Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Achieve corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

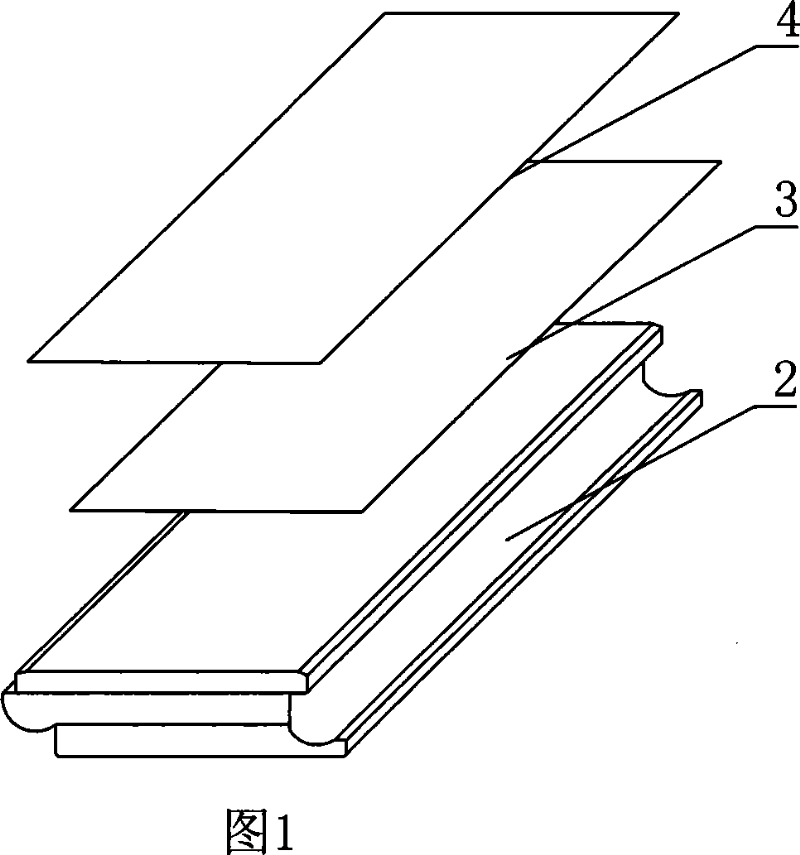

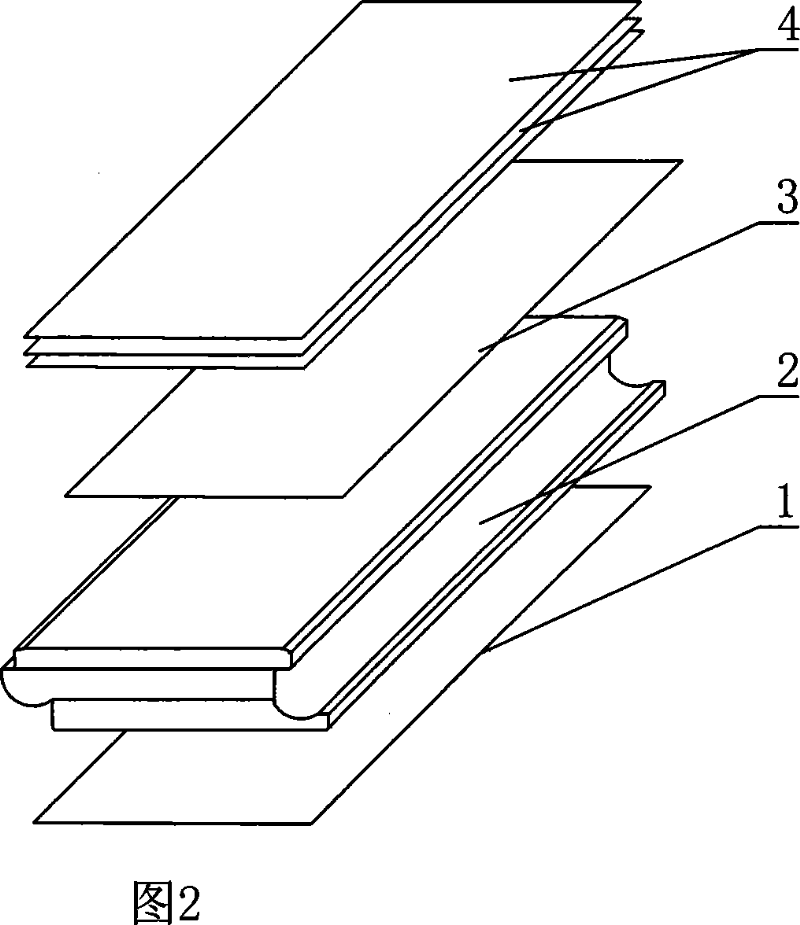

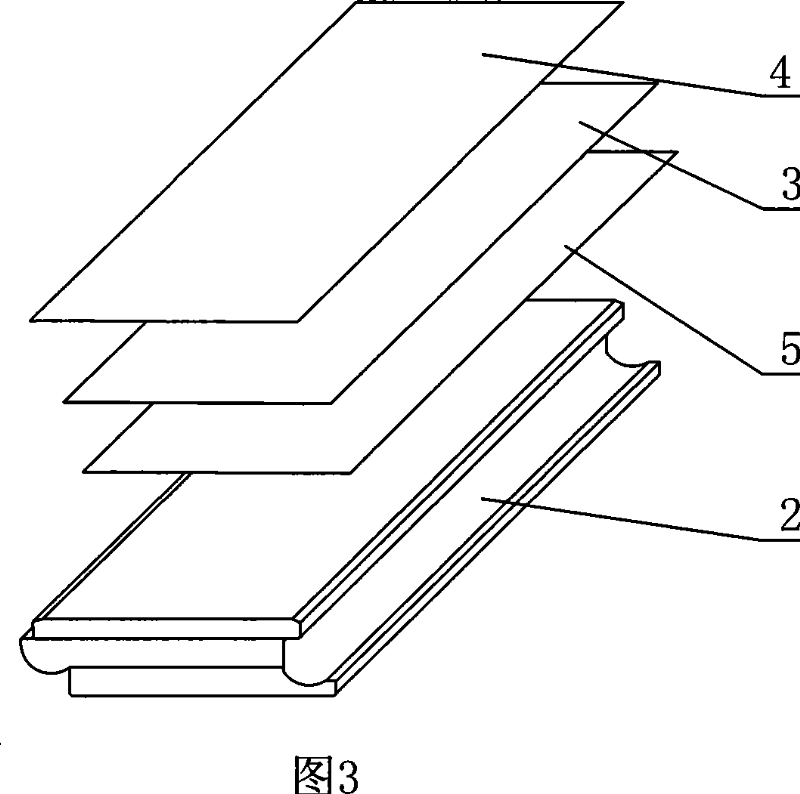

Method for making water-proof floor

A water proof floor is made by dipping 1-3 pieces of anti wearing paper and decorative paper into melamine and dried, applying 2MPa-10MPa pressure with the heating press with these two kinds of paper stacked, in the temperature of 185deg.C-230deg.C, keeping the pressure for 25-60s and cooling naturally to form into the panel, roughening the upper surface of the wood slab or free wax fiber slab to form into uneven surface, applying adhesive agent on the upper surface of the slab, one side of the decorative paper of the panel attached on the up surface of the slab, applying 15MPa-45MPa pressure in normal temperature for 15-60 minutes, sticking the panel to the slab to make a big plate, cutting the big plate to the required strip, having key way vertically and horizontally to make the final product. The floor is not only anti wearing, and water proof, it is also being anti shock, fire resistant, anti erosion, and environment protective in nature.

