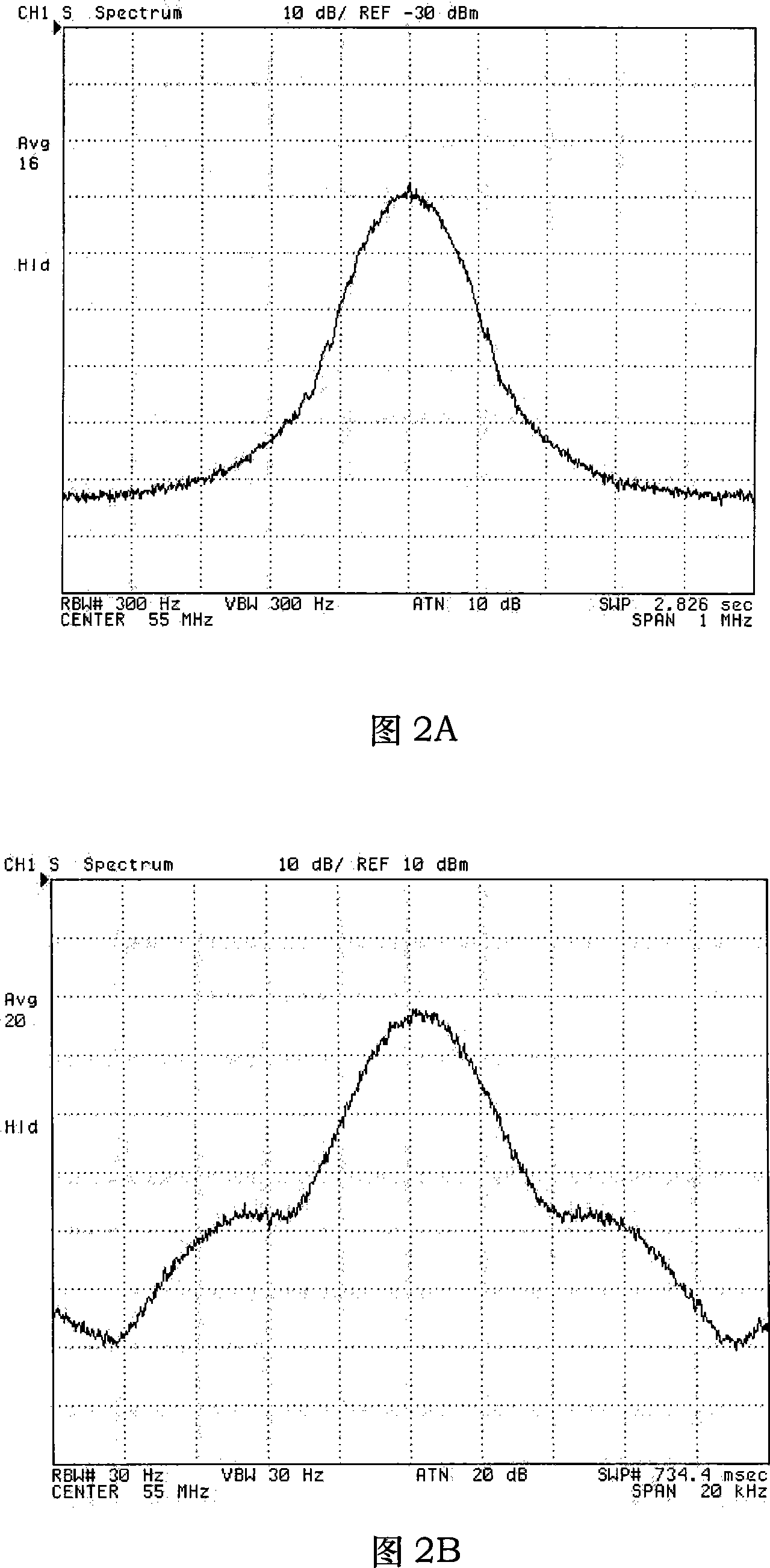

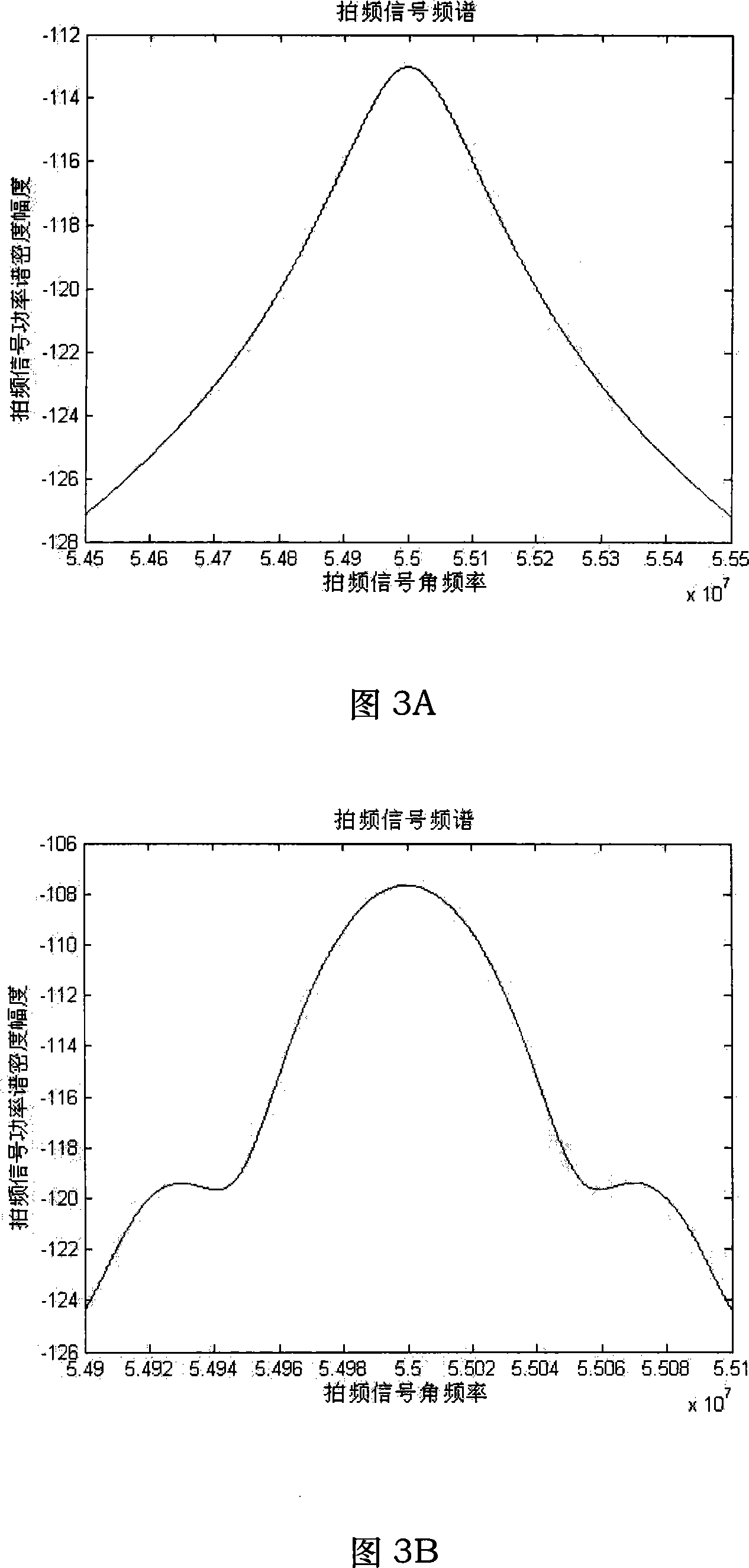

Device for measuring linewidth of narrow linewidth laser based on optical fiber time-delay self heterodyne method as well as method for measuring thereof

InactiveCN101201243ARealize high-precision testingReduce volumeUsing optical meansThree levelSpectrum analyzer

The invention discloses a device of measuring the line-width of a laser with narrow line-width and a method of measuring the line-width based on a optical fiber delay self-heterodyne method; in the hardware device, an optical fiber delay line is connected between a first and a second couplers; an acousto-optic modulator is connected between the first and the second couplers; the measured laser is connected to the input of the first coupler, and a photoelectric detector is connected to the output of the second coupler; the photoelectric detector is connected with a spectrum analyzer. In the line-width measurement, simulation models of the line-width triangle v of the laser and the spectrum-width triangle f of the photoelectric current heterodyne signal are built in the frequency shift delay self-heterodyne methodology, and the function relation between the line-width triangle v of the laser and the spectrum-width triangle f of the photoelectric current heterodyne signal is obtained fitting of the three-level proportion function model. The invention presents that with the short optical fiber delay self-heterodyne method, the device can eliminate the deficiency of greatly reduced measuring precision because of not enough delayed time in the delay self-heterodyne method when the length of the delay optical fiber is less than 6 times coherence length of the laser, so as to provide an effective method of precisely measuring the line-width of the laser with narrow line-width in projects.

