Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Improve the rate of excellent products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester POY spinning finish and production method thereof

The invention discloses a polyester POY spinning finish, comprising 81-88% of lubricating agent, 3-5% of emulsifying agent, 4-7% of tow collecting agent, 3-5% of antistatic agent and 2-4% of additive by weight. The invention also discloses a production method of the polyester POY spinning finish. The product not only can endow the fibers with good processability but also is environment-friendly, overcomes the phenomenon that the finish corrodes equipment and can ideally solve the problem of easy cohesion on guide rolls during apparent cohesion and reduce fluff and broken yarns.

Owner:绍兴市上虞皇马化学有限公司

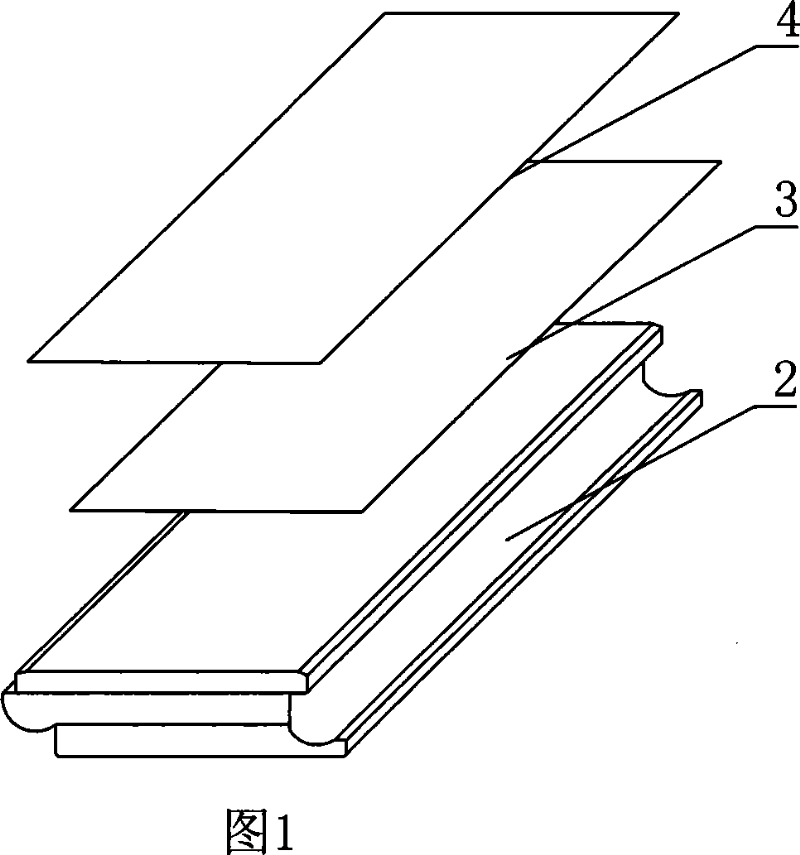

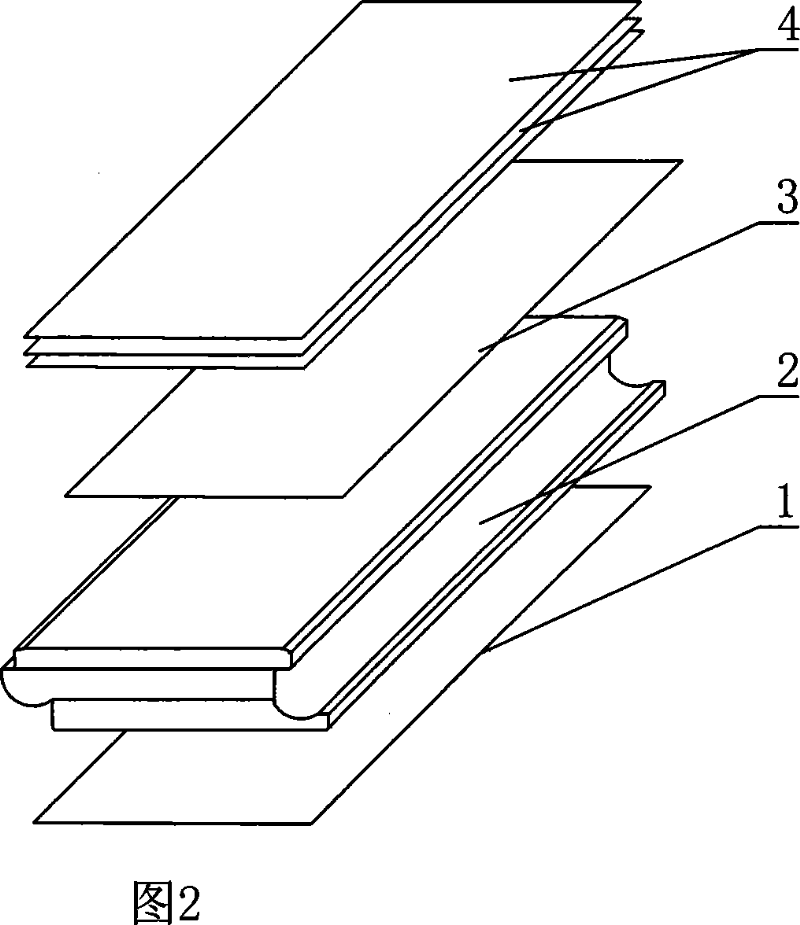

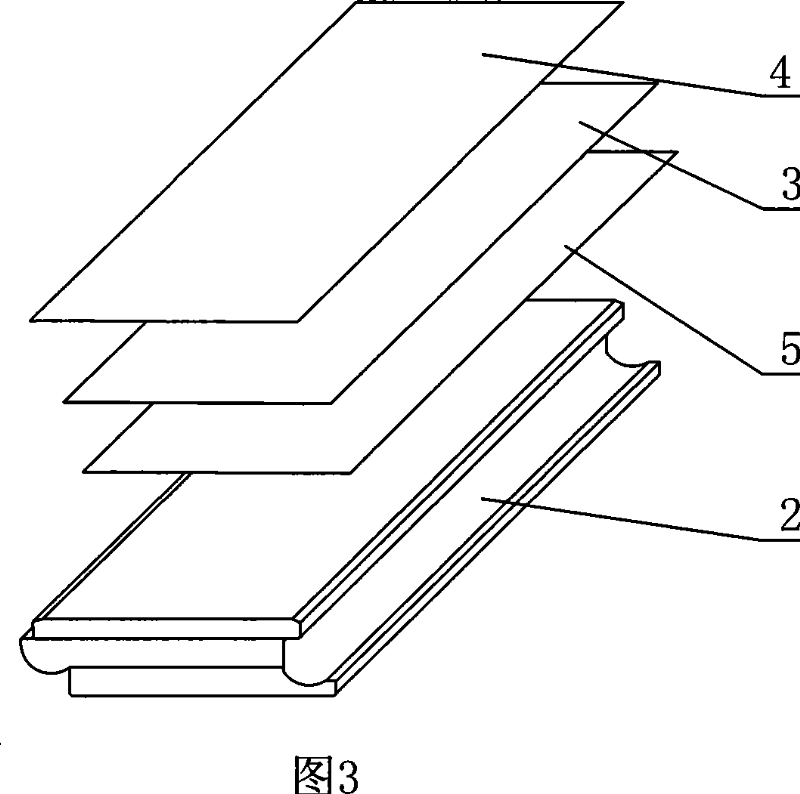

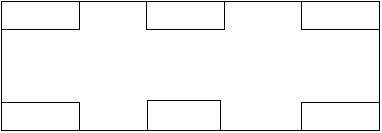

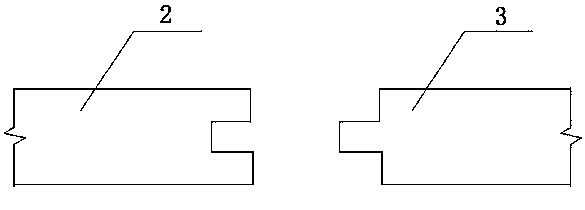

Method for making water-proof floor

A water proof floor is made by dipping 1-3 pieces of anti wearing paper and decorative paper into melamine and dried, applying 2MPa-10MPa pressure with the heating press with these two kinds of paper stacked, in the temperature of 185deg.C-230deg.C, keeping the pressure for 25-60s and cooling naturally to form into the panel, roughening the upper surface of the wood slab or free wax fiber slab to form into uneven surface, applying adhesive agent on the upper surface of the slab, one side of the decorative paper of the panel attached on the up surface of the slab, applying 15MPa-45MPa pressure in normal temperature for 15-60 minutes, sticking the panel to the slab to make a big plate, cutting the big plate to the required strip, having key way vertically and horizontally to make the final product. The floor is not only anti wearing, and water proof, it is also being anti shock, fire resistant, anti erosion, and environment protective in nature.

Owner:高建忠

Nanometer polyester fiber FDY spinning oil prepn and its prepn process

The nanometer polyester fiber FDY spinning oil preparation consists of inorganic nanometer additive, smoothing agent, emulsifier, antistatic agent and other additive. Owing to the added nanometer material, the nanometer polyester fiber FDY spinning oil preparation has excellent smoothing performance, capability of raising the quality of spun yarn, high heat stability, no smoke, simple compounding process, certain antibiotic capacity and other advantages, and is suitable for use in the one-step FDY spinning production line.

Owner:杨国栋

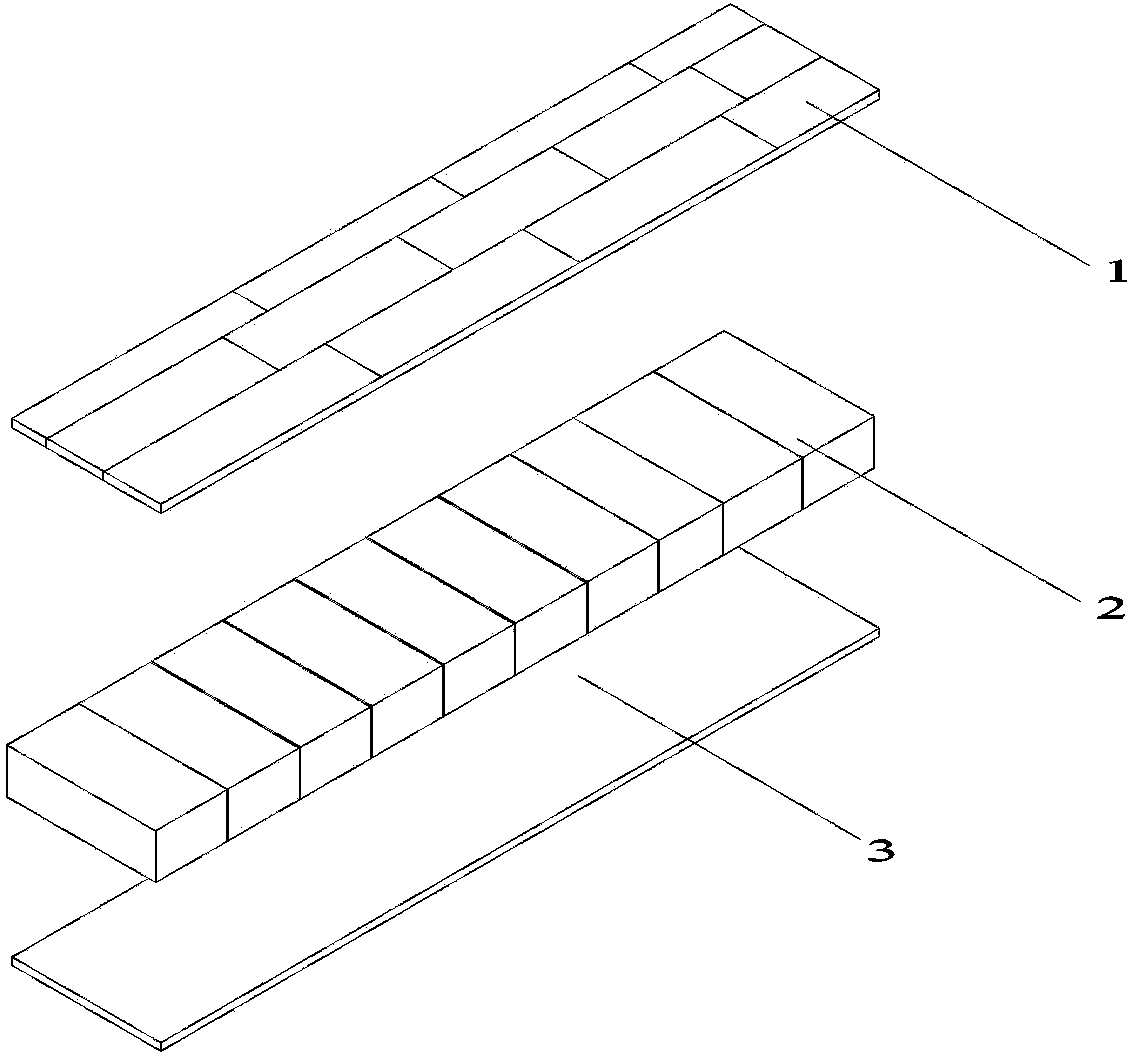

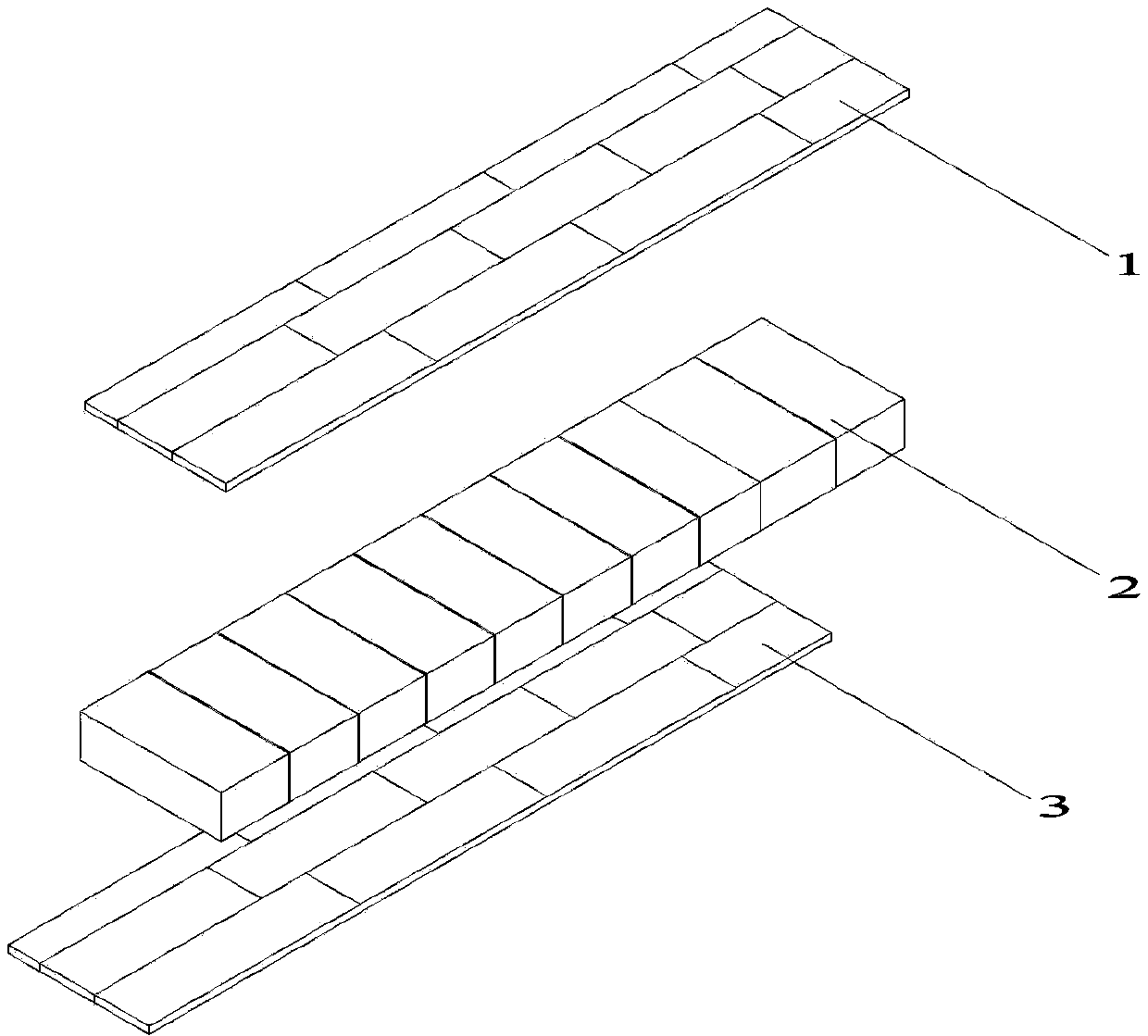

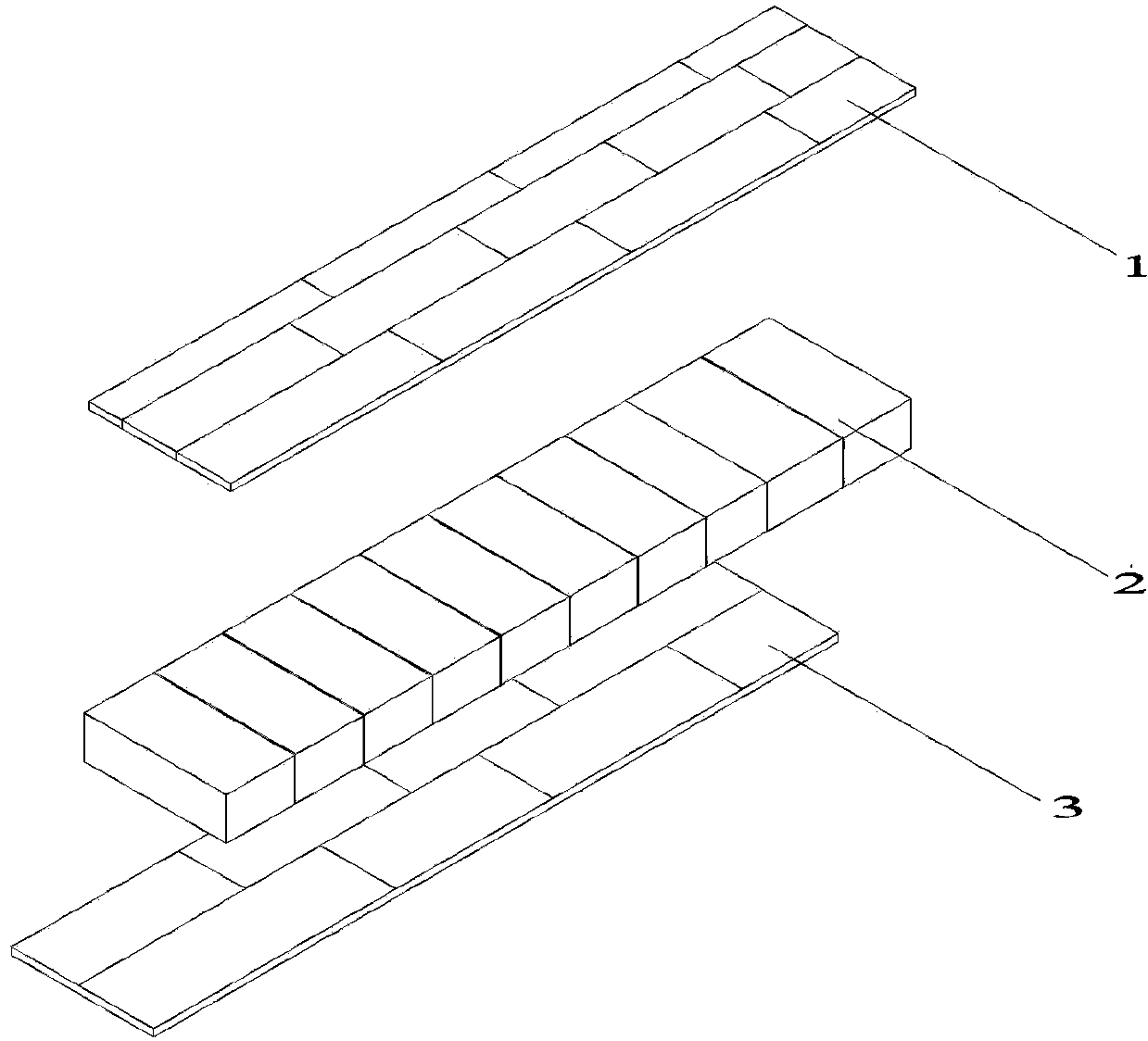

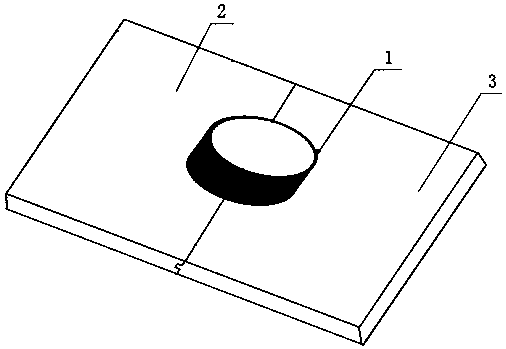

Three-layer composite solid wood flooring made from same type of trees and production process thereof

ActiveCN103395101AOvercome the disadvantage of easy deformationReduce waste of resourcesWood veneer joiningWood layered productsSolid woodPulp and paper industry

The invention belongs to the technical field of building decorative materials, relates to three-layer composite solid wood flooring, in particular to three-layer composite solid wood flooring made from the same type of trees and a production process thereof. The three-layer composite solid wood flooring consists of surface boards, core boards and back boards, wherein the surface boards, the core boards and the back boards are all made from the same type of timber pressed into a whole according to crisscross grains; the thickness of the surface boards is 3-4mm, the thickness of the core boards is 8-9mm, and the thickness of the back boards is 2-3mm. The invention further discloses a production process of the three-layer composite solid wood flooring made from the same type of trees. As the three-layer composite solid wood flooring is made from the same type of trees integrally, physical properties of the three layers are the same, the three layers can be bound effectively during production, and different physical properties can keep consistent highly. Since the solid wood flooring is composited by three layers, the defect that single-unit solid wood flooring is easy to deform is overcome, and the solid wood flooring is more stable and adaptable to geothermal environments. By the production process of the three-layer composite solid wood flooring, valuable timber can be utilized reasonably and the percentage of outturn can be increased while waste of timber can be reduced.