Owner:高建忠

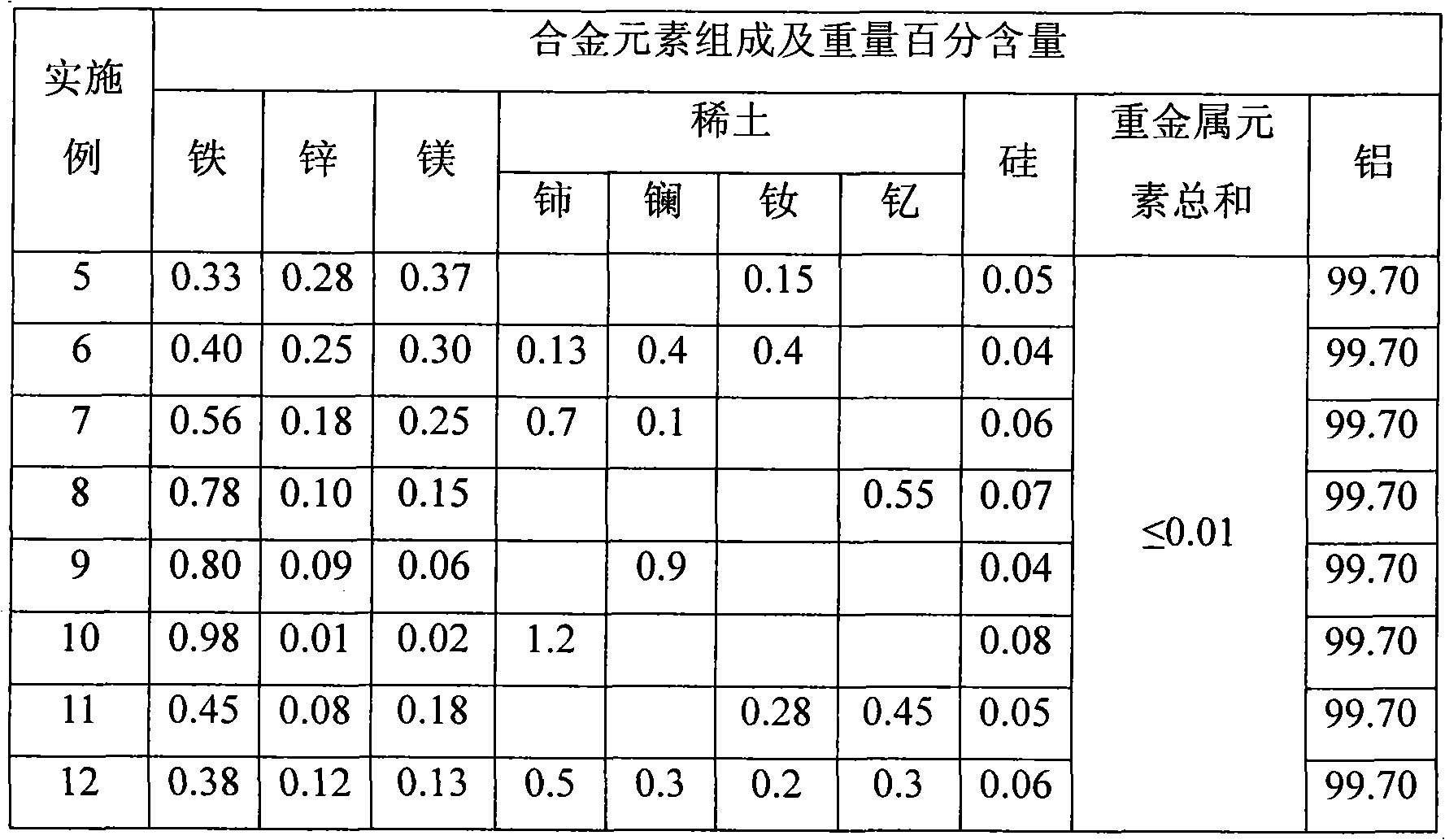

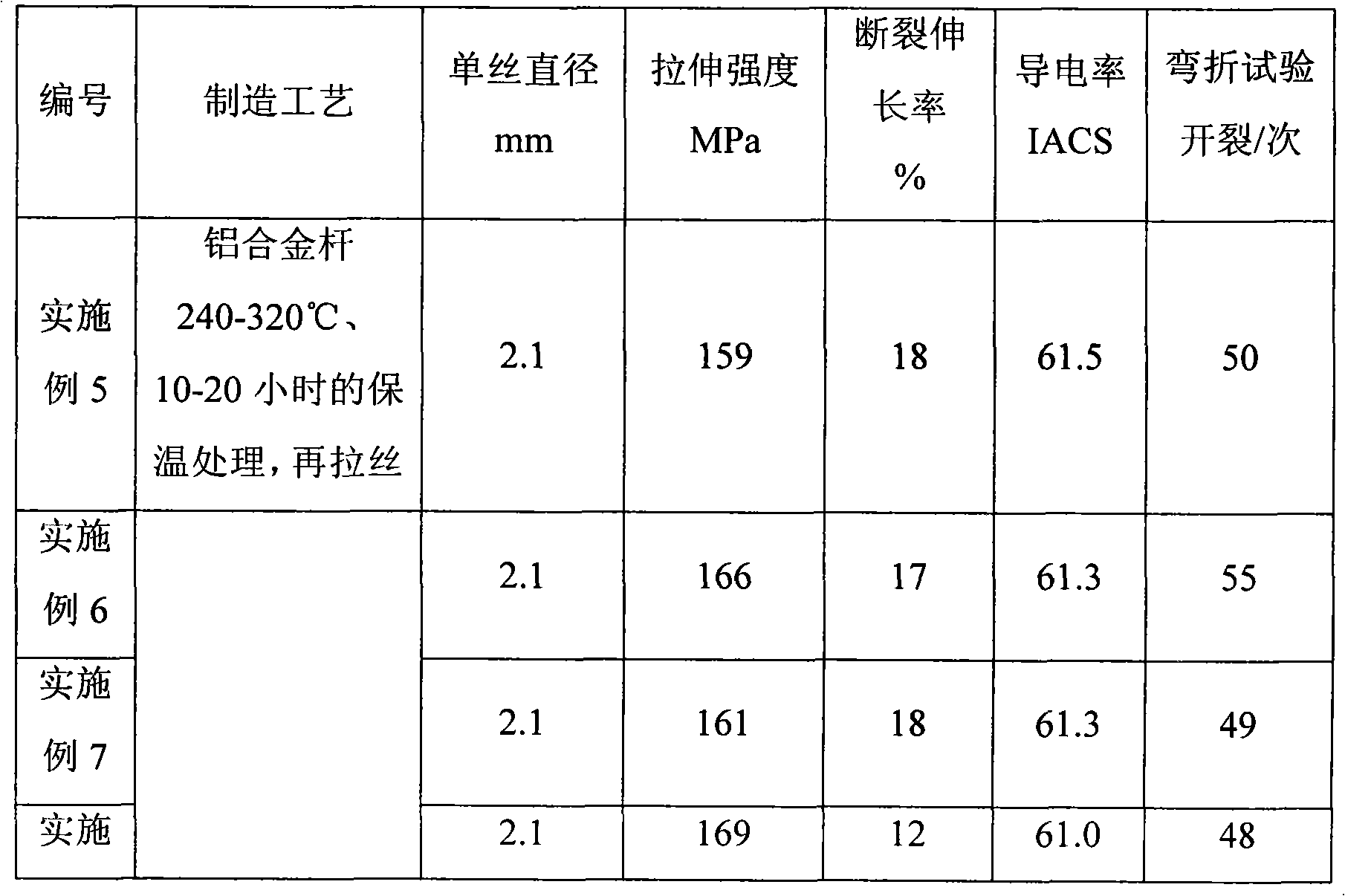

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

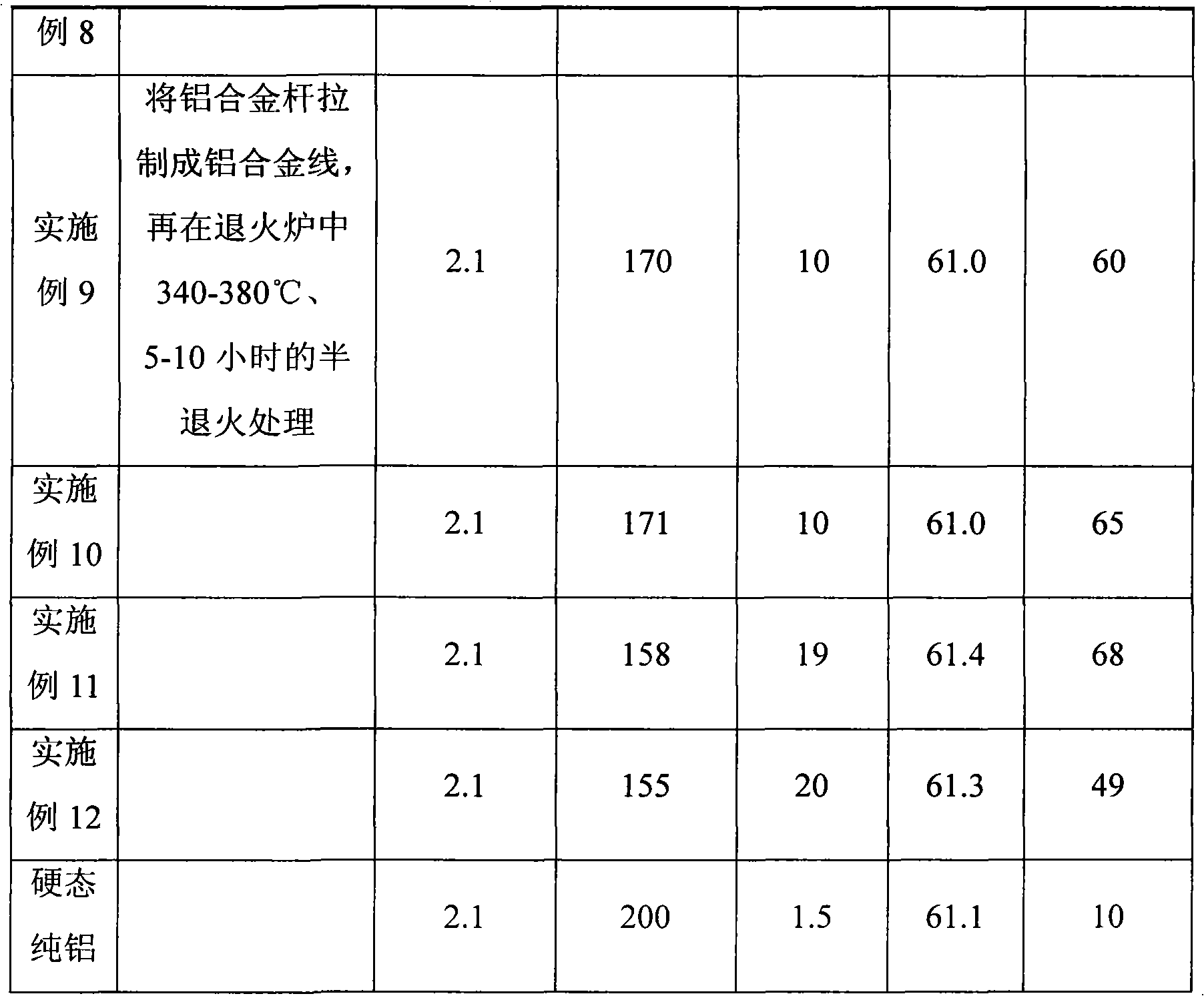

Method for preparing composite nano film on metal surface

InactiveCN101914797AReduce defectsImprove hydrophobicityElectrolytic organic material coatingElectrolysisMetallic materials

The invention discloses a method for preparing a composite nano film on a metal surface and realizes the preparation of the composite nano film by combining electrolysis polymerization with nano self-assembly technology. The method comprises the following steps of: electrolyzing and polymerizing a macromolecular initial-layer nano film bonded with the metal surface through a covalent bond on a cleaned metal surface by an electrolysis polymerization method; and then immersing the macromolecular initial-layer nano film into self-assembly solution and assembling and forming a polymeric macromolecular nano film bonded with an initial-layer macromolecular nano film through a covalent bond by nano self-assembling technology. Due the adoption of the method, the conversion of the metal surface from hydrophilcity to hydrophobicity is realized, the less defects, strong hydrophobicity, corrosion resistance and strong adhesiveness of a modified metal surface are achieved and effective long-term protection for metal materials is realized.

Owner:NORTHWEST A & F UNIV

Preparation method of biodegradable magnesium alloy surface-modified hydroxyapatite coating

InactiveCN103446627AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a preparation method of a biodegradable magnesium alloy surface-modified hydroxyapatite coating. The method specifically comprises the following steps: cutting the magnesium alloy into samples; polishing the samples by aluminum oxide water-resistant abrasive paper to remove surface oxide layers of the magnesium alloy; sequentially ultrasonic-cleaning with deionized water and absolute ethyl alcohol for 5-30 minutes, and drying at room temperature; preparing a conversion liquid by adopting sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate; controlling the molar ratio of calcium and phosphorus at (1:1)-(2:1), the concentration of Ca<2+> at 0.01-0.2M and the P<5+> concentration at 0.01-0.2M; placing pre-treated matrix sample in the conversion liquid to be soaked for 5-100 hours to obtain a calcium and phosphorus coating; preparing the hydroxyapatite coating through the calcium and phosphorus coating by adopting a thermal treatment process: soaking the samples in calcium and phosphorus liquor for 24-72 hours; taking out and directly placing in a Muffle furnace; carrying out thermal treatment at 250-350 DEG C for 2-5 hours; detecting performance. According to the method provided by the invention, the samples taken out from the calcium and phosphorus liquor are placed in the Muffle furnace for direct thermal treatment, so that the method is simpler and easier to operate and control, and the samples can be converted into the hydroxyapatite coating to achieve a considerable corrosion resistant effect.

Owner:TONGJI UNIV

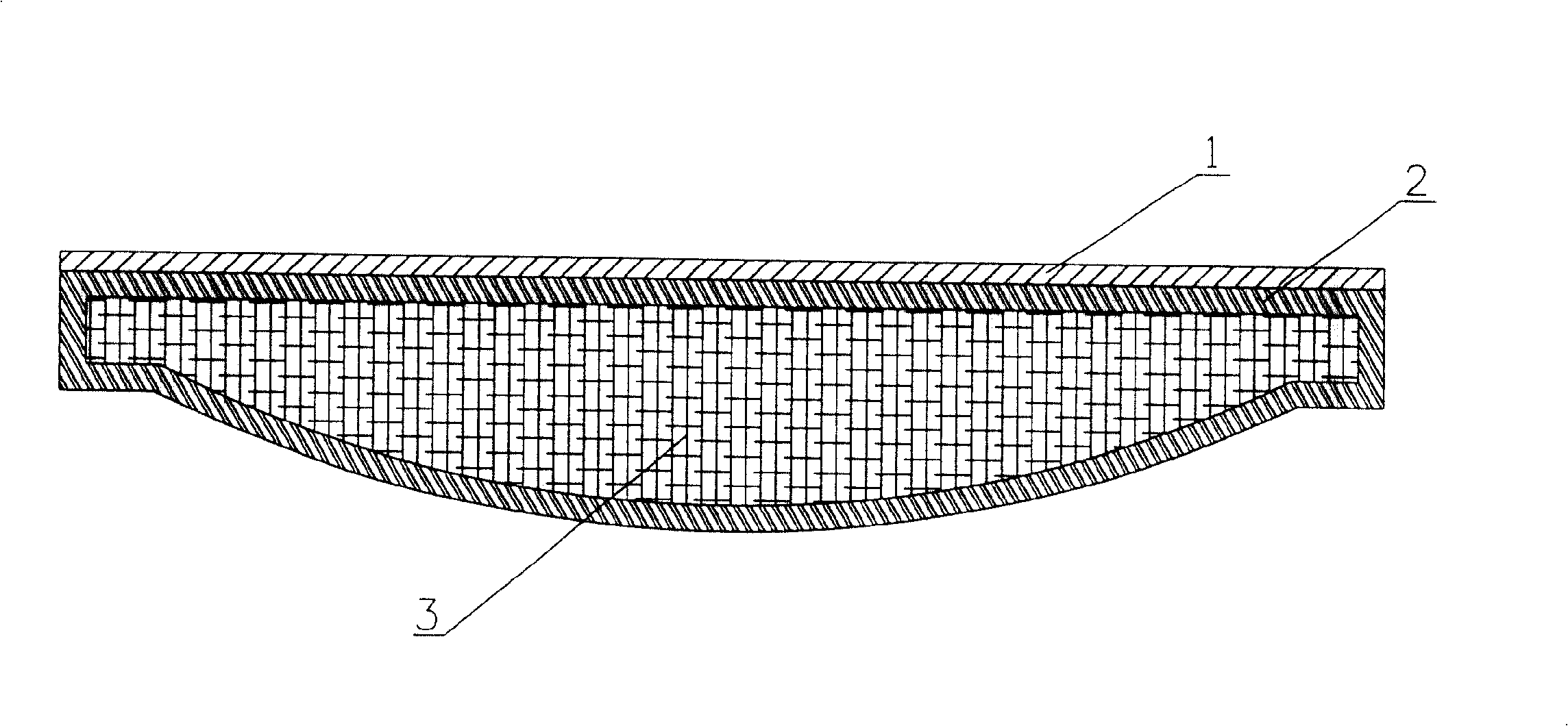

Fiber reinforced resin base composite material manhole cover

InactiveCN1648356AHigh compressive strengthImprove toughnessArtificial islandsUnderwater structuresPolyester resinResin-Based Composite

