Method for producing electrodeposition cobalt

A production method and electrowinning technology, applied in the direction of photographic technology, equipment, photographic auxiliary technology, etc., can solve the problems of high labor intensity, pollution of electrolytic fluid, time-consuming and labor-intensive problems, so as to improve the quality of cobalt products and reduce labor intensity , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

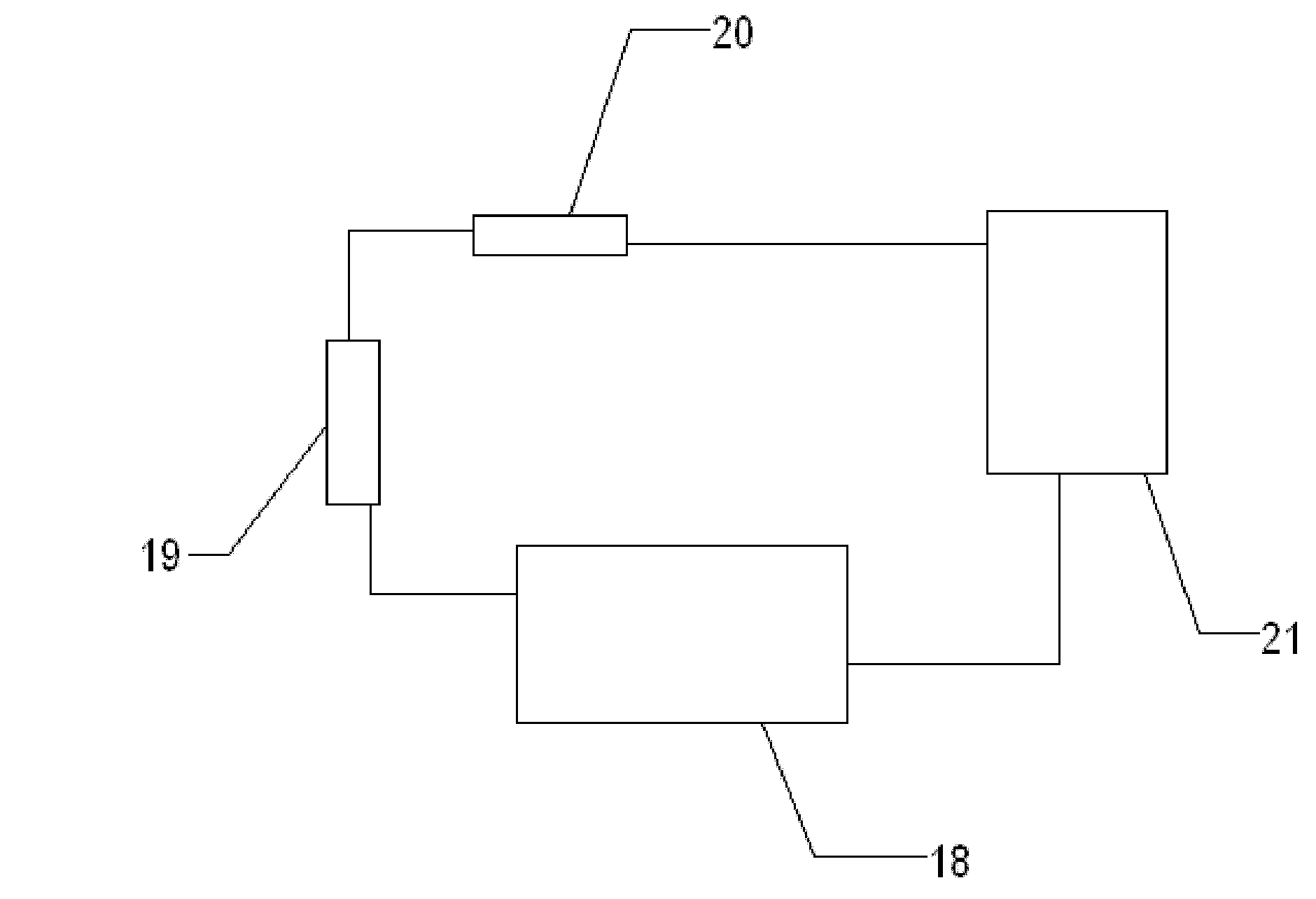

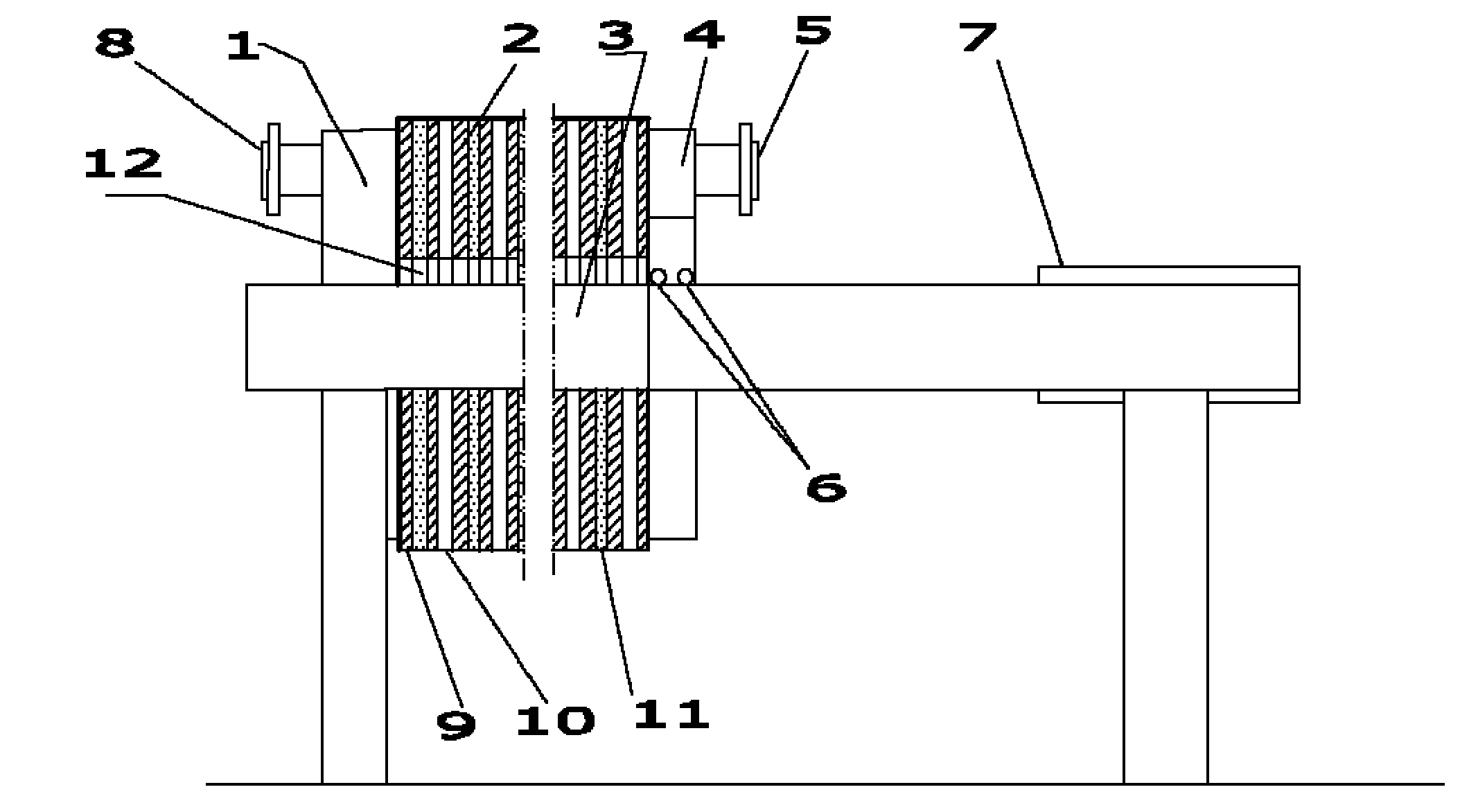

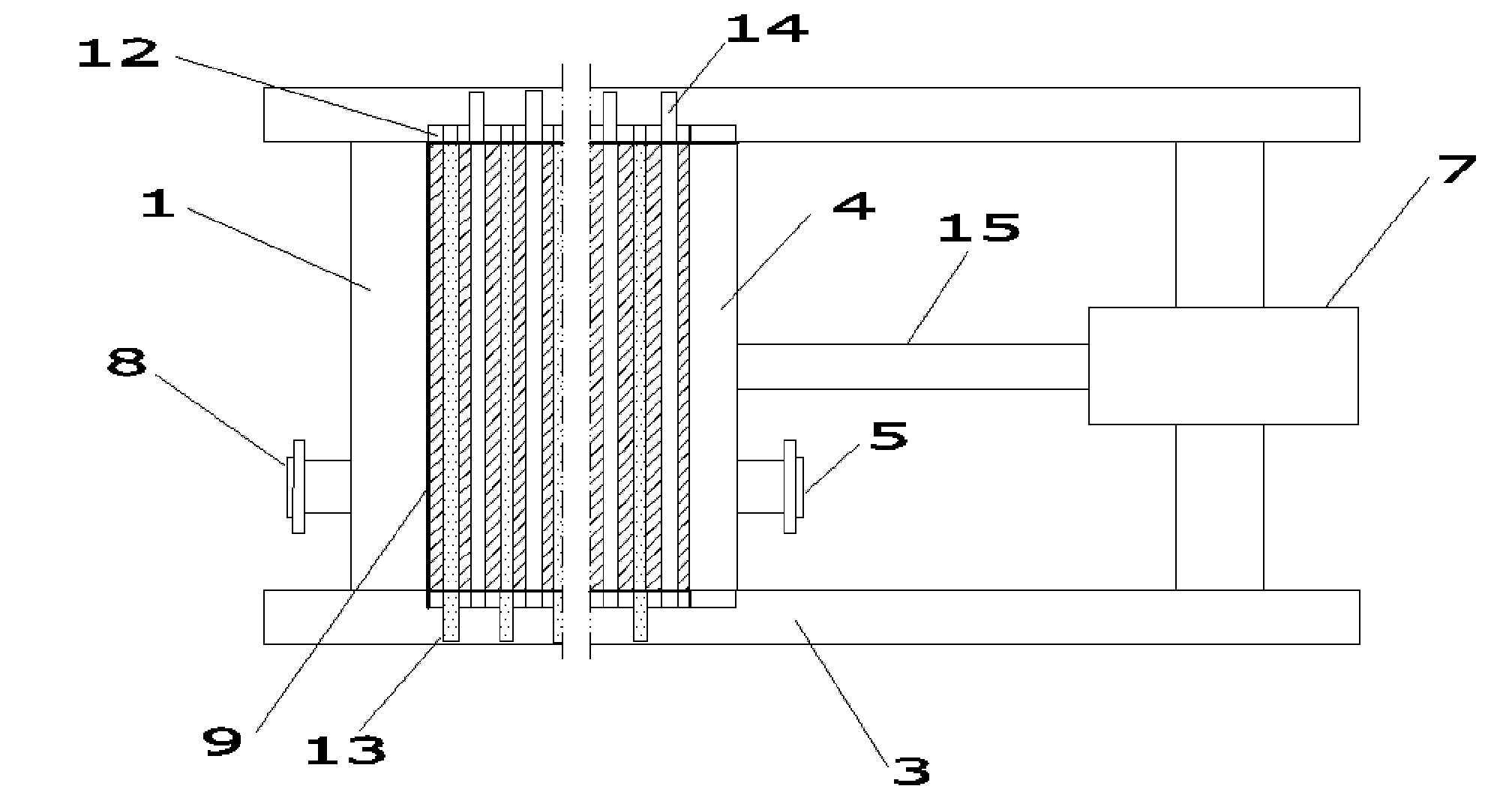

[0045] Cobalt chloride solution (cobalt concentration: 95 g / L; copper: 0.0002 g / L; lead: 0.0003 g / L; iron: 0.0008 g / L; manganese: 0.0005 g / L; zinc: 0.0006 g / L; organic : 5.6ppm; pH value: 4.5), hydroxylamine hydrochloride, hydrochloric acid and deionized water are prepared to form a solution with cobalt concentration of 72 g / L, hydroxylamine hydrochloride 0.05 g / L, pH value of 2.0, and temperature of 55 °C as a circulating fluid, which is added to In the electrolyte storage tank 21. Control the flow rate of 2.8 cubic meters per hour to pump the circulating liquid into the electrowinning tank. When the tank is full, turn on the