Owner:DAYA JIANGSU FLOOR

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

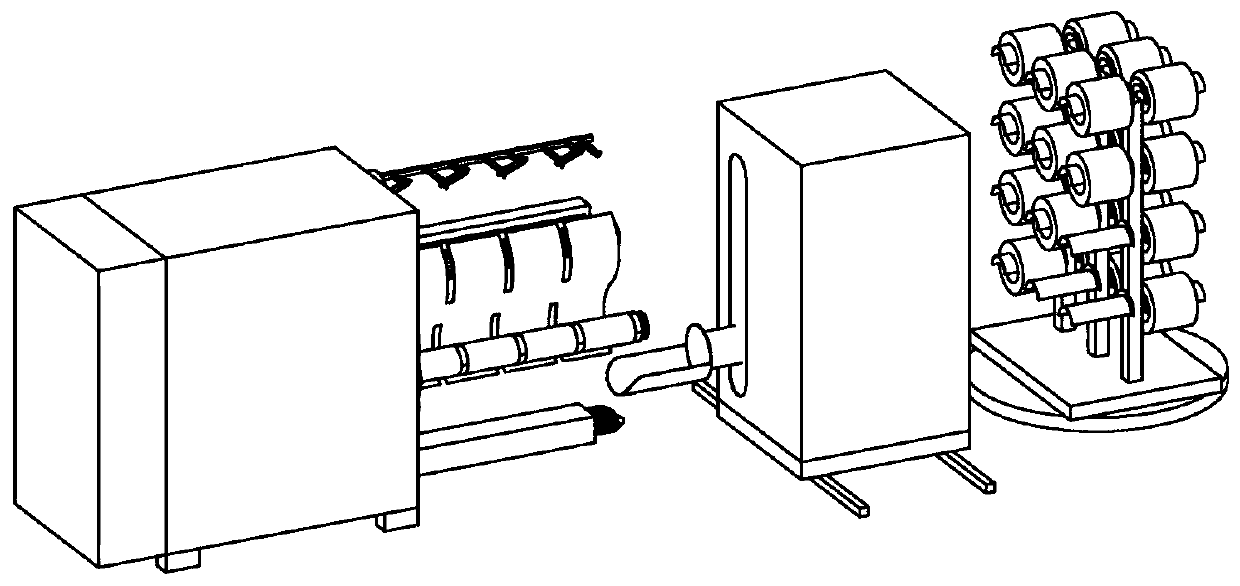

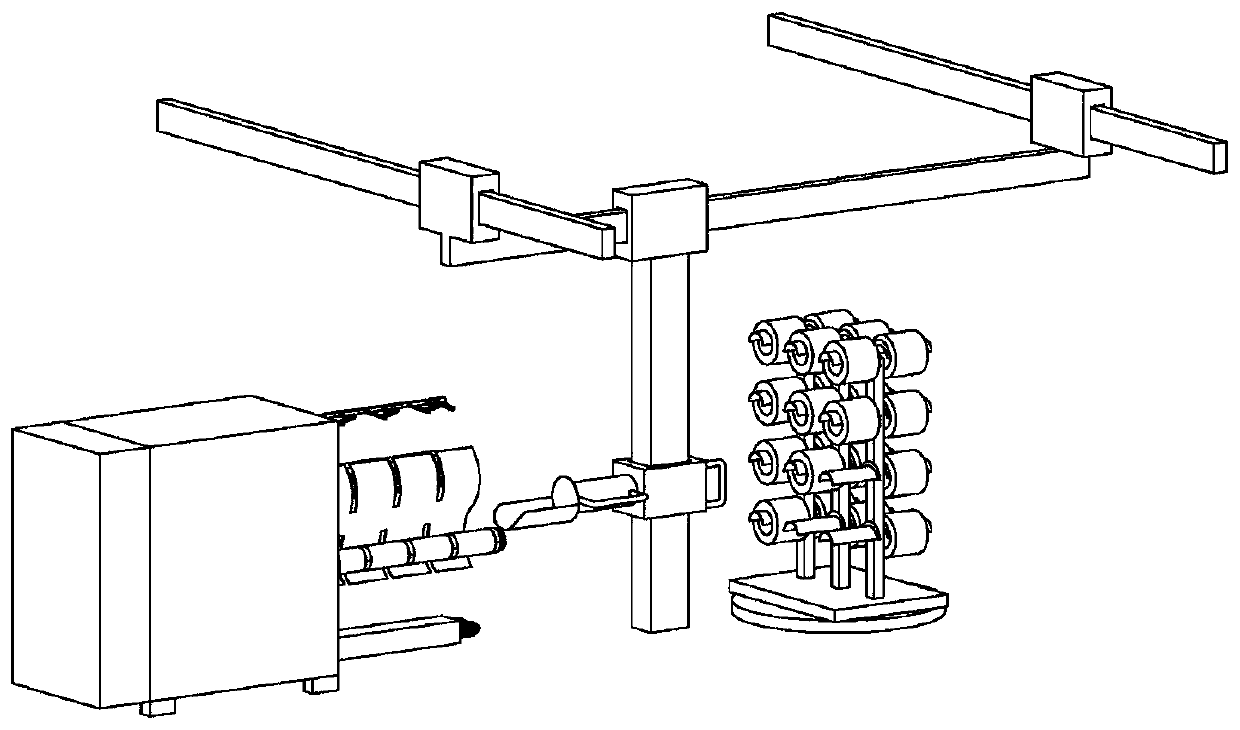

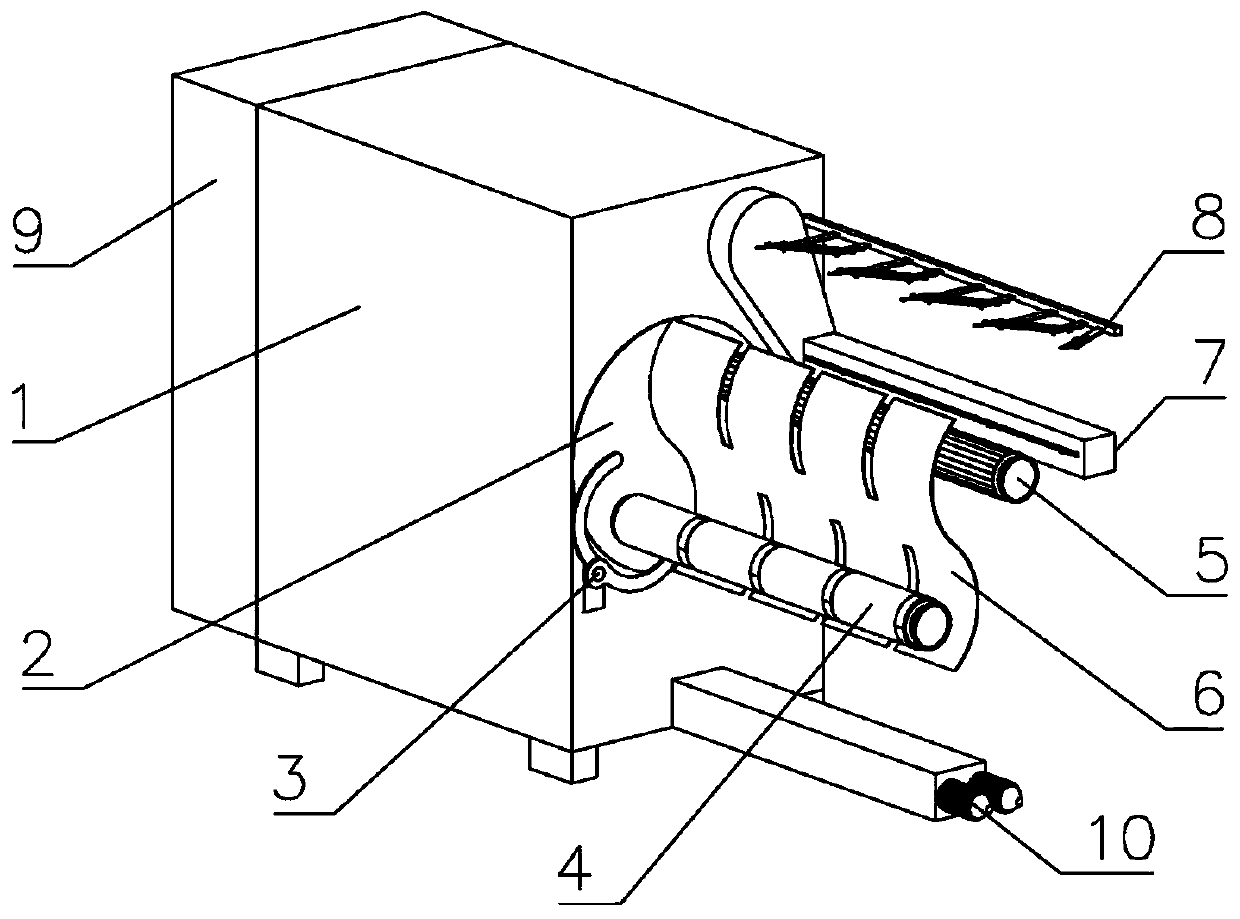

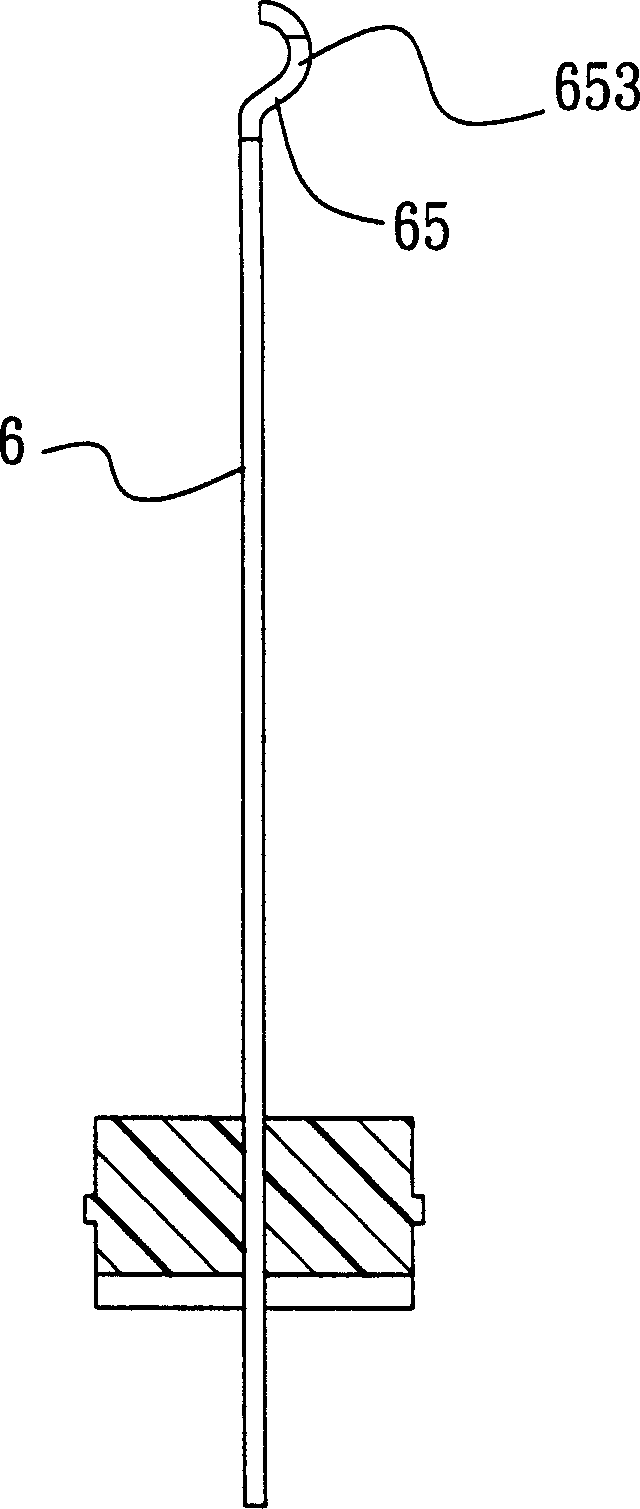

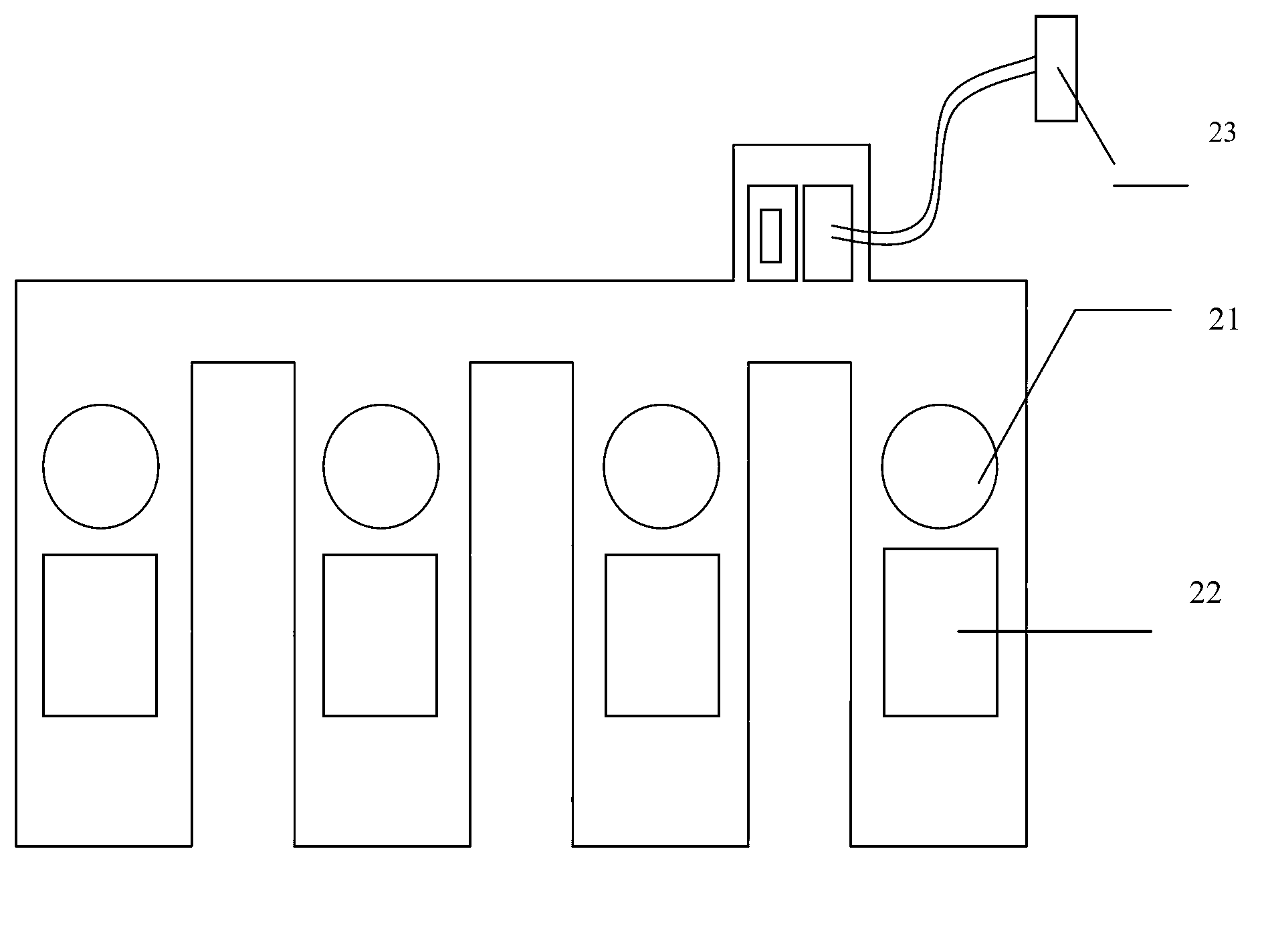

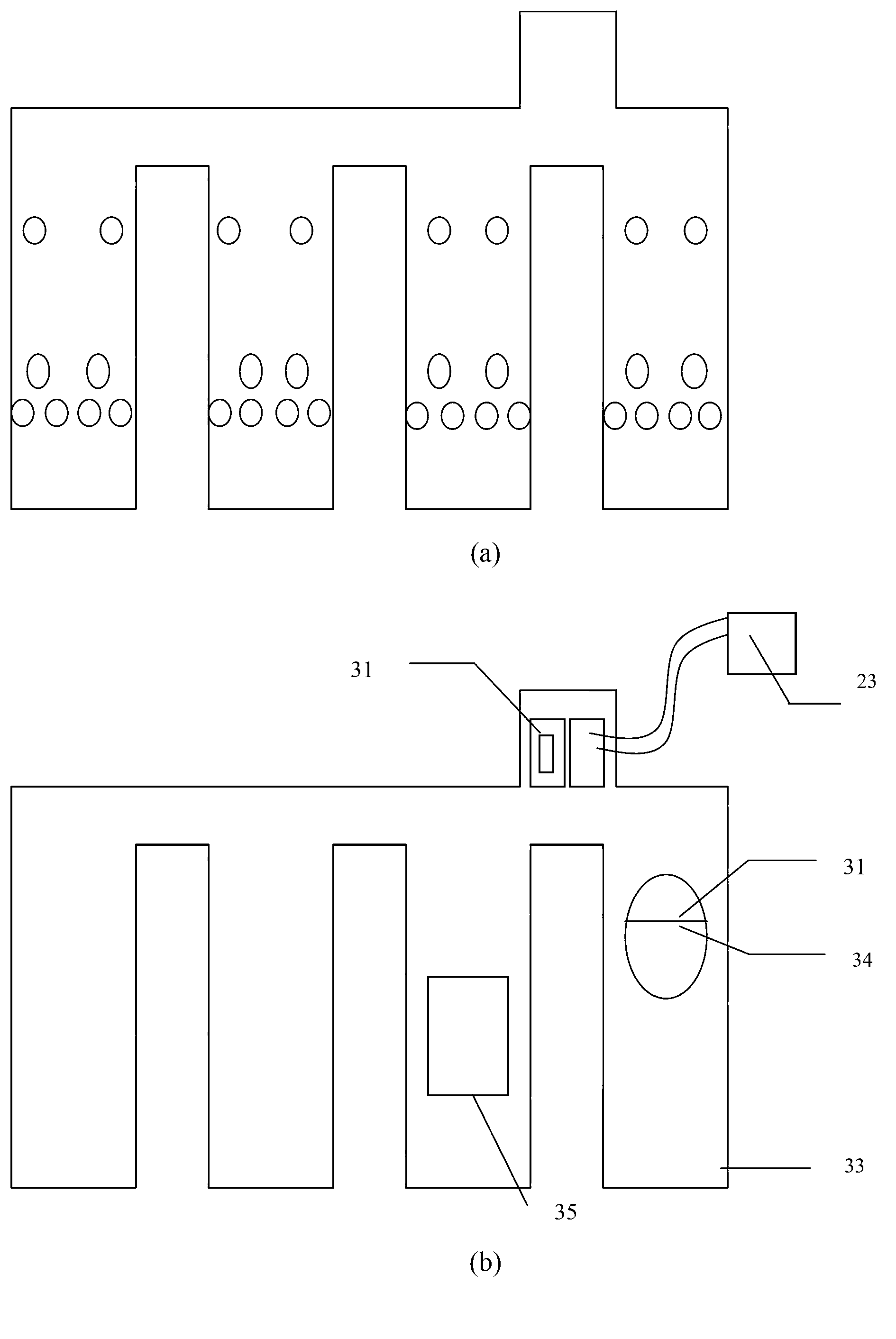

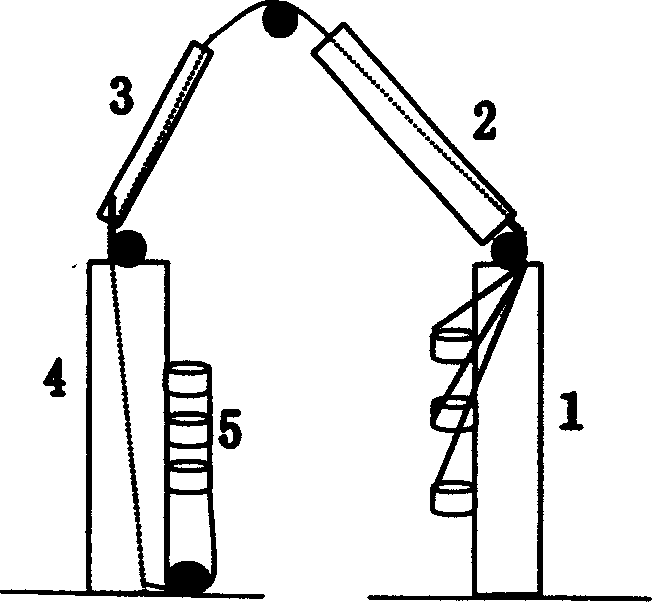

Intelligent glass fiber forming and winding device

An intelligent glass fiber forming and winding device comprises a winding head and a tube changing mechanism installed on a main frame, wherein the tube changing mechanism comprises a rotating disk and a yarn guide, at least one yarn winding tube is sleeved on the winding head and comprises a winding section and a tube changing section, and the tube changing section can be used to cut off and windthe yarn; the yarn guide can rotate clockwise or counterclockwise relative to the main frame and comprises a yarn guide rotating shaft and a tube changing yarn guiding rod and a loading yarn guidingrod that are fixed on the yarn guide rotating shaft, and both ends of the tube changing yarn guiding rod are inconsistent with respect to the axis of the yarn guide rotating shaft such that the yarn guide rotating shaft rotates during the tube changing process, and the yarn can slide from the highest end to the lowest end along the tube changing yarn guiding rod, thereby poking the yarn to the tube changing section on the corresponding winding tube. The intelligent glass fiber forming and winding device provided by the invention has reasonable structure and easy operation, and can effectivelyimprove the production efficiency and product quality of glass fiber.

Owner:ТАЙ'АНЬ ШУНЬМАО НЬЮ МЕТЕРИАЛ ТЕХНОЛОДЖИ КО., ЛТД.

High-activity nitrification inhibition type multifunction fertilizer synergist and preparation method thereof

InactiveCN102910973AEasy to prepareInhibitory activityAgriculture gas emission reductionFertilizer mixturesVitamin CPhosphate

The invention relates to a high-activity nitrification inhibition type multifunction fertilizer synergist and is applicable to the field of agriculture and forestry. The high-activity nitrification inhibition type multifunction fertilizer synergist is composed of following raw materials of, by weight, 3-35% of vitamin C, 3-35% of N-acyl sodium glutamate, 3-35% of 3,4-dimethylpyrazole phosphate (DMPP), 3-35% of farm-oriented rare earth, 5-35% of fulvic acid, 0.5-2.5% of compound sodium nitrophenolate, 15-45% of vermiculite and 15-45% of medical stones. The raw materials are smashed, screened by a 30-100 mesh screen, then stirred and mixed according to a certain ratio to obtain the fertilizer synergist. The fertilizer synergist is applicable to slow-acting nitrogen fertilizers or composite nitrogen fertilizers which use ammonium nitrogen fertilizers or urea as raw materials and is capable of being matched with the ammonium nitrogen fertilizers or the urea to be simultaneously applied to various types of soil, the fertilizer efficiency period of nitrogen fertilizers with the added multifunction fertilizer synergist can be prolonged to 90-110 days, abilities of drought resistance and disease resistance can be obviously improved, soil microorganism activities and crop root system activities can be stimulated, effectiveness and utilization efficiencies of soil fertilizers can be improved, and residual effects on crops are obvious.

Owner:GUANGXI NEW ORIENTATION CHEM IND

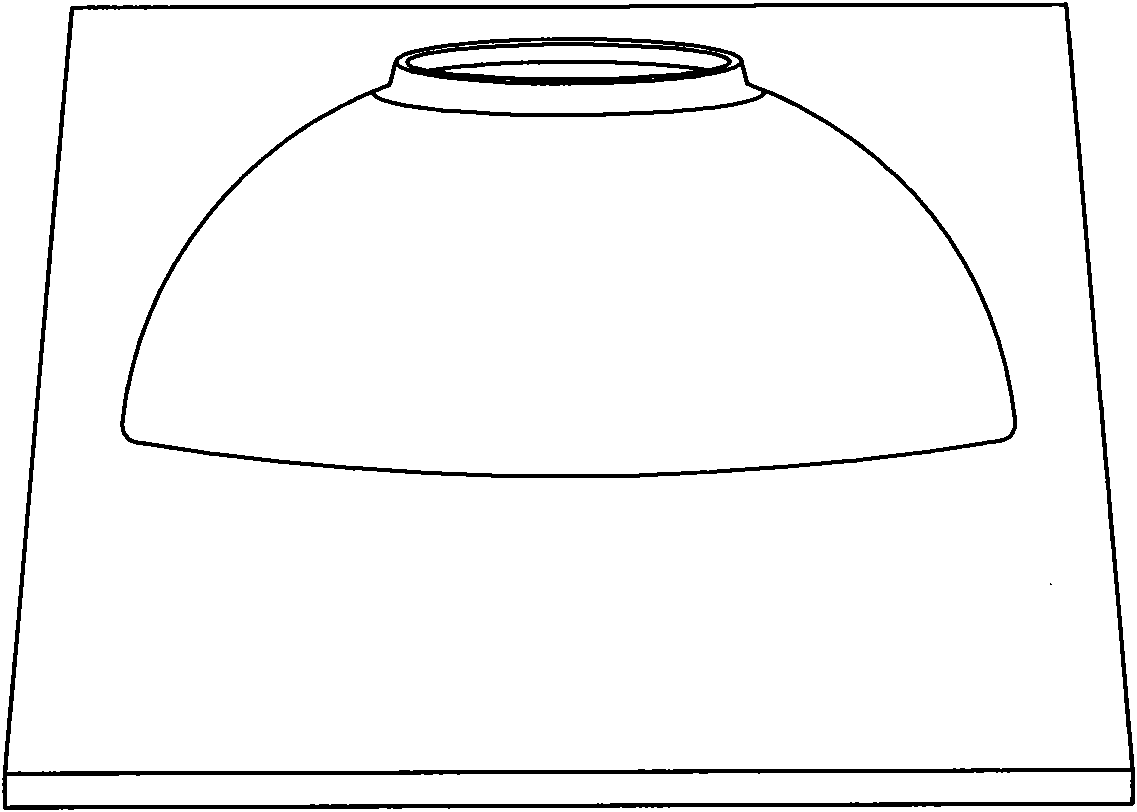

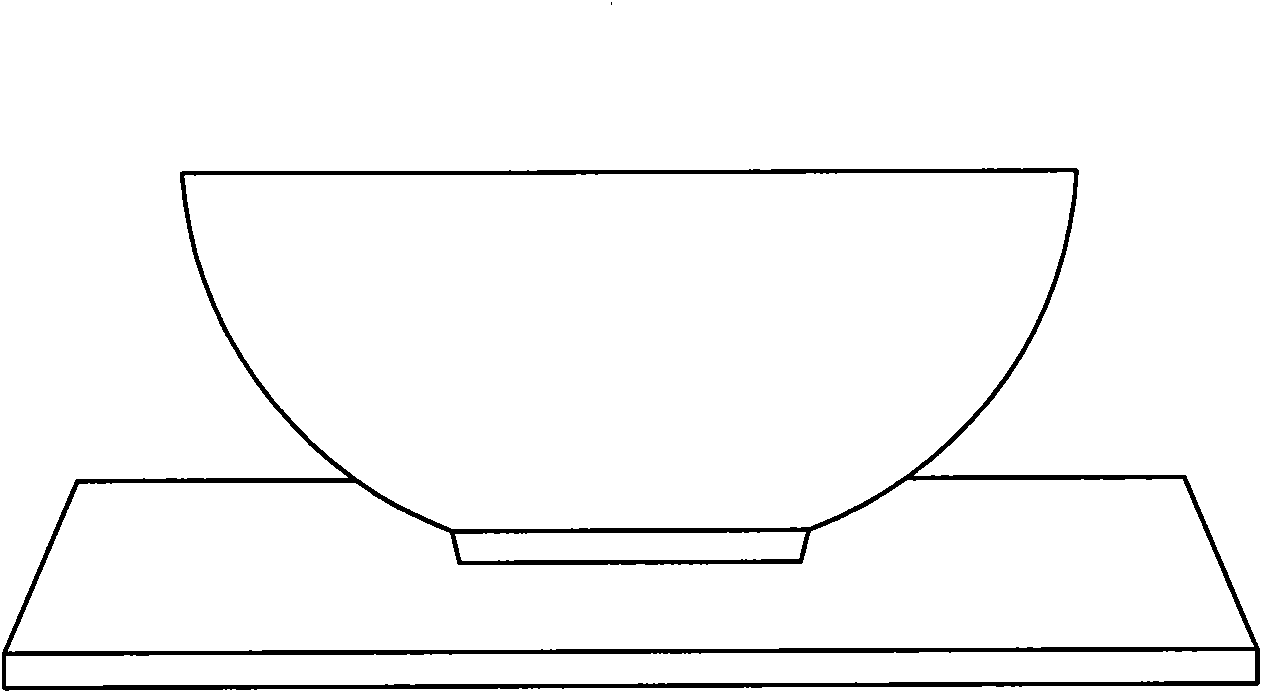

Method for firing domestic porcelain

The invention relates to a method for firing a domestic porcelain, in particular to the method for firing high-grade domestic porcelains, such as bowels and cups. The method comprises the following steps of: 1, drying a finished body, placing the body into a kiln to perform biscuit firing at the low temperature of 800 to 900 DEG C, and polishing the biscuit-fired body to smooth; 2, glazing the biscuit-fired body and removing glaze at the mouth rim and foot of the product; 3, directly placing the product on a refractory slab in a reversing way for primary high-temperature glaze firing; and 4, turning the product over, cleaning and partially glazing the mouth rim of the product, placing the product into the kiln again in an erecting way for secondary high-temperature glaze firing, and cooling the product to obtain the finished product. Compared with the conventional low-temperature biscuit-firing high-temperature glaze-firing method or high-temperature biscuit-firing low-temperature glaze-firing method, the method is convenient to operate, ensures the light weight and high superior quality rate of the fired finished product, and is very applied to the production of various high-grade domestic porcelain products, such as the bowels and the cups.