Owner:BEIHANG UNIV

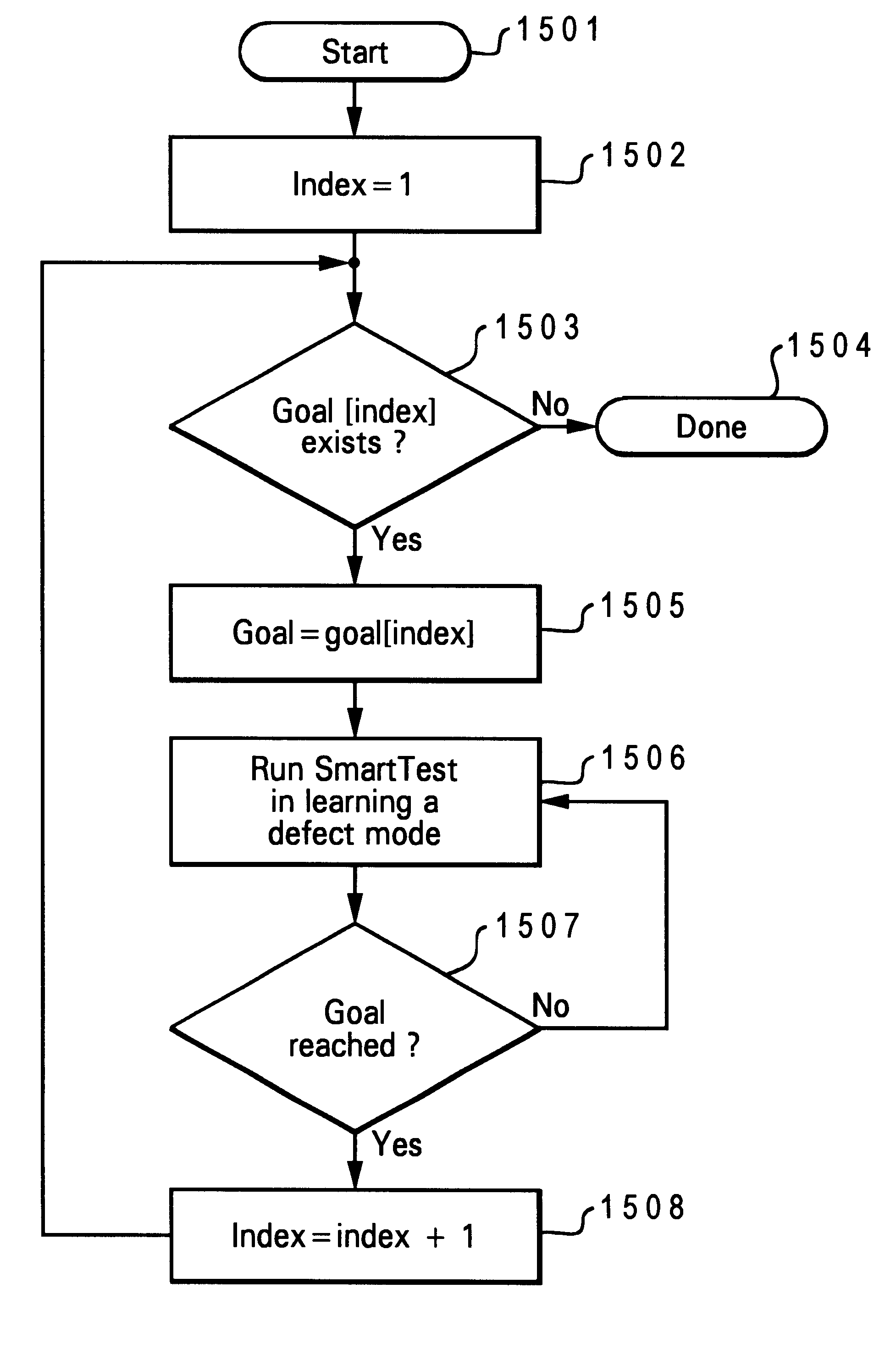

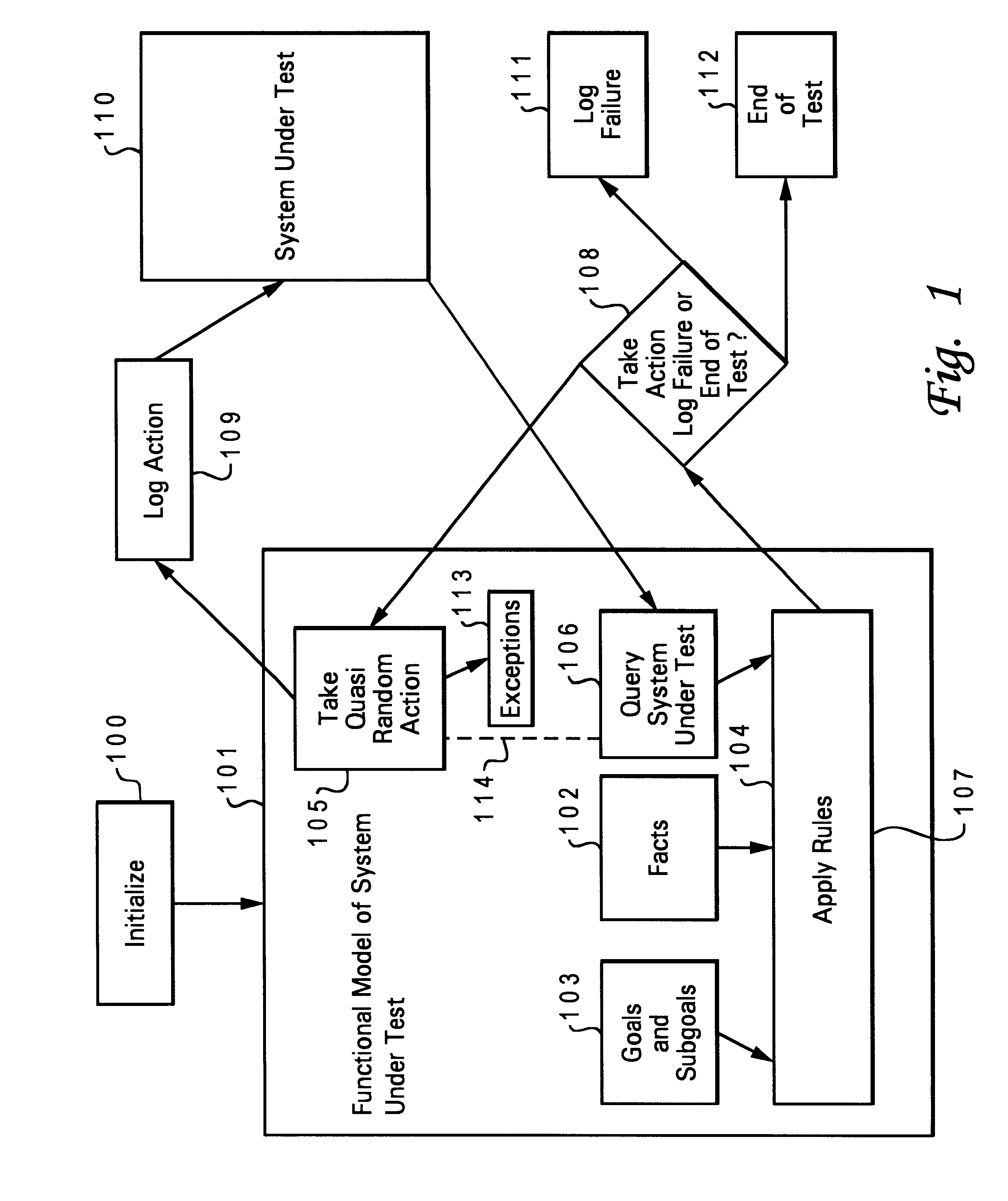

Method and apparatus for training an automated software test

InactiveUS6349393B1Efficient testingSoftware testing/debuggingSpecific program execution arrangementsSystem under testFeature model

An automated software test is provided which includes a functional model of a system to be tested. The automated software test is utilized to operate a system under test in accordance with specified facts, goals and rules. Quasi-random actions are taken within the system in accordance with specified rules and facts until a defined goal has been accomplished. Training the automated software test is accomplished by specifying a particular goal, i.e. identifying a particularly known defect, and thereafter running the test in a quasi-random fashion until the particular goal has been achieved. The number and nature of actions required to achieve that goal are logged and the process is then repeated until the shortest path required to achieve that goal has been determined. The log of actions which eventually reach a particularly defect may also be utilized a probable cause tree structure for future analysis.

Owner:IBM CORP

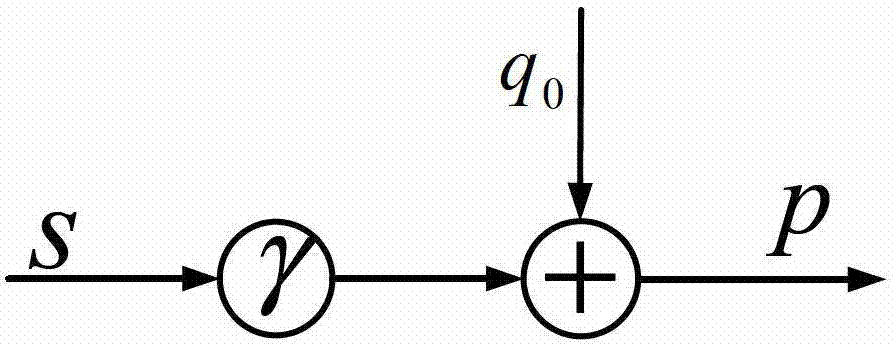

Method of generating a performance model from a functional model

InactiveUS20050256692A1OptimizationHardware monitoringProgram controlResource consumptionTheoretical computer science

A process for generating a performance model from a functional model for a system including a plurality of distributed hardware and software entities that engage to provide a service to at least one user. The process distributes the representative system requests in a finite number of groups and identifies, for each request group, the corresponding execution flow, formalizes the execution flows by a notation that makes it possible to highlight the causal relationships between the different software entities of the system that are involved in the execution flows and the data characterizing the system's resource consumption, develops an intermediate model, and automates the conversion of the developed intermediate model into a performance model.