The present invention relates to manhole cover of composite thermoset resin base material, and especially a kind of manhole well of pre-soaked FRP rib and polyester cemented quartz mortar. The manhole cover has reinforcing ribs of pre-soaked FRP, and its material includes polyester resin 10-30 wt%, pre-soaked FRP ribs 1-8 wt%, aggregate 40-75 wt%, stuffing 5-30 wt%, and nanometer material 1-8 wt%. The manhole cover has high compression strength, high toughness, high impact strength and less damage and cracking, is anticorrosive and noise-less, and may be colorized.

Owner:廖国

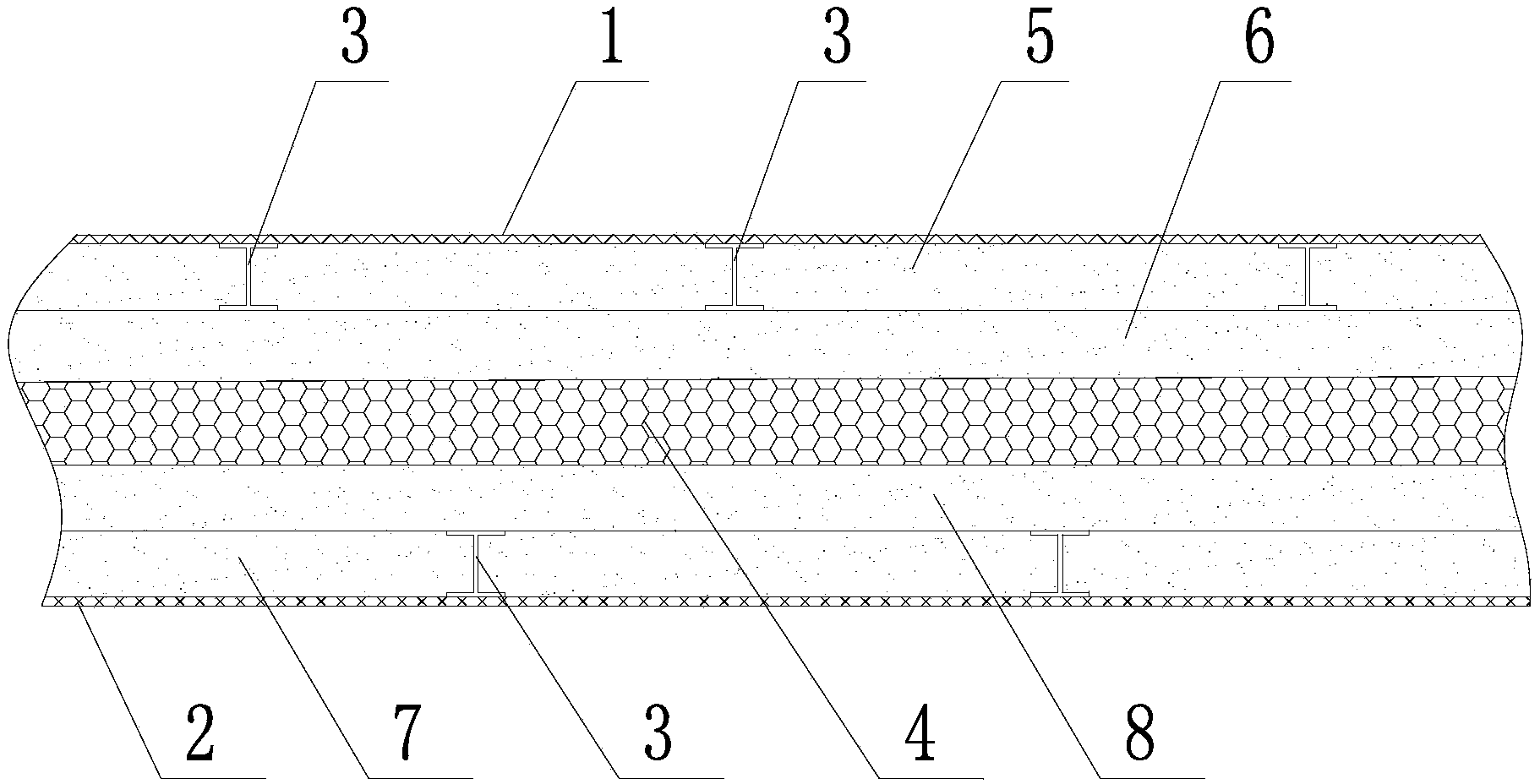

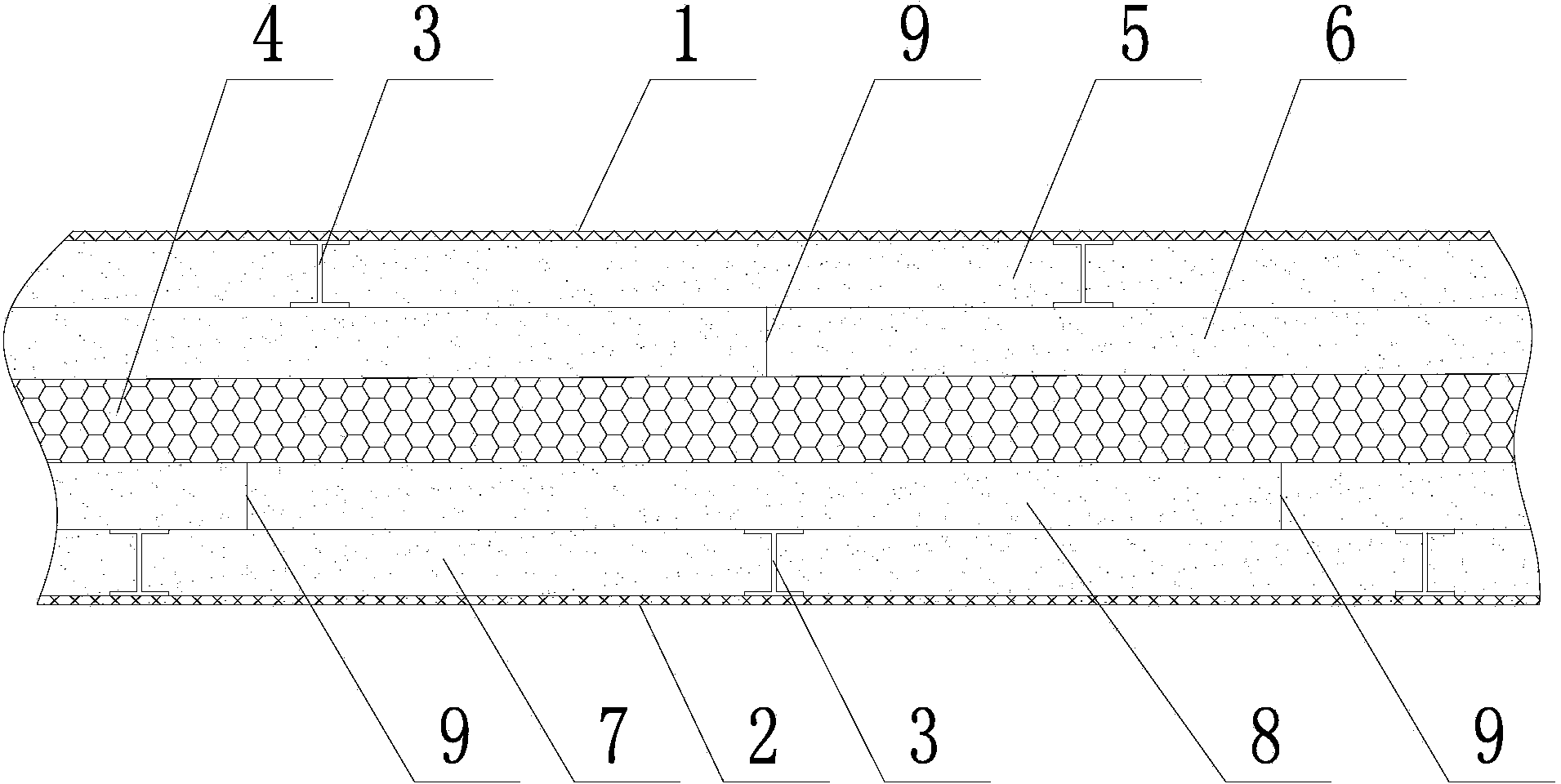

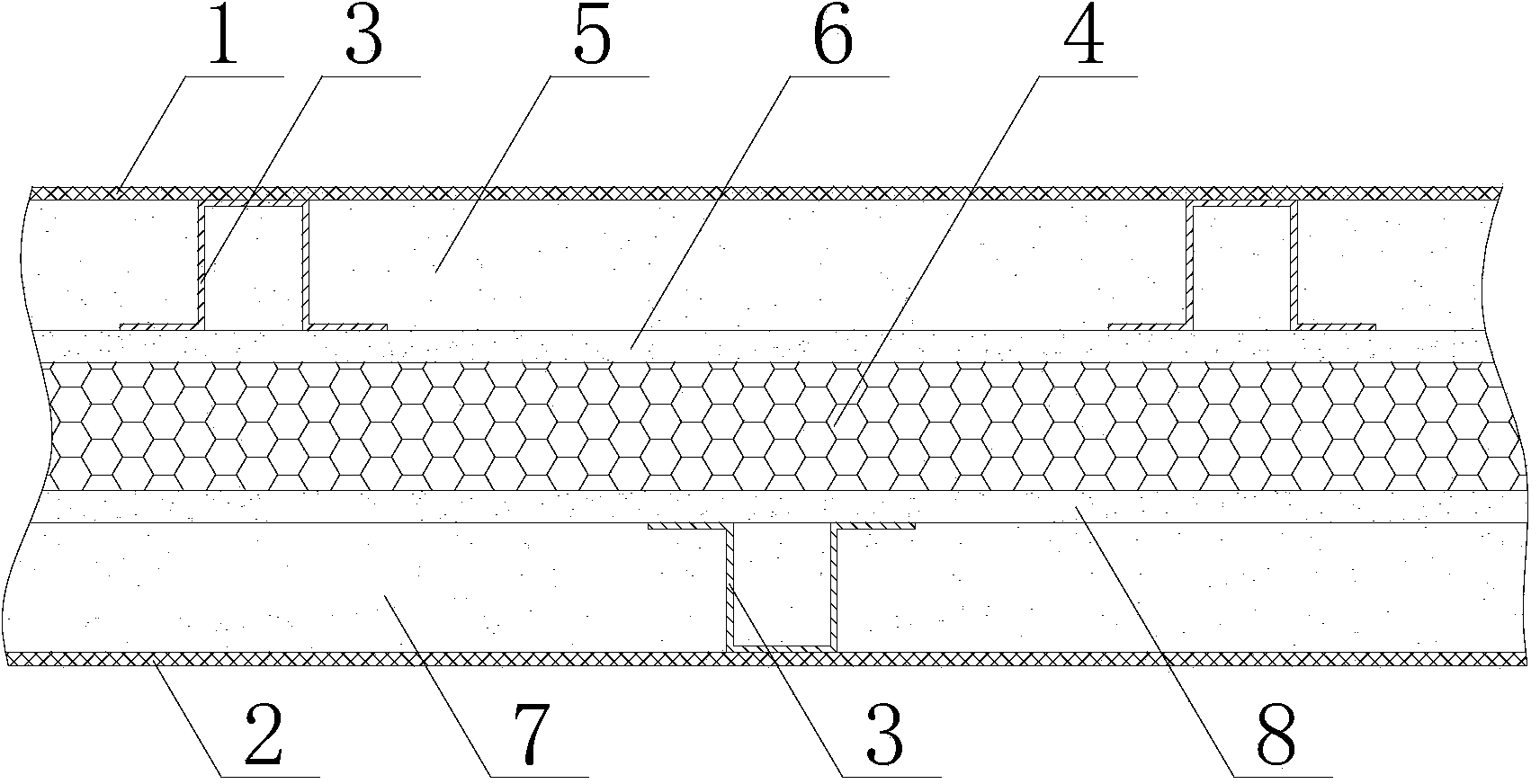

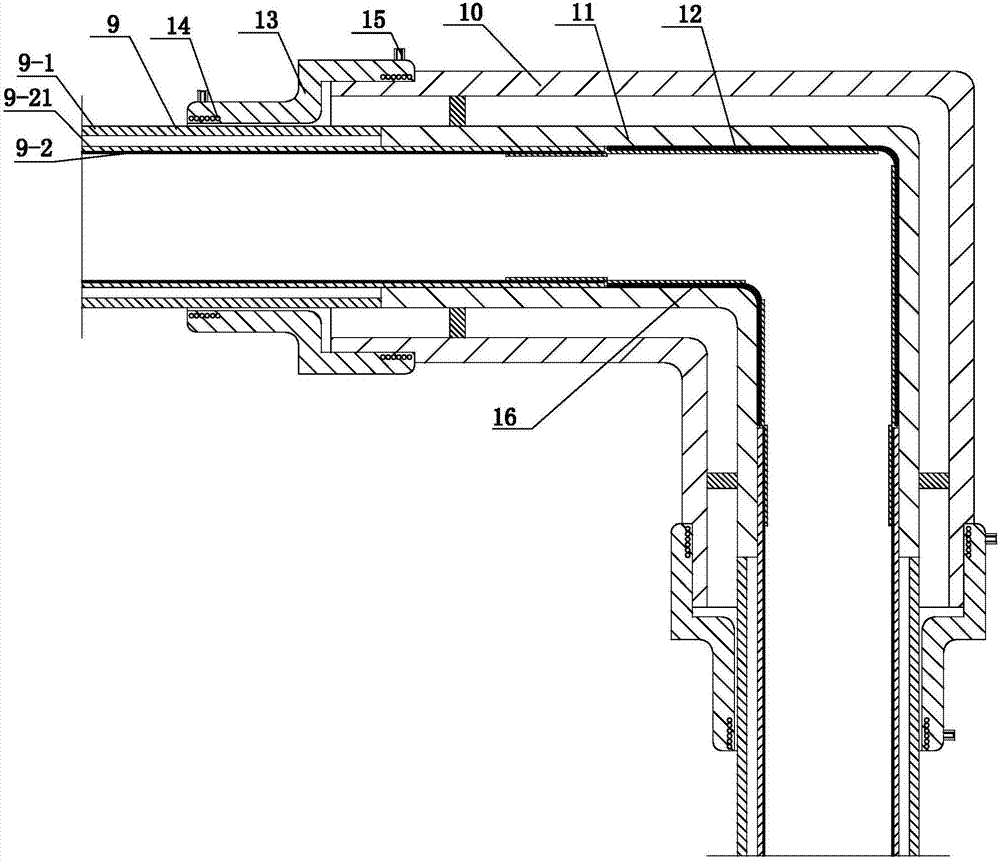

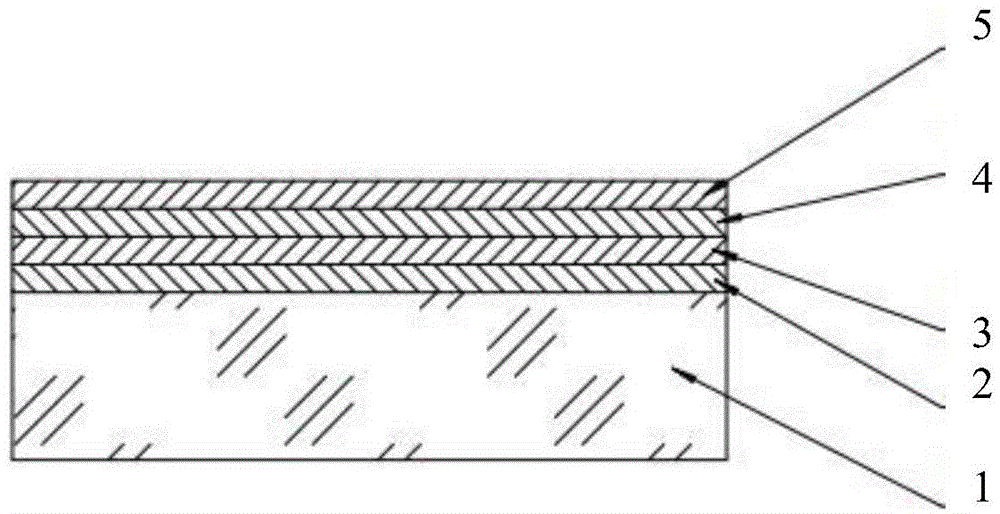

Refrigerated transport car, composite insulation board and manufacturing method of composite insulation board

ActiveCN103660446AHigh strengthAvoid punctureRefrigerated goods vehicleSynthetic resin layered productsThermal insulationArchitectural engineering

The invention discloses a composite insulation board, comprising an inner wall plate, an outer wall plate and a heat-insulated combination layer, wherein the heat-insulated combination layer is fixedly arranged between the inner wall plate and the outer wall plate and comprises reinforcing ribs, a vacuum heat-insulating board, an inner protection layer and an outer protection layer; the inner protection layer and the outer protection layer are fixed at two sides of the vacuum heat-insulating board; the reinforcing ribs are respectively embedded into the inner protection layer and the outer protection layer; and the inner protection layer and the outer protection layer are respectively connected with the inner wall plate and the outer wall plate. The invention also discloses a refrigerated transport car using the composite insulation board disclosed by the invention and a manufacturing method of the composite insulation board. The vacuum heat-insulating board and a rigid polyurethane board are used together; comprehensive cold broken bridge treatment is carried out on inner and outer parts of the composite insulation board, so that the heat insulation and preservation performances are improved and the weight is light. The strength of the composite insulation board is improved by arrangement of a reinforcing layer, and the inner protection layer and the outer protection layer can effectively prevent the vacuum heat-insulating board from being punctured; therefore, the composite insulation board has a long service life, a broad market application and popularization prospects.