Owner:FUJIAN DEHUA JIASHUN CRAFTS

Terylene middle strength filament oil solution and production method thereof

The invention discloses a terylene moderately strong filament finish agent, mainly consisting of polyether, emulsifier, antistatic agent and additive; the invention is characterized by the part of the ingredients by weight: 75-85 parts of polyether, 6-15 parts of emulsifier, 3-8 parts of antistatic agent and 3-7 parts of additive; the preparation method thereof is as follows: according to the weight percentage of the components, exactly measured emulsifier, polyether and antistatic agent are sucked into a reaction kettle, heated to the temperature of 45-55 DEG C and evenly stirred, and then the additive is sucked into the reaction kettle and stirred for 30-50min, after even stirring, the mixture is cooled, filtered and packaged. Compared with the prior art, the finish agent has the advantages that the particles of the latex emulsion are fine, the finish agent is stable and easy to prepare and has no obvious putridity; ossified filament or broken filament is few, and abnormal broken end does not appear; the finish agent has good heat resistance and no obvious smoke; coking is little, winding formation is good, oil is evenly distributed in the fiber, the quality is steady and the elasticity is normal.

Owner:TONGKUN GRP

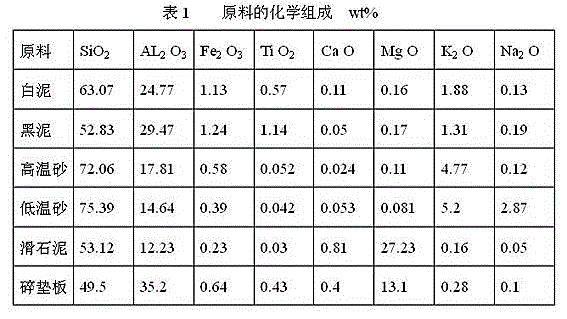

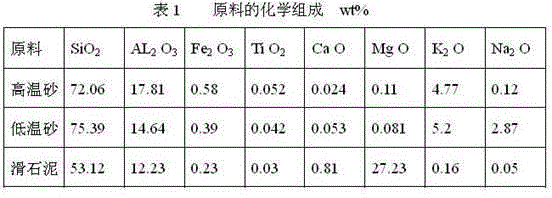

Production method of ultrathin outer wall full-body brick

The invention discloses a production method of an ultrathin outer wall full-body brick, relating to the technical field of architectural ceramics manufacturing. The ultrathin outer wall full-body brick is produced from the following raw materials in percentage by weight: 20% of white mud, 8% of black mud, 6% of high-temperature sand, 40% of low-temperature sand, 8% of talc mud and 18% of broken cushion board. The production method comprises the following steps of: mixing the raw materials, ball-milling the mixture in a ball mill, sieving the slurry, spraying the sieved slurry into powder by using a spray drying tower, and ageing the powder for later use; dry-pressing the powder into a green body with 4.1-4.2 mm in thickness by using a large-tonnage press; and placing the green body on a cushion board through a vacuum absorber, sending the green body placed on the cushion board together with the cushion board into a roller kiln to fire, controlling the firing temperature within the range of 1190 DEG C to 1230 DEG C, and firing the green body for 60 min to obtain the finished product. Compared with the prior art, the breaking strength of the ultrathin outer wall full-body brick is 500 N and meets the requirement that the average breaking strength in the standard Ceramic Thin Brick for Outer Wall is greater than or equal to 350 N.

Owner:岑溪市新建球陶瓷有限公司

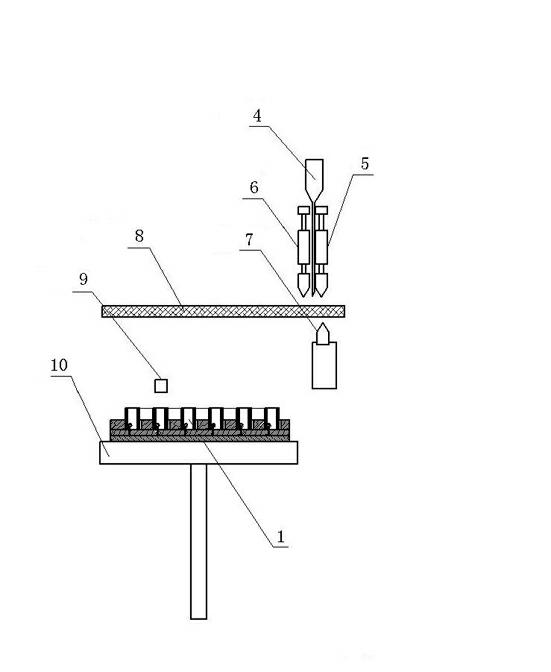

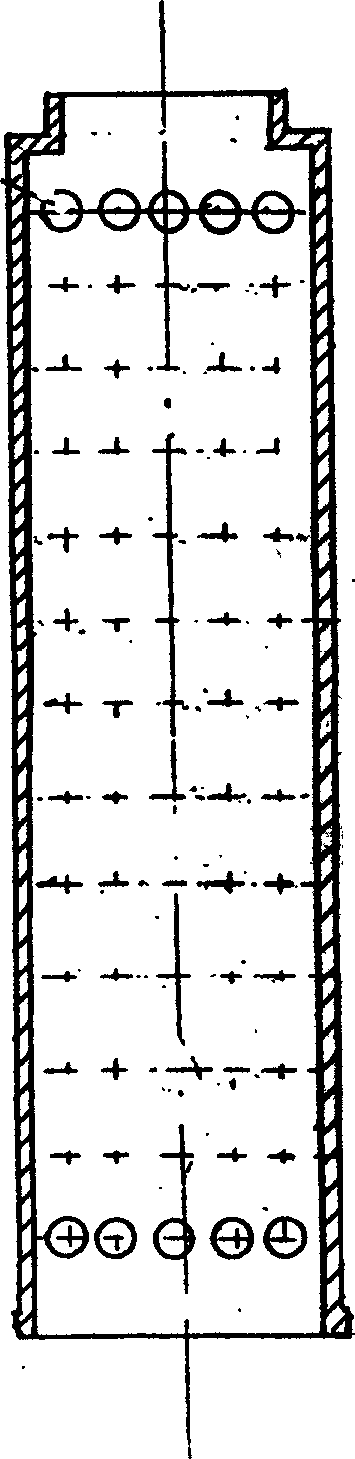

Automatic plane screen paste printing technology for metalizing ceramic discharge tube

ActiveCN102490454AUniform thicknessImprove consistencyScreen printersOther printing apparatusMetallurgySieve

The invention discloses an automatic plane screen paste printing technology for metalizing a ceramic discharge tube. Apart from a paste preparation step, the technology also comprises the following steps of: 1) fixing a ceramic piece; 2) mounting a stainless steel sieve, wherein the screen mesh of the stainless steel sieve is 100, and tension is about 300+ / -20 N / cm<2>; 3) adjusting a doctor blade, an objective table and a leakage blade; 4) uniformly distributing the paste; and 5) printing the paste. Through the invention, the metallized paste layer has uniform thickness, good consistency and smooth surface; the technology adopts automatic operation and has high paste coating efficiency; and the process is easy to control, and the quality is easy to guarantee.