Owner:FRANCE TELECOM SA

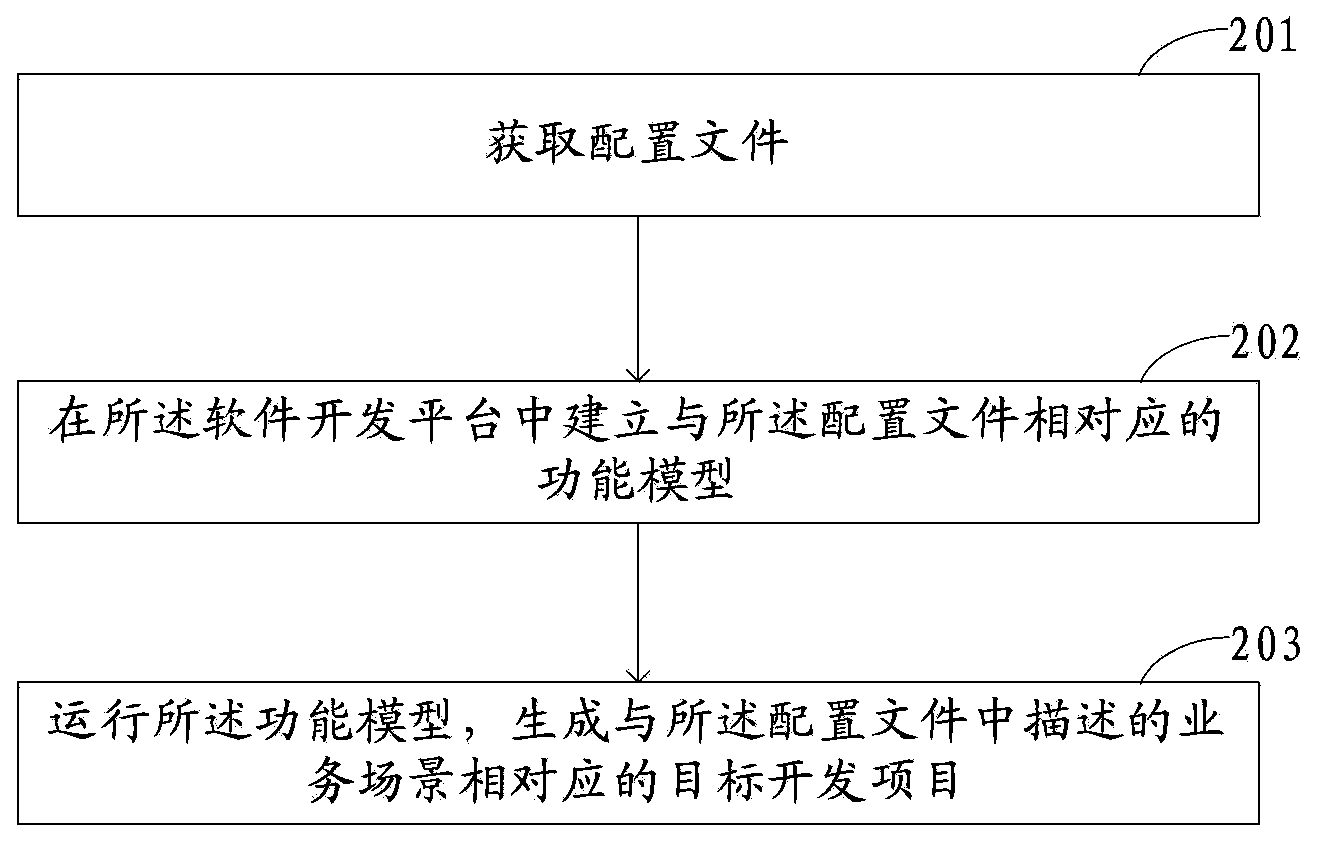

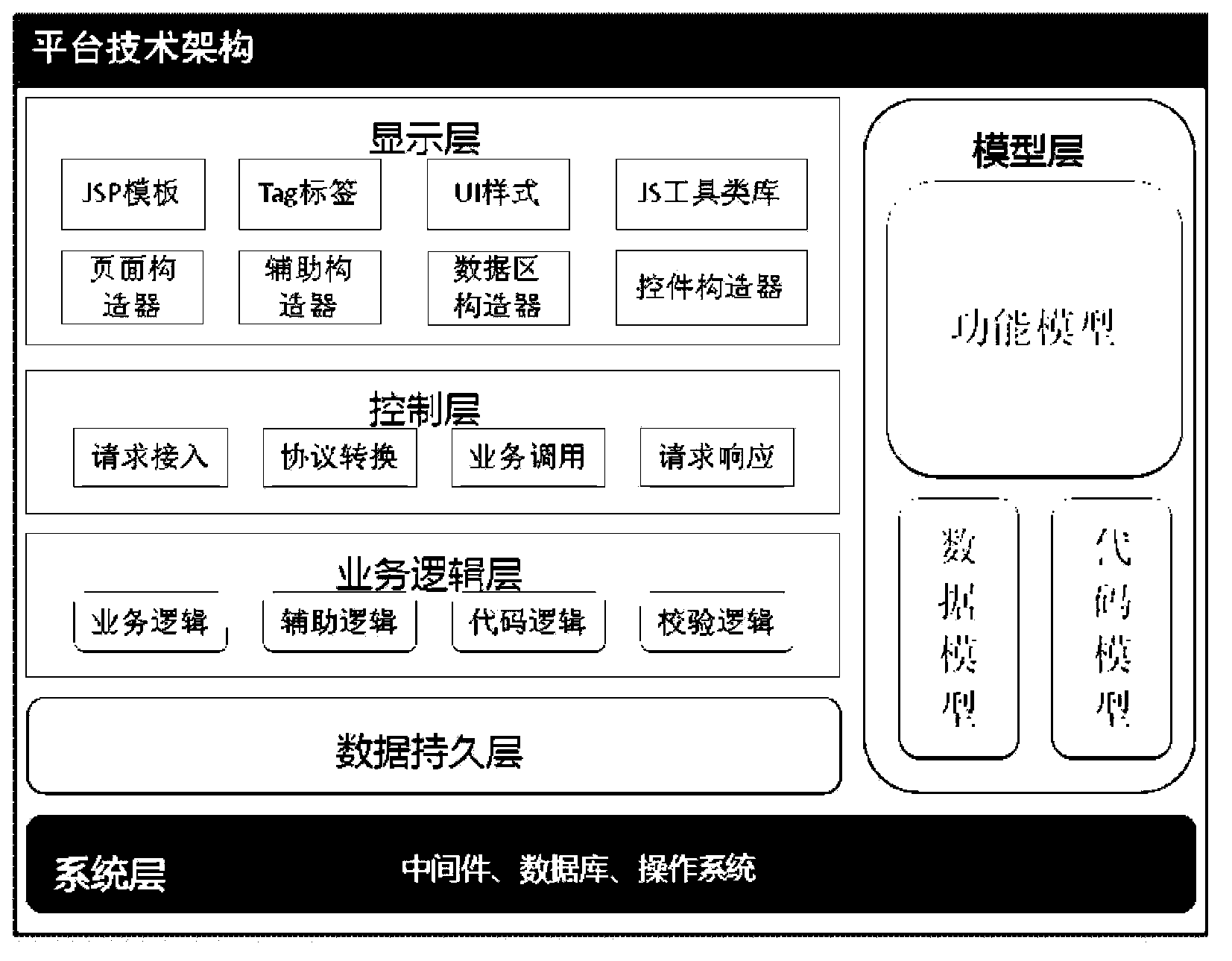

Software project development method and device

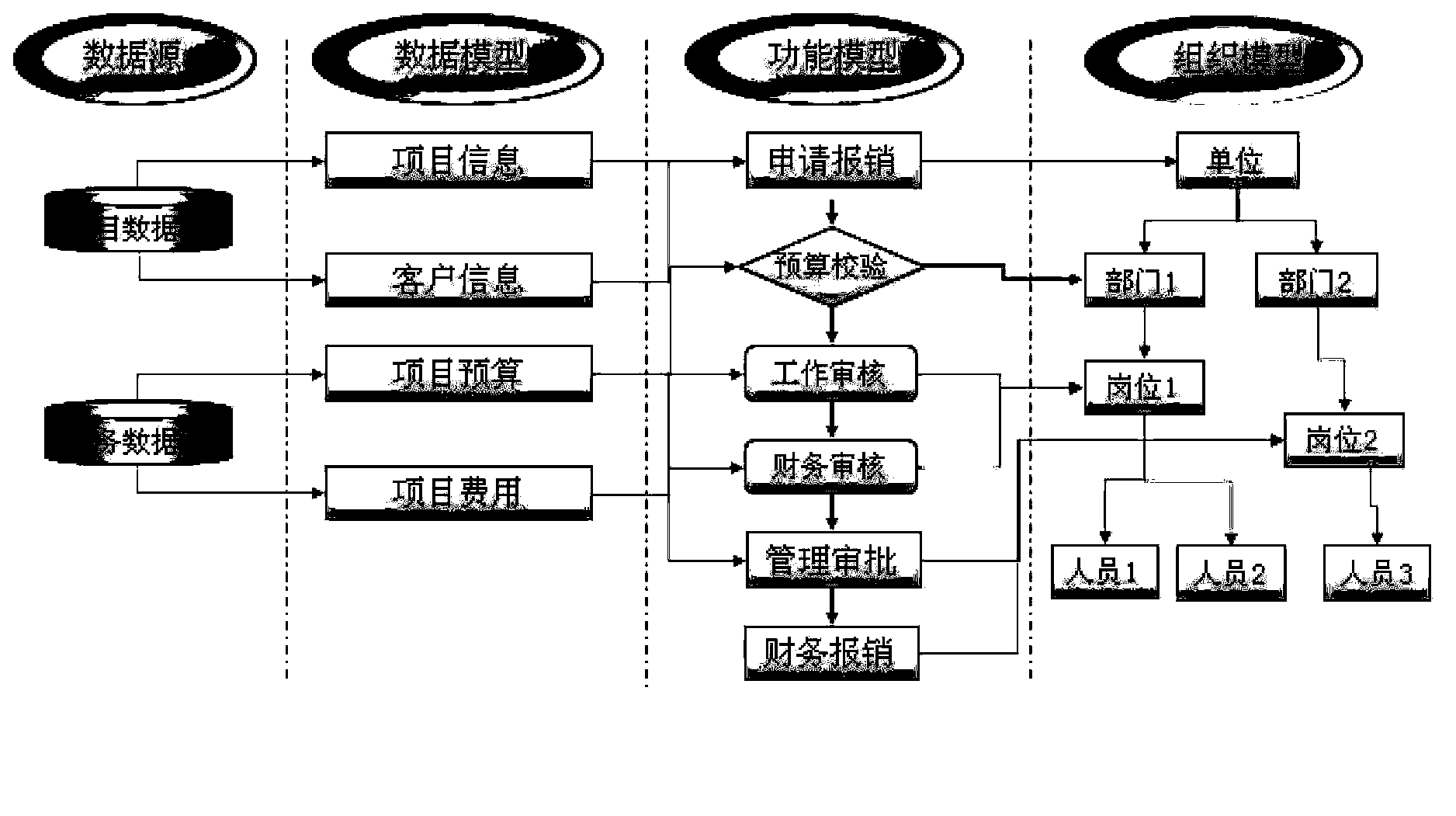

ActiveCN104111826AShort processReduce labor costsSpecific program execution arrangementsData operationsData source

The invention discloses a software project development method and device which is applied to a software development platform. The software development platform is provided with a function model template capable of establishing function models. The software project development method includes acquiring configuration files containing header configuration information of target development projects, page layout configuration information, service logic configuration information, data operation area configuration information, page data source relation configuration information, toolbar configuration information and external resource configuration information; establishing the corresponding function models of the configuration files, wherein the function models include header entries, page layout items, service logic items, data operation area items, page data source relation items, toolbar items and external resource items; running the function models and generating the target development projects corresponding to service scenes described in the configuration files.