Owner:SOUTH CHINA AGRI UNIV

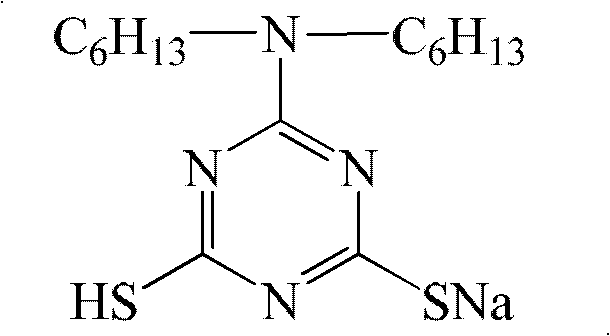

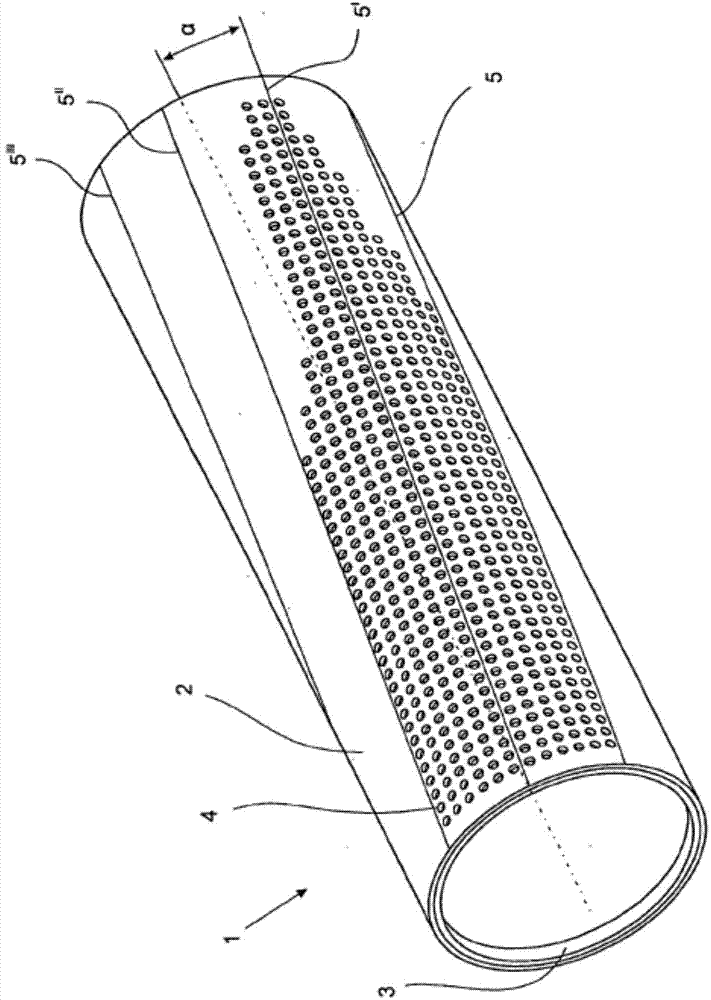

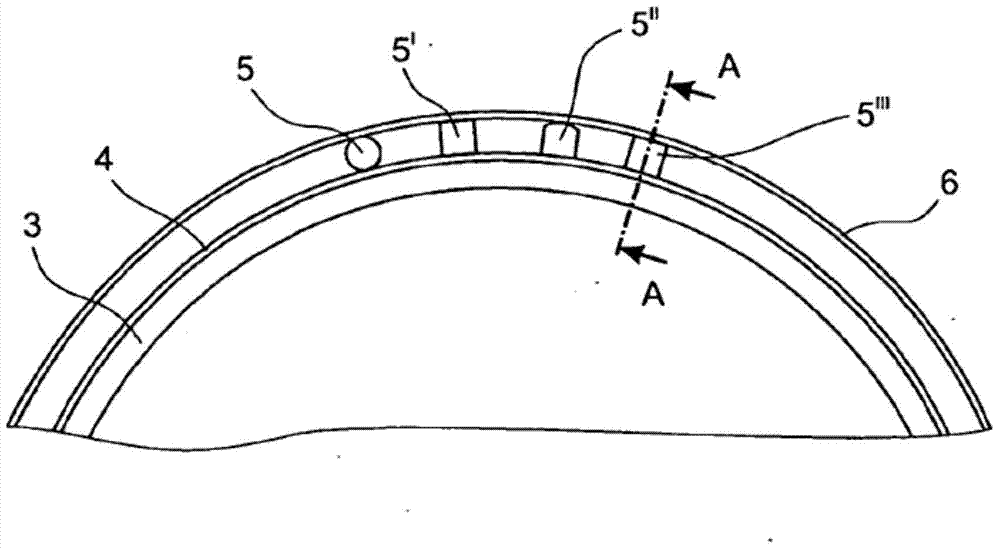

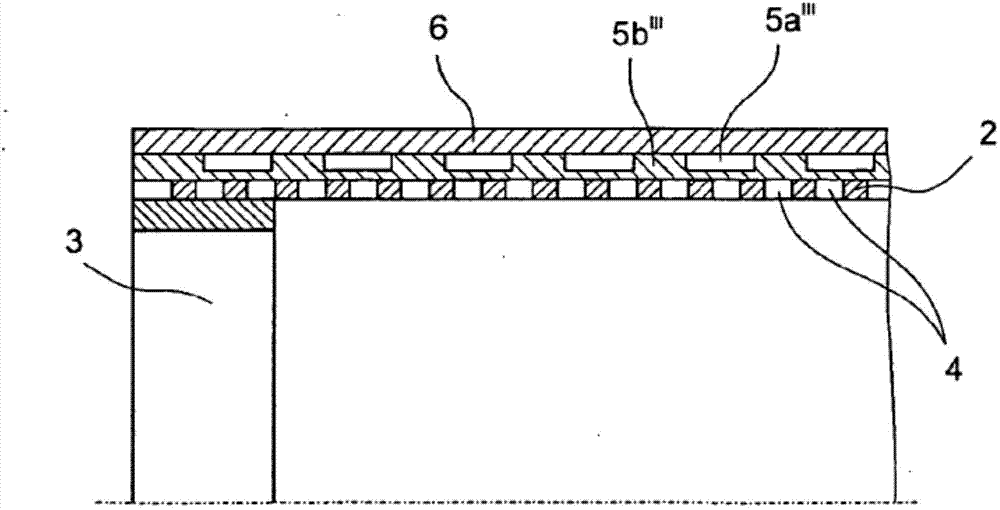

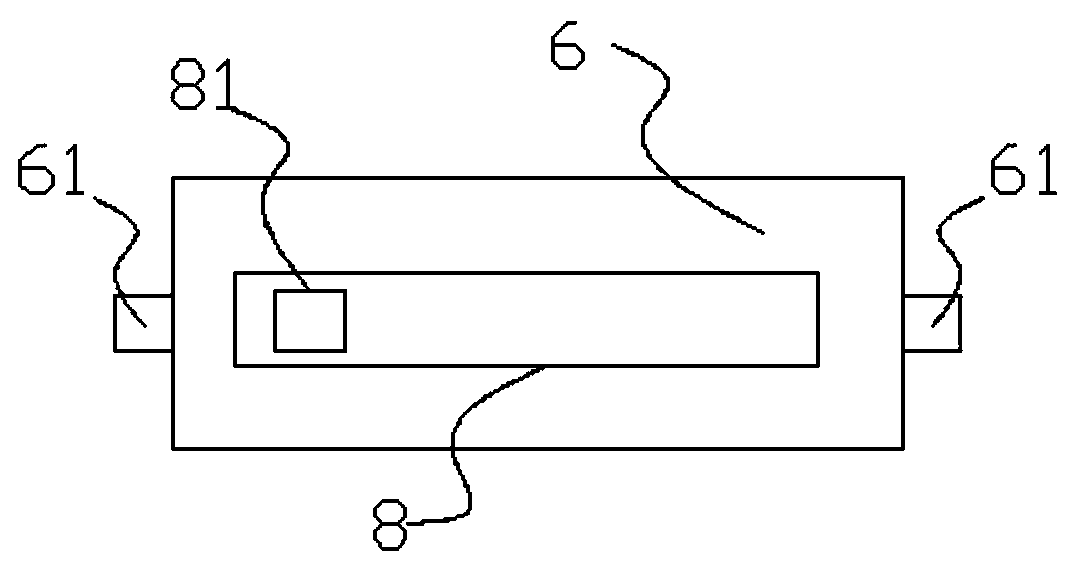

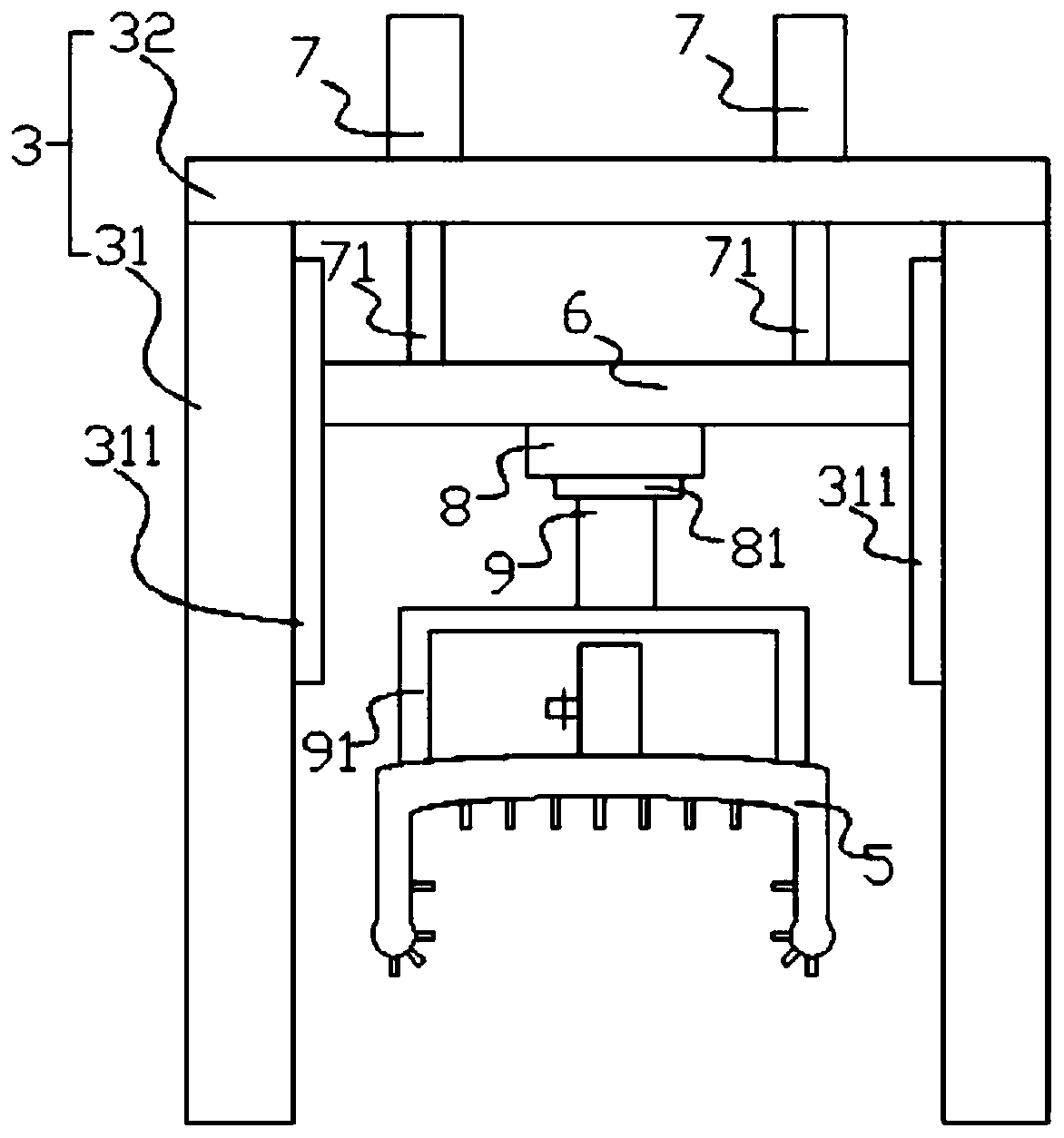

Device for hydrodynamically strengthening nonwovens, wovens or knitted fabrics

ActiveCN104204326AManufacturing flexibilityInexpensive and long-lasting connectionsDrying machines with progressive movementsNeedling machinesEngineeringAngle alpha

The invention relates to a device for hydrodynamically strengthening nonwovens, wovens or knitted fabrics, comprising a base drum (1), which has a plurality of bore holes (4) and on which a structural drum (6) is arranged at a spacing, wherein the distance between the base drum (1) and the structural drum (6) can be produced with a plurality of wires (5, 5', 5", 5"',...) that are arranged on the surface of the base drum (1) and are at least partially integrally joined to the base drum (1), the wires (5, 5', 5", 5"',...) being arranged parallel to each other on the surface of the base drum (1), characterised in that the wires (5, 5', 5", 5"',...) are arranged on the surface of the base drum (1) at an angle alpha of 5° to 45°, preferably 15° to the longitudinal axis of the base drum (1).

Owner:TRUETZSCHLER GRP SE

Artificial joint

ActiveCN104745870AHigh strengthHigh modulus of elasticityJoint implantsSolution treatmentCryogenic treatment

The invention relates to an artificial joint. The artificial joint is made from titanium alloy. A preparation method of the artificial joint comprises the following steps: preparing raw materials, smelting, carrying out precision casting, annealing, artificially ageing, carrying out cryogenic treatment, carrying out solution treatment, and artificially ageing for a second time, so that the artificial joint finished product is obtained, and adjusting of titanium alloy composition and the thermal treatment step are matched, so that strength of the artificial joint, elastic modulus and corrosion resistance of the artificial joint are greatly improved.

Owner:陕西爱骨医疗股份有限公司

Macromolecule composite for manhole cover

InactiveCN1542051AImprove toughnessImprove impact resistanceArtificial islandsUnderwater structuresEpoxyToughness

The composite polymer material for manhole cover is one kind epoxy resin cemented concrete, and consists of epoxy resin fluid an in 10-20 wt% and compounded concrete B in 80-90 wt%. Manhole cover made of the material has high toughness and high shock strength, can prevent damage during transportation, construction and use. It is also anticorrosive, has no noise produced and may be colored.

Owner:东莞市东历复合材料有限公司

Production method for chemically coloring low-chromium stainless steel into black

InactiveCN103031552AAchieve corrosion resistanceHigh in ironMetallic material coating processesHigh concentrationHigh energy

The invention discloses a production method for chemically coloring low-chromium stainless steel into black. In the conventional stainless steel chemical coloring, a chromium-iron alloy of which the chromium content is over 13 percent is selected mostly, and a process for using high-temperature and high-concentration chromic acid and sulfuric acid is adopted, so that defects on the aspects of the performance of a black film and color control and the defects of high energy consumption, high pollution, high cost and the like exist. Stainless steel of which the chromium content is 11.7-13 percent is taken as a substrate material, and a chemical coloring liquid of a low-temperature, low-concentration and nontoxic oxidant is adopted; and a black oxide film which is dense on the appearance and has luster is formed on the surface of low-chromium stainless steel, and a corrosion resisting effect which is the same as that of high-chromium stainless steel is achieved.

Owner:张晓波

Phosphate-silicate all glass hybrid optical fiber for high-power optical fiber laser

The invention discloses a phosphate-silicate all glass hybrid optical fiber for a high-power optical fiber laser. The phosphate-silicate all glass hybrid optical fiber is characterized by being prepared by taking phosphate glass as a fiber core, silicate glass as the glass of inner and outer claddings, and phosphorus pentoxide (P2O5) and silicon dioxide SiO2 as main units in the respective phosphate glass and silicate glass structures, and by adding an alkali metal oxide, an alkaline earth metal oxide, an intermediate oxide and a rare earth oxide all capable of changing the physical and chemical properties of the glass; as the phosphate glass is taken as the fiber core, the photo-darkening phenomenon commonly existing in a quartz optical fiber is greatly reduced and even completely eliminated. The glass composition in the phosphate-silicate all glass hybrid optical fiber can be adjusted in a relatively wide range so that both the numerical aperture between the fiber core and the glass of the inner cladding of the optical fiber, and the numerical aperture between the glass of the inner cladding and the glass of the outer cladding can be adjusted in a relative large range, and the glass also has chemical durability, and therefore, the erosion to the environment can be effectively resisted; the phosphate-silicate all glass hybrid optical fiber also can be well welded with the traditional quartz optical fiber.