Owner:XIAOGAN HANDA ELECTRONICS COMPONENT

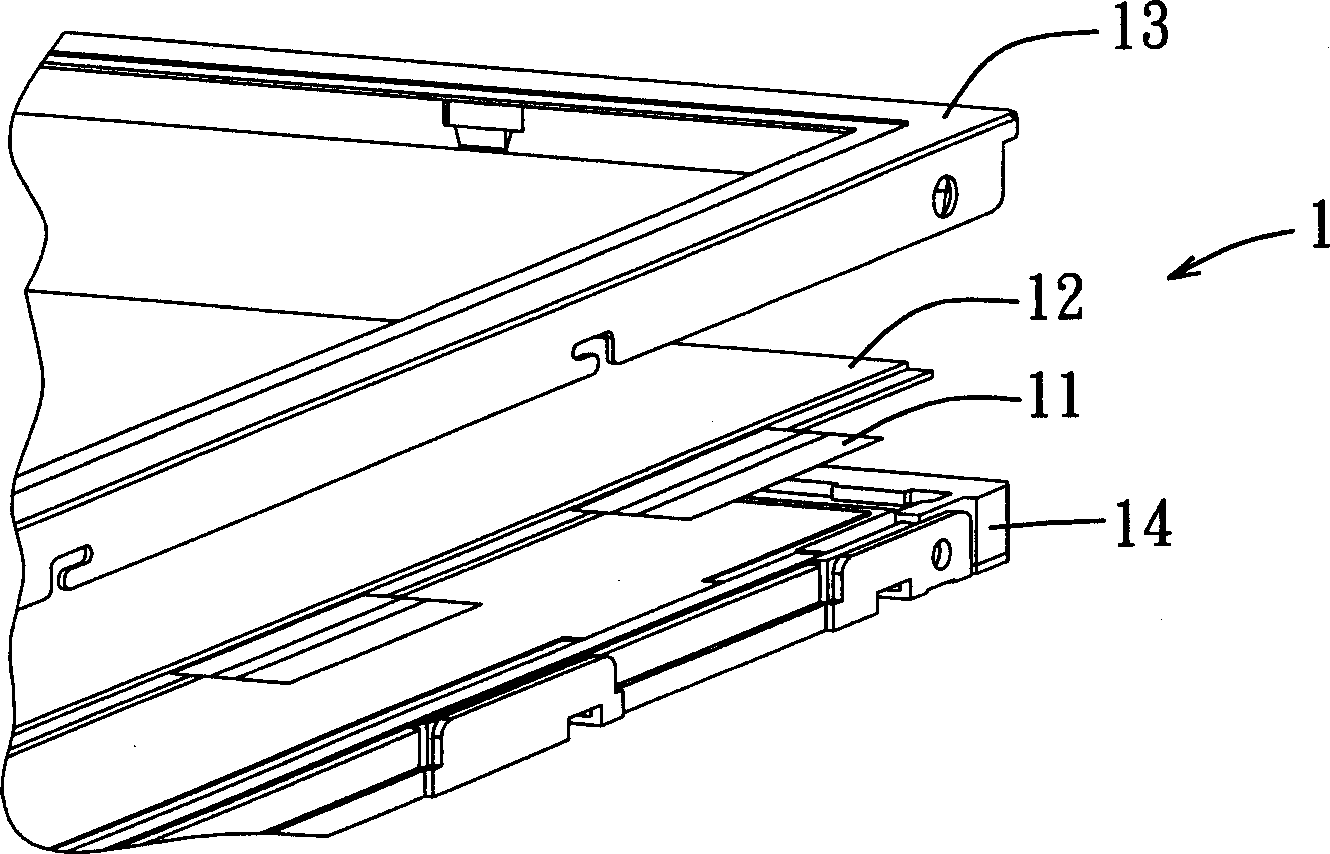

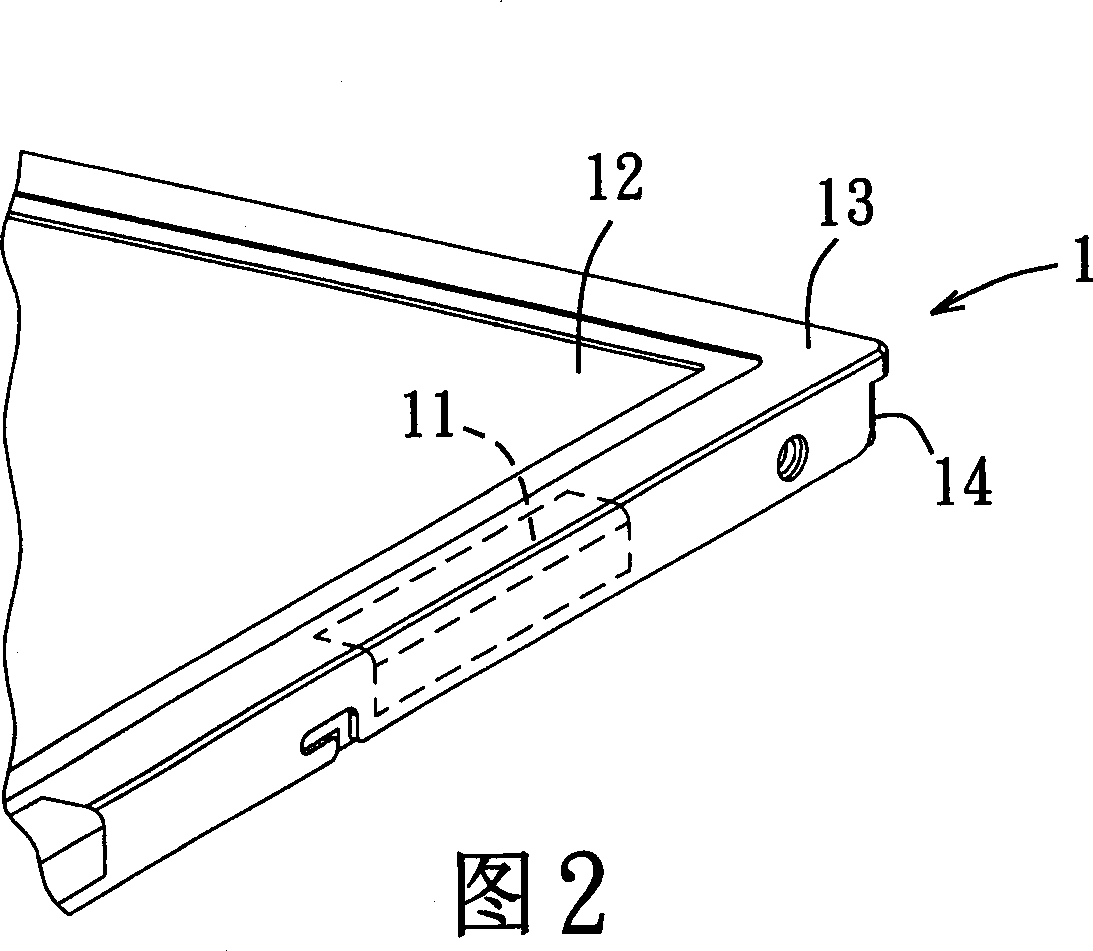

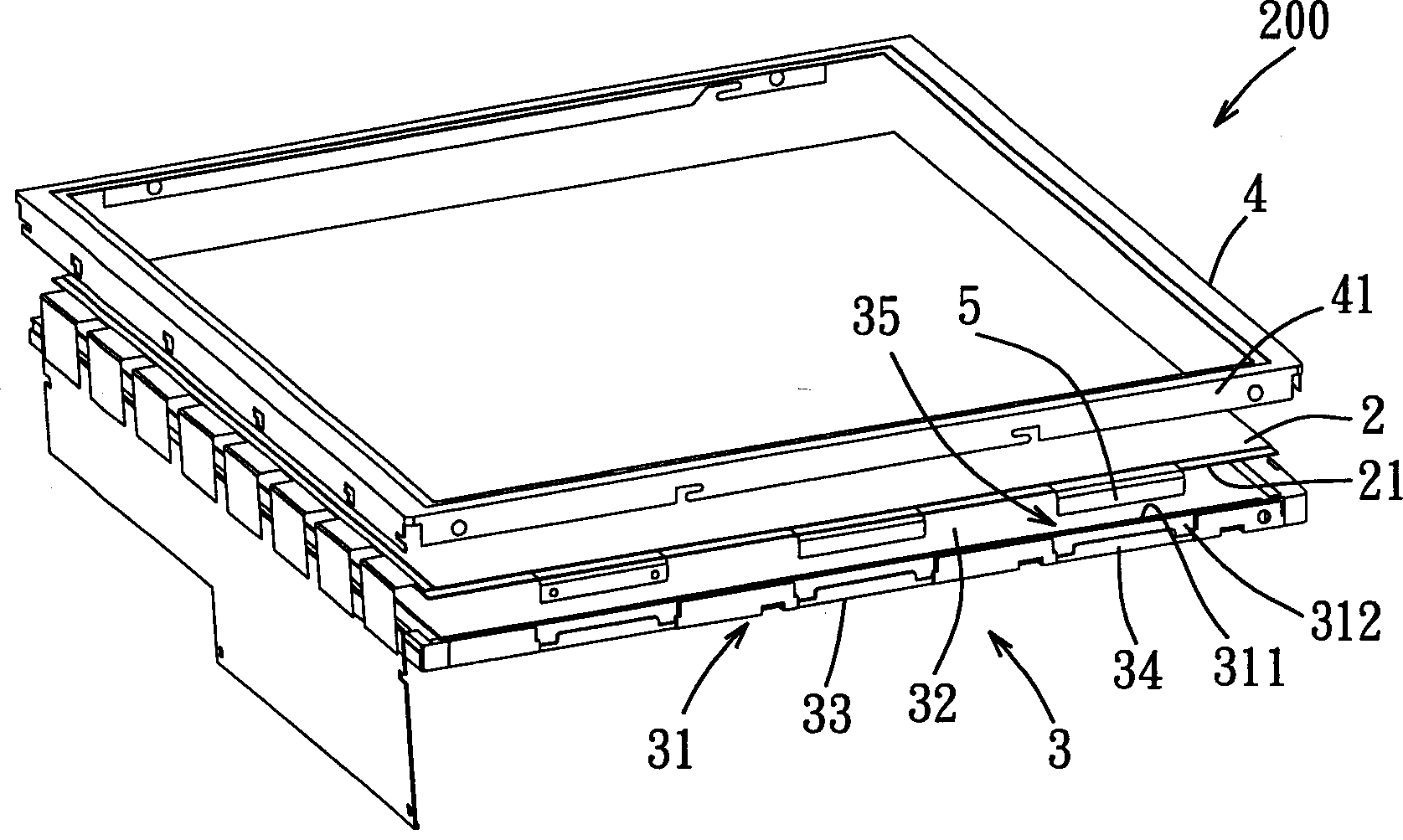

Liquid crystal panel module with coated film limiting device

InactiveCN1815307ACause scratchesNo adverse effectsStatic indicating devicesSemiconductor/solid-state device manufacturingComputer moduleEngineering

The module includes a liquid crystal faceplate, a base, and an outline border bonded the base. Multiple pieces of polycrystalline film with spacer connected electrically are installed on selected side of the liquid crystal faceplate. The base possesses accommodation space enclosed by stand-up sidewalls for the liquid crystal faceplate to be placed. Position-limited parts are setup at outside of the vertical sidewalls corresponding to places, where pieces of polycrystalline film are installed. Multiple pieces of polycrystalline film are bent and constrained on position limited parts so that in procedure of assembling module, pieces of polycrystalline film will not be scratched caused by pressing outline border together. Therefore, unflavored influence on polycrystalline film in assembled module caused by vibration of force can be avoided, so as to raise ratio of fine products.