Owner:杭州新世纪电子科技有限公司

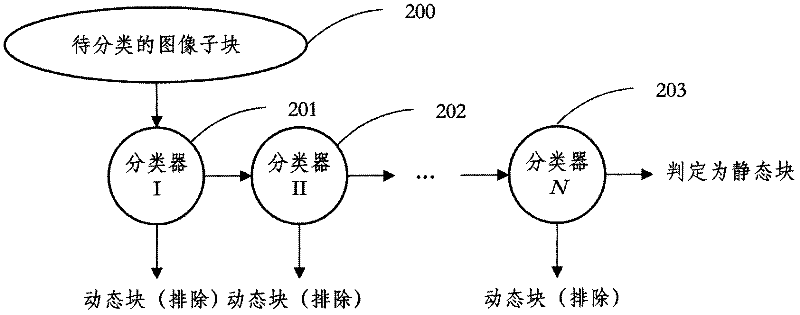

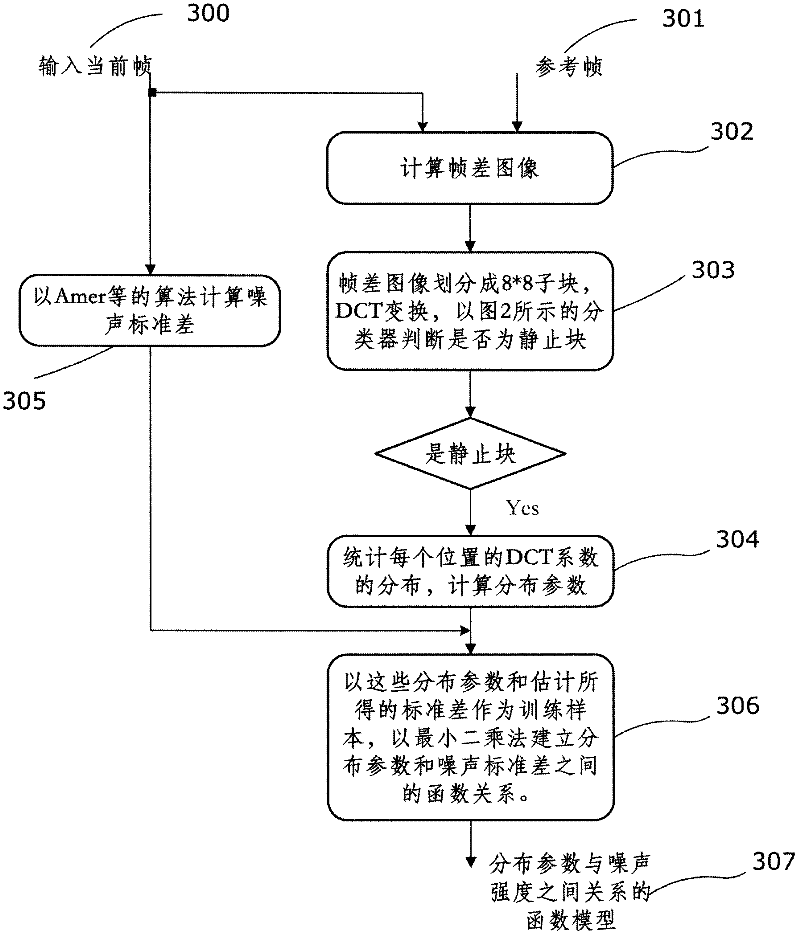

Adaptive noise intensity video denoising method and system thereof

InactiveCN102368821AKeep Edges SharpImprove time and efficiencyCharacter and pattern recognitionTelevision systemsPattern recognitionNoise reduction

The invention discloses an adaptive noise intensity video denoising method which is based on motion detection and is embedded in an encoder. The method comprises the following steps: (1) taking a sum of regularization frame differences in a neighborhood as an observed value, dividing input pixels into a static pixel and a dynamic pixel and using filters in different supporting domains for the two kinds of the pixels, wherein a filtering coefficient is adaptively determined according to noise intensity and an image local characteristic; (2) taking a single DCT coefficient or the sum of the several DCT coefficients as the characteristic, using AdaBoost as a tool to construct a cascade-form classifier and using the classifier to select a static block; (3) establishing a function model of connection between DCT coefficient distribution parameters of the video noise intensity and the static block and using the model to estimate the noise signal standard difference. By using noise intensity estimation embedded in the video encoder and a noise reduction technology provided in the invention, few computation costs can be used to acquire the parameters and the information needed by noise filtering. A time efficiency is good. Because a reliable clue is used to determine whether the pixels accord with a static hypothesis, the filter of the invention can effectively filter the noise and simultaneously maintain marginal sharpness of the static image. And motion blur caused by filtering in a motion area can be avoided.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Combination machining method for removing high-frequency errors in optical elements

ActiveCN102848287AImprove high frequency errorOptical surface grinding machinesEngineeringSpectral density

The invention discloses a combination machining method for removing high-frequency errors in optical elements. The combination machining method includes measuring surface shape errors of an optical element to be machined by an interferometer, carrying out PSD (power spectral density) analysis, and determining distribution characteristics of the medium and high-frequency errors on the basis of a DSD curve; acquiring an optimized removal function model according to predetermined machining time and machining precision, and acquiring an amplitude spectral line of a removal function; acquiring cut-off frequency of the removal function according to the amplitude spectral line; machining by a magneto-rheological finishing process if correctable medium and high-frequency errors with the frequency lower than the cut-off frequency exist according to the frequency distribution of the medium and high-frequency errors; and machining by a computer controlled optical surfacing process if uncorrectable medium and high-frequency errors with the frequency higher than the cut-off frequency exist according to the frequency distribution of the medium and high-frequency errors. By the combination machining method, technical advantages of MRF (magneto-rheological finishing) and technical advantages of CCOS (computer controlled optical surfacing) can be sufficiently combined, efficient uniform convergence of all-band errors of the optical element can be realized, and performance of the optical element is effectively improved.

Owner:NAT UNIV OF DEFENSE TECH

Blur function modeling for depth of field rendering

ActiveUS20110229052A1Large apertureTelevision system detailsImage enhancementDepth of fieldImage capture

A method and apparatus of depth of field rendering which simulates larger apertures for images captured at a smaller aperture. The depth of field rendering provides selective simulation of out-of-focus effects which are attainable with cameras having a larger aperture when capturing images at a smaller aperture. A blur function model is created based on the relationship between the blur change and the aperture change. This model is used to determine the blur difference which would arise between two images taken at two different apertures. Then the out-of-focus effect is generated by blurring the image in a rendering process based on the blur difference.

Owner:SONY CORP

A page generation method facing to Web application system

ActiveCN101676910AAdd customizable operationsIncrease flexibilitySpecial data processing applicationsDatabase interfaceWeb application

The invention discloses an automatic page generation method facing to Web application system. The method adopts Unified Modeling Language (UML) modeling technology and Extensive Makeup Language (XML) technology, and adopts FMDP model. The method includes steps of: generating a function model, an inner model, a database interface model and an expression model of the Web application system; generating system customized information based on the models, and concentrating in documents in format of XML to store in the system server terminal; and providing client subscriber a function of conveniently modifying the original customized information based on the customization needs. Customization of the Web application system is realized in the genuine meaning by the invention, and customized Web application system can be quickly generated by using the invention, and regulation of system demand can be realized on the premise of avoiding recompilation of the whole system, to improve the development efficiency of the Web software.

