Multi-chamber rotary furnace and numerical simulation method for performing catalyst particle heating

A rotary kiln and catalyst technology, applied in 3D modeling, image data processing, electrical digital data processing, etc., can solve the problems of difficult determination of related parameters, time-consuming and labor-intensive, difficult and other problems, and achieve good drying effect, low energy consumption, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

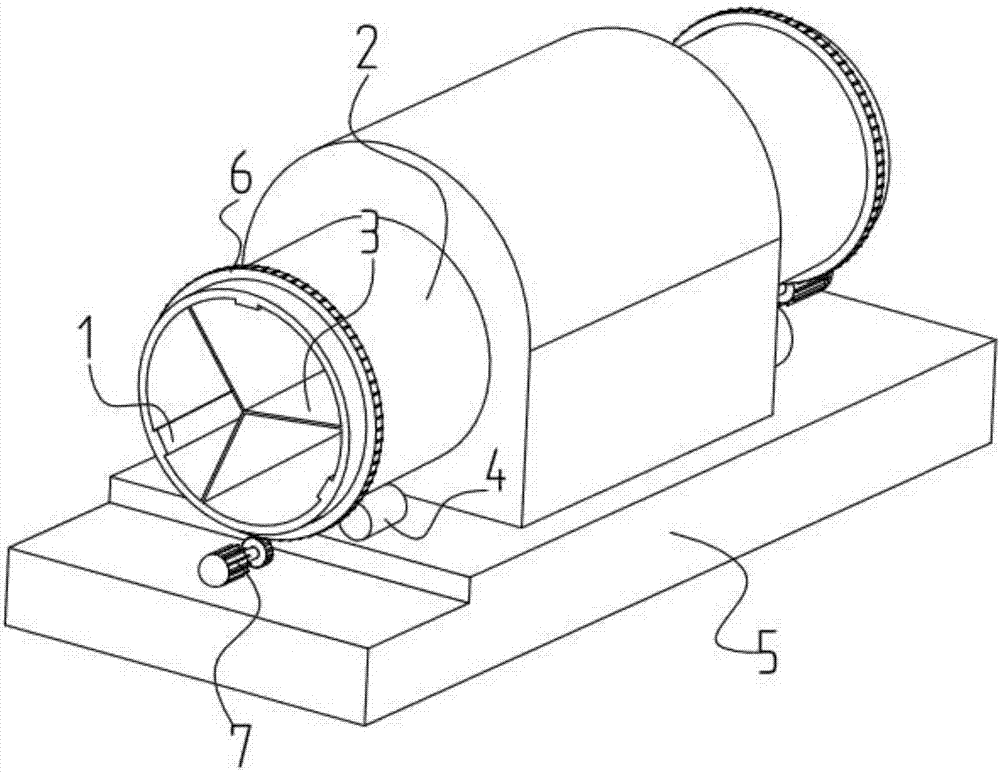

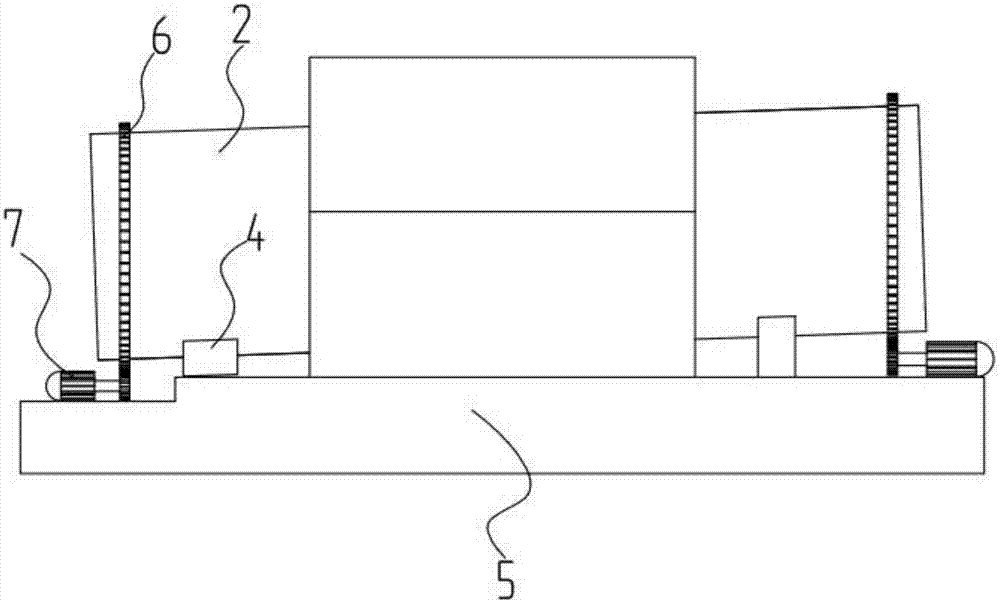

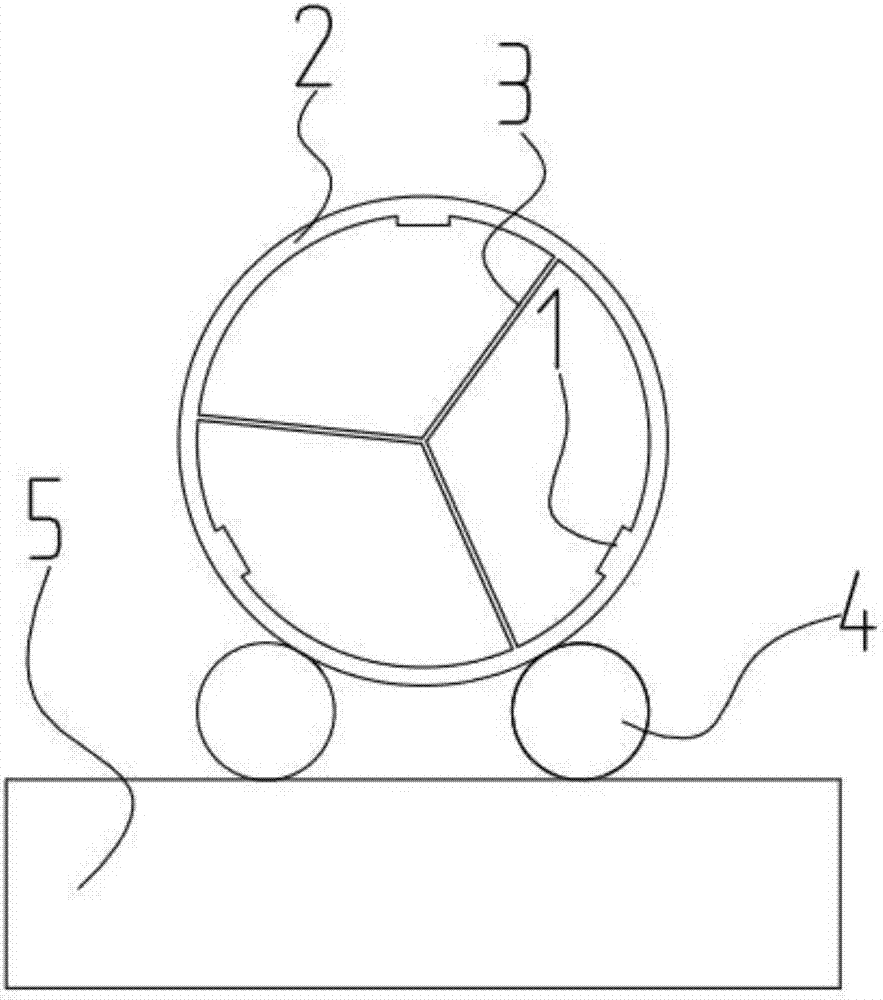

[0046] In this example, see Figure 1~4 , a multi-chamber rotary furnace, including a combustion chamber, a rotary furnace body 2 and a support platform 5, the front and rear ends of the rotary furnace body 2 are rotatably mounted on the support platform 5, and the hot end of the heating device 9 arranged in the combustion chamber The heating section of the rotary furnace body 2 can be heated. The rotary furnace body 2 is rotatably installed in the combustion chamber. The outer wall of the front end of the rotary furnace body 2 outside the room is fixedly connected to the outer ring gear 6, and the drive motor 7 is fixedly installed on the support table 5. The drive motor 7 drives the outer ring gear 6 through the gear transmission mechanism, and then drives the rotary furnace body 2 to rotate. Three heat conducting plates 3 are fixedly installed in the inner cavity of the rotary furnace body 2, and each heat conducting plate 3 is extended and installed along the axis of the r...

Embodiment 2

[0082] This embodiment is basically the same as Embodiment 1, especially in that:

[0083]In this embodiment, the number of heat conducting plates 3 is 4 pieces, the angle between any two adjacent heat conducting plates 3 is 90°, and the inner cavity of the rotary furnace body 2 is evenly divided into 4 equal parts; and The number of plates 1 is four. On the basis of the multi-chamber rotary furnace in this embodiment, the numerical simulation method of catalyst particle heating is carried out, and the computational fluid dynamics software CFX is used to numerically calculate the heating process of the catalyst material in the gas-fired multi-chamber rotary furnace and the accompanying heat transfer process, and also To a certain extent, it avoids the high cost and technical risks caused by experiments or blind design, and has certain guiding significance for the actual operating conditions of multi-chamber rotary furnaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com