Owner:CHUNGHWA PICTURE TUBES LTD

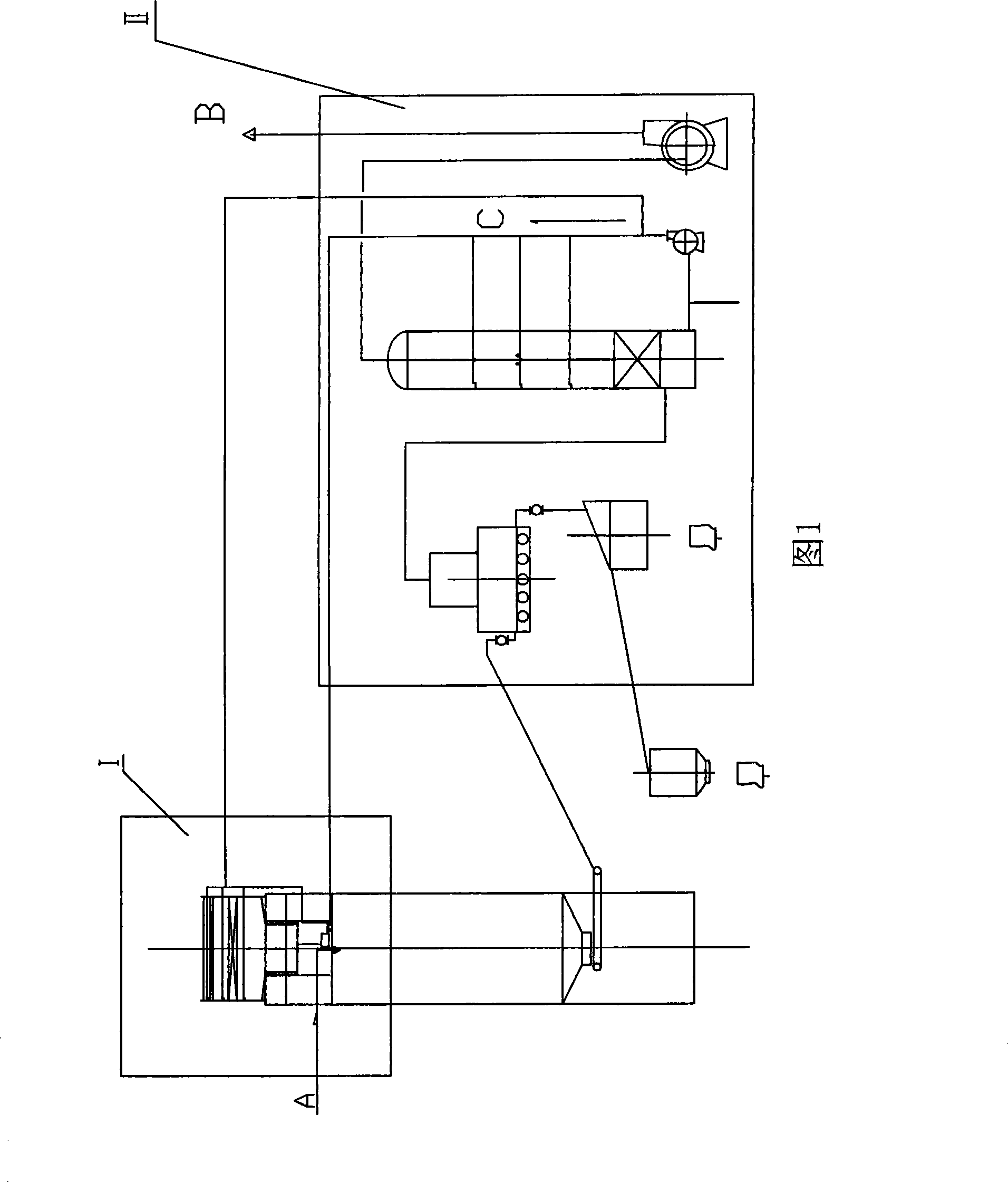

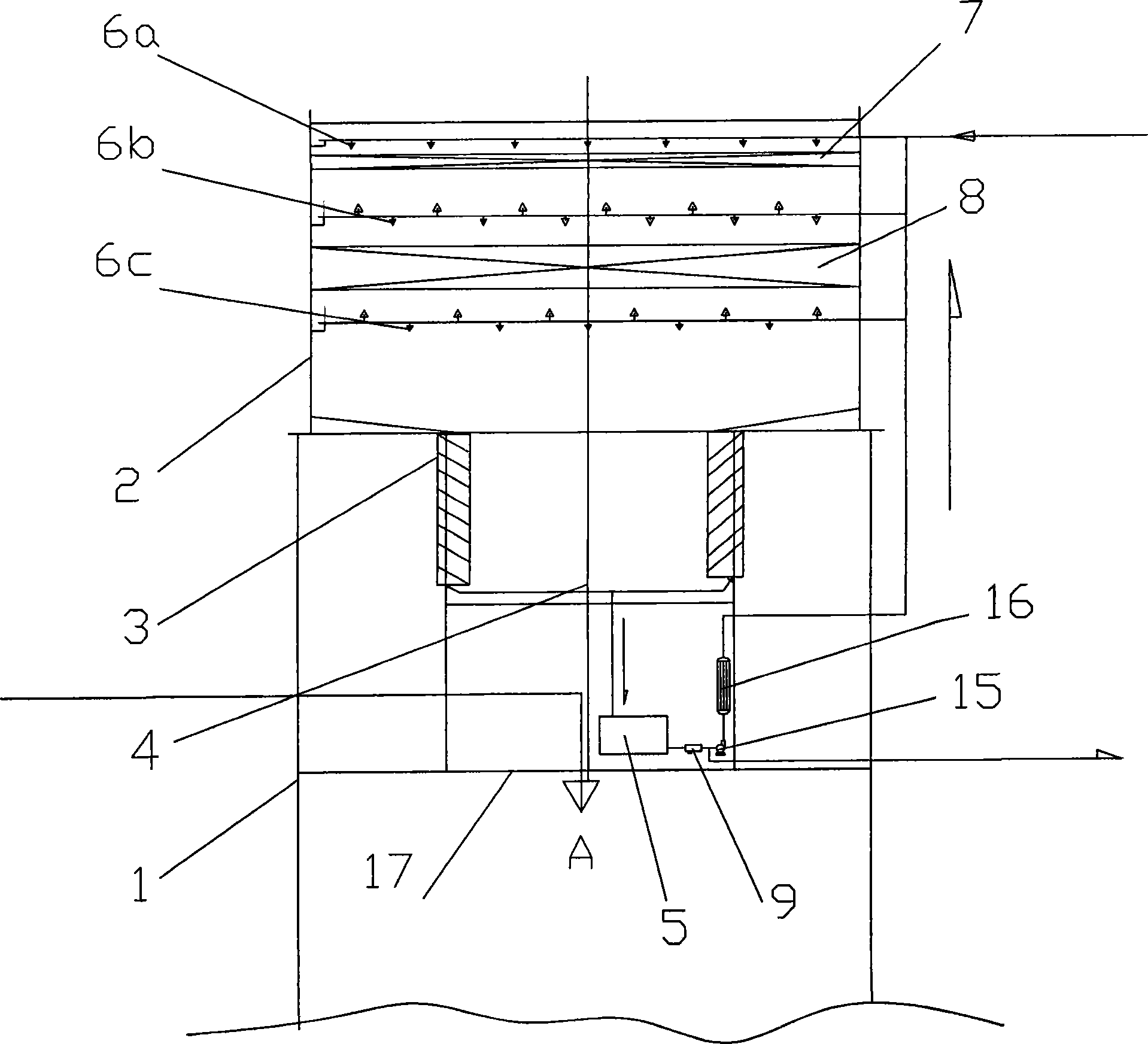

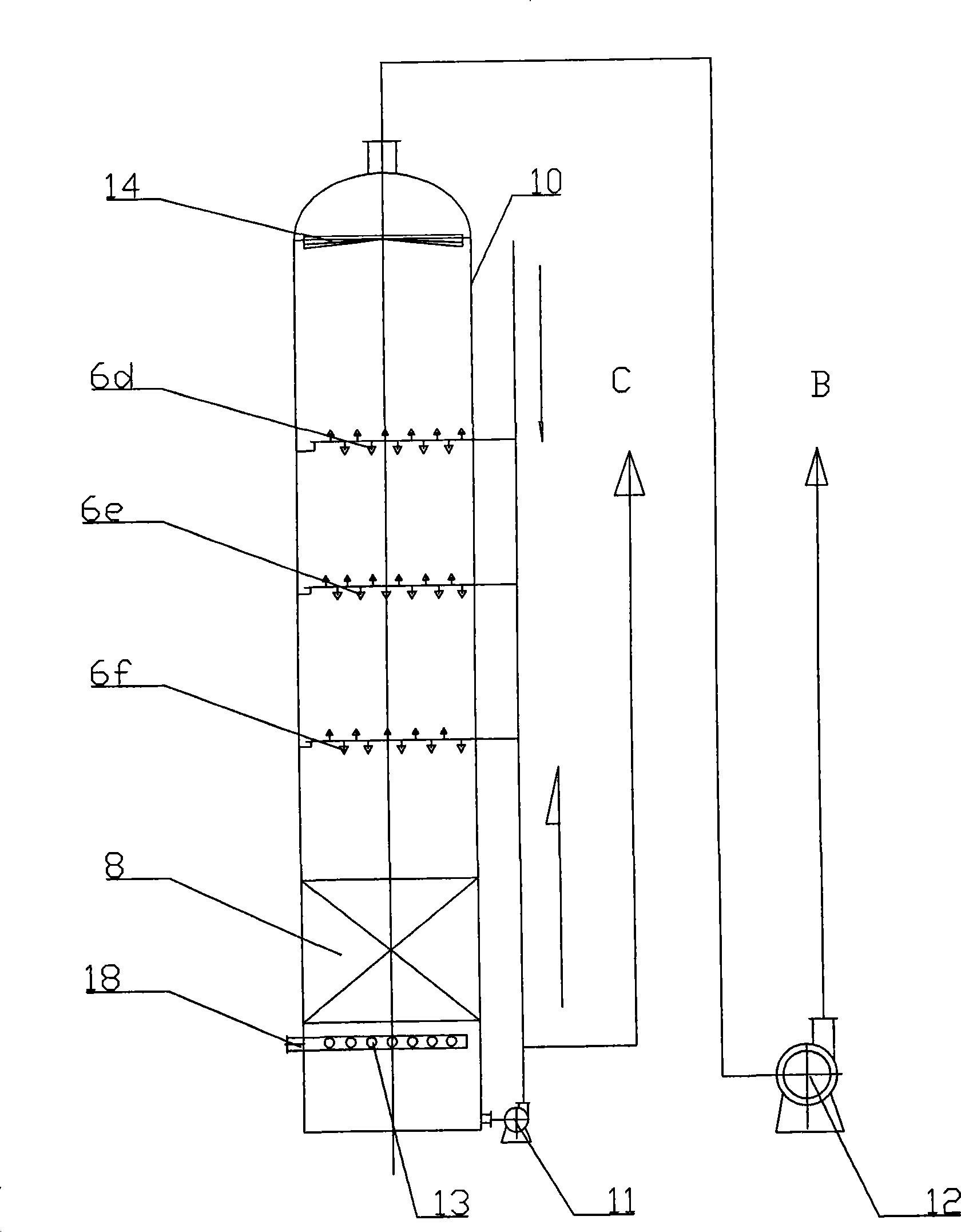

Method and device for recovering dust of urea granulation

InactiveCN101239268AImprove the rate of excellent productsReduce resistanceDispersed particle separationRecovery methodPotential difference

The present invention provides a dust recycling method and apparatus of urea prilling, the recovery method is synchronous recycling prilling dust and cooling dust when a water absorption liquid processes closed-circuit in multiple system or series connected system set in the prilling tower top device (I) and the flooring device (II). A multilevel nozzle is set in the device I and the device II, dust is absorbed respectively by atomizing water, the absorption liquid absorbs prilling dust and then returns to the fluid storage tank (5) in the device I, and cycled to the device I after absorbing cooling dust by potential difference in the device II. A gas distributed device and a gas-liquid separating device, pumps (15, 11) are respectively set in the device I and the device II to cycle, when the concentration of urea in absorption fluid is > / = 25%, the absorption fluid is transferred to the steam evaporating system to recycling urea. The method and device recycle the prilling dust and the cooling dust at the same time, not only improve the super quality efficiency of the product, but also the discharging tail gas keep with the national environmental protection standards.

Owner:HARBIN HUIZHONG ENVIRONMENTAL PROTECTION TECH DEV CO LTD

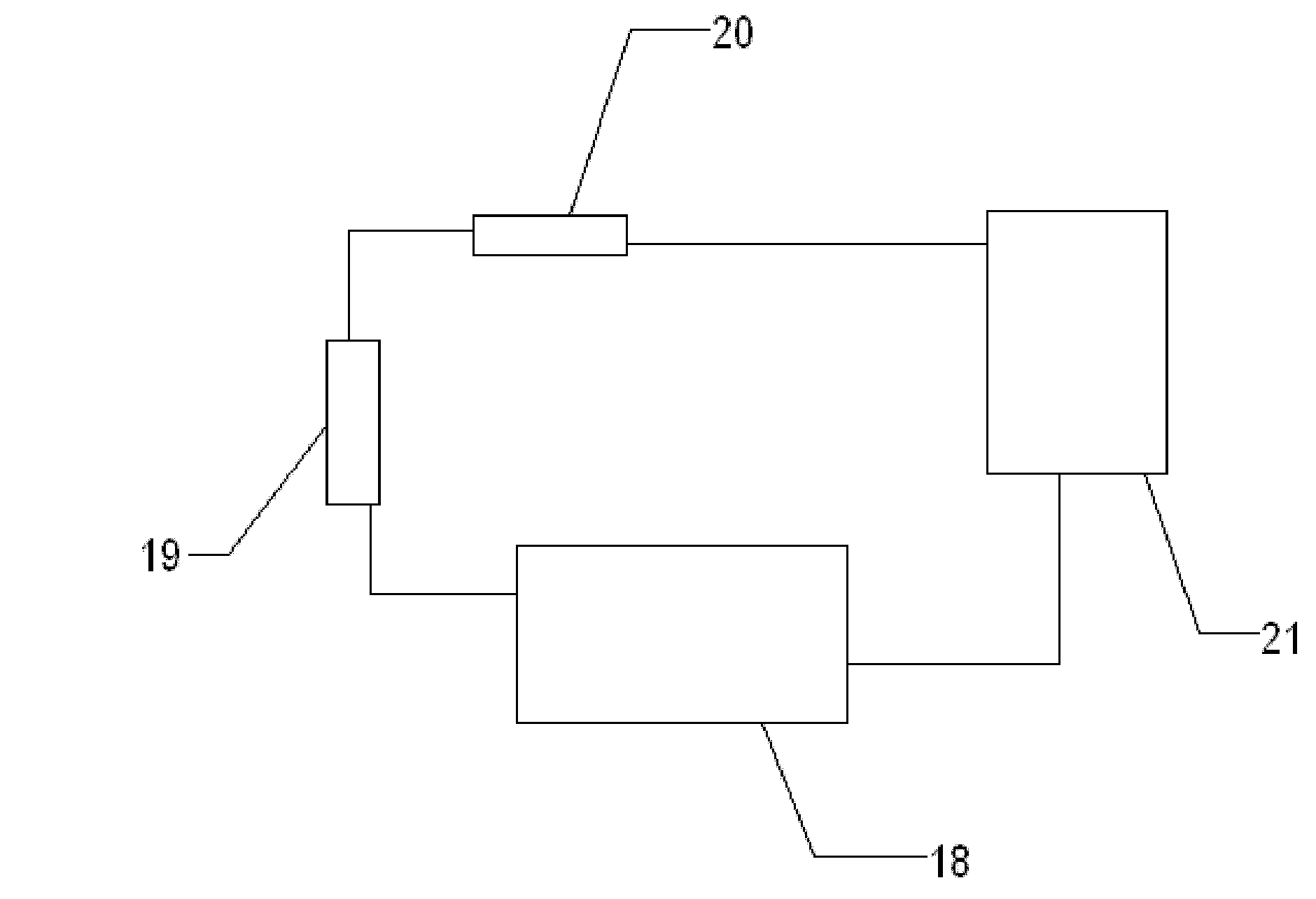

Method for producing electrodeposition cobalt

ActiveCN101914784AQuality improvementHigh recovery ratePhotography auxillary processesSlagWorking environment

The invention relates to a method for producing electrodeposition cobalt, which can effectively inhibit the generation of anode slag and improve the recovery rate of cobalt. In the method, an electrodeposition solution contains CoCl2 and hydroxylamine hydrochloride, the concentration of the hydroxylamine hydrochloride in the electrodeposition solution is 0.03-0.06g / l, the pH value of the electrodeposition solution is 1.5-2.5, and preferably, the electrodeposition time is 60-80h. The electrodeposition is carried out preferably in a closed electrodeposition device which comprises an electrodeposition tank, a tail gas absorbing device, a circulating pump and an electrolyte storage tank that are serially connected, wherein the tail gas absorbing device is connected with the outlet of the electrodeposition tank. The invention has the advantages of remarkably improving the quality and the recovery rate of a cobalt product, having small occupation area and simple operation, lowering the labor intensity, ensuring the high yield of high-class cobalt products, and effectively improving the working environment and preventing the pollution when the whole procedure is carried out under the fully-closed condition.

Owner:GEM JIANGSU COBALT IND CO LTD +1

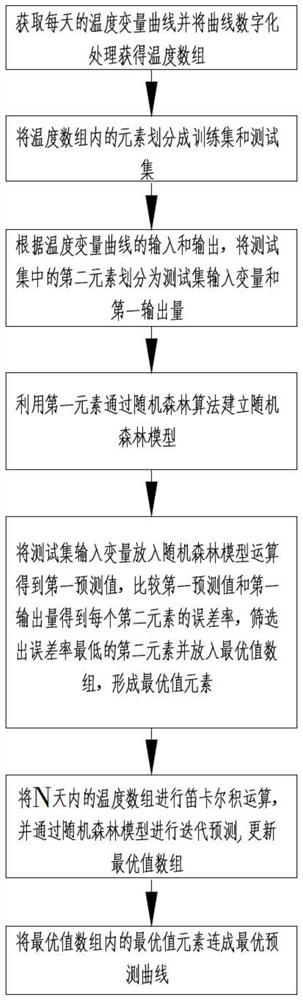

Data analysis method and data analysis system for firing system of architectural ceramic kiln

PendingCN113642800AImprove the rate of excellent productsIncrease productionForecastingCharacter and pattern recognitionData acquisitionData analysis system

The invention discloses a data analysis method and a data analysis system for a firing system of an architectural ceramic kiln. The data analysis method comprises generating an optimal prediction curve through a data obtaining step, a model building step, a data prediction step and an optimal prediction curve forming step. According to the model building step, Cartesian product operation is carried out on a temperature array value_range within N days, iterative prediction is carried out through a random forest model, and an optimal value array is updated; a data analysis system generates the optimal prediction curve through a data acquisition module, a model building module, a data prediction module and an optimal prediction curve forming module. According to the data analysis method and the data analysis system for the building ceramic kiln firing system, the optimal prediction curve is formulated, so that the problem that the firing efficiency and the yield of ceramic tiles are affected due to long service time of manual adjustment is solved.

Owner:西藏众陶联供应链服务有限公司

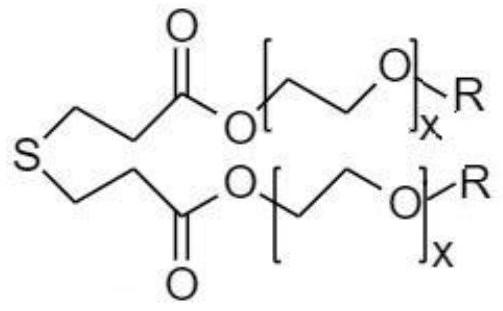

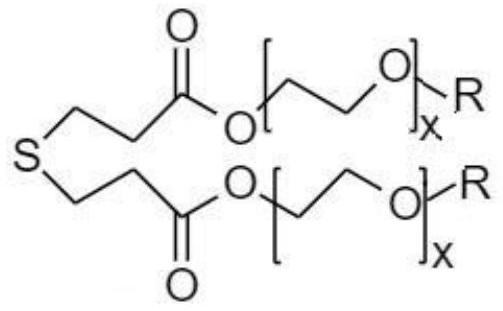

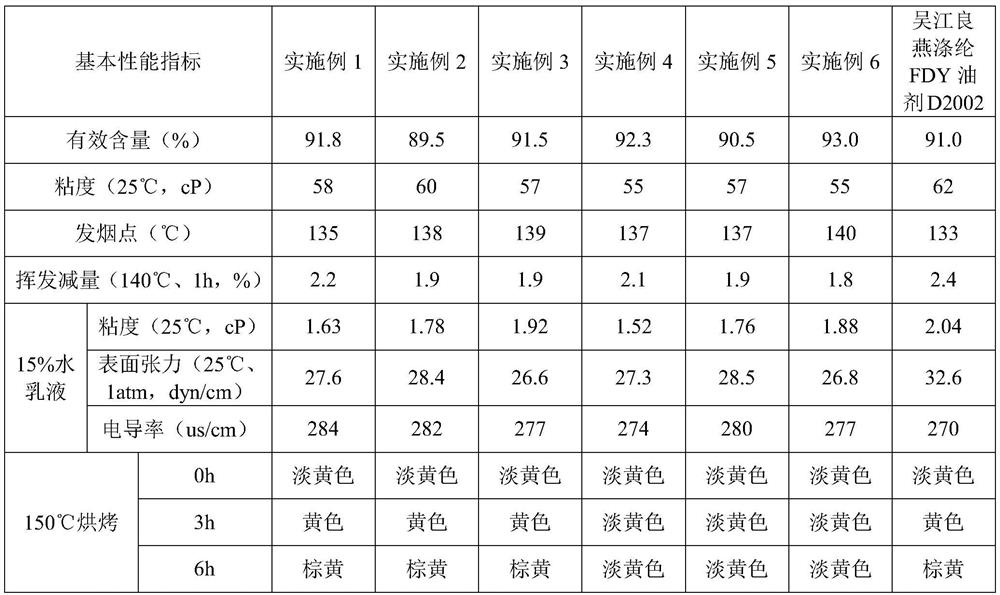

Dacron FDY oiling agent and preparation method thereof

The invention discloses a dacron FDY oiling agent and a preparation method thereof, and relates to the field of dacron spinning oiling agents. The dacron FDY oiling agent is composed of the followingcomponents of, in percentage by weight, 14%-33% of base oil, 24%-38% of a smoothing agent, 7%-11% of a bundling agent, 7%-11% of an emulsifier, 5%-7% of an antistatic agent, 1%-3% of a penetrant, andthe balance additives. According to the dacron FDY oiling agent and the preparation method thereof, through the selection and proportioning of monomers, the prepared FDY oiling agent has good comprehensive properties of smoothness, bundling, static electricity resistance, permeation, heat resistance, sizing and uniform adhesion, is good in spinnability, greatly reduces abnormal broken filaments, broken ends, white powder and tension fluctuation and winding phenomena, and can significantly improve the superior product rate under the same spinning process conditions. In the subsequent printing and dyeing process, dyeing is difficult, the phenomenon of uneven dyeing is reduced, and the fiber dyeing M rate is increased.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

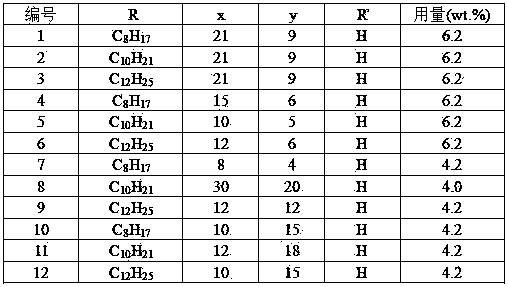

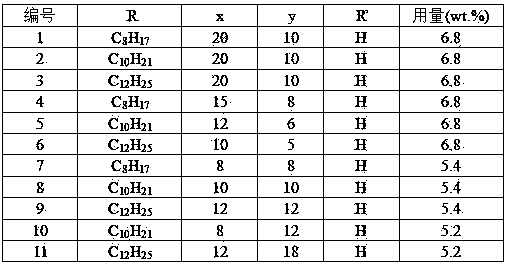

High-speed spinning oil used for polyester pre-oriented yarn (POY)

The invention relates to high-speed spinning oil used for polyester pre-oriented yarns (POY). The high-speed spinning oil used for the POY comprises a main part which contains more than twenty polyether type compounds of multiple components and multiple structures and accounts for 70-92% of the total mass, and the rest part is additive. A molecular structure of the polyether type compounds is RO[(EO)x / (PO)y]R', wherein end groups R and R' are H, or C1-C18 alkane, aryl, acyl or acylamino, or inorganic acid radical; [(EO)x / (PO)y] is a polyether chain segment composed of oxoethylene group and / or isopropoxy. The high-speed spinning oil used for the POY is applicable to polyester pre-oriented high-speed spinning and a subsequent textured yarn production technology and can give good smoothness and bundling property, overall viscosity-temperature-concentration characteristic and excellent thermal property to fibers, fewer broken filaments of the fibers are produced in the next drafting process, evenness and dyeing are uniform, little smoke is produced by a processing hot box, little white powder and coke are produced, a cleaning period is long, and product quality and stability are good.