power supply, maintain a tank voltage of 2.5 volts and a current density of 430 amps / square meter for electrowinning, and keep the electrolyte storage tank The concentration of Co in the circulating fluid is 60-75 g / L, and the concentration of hydroxylamine hydrochloride is 0.04-0.05 g / L. After 72 hours, it can be stripped out of the tank to obtain an el...

Embodiment 2

[0050] Cobalt chloride solution (cobalt concentration: 95 g / L; copper: 0.0002 g / L; lead: 0.0003 g / L; iron: 0.0008 g / L; manganese: 0.0005 g / L; zinc: 0.0006 g / L; organic : 5.6ppm; pH value: 4.5), hydroxylamine hydrochloride, hydrochloric acid and deionized water are formulated into a solution with cobalt concentration of 65 g / L, hydroxylamine hydrochloride 0.05 g / L, pH value of 2.0, and temperature of 50°C as a circulating fluid, which is added to In the electrolyte storage tank 21. Control the flow rate of 2.8 cubic meters per hour to pump the circulating liquid into the electrowinning tank. When the tank is full, turn on the power supply, maintain a tank voltage of 3.0 volts and a current density of 380 amps / square meter for electrowinning, and keep the electrolyte storage tank The concentration of Co in the circulating liquid is 60-75 g / L, and the concentration of hydroxylamine hydrochloride is 0.04-0.05 g / L. After 68 hours, it can be stripped out of the tank to obtain an ele...

Embodiment 3

[0052] Cobalt chloride solution (cobalt concentration: 95 g / L; copper: 0.0002 g / L; lead: 0.0003 g / L; iron: 0.0008 g / L; manganese: 0.0005 g / L; zinc: 0.0006 g / L; organic : 5.6ppm; pH value: 4.5), hydroxylamine hydrochloride, hydrochloric acid and deionized water are formulated into a solution with cobalt concentration of 69 g / L, hydroxylamine hydrochloride 0.05 g / L, pH value of 2.0, and temperature of 58°C as a circulating fluid, which is added to In the electrolyte storage tank 21. Control the flow rate of 2.8 cubic meters per hour to pump the circulating liquid into the electrowinning tank. When the tank is full, turn on the power supply, maintain a tank voltage of 2.3 volts and a current density of 400 amperes per square meter for electrowinning, and keep the electrolyte storage tank The concentration of Co in the circulating fluid is 60-75 g / L, and the concentration of hydroxylamine hydrochloride is 0.04-0.05 g / L. After 65 hours, it can be stripped out of the tank to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com