Owner:HFB PHOTONICS CO LTD

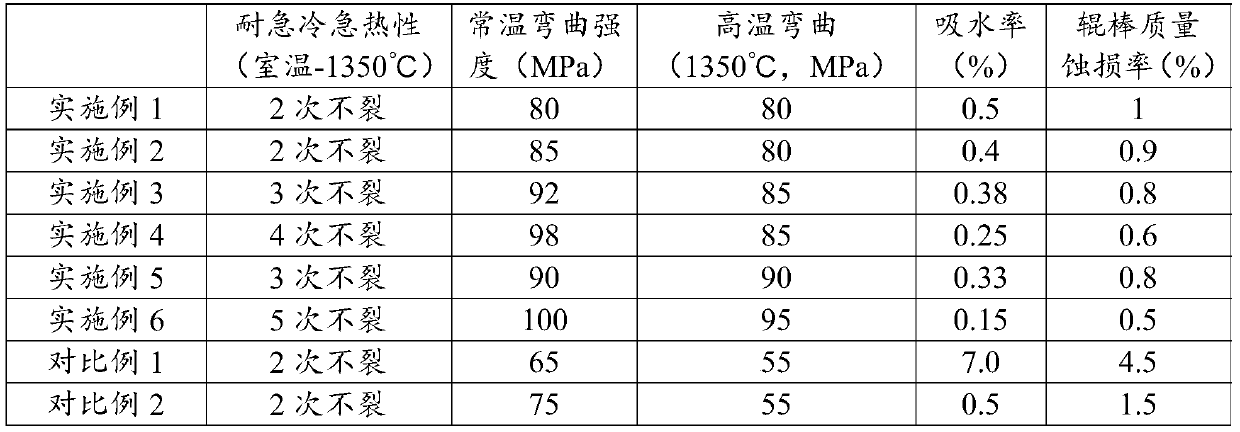

Corrosion-resistant ceramic roller and preparation method thereof

The invention discloses a corrosion-resistant ceramic roller. The ceramic roller is mainly prepared from kaolin, refractory clay, alumina, a sintering aid and other raw materials. The invention also discloses a preparation method of the corrosion-resistant ceramic roller. The prepared corrosion-resistant ceramic roller is resistant to rapid cooling and rapid heating and does not crack after beingcycled at 1350 DEG C-room temperature 2 times or more, has normal temperature bending strength being higher than or equal to 80 MPa, high temperature bending strength being higher than or equal to 80MPa at 1350 DEG C, water absorption being lower than or equal to 0.5% and roller mass erosion rate being lower than or equal to 1% , has significant corrosion resistance, and can be widely used in production of ceramic products and magnetic materials.

Owner:JIN GANG NEW MATERIALS +1

Glass fiber reinforced macromolecule composite material well cover

InactiveCN1634698AAnti-theftHigh compressive strengthSewerage structuresGlass fiberResin-Based Composite

This invention relates to glass fiber strengthening and thermosetting resin compound materials well cover, which comprises the following: inner core materials layer composed of materials and function stuff; outer strengthening structure layer formed by unsaturated resin and glass fiber; and antifriction layer. The outer strengthening structure layer comprises the following countered as weight proportion: unsaturated polyester resin glue liquid A for 10 úÑí½30 úÑ; glass fiber B for 3 úÑí½15 úÑ. The inner core materials layer comprises materials C for 45 úÑ-78 úÑ and stuff materials D for 5 úÑ-20 úÑ and anti-friction materials E for 3 úÑ-15 úÑ.

Owner:东莞市东历复合材料有限公司

Glass fiber reinforced macromolecule composite material well cover

InactiveCN100446964CAnti-theftHigh compressive strengthSewerage structuresGlass fiberPolyester resin

Owner:东莞市东历复合材料有限公司

Silicate full-glass optical fiber for high-power optical fiber laser

ActiveCN103951267AOptimize chemical compositionAchieve corrosion resistanceAlkali metal oxideRare earth

The invention discloses a silicate full-glass optical fiber for a high-power optical fiber laser. The silicate full-glass optical fiber is characterized by being prepared by taking SiO4 as a main unit and adding alkaline metal oxide, alkaline earth metal oxide and rare earth oxide, wherein SiO4 has the structural groups same as those of silica optical fiber glass, and the alkaline metal oxide, the alkaline earth metal oxide and the rare earth oxide are capable of changing the physical and chemical properties of the glass. The components of silicate glass in the silicate full-glass optical fiber can be regulated within a relatively wide range to ensure that the numerical aperture between inner cladding glass and outer cladding glass of the optical fiber can also be within a relatively wide range, and the chemical durability can be generated, so that the environment corrosion can be effectively avoided. The silicate full-glass optical fiber can also be well welded together with the traditional silica optical fiber because of having the same main chemical structural unit with silica glass.

Owner:HFB PHOTONICS CO LTD

Nanometer protective coating special for aluminum non-stick pan, preparing method and coating technology of coating

InactiveCN110066596AImprove appearance qualityAchieve corrosion resistanceFireproof paintsCooking-vessel materialsUV curingAlcohol

The invention discloses a nanometer protective coating special for an aluminum non-stick pan. The nanometer protective coating is prepared from, by weight, 70-80 parts of polyamideimide, 10-20 parts of nanoscale graphene, 15-30 parts of nanometer calcium carbonate, 30-40 parts of isomeric alcohol ethoxylates, 1-5 parts of a dispersing agent and 20-50 parts of a solvent. A special technical formulais adopted, a graphene mother liquor is added, and the good effects of easy cleaning, good thermal performance, and resistance to corrosion, high temperature and chemicals can be achieved; meanwhile,through a unique coating technology, surface treatment is conducted in advance, so that the coating has good adhesive force during spray coating, through the technologies of multiple times of spray coating, drying and UV curing, the requirement for spray-coating attractiveness is met, and the appearance quality of spray-coated colored paint is improved.

Owner:北京百年初心科技有限公司

Resin inspection well and manufacturing method thereof

InactiveCN102828530AShorten the installation cycleReduce construction costsArtificial islandsSewerage structuresCorrosionEngineering

The invention discloses a resin inspection well and a manufacturing method thereof. The resin inspection well comprises a well body, a flange ring, a plurality of reinforcing ribs and a pipeline joint, wherein the reinforcing ribs are evenly distributed on the outer side of the well body; the pipeline joint is arranged at the lower end of the well body; and the flange ring is sheathed with the upper end of the well body. The detailed manufacturing method comprises the steps as follows: 1, stirring resin, glass fibers, a bulking agent, a coloring agent and a curing agent (group A); 2, mixing the stirred resin with the curing agent (group B) and casting into a mold; and 3, demolding. According to the invention, the resin is used as a primary material for manufacturing the inspection well, and is mixed with the materials such as the bulking agent and the like, so that the inspection well has the effects of corrosion resistance, high-pressure resistance, aging resistance and the like; the manufactured flange ring is sleeved on the well body, so that the overall height of the inspection well can be adjusted; and in addition, the reinforcing bars enable the inspection well to bear higher pressure. Therefore, the resin inspection well provided by the invention can completely replace the existing inspection wells built by bricks and cement. As a result, the mounting period is shortened greatly, and a large amount of construction cost is saved.

Owner:巢善鸣 +1

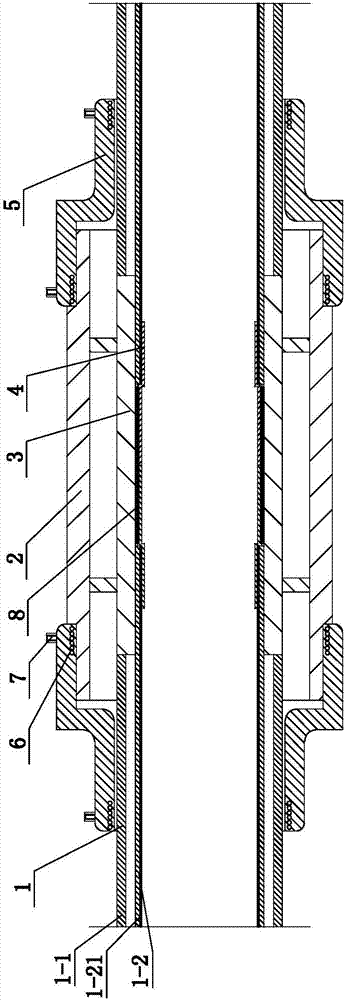

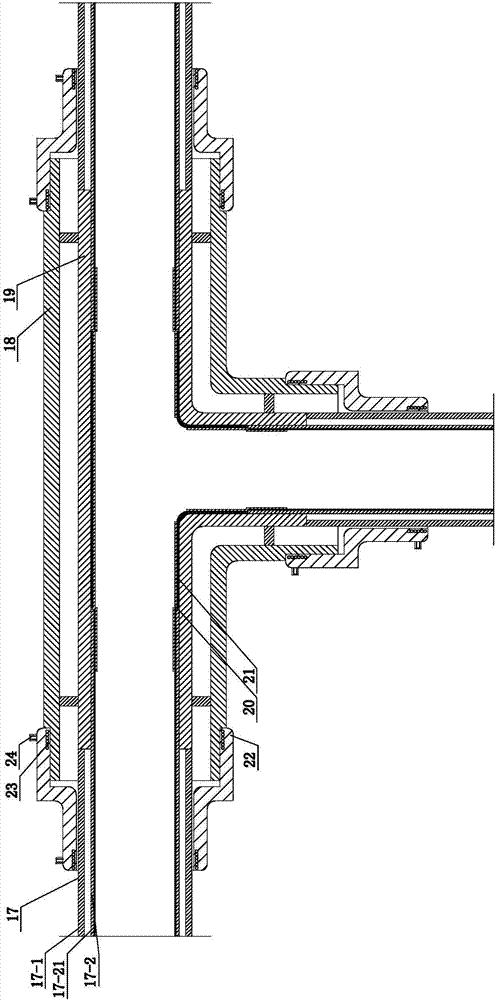

Static-conducting connecting structure of coupling for double-layered pipes

InactiveCN107191728AFirmly connectedImprove sealingBranching pipesPipe-jointsElectrical conductorCoupling

The invention discloses a static-conducting connecting structure of a coupling for double-layered pipes, and relates to the technical field of pipe connection. The structure comprises an outer connecting pipe and an inner connecting pipe which are both straight pipes. The two end ports of the inner connecting pipe are internally provided with tubular inserts correspondingly. One ends of the inserts are sleeved with the inner connecting pipe in a sealed mode, and the other ends of the insert are sleeved with inner oil conveying pipe bodies. The inner oil conveying pipe bodies are sleeved with outer oil conveying pipe bodies. The two ends of the outer connecting pipe are sleeved with connecting sleeves correspondingly. The connecting sleeves are used for enabling the outer connecting pipe and the outer oil conveying pipe bodies at the corresponding ends to be integrated in a sealed mode. The inner wall of the inner connecting pipe is coated with a second static conductor layer which is connected with the inserts in the two end ports of the inner connecting pipe at the same time. According to the static-conducting connecting structure, through the inserts arranged in the both end ports of the inner connecting pipe, and the second static conductor layer, first static-conducting layers of the inner oil conveying pipe bodies are connected, and it is guaranteed that good static-conducting performance is achieved between oil conveying pipes.

Owner:江苏法利沃环保科技有限公司

Technology for producing carbon fiber static smoking-control product

InactiveCN106381578AHigh specific strengthHigh specific modulusElectroconductive/antistatic filament manufactureCarbon fibresTarCorrosion

The invention discloses a technology for producing a carbon fiber static smoking-control product. The technology comprises the following steps: 1) extracting protofilament; 2) pre-oxidizing; 3) charing at low temperature and stretching; 4) processing a die and special texture on the surface; and 5) withdrawing and packaging the product. Compared with the prior art, the carbon fiber finished product produced by a carbon fiber material has an adsorption function or a-micro magnetic field function through the special production technology, is used for placing the cigarettes, can change a nicotine molecules structure stored in cigarettes, reach a release effect, gradually reduce the nicotine and tar content in tobacco, and reduces dependency of a smoker to nicotine from a fountainhead. The carbon fiber finished product has the excellent performances of high specific strength, high specific modulus, high temperature resistance, corrosion resistance, fatigue resistance, creep resistance, electric conduction, heat transfer and small thermal expansion coefficient, and can finally reach a purpose of controlling smoking and quitting smoking.