Owner:江苏天音化工有限公司

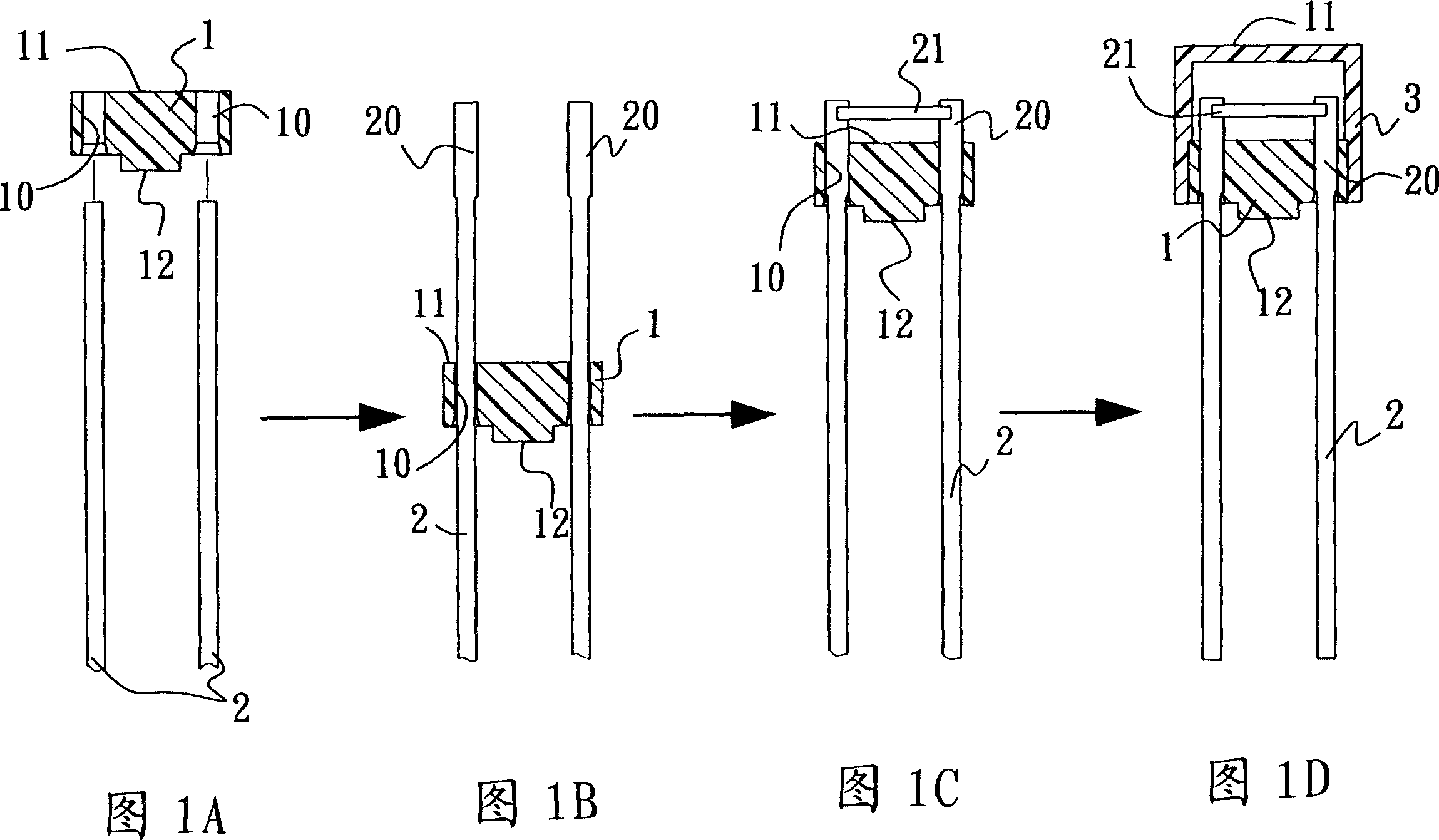

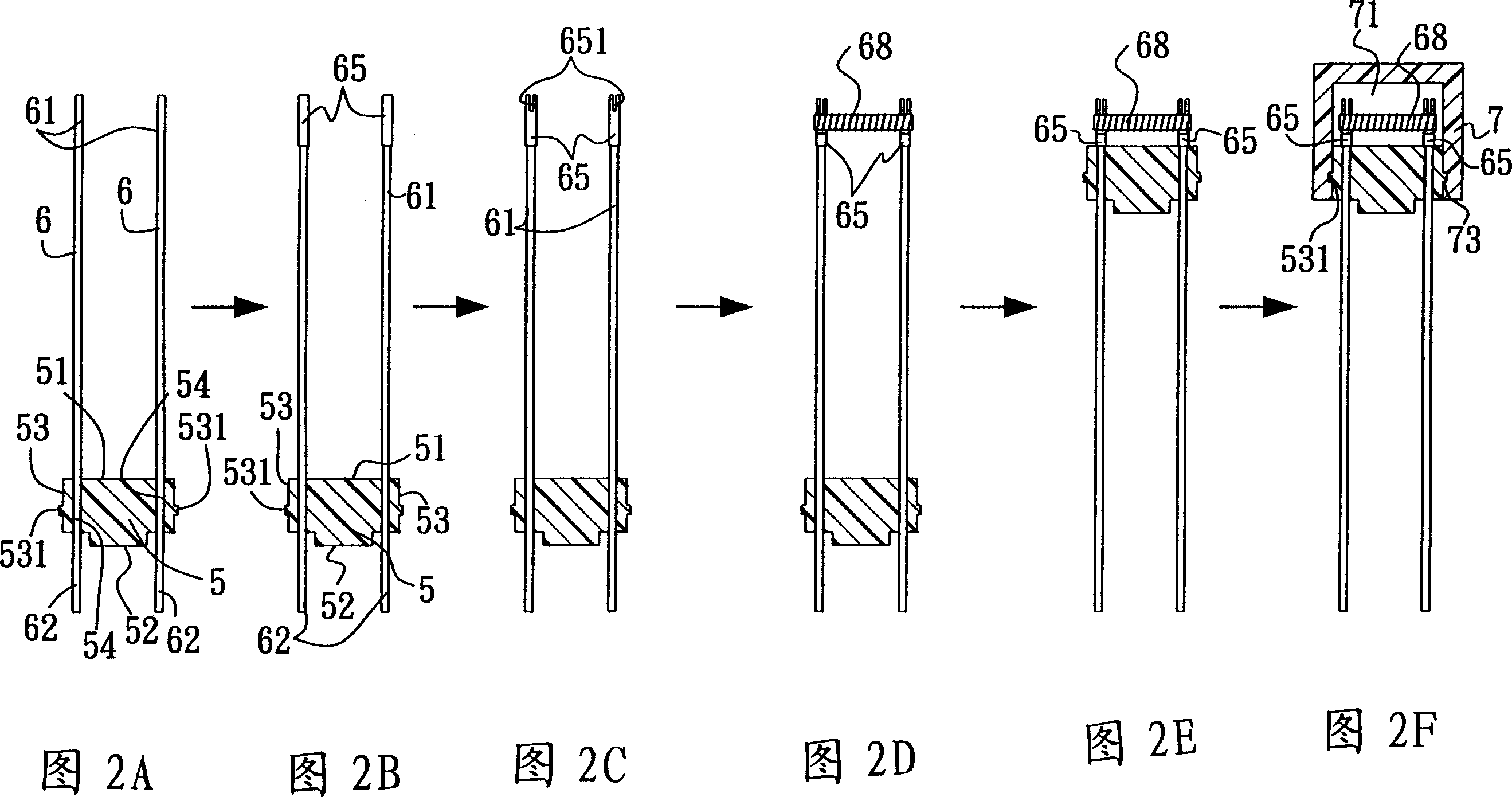

Manufacture of miniature industrial fuse

InactiveCN1469410AAids in welding workReduce the impedance valueFuse device manufactureEngineeringMechanical engineering

The manufacture of miniature industrial fuse includes the following steps: forming fuse seat with two parallel holes; threading two wires with connecting part in the same side of the fuse seat through the two holes; flattening the connecting parts, cutting notches and forming curved slots; welding one fuse onto the curved slots; and covering the seat with one cover to cover the two connecting parts and the fuse. Welding in the connecting parts results in stable connection and high product quality.

Owner:邱鸿智

Water seepage preventing performance testing method for floor

InactiveCN108051151AEasy accessThe testing process is simpleDetection of fluid at leakage pointEngineeringColor changes

The invention provides a water seepage preventing performance testing method for a floor. The method includes: 1, sampling a product; 2, sticking a water containing pipe at a surface joint of a samplefloor; 3, injecting water into the water containing pipe and dropping red ink into the water containing pipe; 4, allowing to stand and observing whether the back face and the surrounding of the jointof the sample floor corresponding to the water containing pipe meets water seepage or not, determining the sample floor to be qualified if no color change occurs, otherwise, determining the sample floor to be unqualified. According to the invention, through simulating the use condition of the floor in a humid environment, the waterproof performance of the floor lock catch joint is detected. The required detection instrument and material are easy to acquire and the testing process is simple and effective. The product quality can be controlled effectively and the superior product rate can be improved.

Owner:圣象(江苏)木业研究有限公司

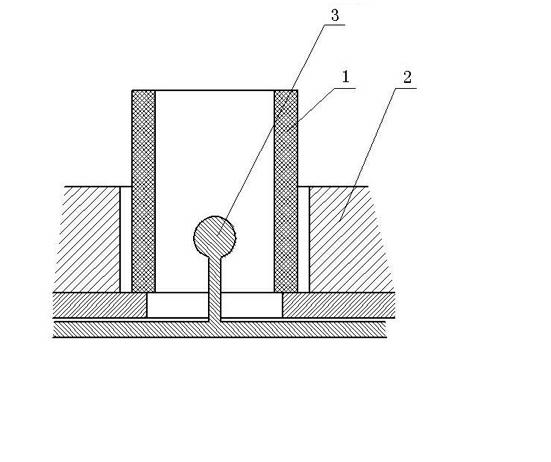

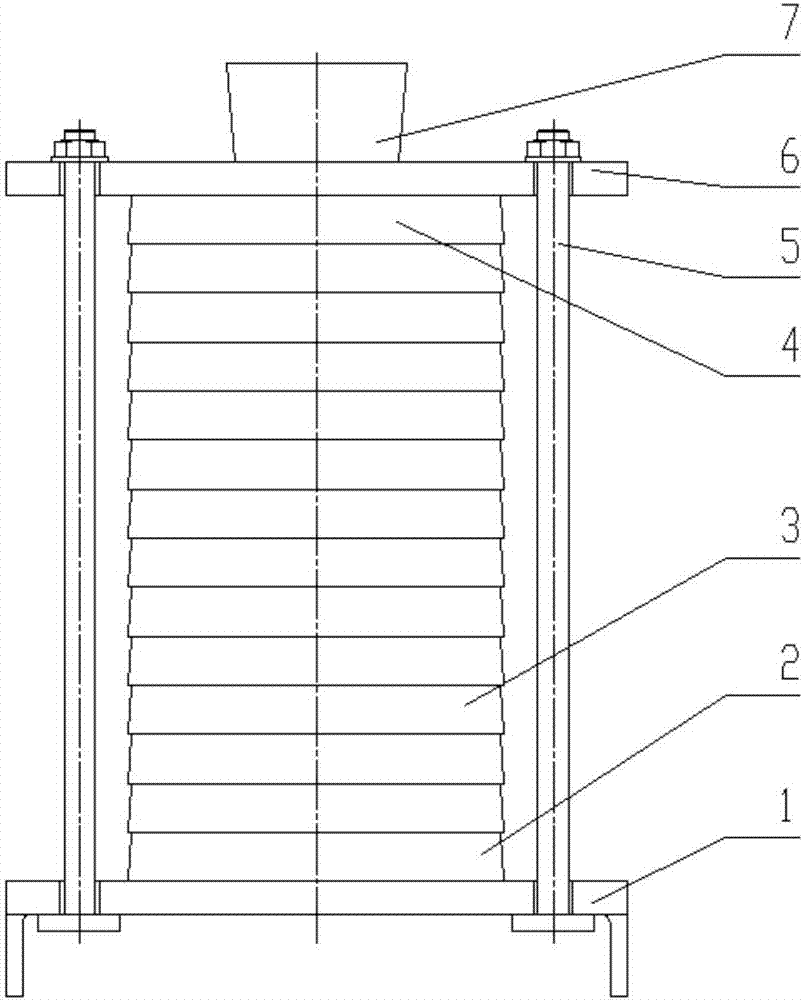

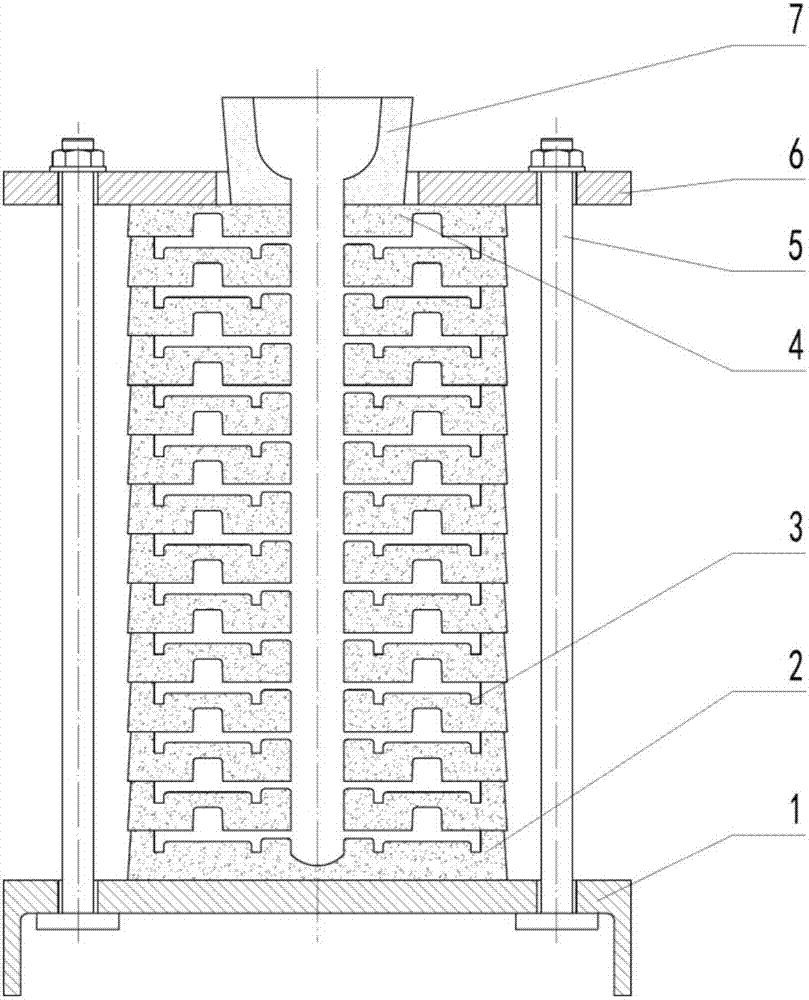

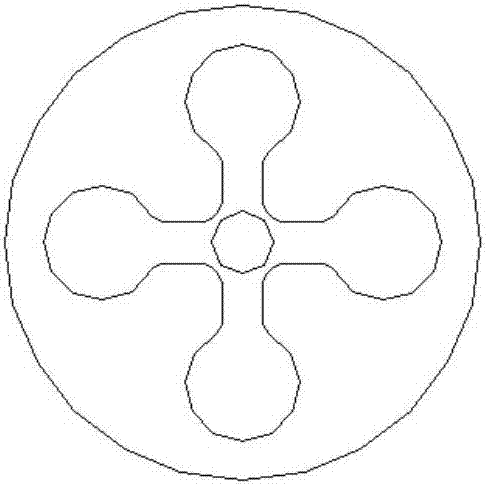

Vertical cluster casting die for cast steel parts and cluster casting method thereof

InactiveCN106964756ASimple structureStable structureFoundry mouldsFoundry coresProduction ratePass rate

The invention discloses a vertical cluster casting die for cast steel parts and a cluster casting method thereof, and belongs to the field of metal part casting. The vertical cluster casting die for the cast steel parts and the cluster casting method thereof aim to solve the problems that in the prior art, the number of procedures is large, the period is long, the productivity is low, the cost is high, the product quality stability is poor, and the product qualification rate is low. The vertical cluster casting die comprises a bottom plate and a cover plate, wherein the bottom plate and the cover plate are fixed through bolts to form a casting cavity, and a casting module is arranged in the casting cavity; and the casting module comprises a bottom block, middle blocks and an upper block, a groove is formed in the middle of the bottom block, casting structures are correspondingly arranged on the periphery of the bottom block, a through hole is formed in the middle of each middle block, a plurality of casting structures are arranged on the periphery of each middle block, a through hole is formed in each casting structure, a through hole is formed in the middle of the upper block, and casting structures are correspondingly arranged at the periphery of the upper block. According to the vertical cluster casting die for the cast steel parts and the cluster casting method thereof, the number of procedures is small, the period is short, the productivity is high, the cost is low, the product quality stability is high, and the product qualification rate is high.

Owner:MAANSHAN HUADA METALLURGICAL & MACHINERY

Oxide-based high-entropy alloy ceramic binding agent special for PCBN

The invention discloses an oxide-based high-entropy alloy ceramic binding agent special for PCBN. The binding agent is composed of, by mass, 30-65% of high-entropy alloy and 35-70% of oxide ceramic. The high-entropy alloy in the binding agent can form a high-mixing-entropy stable solid solution, multiple types of special effects are generated, such as a high-entropy effect on thermodynamics, a lattice deformation effect in structure, a synergistic effect among multiple components and a 'cocktail' effect in performance. Therefore, compared with traditional alloy, the high-entropy alloy can achieve homogenization and alloying more easily, the alloy melting point is lower, and excellent performance, such as high strength, high hardness, high abrasion resistance, high electric resistance, high thermal resistance and corrosion resistance, to which the traditional alloy is inferior is achieved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