Owner:PEKING UNIV +2

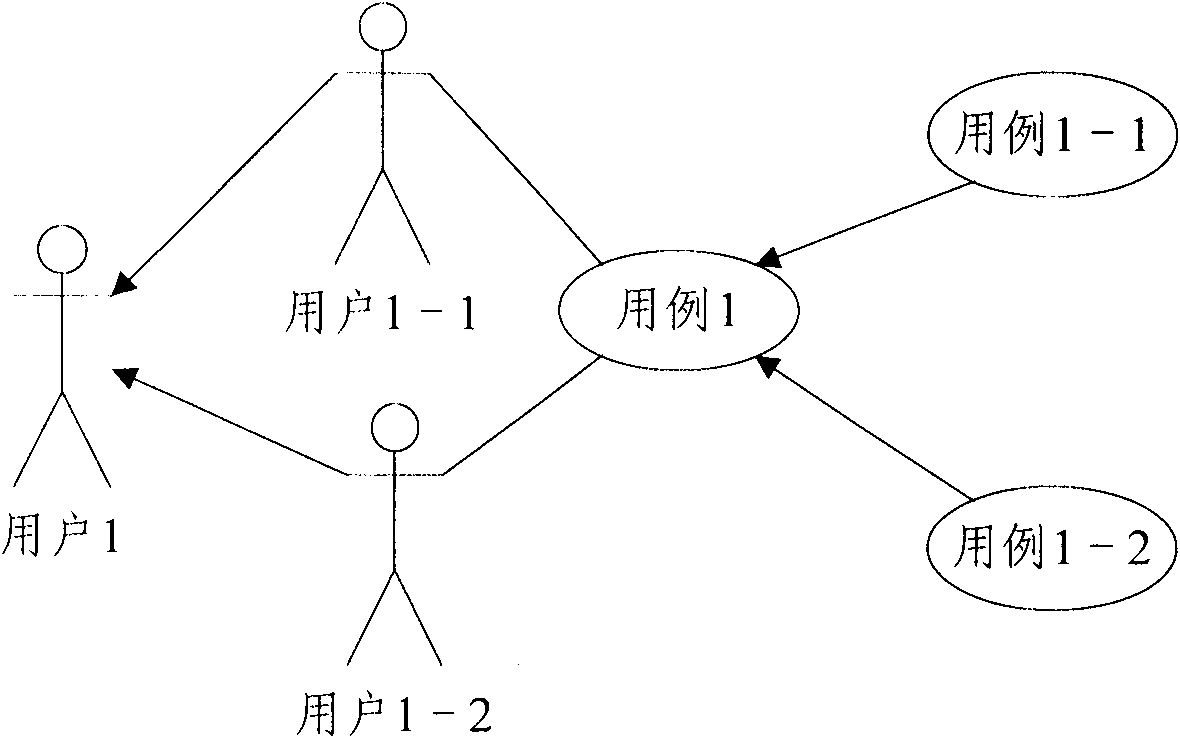

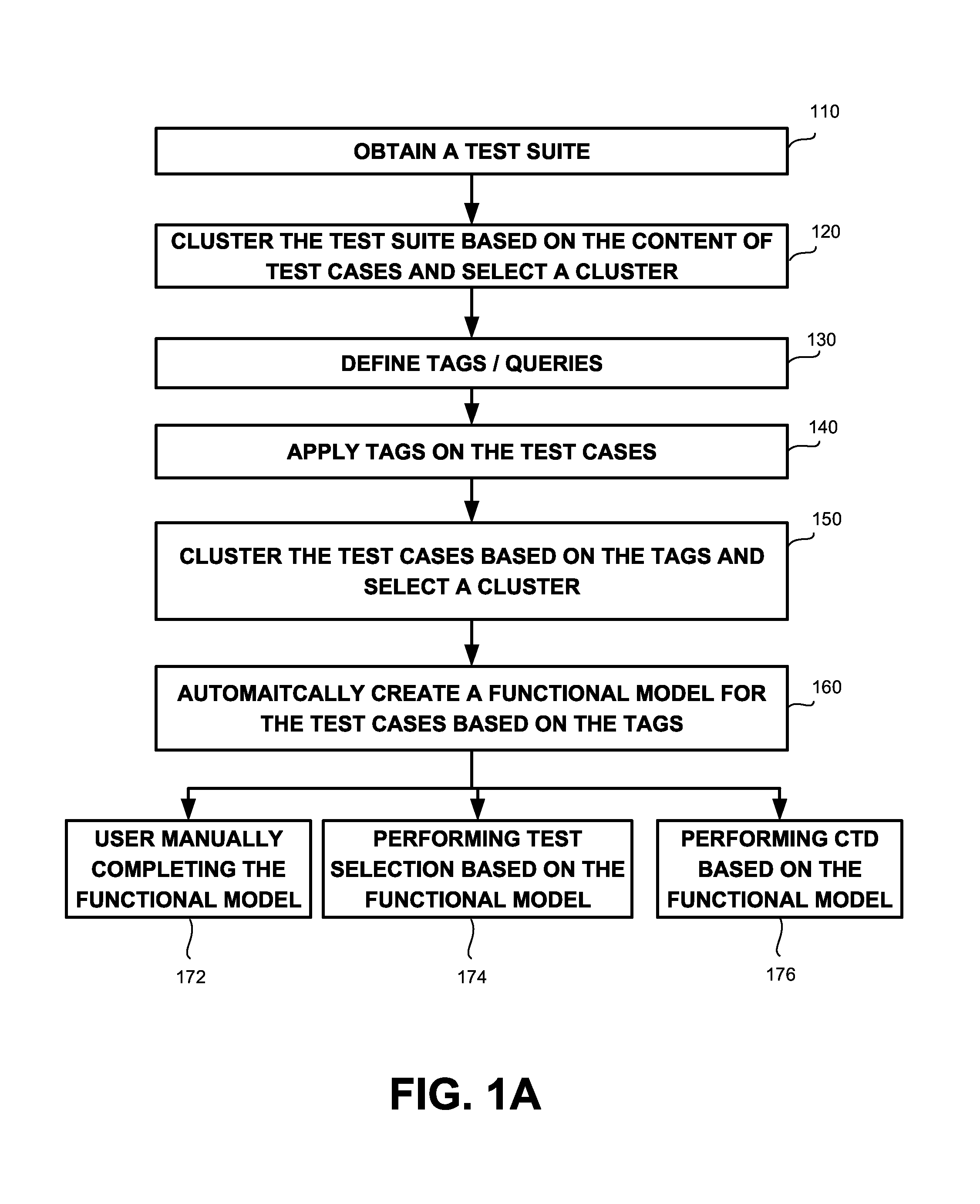

Method and system for creating functional model of test cases

A method, product and apparatus for creating functional model of test cases. The method comprising obtaining a set of test cases, wherein each test case of the set of test cases comprises free-text; defining one or more tags, wherein each tag of the one or more tags is associated with a query that is configured, when applied, to determine possession of the tag with respect to a test case based on the free-text; applying the queries on the set of test cases to determine possession of the of the one or more tags for each test case; and generating a functional model based on the set of test cases, wherein the functional model comprising for each tag of the one or more tags, a corresponding functional attribute.

Owner:AIRBNB

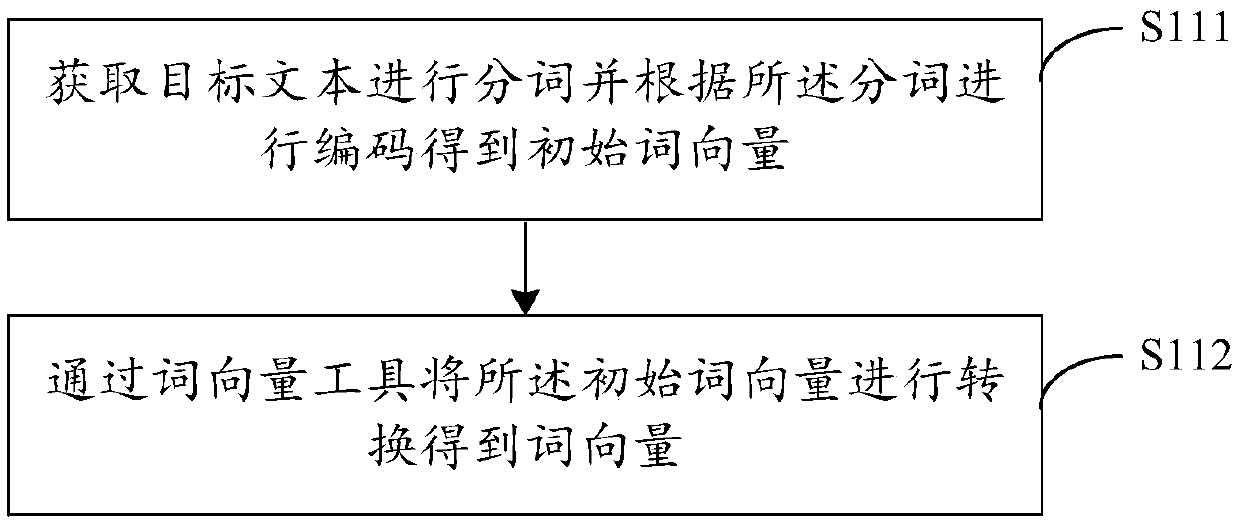

Text abstract generation method and device, computer equipment and storage medium

PendingCN109657051AHigh precisionImprove reading experienceNatural language data processingNeural architecturesTarget textComputer equipment

The embodiment of the invention discloses a text abstract generation method and device, computer equipment and a storage medium. The method is applied to the field of neural networks in prediction models. The method comprises the steps that a target text is preprocessed, and the preprocessed target text is converted through a word vector tool to obtain a word vector; Constructing a text abstract model taking coding and decoding as a framework, taking the word vectors as input of the text abstract model, and training the text abstract model in a loop iteration mode to output a sentence to be extracted; Preprocessing the to-be-processed text, converting the to-be-processed text into word vectors, inputting the word vectors of the to-be-processed text into the trained text abstract model, andoutputting a plurality of sentences to be extracted; And scoring the plurality of sentences to be extracted according to a preset scoring function model, and generating a text abstract according to the scores of the sentences to be extracted. By implementing the method provided by the embodiment of the invention, the text abstract can be quickly generated, and the precision of the text abstract is effectively improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