Owner:上海贝爱珠宝设计工作室(有限合伙)

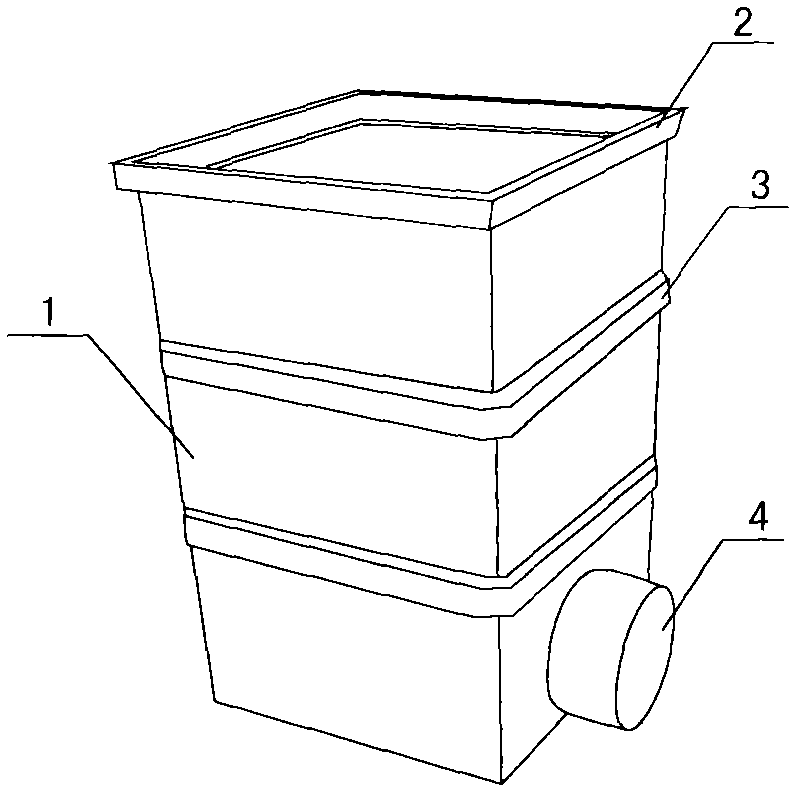

Multifunctional environmental-friendly tank

InactiveCN108584239ASolve the problem of inconvenient chargingWill throw awayWaste collection and transferRefuse receptaclesWater storageCells panel

The invention relates to the technical field of environment protection, in particular to a multifunctional environmental-friendly tank which comprises a top cover, a base, an unrecyclable garbage canand a recyclable garbage can. Solar cell panels are arranged on two sides of the top part of the top cover. According to the multifunctional environmental-friendly tank provided by the invention, thesolar cell panels are arranged on the top cover, energy can be stored in a storage battery, and multiple sockets and charging interfaces are arranged, so that pedestrians can charge conveniently, andthe problem of inconvenience in charging is solved; an illuminating lamp is arranged on the inner side of the top cover of the environmental-friendly tank, and a fluorescent band is arranged on a marker at the front end of a tank body, so that the multifunctional environmental-friendly tank can be used for illuminating at night, and people can throw garbage conveniently; a filter plate is arrangedin the unrecyclable garbage can, so that the moisture of the garbage can be filtered into a water storage box through the filter plate so as to be conveniently treated; and reinforcement layers are arranged in the unrecyclable garbage can and the recyclable garbage can, so that on one hand, the effects on deodorizing and sterilizing can be achieved, and on the other hand, the effects on preventing water and corrosion can be achieved.

Owner:徐康康

A production process of carbon crystal geothermal floor

ActiveCN103144174BReduce hydroxyl concentrationReduce moisture absorption performanceWood dampingWood charring/burningOxygenInternal stress

The invention discloses a production technology for a carbon crystal geothermal floor, which comprises the steps of sawing raw wood into a cuboid wood floor blank, conducting carbon crystal physicochemical treatment, life preserving, micro-molecular carbon crystal treatment, balanced life preserving, back optical treatment, four-face dressing, four-side rabbeting, four-side painting and front and back paint decoration on the wood floor blank in sequence, and finally packaging a finish product. According to the technology, due to pyrolysis treatment (namely the carbon crystal physicochemical treatment) and the micro-molecular carbon crystal treatment under a high-temperature oxygen separation condition, the concentration of hydroxyl in the wood is reduced, hygroscopicity and internal stress of the wood are reduced, so that the purpose of improving the stability of the wood is achieved, and the carbon crystal geothermal floor is attractive in color, does not have a jet-black surface as the common carbonized wood floor, and has the characteristics of durability and corrosion resistance.

Owner:浙江上臣家居科技有限公司

Outer cladding glass for silicate all-glass fibers of high-power fiber lasers

InactiveCN104496173AAchieve corrosion resistanceAchieving Numerical Aperture RequirementsAlkali metal oxideRare earth

The invention discloses an outer cladding glass for silicate all-glass fibers of high-power fiber lasers. The invention is characterized in that the outer cladding glass is composed of 5-20% of silicon dioxide, 50-70% of phosphorus pentoxide, at most 25% of alkali oxide, at most 10% of alkali-earth oxide, 10-20% of intermediate oxide and at most 10% of rare-earth oxide. The glass composition can be adjusted within a wider range, so that the number aperture between the inner cladding and outer cladding can be adjusted within a wider range, thereby easily satisfying the requirement of the all-glass high-power fiber laser for the number aperture of between the inner cladding and outer cladding of the fiber. Besides, the chemical composition of the outer cladding glass can be effectively optimized, so that the glass can achieve similar corrosion resistance to quartz glass so as to effectively prevent corrosion from the external environment, and can also be well welded with the traditional silica fiber.

Owner:HFB PHOTONICS CO LTD

Method for repairing frame type composite material forming die through supersonic thermal spraying process

The invention discloses a method for repairing a frame type composite material forming die through a supersonic thermal spraying process, and belongs to the technical field of aviation. The method comprises the following steps that the surface of a workpiece is pretreated; the pretreated workpiece is preheated at the temperature of 60-120 DEG C for 1-2min; the surface of the workpiece is sprayed;surface repair is carried out by using a nickel-base alloy spraying material, wherein when the spraying material is heated to a molten or semi-molten state, the spraying material is accelerated to beup to the speed of 1000-1400m / s to be sprayed to the working surface; laser detection is carried out; the sprayed profile is detected by using a laser tracker, detection data is compared with theoretical data to determine whether the workpiece is qualified, and workpiece coating polishing treatment in the next step is carried out on the qualified workpiece; the workpiece coating is polished; the profile is machined through a numerical control machine tool, the coating surface is polished after machining, and it is ensured that the polished profile finish degree Ra is 1.6-0.8. The frame type composite material forming die can meet the die precision requirements, using requirements and the like after being repaired by the method.

Owner:GUANGLIAN AVIATION IND CO LTD

Corrosion-resistant flat bulb steel used in cargo oil tank of oil tanker and smelting technology thereof

The invention relates to a corrosion-resistant flat bulb steel used in the cargo oil tank of an oil tanker and a smelting technology thereof. The C, Si, Mn, and Alt contents of the flat bulb steel are all controlled according to the classification society standards, and other elements are strictly controlled in a designed range. The steel can satisfy the classification society requirements, and can be used in the ship-making industry without authentication. The steel can be used in the cargo oil tank of an oil tanker without being painted, has a protective effect and a corrosion-resistant effect, can reduce the maintenance cost, and prolongs the service life of ship body.

Owner:NANJING IRON & STEEL CO LTD

Energy-saving and environment-friendly novel process for stainless steel passivation

InactiveCN103602973ANo pollution in the processToxicMetallic material coating processesSS - Stainless steelAccelerant

The invention relates to an energy-saving and environment-friendly novel process for stainless steel passivation. An adopted passivator contains the ingredients in percentage by mass: 20-50% of polybasic weak acid, 10-30% of catalysis promoter, 0-5% of thickener and the balance of water. The process comprises the specific process flows: (1) coating through brushing or mopping, drying through wiping, ageing, naturally drying or baking, and inspecting; or (2) coating through dipping or spraying, drying through dripping, ageing, cleaning or drying through wiping, naturally drying or baking, and inspecting. According to the process, toxic and harmful ingredients, such as chromate, hydrofluoric acid, sulfuric acid and nitric acid, are abolished fundamentally, and a polybasic weak acid and catalysis promoter technology is adopted, so that the process is completely non-toxic and harmless, is free from environmental pollution, is moderate in odor and is beneficial to health; the requirements on high corrosion resistance and high integrity can be met by the passivating depth of only 20 microns, so that the mechanical and physical properties of stainless steel are better protected from being affected by passivating corrosion. According to the process, washing is required or not, and then, water is saved by over 80%, so that the process is worthy of being popularized and applied to the stainless steel passivation in the fields of food, medical treatment, aviation, aerospace, nuclear power and the like.

Owner:SHANGHAI JINTIAN RUST REMOVAL & RUST PROOF CO LTD

Processing technology of circuit board with super-high corrosion resistance

ActiveCN108882546AIncrease roughnessImprove uniformityInsulating substrate metal adhesion improvementNon-metallic protective coating applicationSurface roughnessOxidation resistant

The invention relates to processing technology of a circuit board with super-high corrosion resistance. The processing technology comprises the following steps that S1, the solder resist pretreatmentis adjusted, the board surface roughness is increased, and the binding force of the board surface and ink is enhanced; S2, ink formula is upgraded, the ink with the super-high corrosion resistance isused, and it is realized that the circuit board has the super-high corrosion resistance; and S3, a potion with corrosion slow and oxidation resistance is chosen, after the board is subjected to solderresist, the board can pass through the copper surface covered by the ink, and when the board reaches an oxidation resistance line, the potion with corrosion slow and oxidation resistance is chosen toensure the corrosion resistance of the copper surface. The processing technology can enable the circuit board to have the super-high corrosion resistance, the service life of a main board is prolonged, and the performance stability of the main board is ensured.