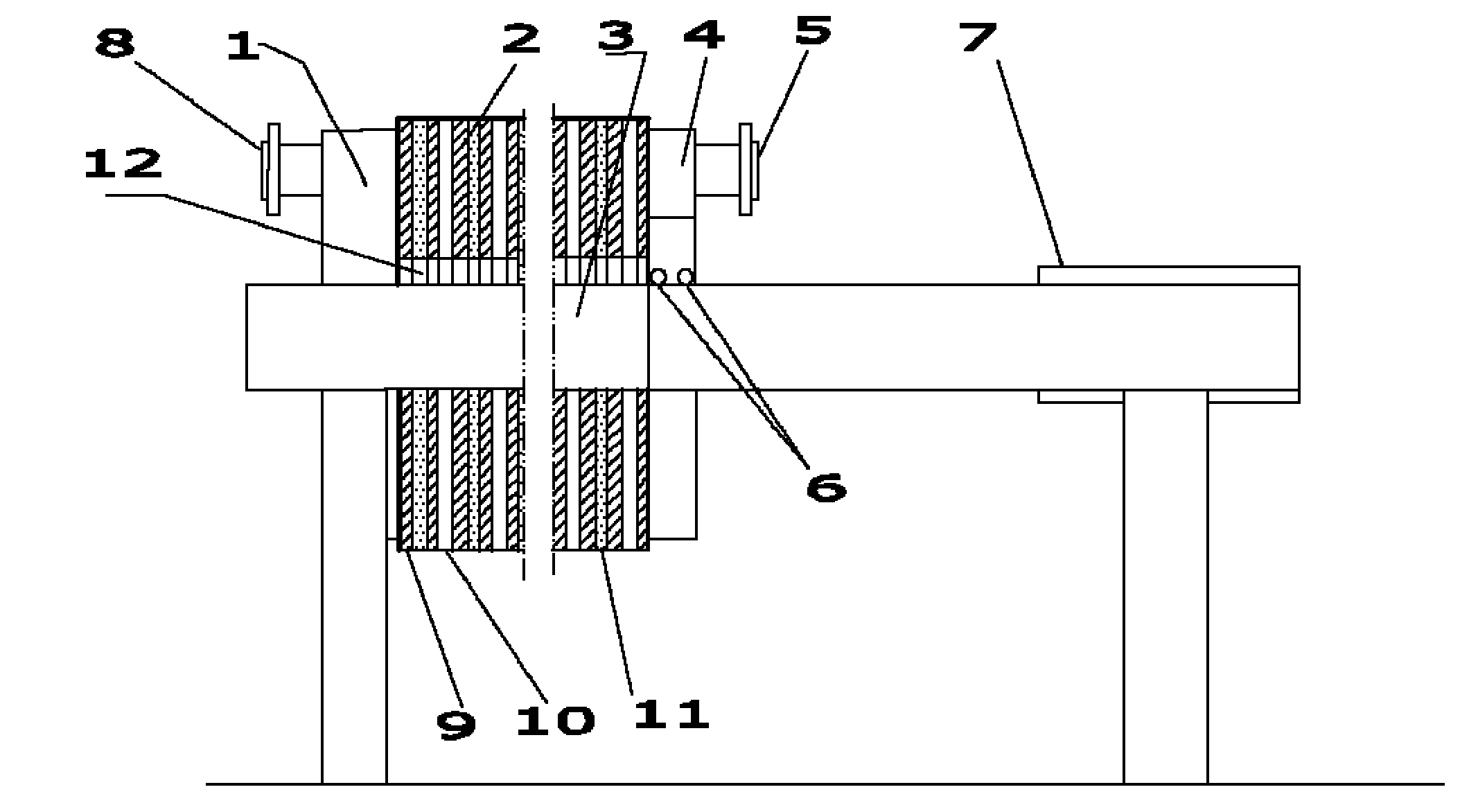

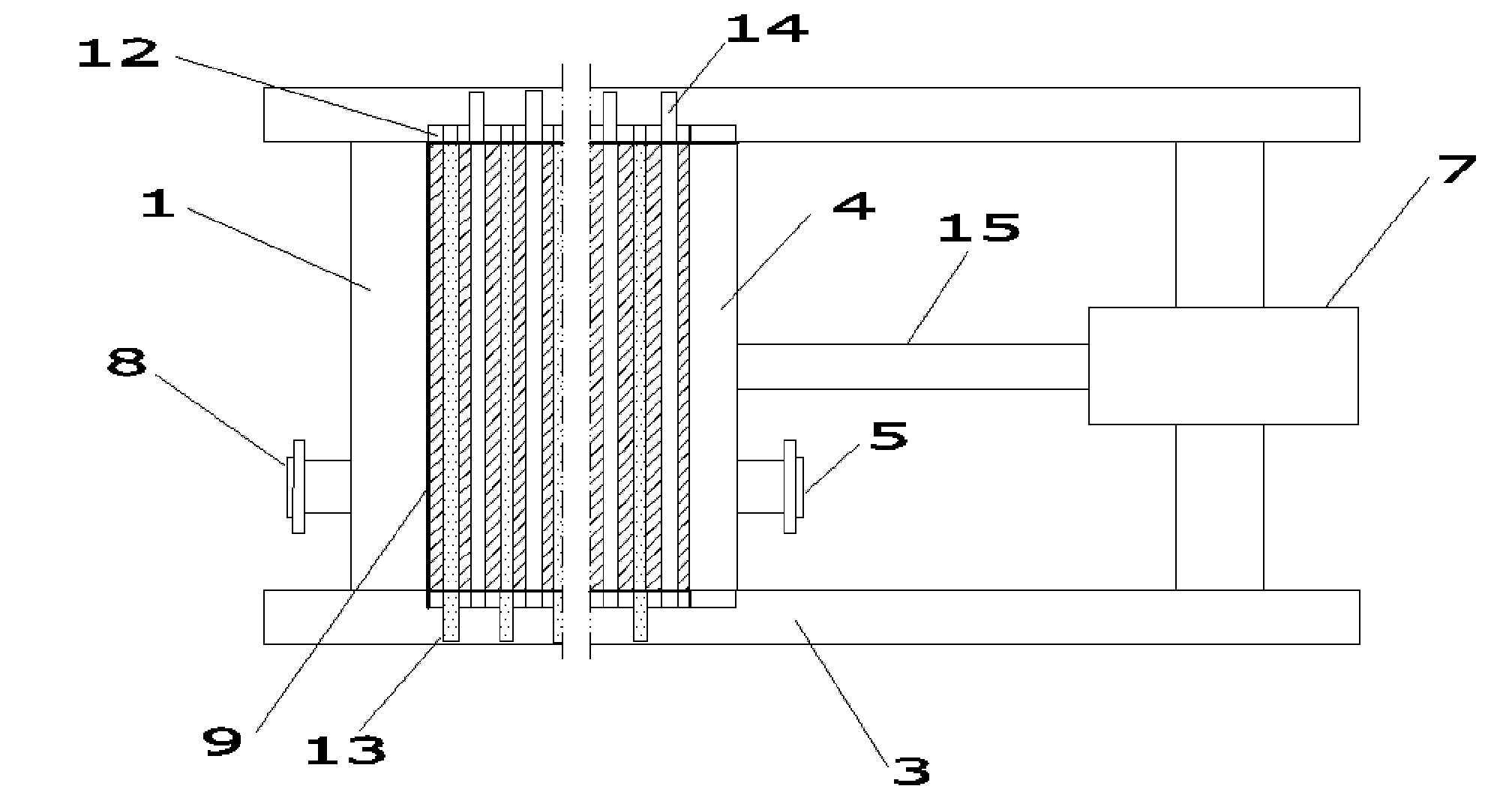

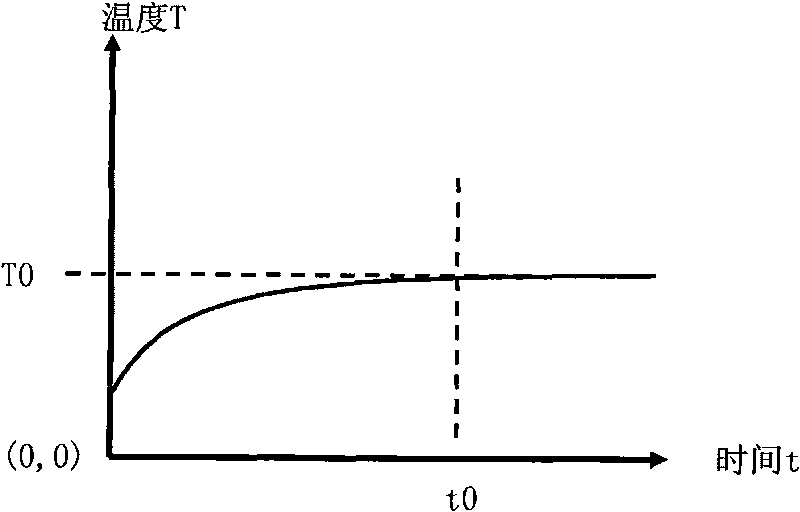

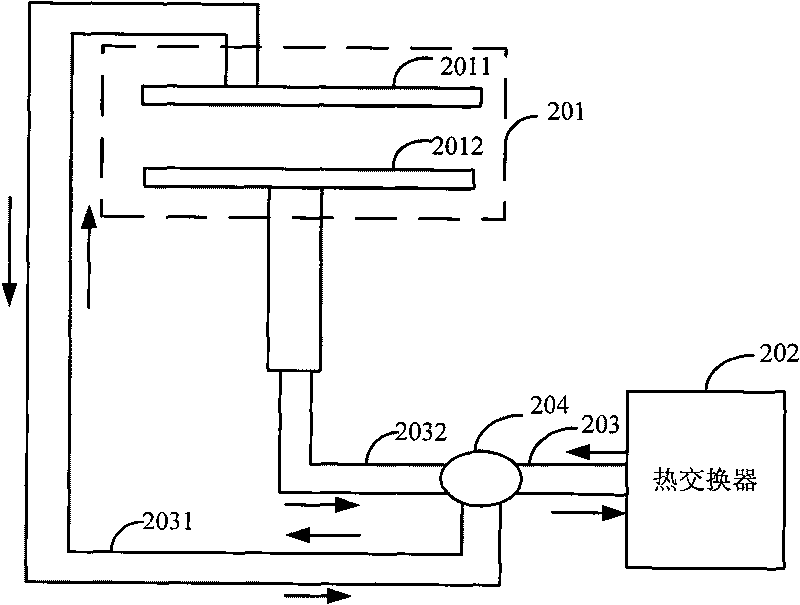

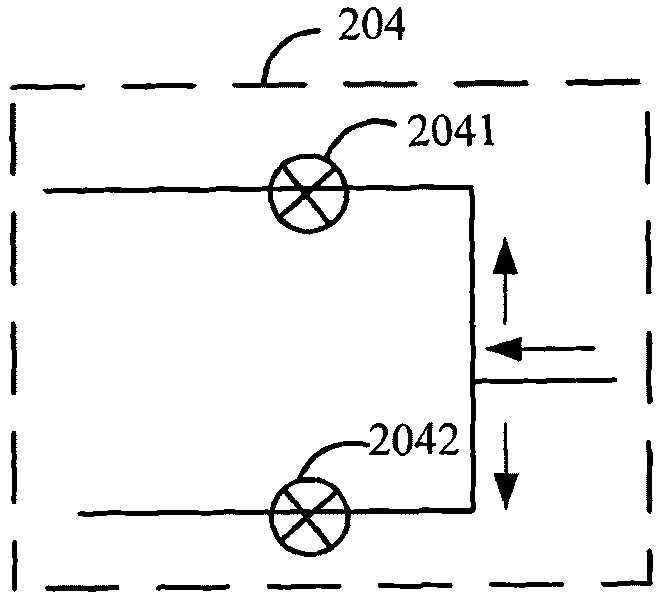

Plasma-enhanced chemical vapor deposition PECVD equipment

ActiveCN101693991AAvoid the "first cell effect"Quality improvementChemical vapor deposition coatingEquipment temperatureEngineering

The invention discloses a plasma-enhanced chemical vapor deposition PECVD equipment comprising a PECVD chamber, a heat exchanger and a heat exchange pipeline, wherein the PECVD chamber comprises a supporting plate and a base plate; the heat exchanger is used for heating the fluid in the heat exchange pipeline; one end of the heat exchange pipeline is connected with the heat exchanger and the other end thereof is divided into two branch pipelines which respectively lead to the supporting plate and the base plate of the PECVD chamber and are used for heating the supporting plate and the base plate so as to stably reach the temperature state for normally generating a deposition reaction; and in the production process of 'a first battery plate', the equipment can avoid the problem that the first battery plate effect is generated as the equipment temperature does not reach the temperature state for normally generating the deposition reaction and improve the quality of the product and the yield rate of good products.

Owner:ENN SOLAR ENERGY

Light-weight wall tile

InactiveCN104876555AEliminate pollutionImprove effective utilizationSolid waste disposalBrickResource utilization

The invention discloses a light-weight wall tile and relates to the technical field of architectural pottery manufacture. The light-weight wall tile is prepared from the following raw materials: 5-10 parts of high-temperature sand, 30-40 parts of low-temperature sand, 5-15 parts of talc mud and 15-50 parts of ceramic polishing waste. Compared with the prior art, the light-weight wall tile makes the best of ceramic polishing waste, so that environmental pollution caused by the waste is eliminated, the effective resource utilization ratio is improved, and the produced wall tile is light in mass and high in strength.

Owner:LIUZHOU YITING TRADE

Printing-supplies storage chip

The invention discloses a printing-supplies storage chip. A base board is provided with a control unit, an ink cartridge identity information identifying unit, a storage unit, an interface unit and a reset detection unit, a group of golden finger contacts is arranged on one surface of a base board partition, the control unit is respectively connected with the ink cartridge identity information identifying unit, the storage unit, the interface unit and the reset detection unit, the interface unit is respectively connected with the ink cartridge identity information identifying unit and the reset detection unit, the storage unit is respectively connected with the control unit and the ink cartridge identity information identifying unit, the control unit is used for receiving an initialization signal, information in the storage unit and information data, the initialization signal is generated by the reset detection unit, the information data are outputted by an imaging unit and received by the interface unit, and the control unit transmits the information in the storage unit to the imaging unit through the interface unit. A plurality of ink cartridges are controlled by only one printing storage chip, and correctness of storage information can be ensured even if an imaging device and the storage chip have error signals in the high-speed communication process.

Owner:HANGZHOU CHIPJET TECH

Preparation method of high-speed polyester POY (Pre-Oriented Yarn) spinning oil agent

The invention provides a preparation method of a high-speed polyester POY (Pre-Oriented Yarn) spinning oil agent. A pure oil agent except for water in the oil agent is composed of a main body part and an additive, wherein the main body part includes over 20 kinds of polyether compounds and the rest components belong to non-polyether additive. The preparation method comprises the following steps: firstly, metering the main body component of the oil agent, pumping the main body component into a reaction kettle in vacuum, stirring, heating to 50-70 DEG C, stirring, metering the additive components and water, and adding the metered additive components and water into the reaction kettle, stirring, heating to 70-80 DEG C, keeping the temperature for 40-50min, closely filter-pressing a product, and subpackaging the product after the product is checked to be qualified. The oil agent prepared by using the method provided by the invention is suitable for high-speed polyester POY spinning and a production process of a subsequent deform yarn; the oil agent endows the fiber good smoothness and bundling and favorable total viscosity-temperature and viscosity-concentration characteristics; the fiber is few in broken filament breaks, even and uniform in dyeing in the later drafting process; the smoke formation amount of a hot processing tank is small, generated white powder and coke amount are small and the cleaning period is long; a product is good in quality and stability.

Owner:江苏天音化工有限公司

Polyester filament yarn POY finish and preparation method thereof

InactiveCN111607963AEasy to bundleImprove antistatic performanceLight resistant fibresHeat resistant fibresPolymer scienceSpinning

The invention discloses a polyester filament yarn POY finish and a preparation method thereof, and relates to the field of polyester filament yarn finishes. The polyester filament yarn POY finish is prepared from the following components in percentage by weight: 7-12% of base oil, 62-75% of a smoothing agent, 7-12% of an emulsifier, 5-7% of an antistatic agent and the balance of an additive. According to the preparation method, through the specific selection of various functional components and strictly limiting the proportion of the components, the polyester filament yarn POY finish with goodsmoothness, bunching, antistatic performance, excellent heat resistance and fast wettability is prepared, the spinnability is good, the serious problem of coking in the subsequent stretching deformation process and the instability of viscosity temperature and viscosity concentration characteristics in application are effectively solved, the filament broken and end breakage rate is decreased, andunder the same spinning process conditions, the excellent product rate can be significantly improved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

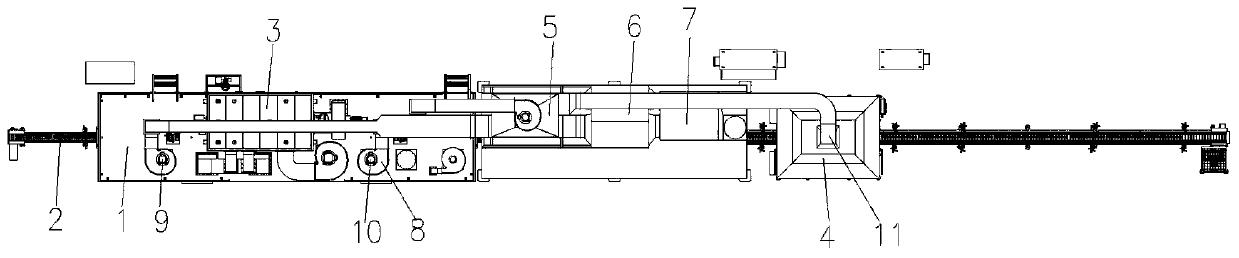

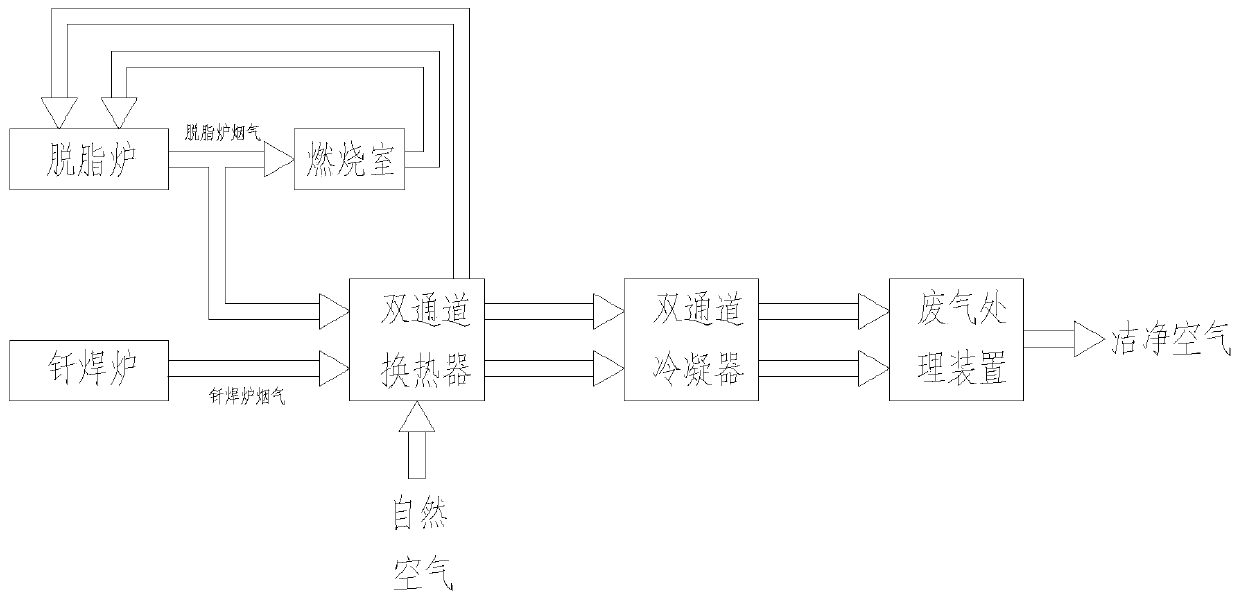

Integrated production line degreasing brazing machining process for air conditioner heat exchanger

ActiveCN110961737AReduce energy consumptionPrevent deflagrationDrying solid materials with heatHearth type furnacesFlue gasProcess engineering

The invention discloses an integrated production line degreasing brazing machining process for an air conditioner heat exchanger. The process comprises the steps that a), a product is manually fed from a front end of a degreasing furnace; b) the product passes through the degreasing furnace at a constant speed for automatic degreasing and drying; c) a small U-shaped pipe is manually inserted intothe product on line at the front end of a brazing furnace; d) the product enters into the brazing furnace at the constant speed so as to automatically weld the small U-shaped pipe; e) the product discharged from the brazing furnace is manually assembled and other accessories are welded; and f) the product is manually discharged from a tail end of a conveying line 3. In the invention, the machiningprocess is improved, reasonable process modes are adopted for bridging in cooperation with an equipment size height and a transition mode, production efficiency is higher, and a superior product rateof the products is increased; equipment is high in linkage performance and more stable; and a flue gas of a degreasing furnace and a brazing machine can be preheated and recycled to be used by the degreasing furnace, energy consumption of the degreasing furnace is reduced, a temperature of the flue gas of a production line is greatly reduced under an effect of a heat exchanger, and a phenomenon of deflagration of a flue gas exhaust pipeline is further avoided.

