Brake structure of chain saw and chain saw

A chain saw and brake technology, applied in the field of chain saw braking, can solve the problems of complexity, the overall structure of the chain saw brake device is complicated, and achieve the effect of solving internal space problems, wide market application and promotion prospects, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

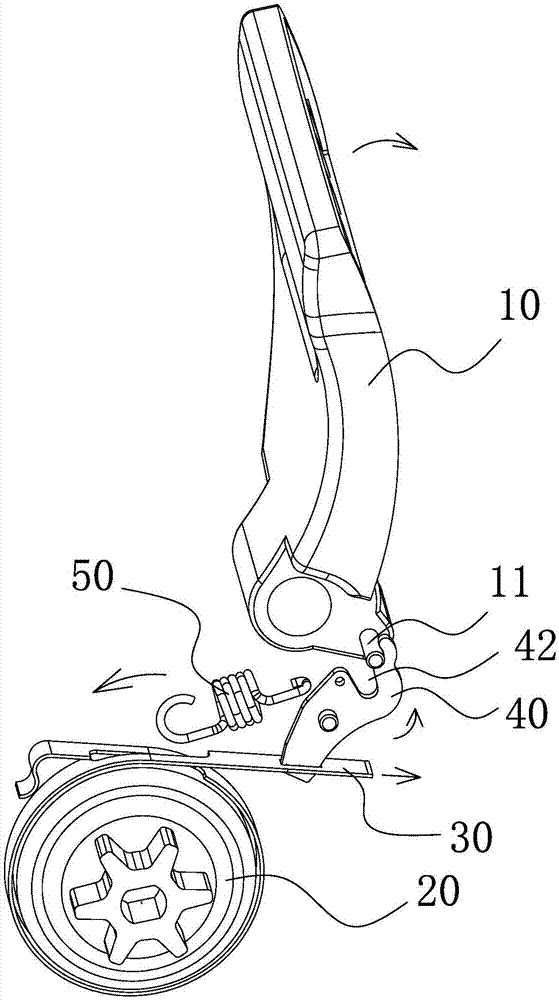

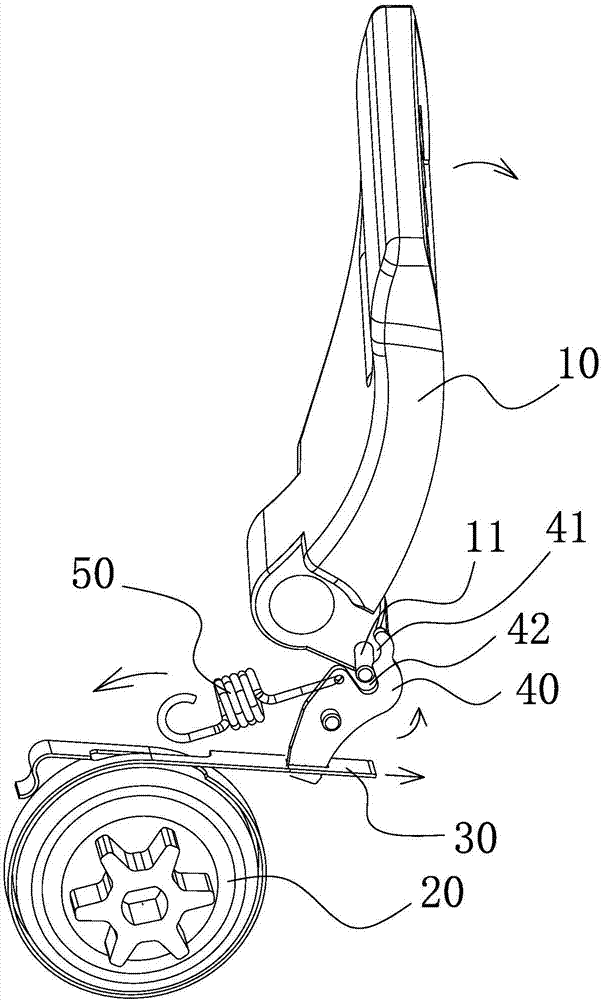

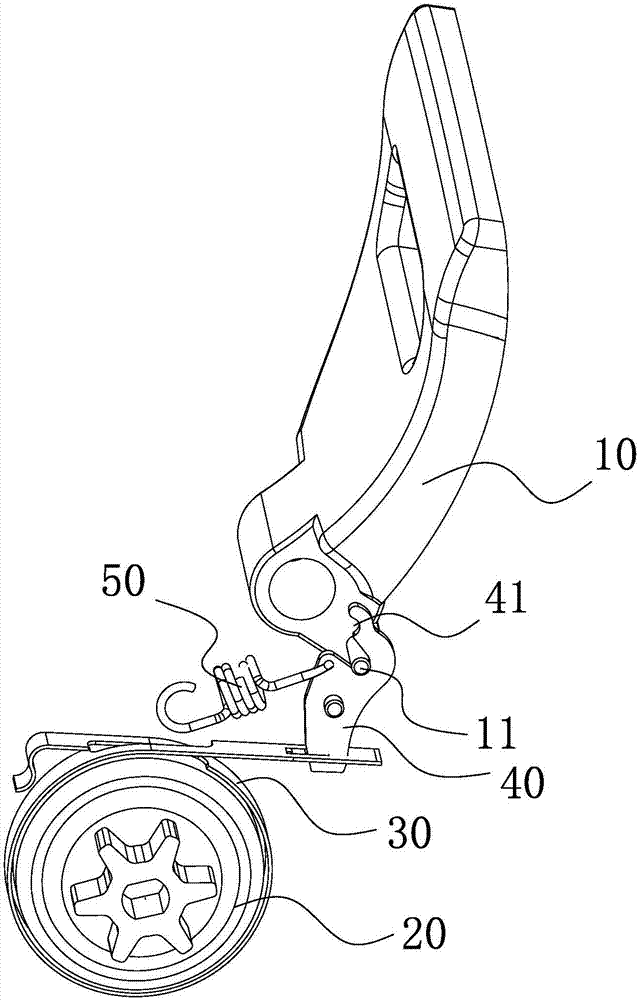

[0025] Combine below Figure 1 to Figure 4 The technical solution provided by the present invention is described in more detail.

[0026] Such as Figure 1 to Figure 3 As shown, the brake structure of this chain saw includes:

[0027] Chainsaw frame (not shown in the figure);

[0028] The protective plate 10 is hinged on the chainsaw frame and the lower end thereof is provided with a limit column 11;

[0029] The brake disc 20 is tightly surrounded by a brake steel belt 30 on the periphery of the brake disc 20;

[0030] Brake 40, the middle of which is hinged on the chainsaw frame, the lower end of the brake 40 is connected with the brake steel belt 30, and the upper end is provided with a limit groove 41 adapted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com