Owner:CHANGZHOU AOHONG ELECTRONICS

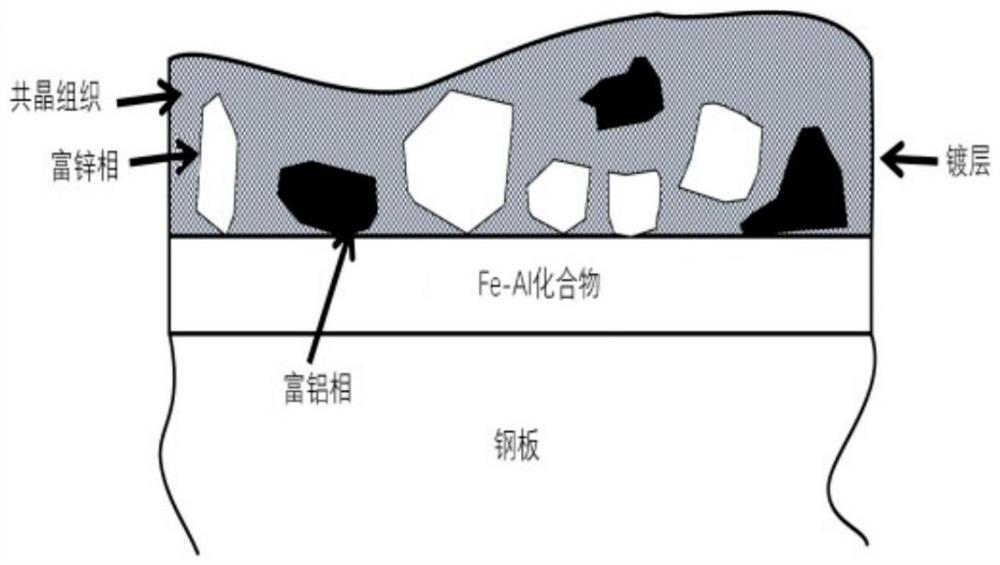

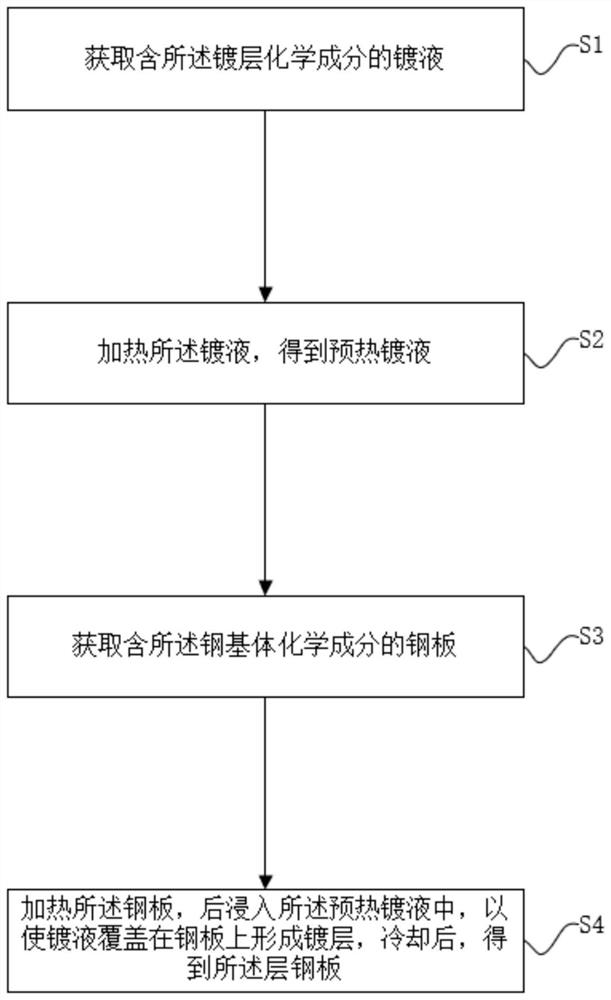

Hot-dip galvanized coated steel sheet and preparation method thereof

PendingCN114369783ALarge grainUniform grainHot-dipping/immersion processesRare-earth elementChemical composition

The invention relates to the field of steel coating and plating preparation, in particular to a hot-dip galvanizing coated steel plate and a preparation method thereof, and the coated steel plate comprises a steel substrate and a coating; the steel matrix comprises the following components in percentage by weight: 0.01%-0.2% of C, 0.01%-2% of Mn, 0.01%-0.4% of Si, 0.02%-0.4% of Cr, 0.0001%-0.001% of B and 0.03%-0.6% of Al; the plating layer comprises 1-4% of Mg, 5-8% of Al, less than or equal to 1% of rare earth elements and the balance of Zn and inevitable impurities; the preparation method comprises the following steps: obtaining a plating solution containing chemical components of the plating layer; heating the plating solution to obtain a preheated plating solution; obtaining a steel plate containing the chemical components of the steel substrate; heating the steel plate, immersing the steel plate in the preheating plating solution, and cooling to obtain the plated steel plate, by controlling the chemical components of the steel substrate and the plating layer and then through the preparation method, balance control over the corrosion resistance and the plating layer thickness of the plated steel plate is achieved.

Owner:SHOUGANG CORPORATION +1

Vacuum silver coated glass and preparation process thereof

ActiveCN104402244AImprove reflectivitySoft and bright surface glossGlass/slag layered productsTectorial membraneWeather resistance

The invention belongs to the technical field of vacuum coating products, and in particular relates to vacuum silver coated glass and a preparation process thereof. The vacuum silver coated glass comprises a glass substrate, a first reflective film layer, a second reflective film layer, a first protection film layer and a second protection film layer, the first reflective film layer, the second reflective film layer, the first protection film layer and the second protection film layer are successively placed on the glass substrate, the first reflective film layer is a pure silver layer, the second reflective film layer is a pure aluminum layer, the first protection film layer is a pure titanium layer, and the second protection film layer is a titanium oxide layer. The vacuum silver coated glass has high reflectivity and coating physical properties, more soft and bright gloss, better appearance effect, high surface hardness, and good water resistance and weather resistance.

Owner:GUANGDONG ZHENHUA TECH CO LTD

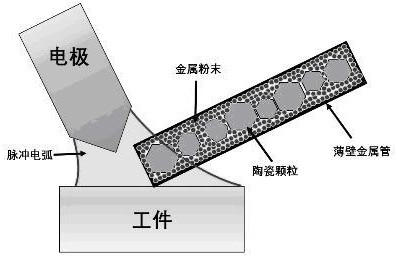

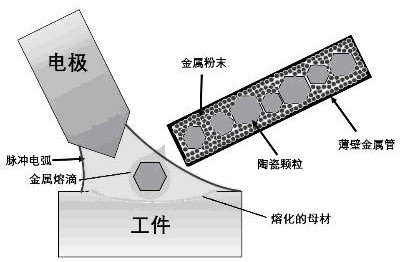

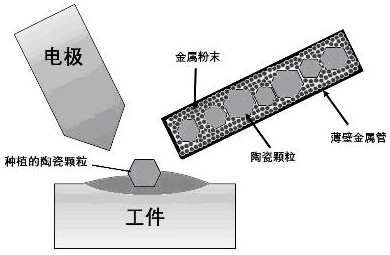

Pulsed arc particle planting method for particle mixed powder-cored welding wire

ActiveCN112296481AAchieve antioxidant propertiesAchieving wear resistanceArc welding apparatusMetallic material coating processesMetal alloyMetal powder

The invention provides a pulsed arc particle planting method for a particle mixed powder-cored welding wire. The pulsed arc particle planting method comprises the steps of polishing the surface of a to-be-planted workpiece to remove impurities and cleaning the workpiece; preparing the particle mixed powder-cored welding wire, mixing metal alloy powder and ceramic particles in proportion, and thenloading the mixture into a thin-wall metal tube; setting welding parameters; and turning on a circuit and achieving and completing a ceramic particle planting process. According to the pulsed arc particle planting method for the particle mixed powder-cored welding wire provided by the invention, the thin-wall metal tube can be filled with metal powder with special performance according to needs, so that the functions of oxidation resistance, abrasion resistance, corrosion resistance and the like of the particle planting surface are achieved, the exposed height of the particles can be adjustedby adjusting the proportion of the metal powder to the ceramic particles, and planting of any ceramic particles is achieved.

Owner:NANCHANG HANGKONG UNIVERSITY

Magnesium alloy plate machining method and magnesium alloy plate

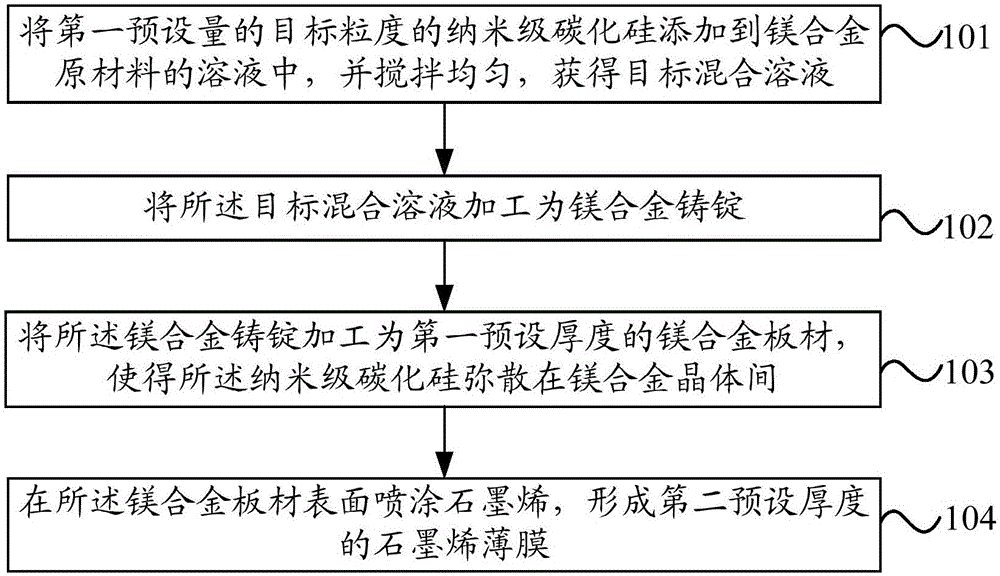

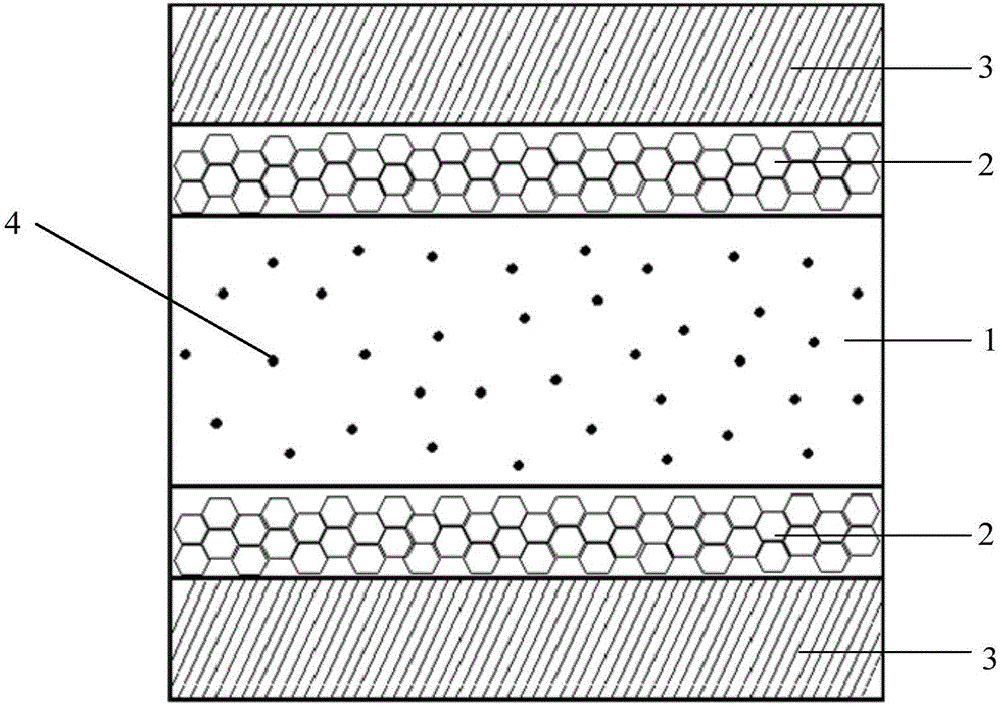

The invention provides a magnesium alloy plate machining method and a magnesium alloy plate. The method comprises the following steps: a first preset quantity of nanoscale silicon carbide with a target particle size is added in solution of a magnesium alloy raw material for uniform stirring to obtain target mixed solution; the target mixed solution is machined as a magnesium alloy ingot; the magnesium alloy ingot is machined as a magnesium alloy plate with a first preset thickness, so that the nanoscale silicon carbide is dispersed in a magnesium alloy crystal; and graphene is sprayed on the surface of the magnesium alloy plate to form a graphene film with a second preset thickness. The nanoscale silicon carbide particles are added in a magnesium alloy to disperse in the magnesium alloy crystal; a graphene corrosion resistant film is sprayed on the surface of the magnesium alloy to obtain the magnesium alloy plate with high strength and corrosion resistance; the application range is widened; and the problems of low strength and weak corrosion resistance in a traditional magnesium alloy plate are solved.

Owner:BEIJING ELECTRIC VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com