Owner:佛山市泓实机械制造有限公司

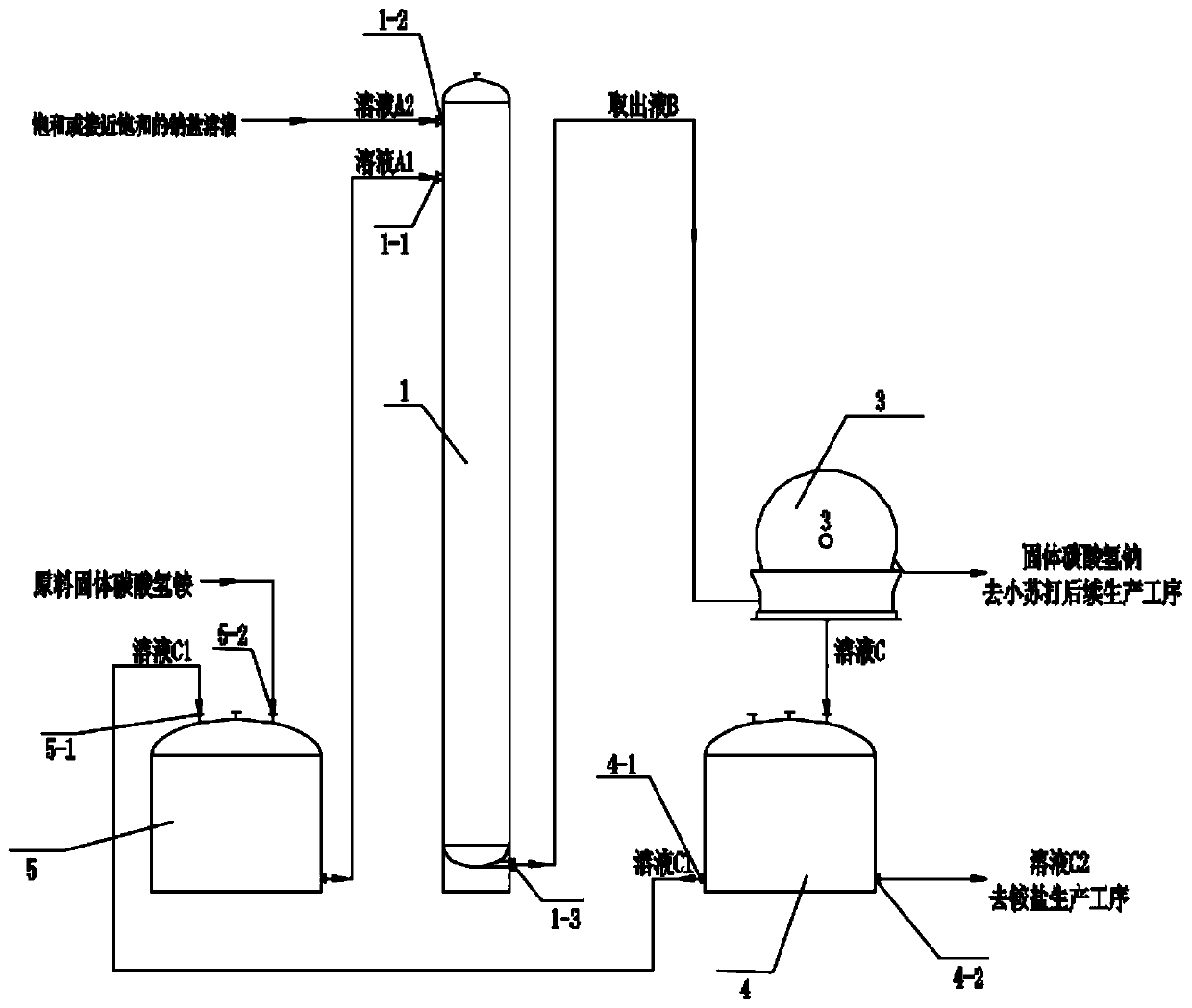

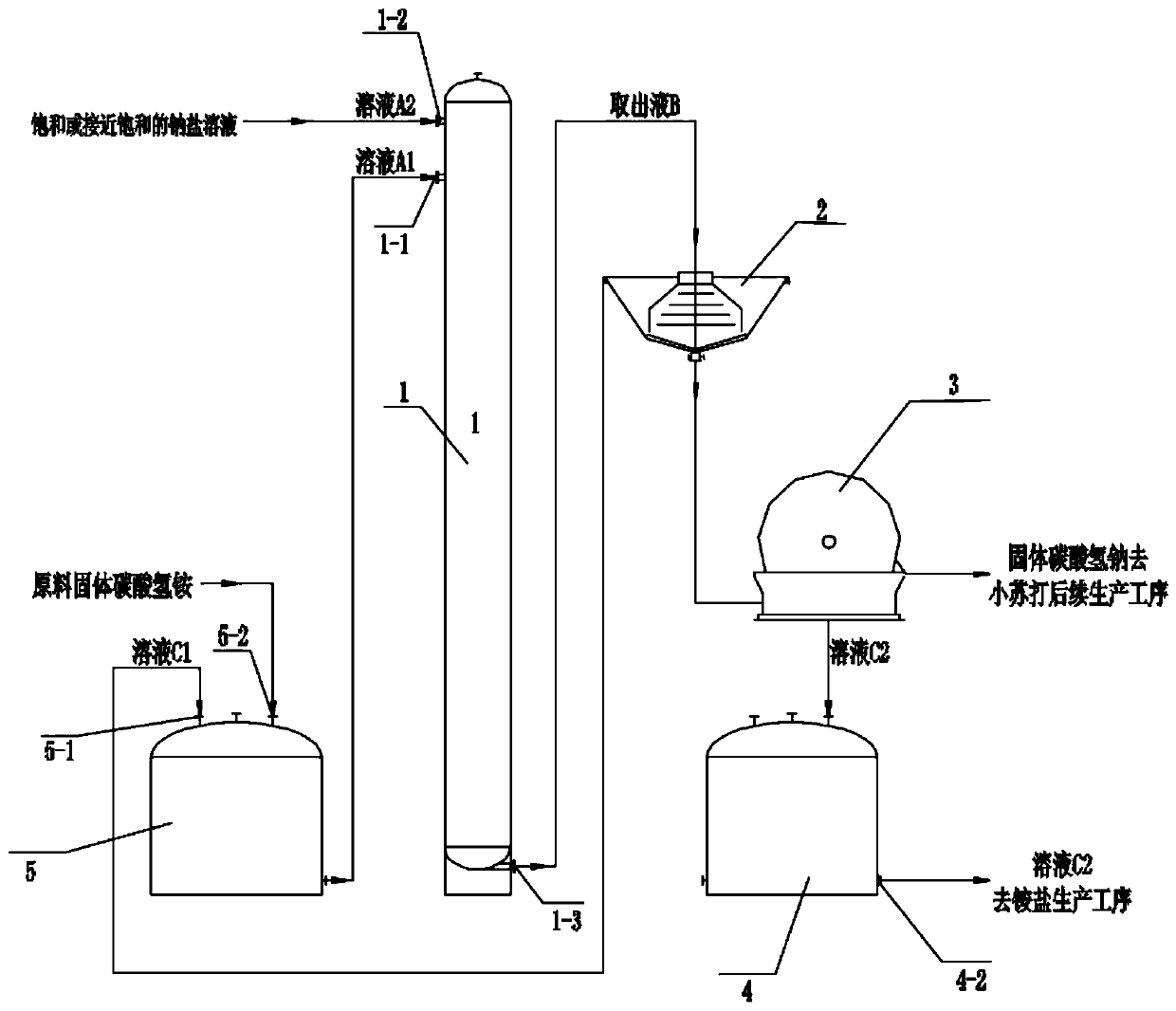

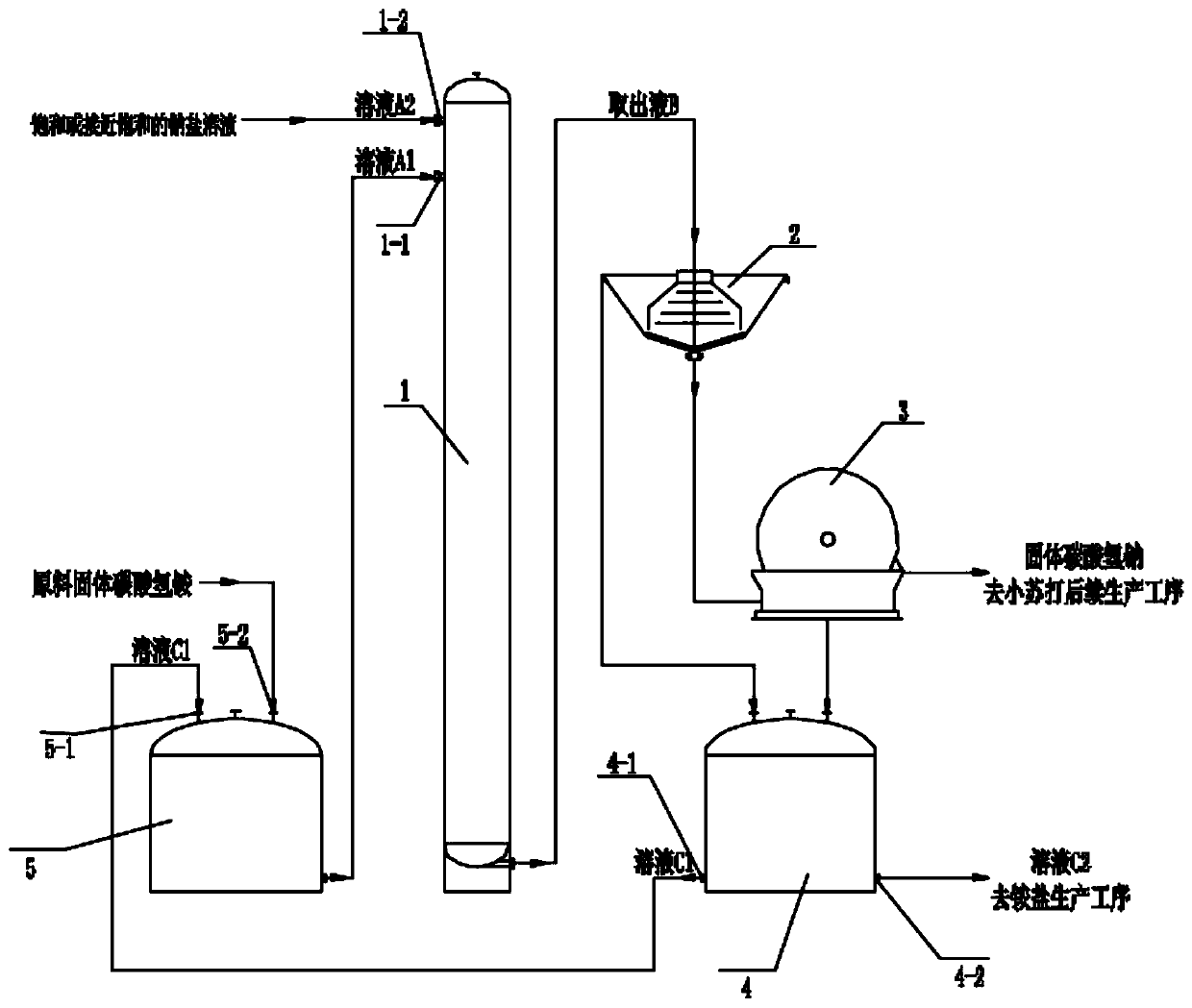

Method for preparing baking soda by metathesis

PendingCN110282638AImprove utilizationLess quantityCarbonate preparationCooking & bakingSodium bicarbonate

The invention provides a method for preparing baking soda by metathesis. The method is characterized in that a solution C obtained after separating solid sodium hydrogen carbonate from metathesis reactor extraction liquid B by a solid-liquid separator is divided into two parts of C1 and C2, the solution C1 enters an ammonium hydrogen carbonate dissolver, and the solution C2 enters an ammonium salt production process; the solid sodium hydrogen carbonate separated from the metathesis reactor extraction liquid B by the solid-liquid separator enters the subsequent production process of the baking soda; raw material solid ammonium hydrogen carbonate is added into the ammonium hydrogen carbonate dissolver, and a solution A1 discharged out of the ammonium hydrogen carbonate dissolver enters a metathesis reactor; a saturated or nearly-saturated solution A2 of a raw material sodium salt enters the metathesis reactor; the ammonium hydrogen carbonate and the sodium salt are subjected to a metathesis reaction in the metathesis reactor to produce the sodium hydrogen carbonate. By adopting a process provided by the invention, the utilization rate can reach 99.6% or above, the production cost is reduced, the amount of the solid ammonium hydrogen carbonate entering the product baking soda along with the sodium hydrogen carbonate is reduced, the ammonia content of the product baking soda is lowered, and the situation of sale difficulty of the baking soda is solved.

Owner:武汉德泽环保科技有限公司

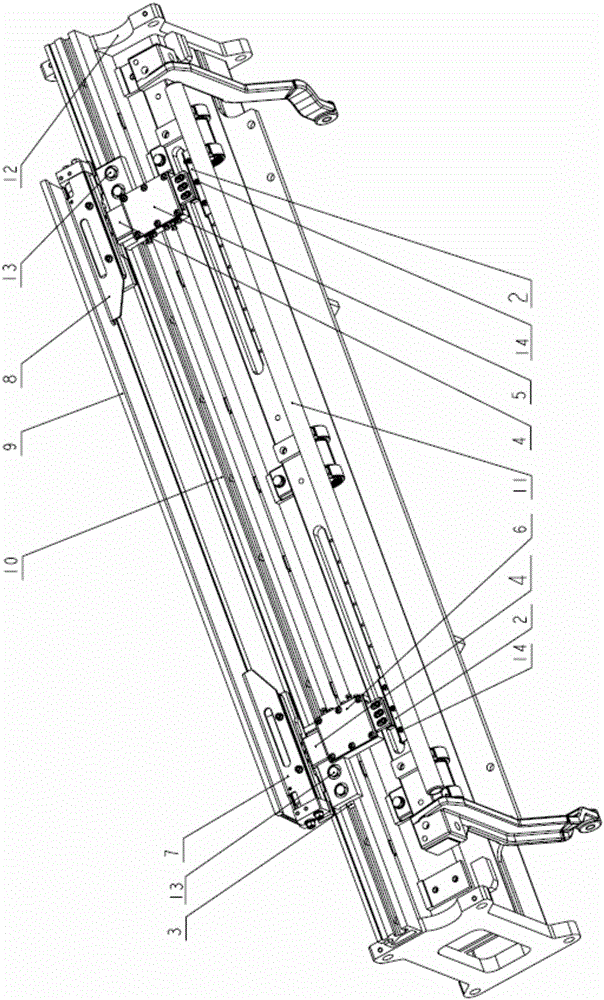

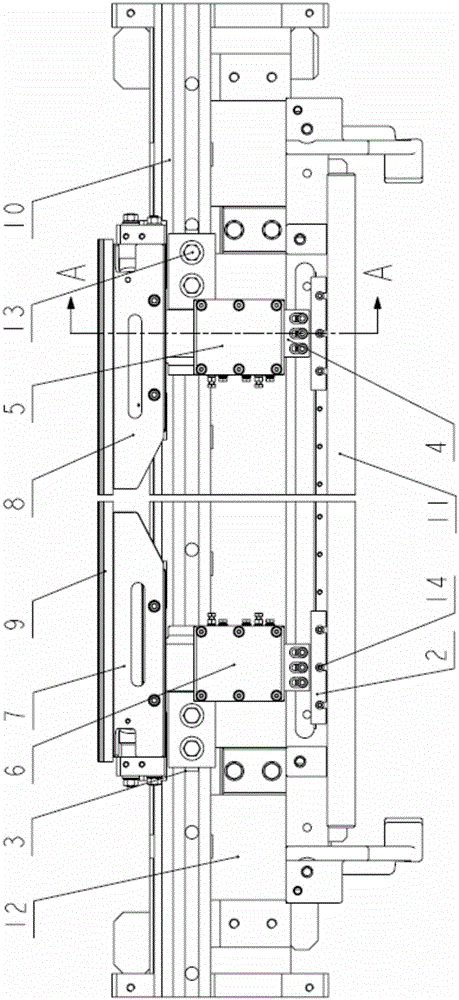

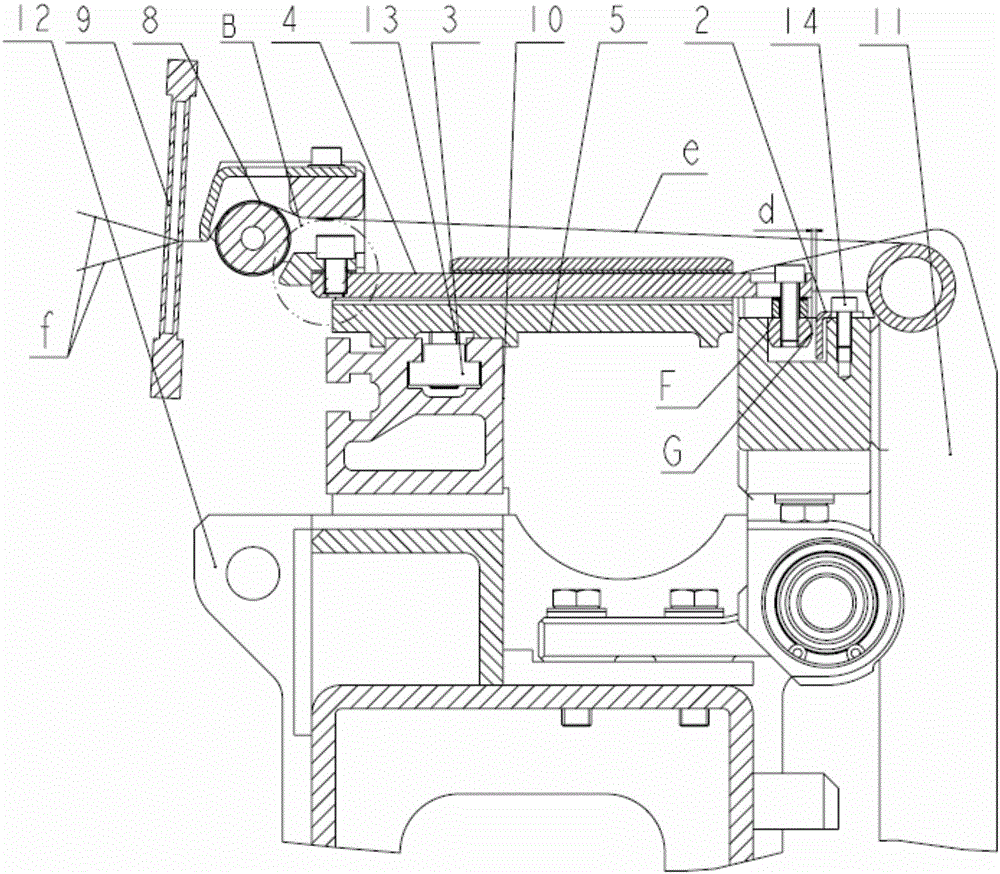

Stroke-adjustable movable temple device

The invention discloses a stroke-adjustable movable temple device. The stroke-adjustable movable temple device comprises two moving bodies, a right moving body supporting seat, a left moving body supporting seat, a left temple roller, a right temple roller, a front swing beam and a breast beam frame. The left moving body supporting seat and the right moving body supporting seat are symmetrically arranged on the left and right sides of fabric and fixed to a supporting profile of the loom breast beam frame, the positions of the left moving body supporting seat and the right moving body supporting seat can be adjusted in the left-and-right direction, and the middle portions of the two moving bodies are matched with moving body channels of the left moving body supporting seat and the right moving body supporting seat respectively. The left temple roller and the right temple roller are installed on the sides, close to warp yarn, of the rear ends of the corresponding moving bodies respectively and move along with the moving bodies. The rate of high-grade products can be increased, weaving efficiency can be improved, variety adaptability can be improved, the precision retaining capacity of the device is improved, the service life is prolonged, noise is lowered, and the use and maintenance cost is lowered because maintenance is not needed.

Owner:SHANDONG RIFA TEXTILE MACHINERY

Technique for producing chromonema, yarn

InactiveCN1462825AReduce pollutionShorten the production cycleLiquid/gas/vapor yarns/filaments treatmentBobbinPetrochemical

A technology for preparing the dyed fibres (including natural fibre, protein fibre, chemical fibre, or artificial fibre), or yarn includes fusing the polyester chips, drawing-spinning to become filaments, preheating, boarding, winding on steel bobbin with dense through holes, and dyeing by putting the bobbin in dyeing machine. Its advantage is high dyeing quality.

Owner:金国周

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com