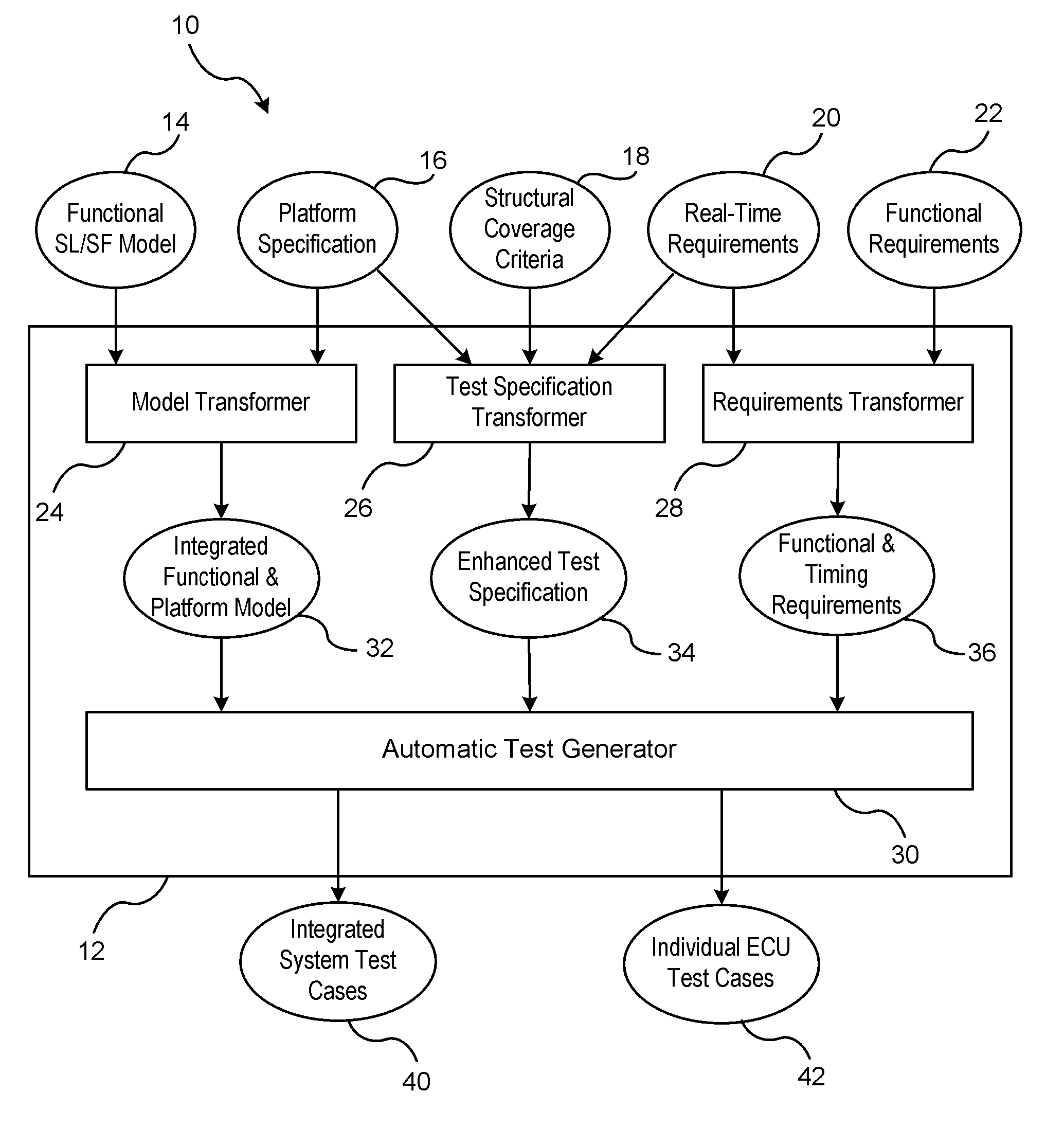

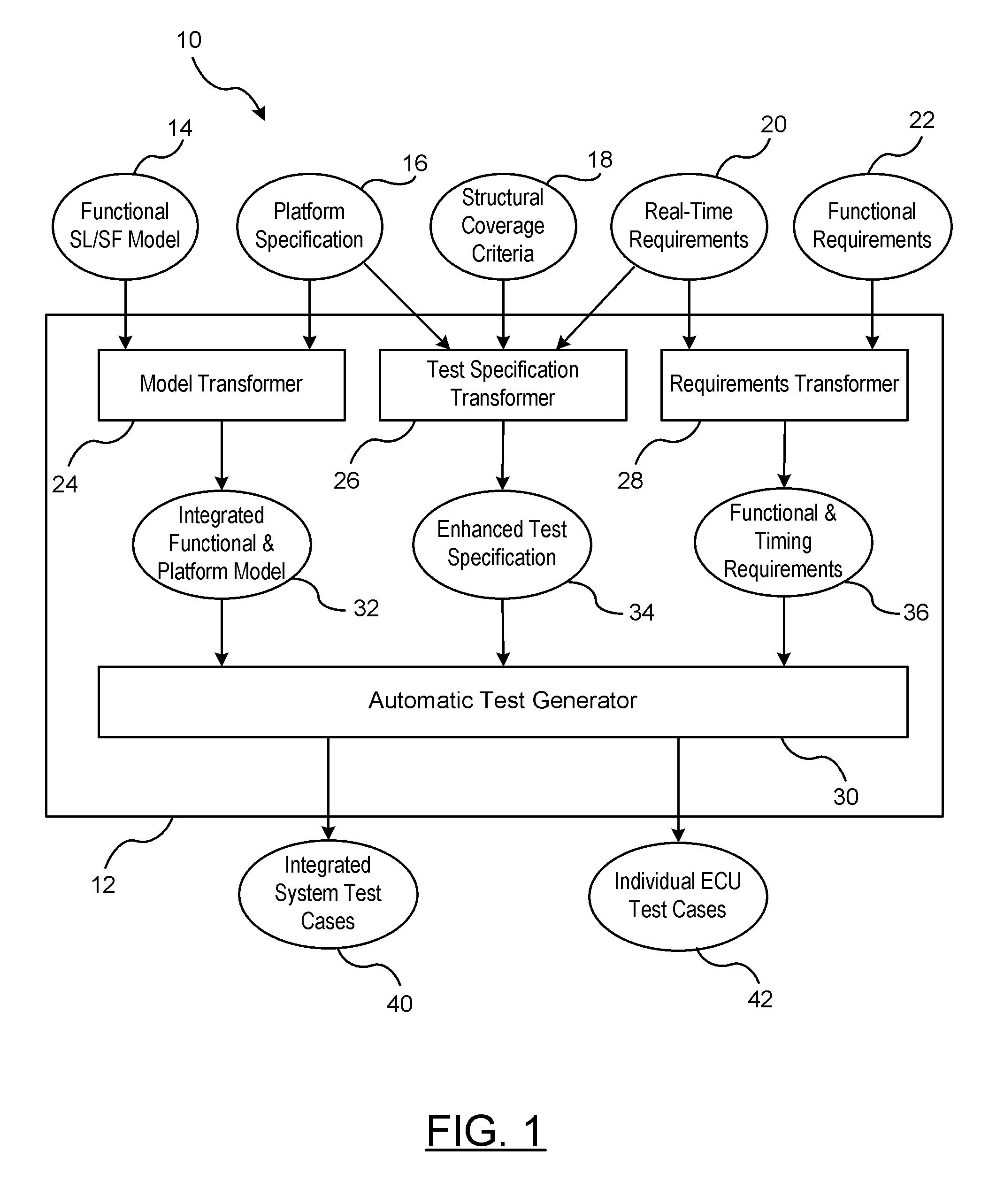

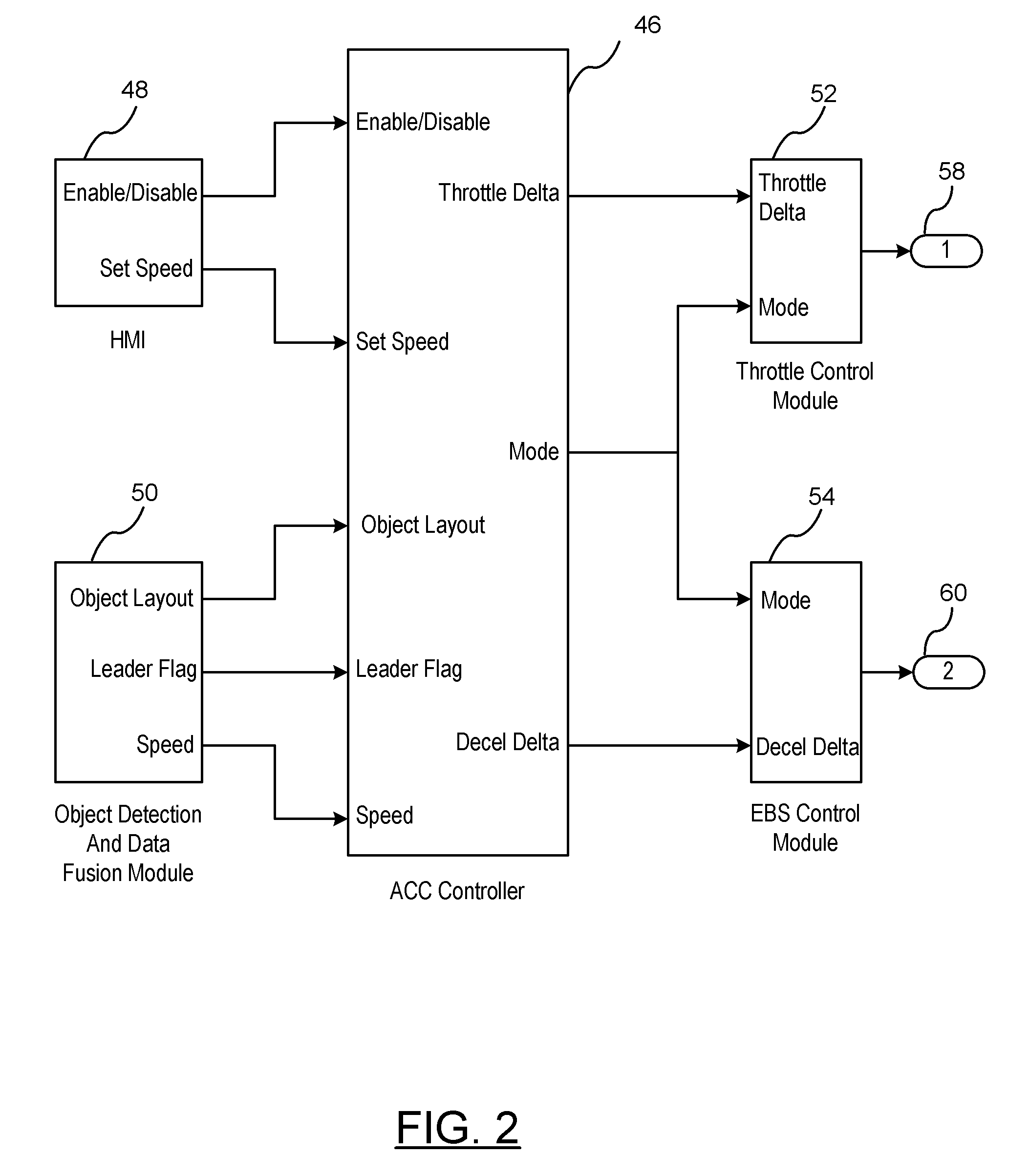

Method and System for Automatic Test-Case Generation for Distributed Embedded Systems

InactiveUS20110083121A1Error detection/correctionSpecific program execution arrangementsSystem integrationFault tolerance

An automatic test-case generation system generates test-cases for validating a test specification for timing constraints, fault tolerances, distributed deadlocks, and synchronization at a system integration level of a distributed system. The automatic test-case generation system includes a model transformer for integrating functional model and platform specification. The functional model relates to an abstract model of at least one controller and the platform specification relates to details of platform components. A test specification transformer integrates platform specification, real-time requirements, and structural coverage criteria for generating an enhanced test specification for testing the distributed system. A requirements transformer integrates real-time requirements and functional requirements for the distributed system. An automatic test-case generator generates a set of test-cases that validate the test specifications of the distributed system as a function of the outputs of the model transformer, test specification transformer, and requirements transformer.

Owner:GM GLOBAL TECH OPERATIONS LLC

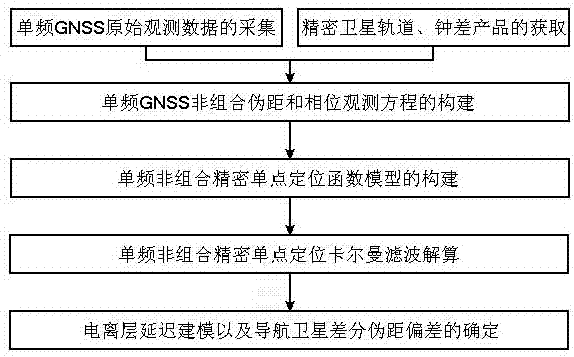

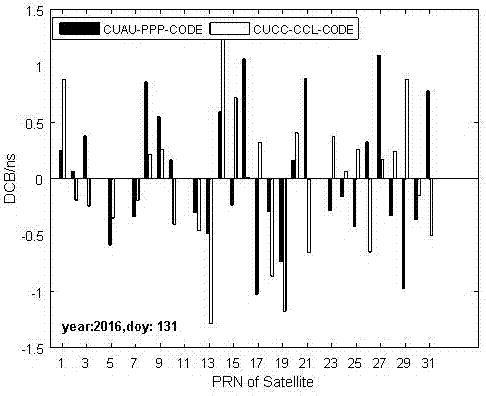

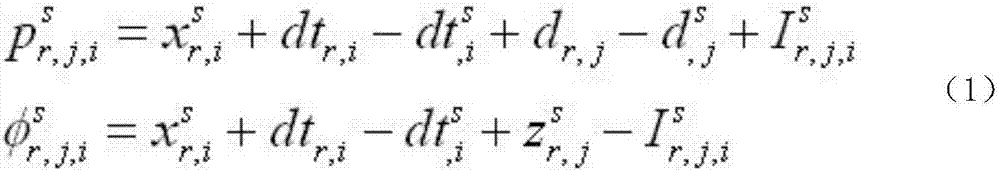

Method for determining satellite differential pseudo-range deviation based on single-frequency navigation satellite data

The invention discloses a method for determining the satellite differentia pseudo-range deviation based on single-frequency navigation satellite data, and relates to a satellite differential pseudo-range deviation determination and correction technology in satellite navigation applications. The method comprises the steps of A, acquiring single-frequency GNSS original observation data and obtaining precision satellite orbit and clock error products; B, building single-frequency GNSS non-combination pseudo-range and phase observation equations; C, building a single-frequency non-combination precision single-point positioning function model; D, solving single-frequency non-combination precision single-point positioning Kalman filtering; and E, performing ionospheric delay modeling and determining the navigation satellite differential pseudo-range deviation. Determination for navigation satellite differential pseudo-range deviation parameters is realized by using a single-frequency receiver, and the hardware cost of an existing navigation satellite differential pseudo-range deviation estimation method can be reduced by more than 90%. Meanwhile, the method is reasonable and simple in design and improves the efficiency. The design is not only low in cost, but also high in efficiency.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

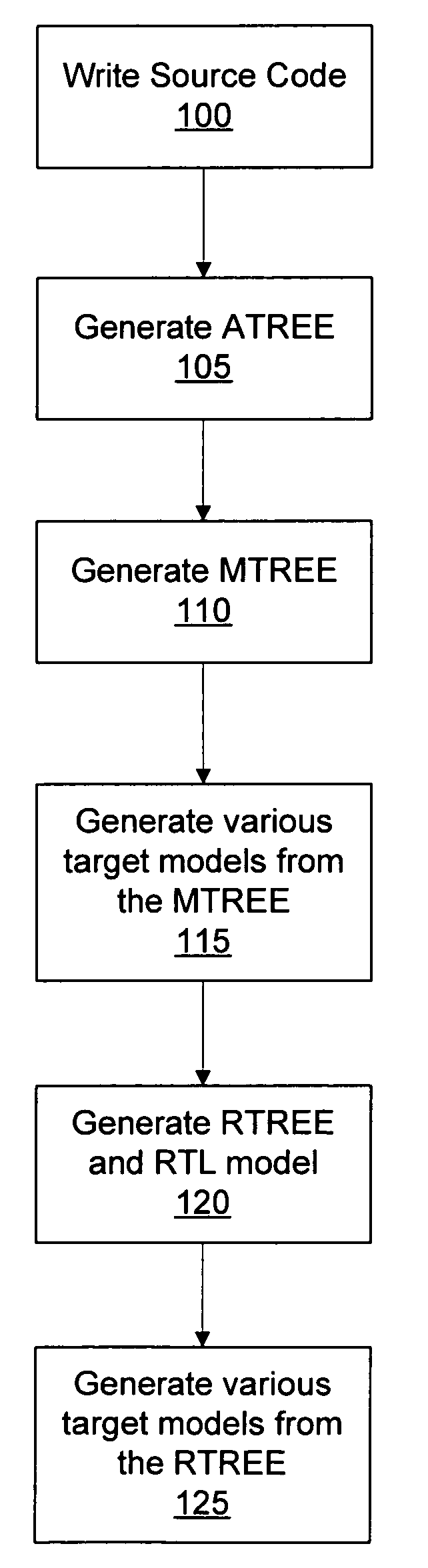

Building integrated circuits using a common database

InactiveUS7363610B2Improved performance per watt of power consumptionCAD circuit designSoftware simulation/interpretation/emulationComputer architectureHigh-level programming language

Systems and methods for designing and generating integrated circuits using a high-level language are described. The high-level language is used to generate performance models, functional models, synthesizable register transfer level code defining the integrated circuit, and verification environments. The high-level language may be used to generate templates for custom computation logical units for specific user-determined functionality. The high-level language and compiler permit optimizations for power savings and custom circuit layout, resulting in integrated circuits with improved performance per watt of power consumption.

Owner:NVIDIA CORP

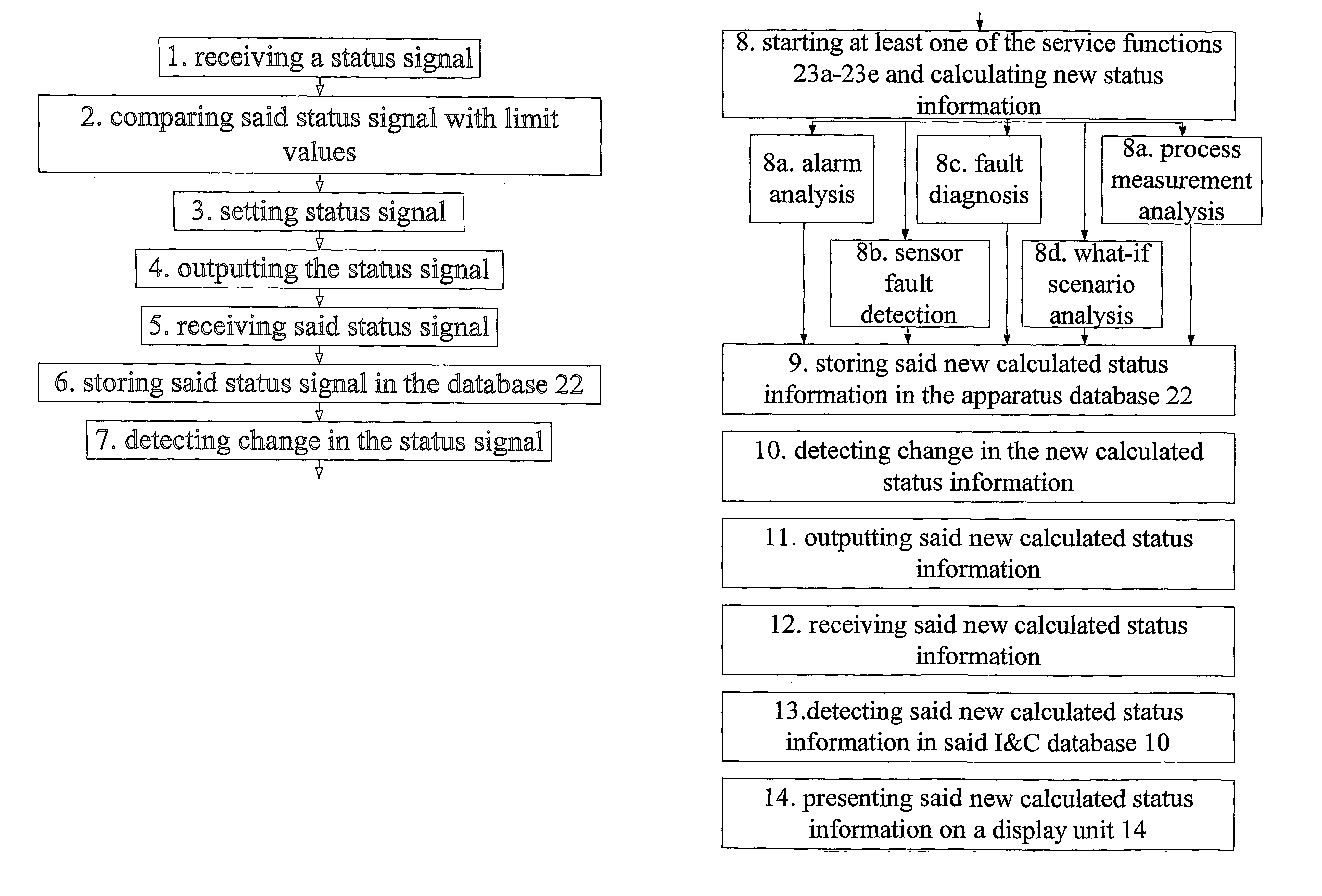

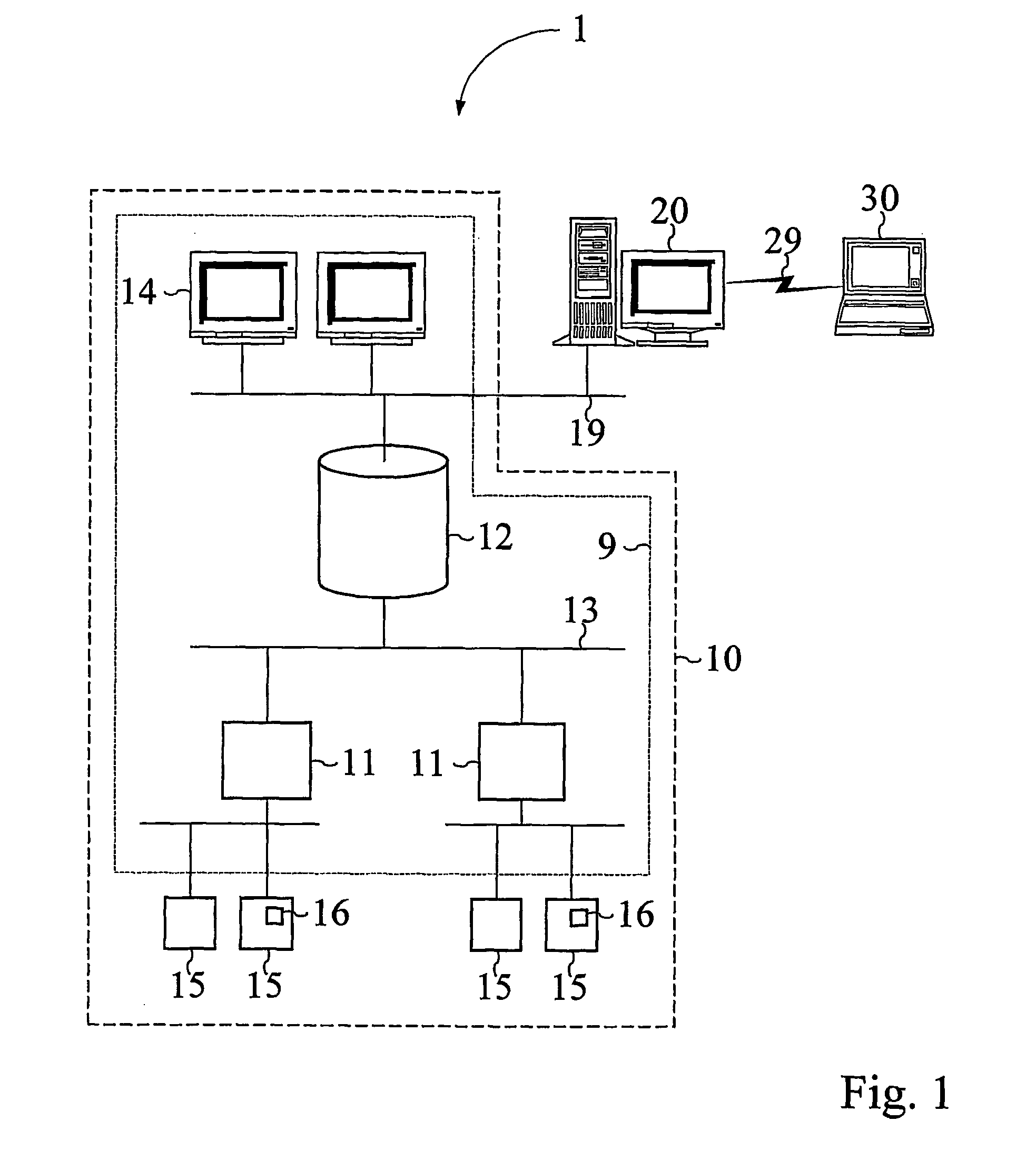

System apparatus and method for diagnosing a flow system

InactiveUS20040133289A1Correct and quick measureImprove understandingSafety arrangmentsComputer controlStopped workProcess measurement

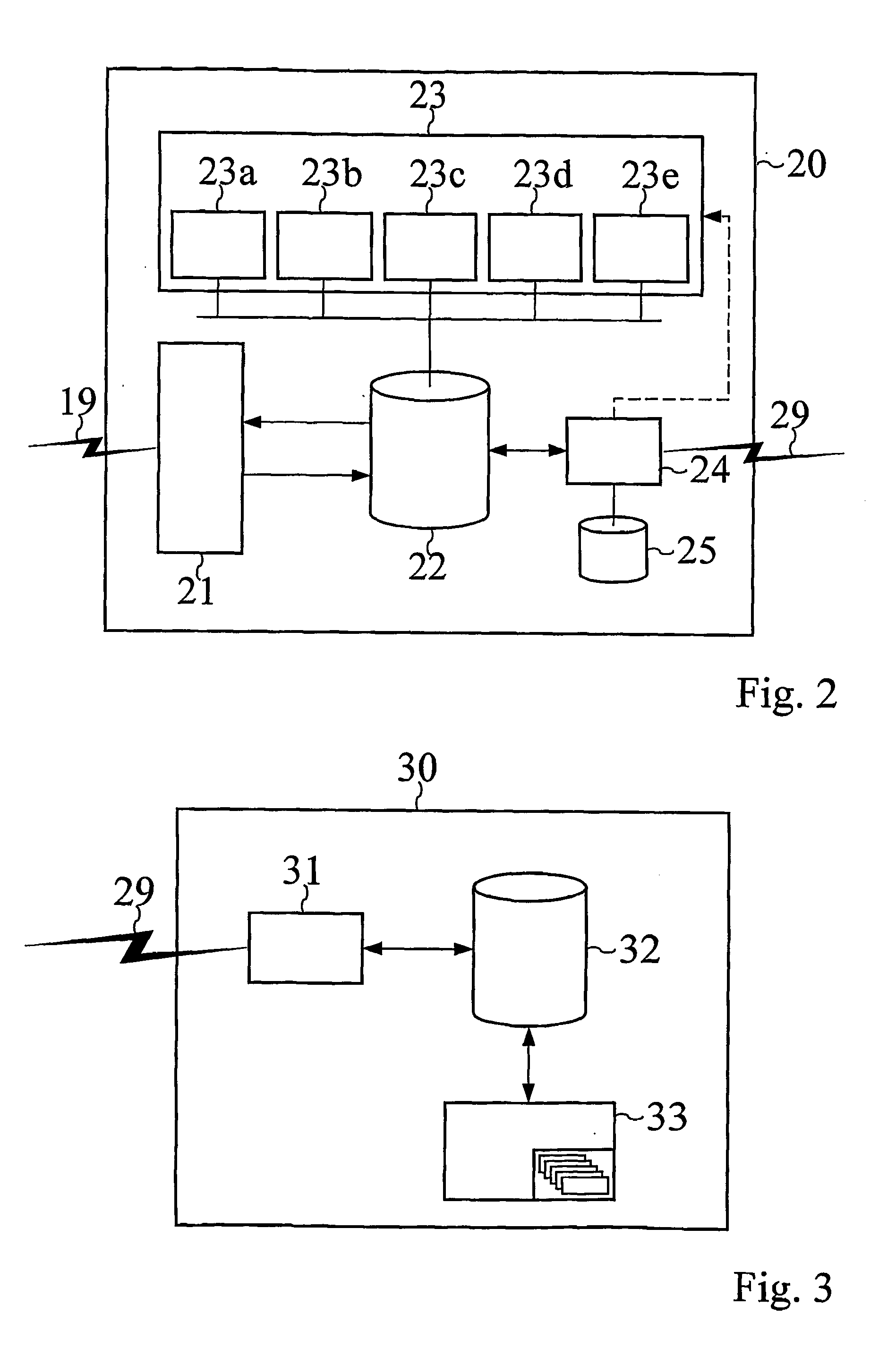

The present invention deals with diagnosing of a flow system, using status signals carrying information about said flow system, whereby new status information is generated, which relates to a plurality of aspects of the flow system based on said status signals and dependent on a functional model and on a set of predetermined rules. The invention comprises a diagnostic apparatus (20) arranged to analyze the status signals for example by means of an alarm analyzer (23a) arranged to separate alarms into primary and secondary alarms, a sensor fault detector (23b) arranged to detect sensor values that probably are wrong or a fault diagnozer (23c) arranged to find the root causes for unfulfilled goals. Further the invention can comprise a failure mode analyzer (23d) arranged to detect functions that can stop working in the future or a process measurement analyzer (23e) arranged to analyze the status signals of a specific process.

Owner:GOALART

Wireless sensor network temperature monitoring method based on improved Kriging algorithm

ActiveCN106714336AThe science of predicting outcomesEnergy saving life cycleThermometer detailsTransmission systemsTerrainStructure analysis

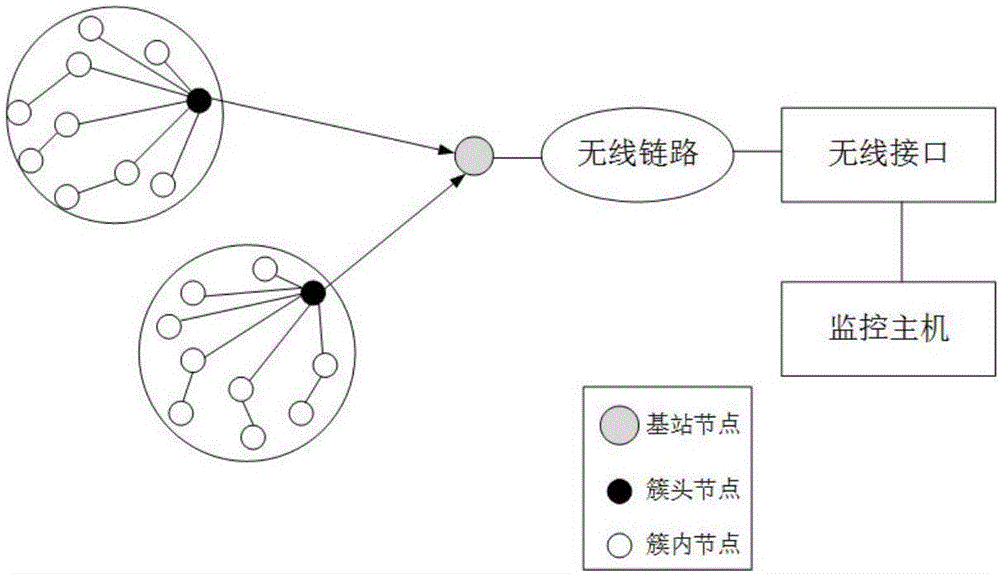

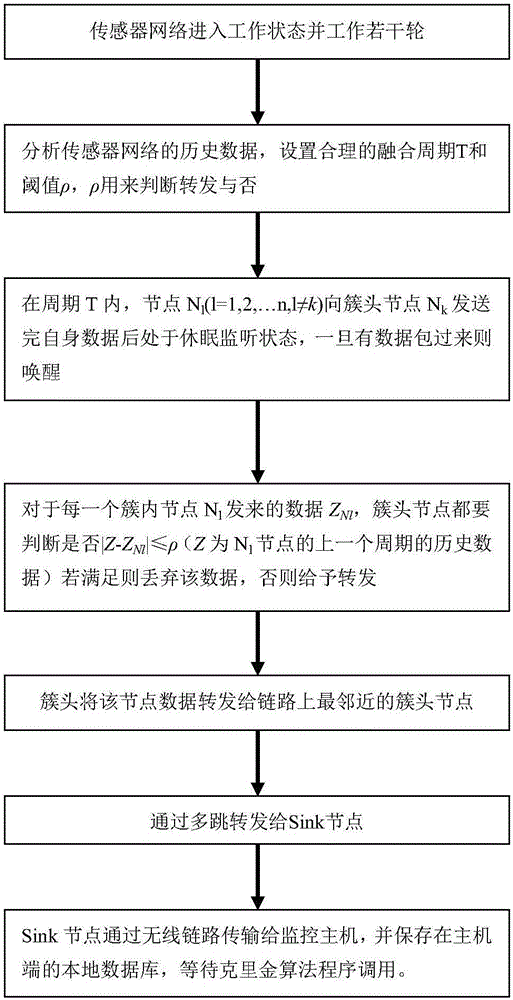

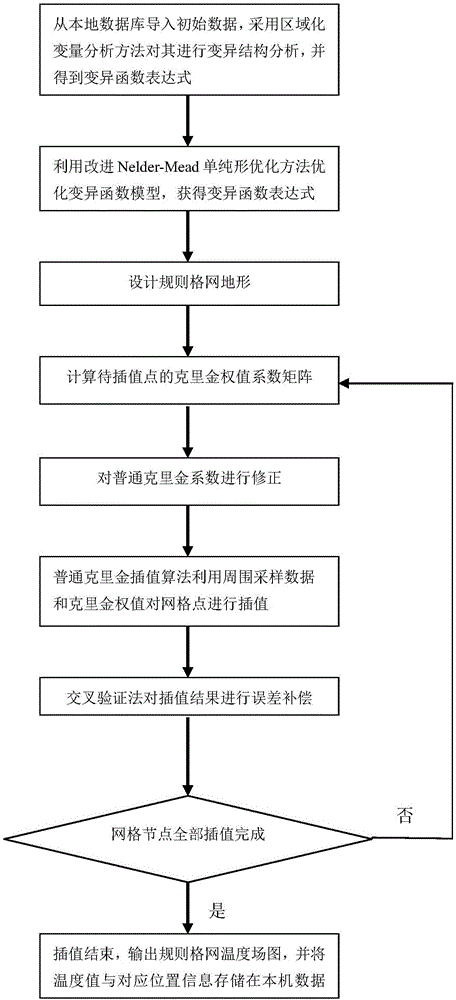

The invention discloses a wireless sensor network temperature monitoring method based on an improved Kriging algorithm. The wireless sensor network temperature monitoring method comprises the steps of: firstly, establishing a layer cluster type wireless sensor network topological structure, analyzing historical temperature data of a target region, setting a threshold value rho and a fusion cycle T, performing periodic fusion on in-cluster node data at a cluster head node based on the threshold value rho, acquiring initial temperature data, transmitting the initial temperature data to a monitoring host by means of a wireless link and saving the initial temperature data in a local database; importing the initial temperature data, and performing variable structure analysis on the initial temperature data to generate a variation function expression; and optimizing a variation function model by utilizing an improved Nelder-Mead simplex method, designing a regular grid terrain, performing temperature interpolation by adopting an ordinary Kriging algorithm, carrying out error correction, and outputting a regular grid temperature field pattern. The wireless sensor network temperature monitoring method optimizes the variation function model by utilizing the improved Nelder-Mead simplex method, corrects weights of the ordinary Kriging algorithm, performs error compensation on the interpolation result, and makes the interpolation result more scientific and closer to the actual situation.

Owner:NANJING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com