Light-weight wall tile

A wall brick, lightweight technology, applied in the field of building ceramics manufacturing, can solve the problems of ineffective utilization, pollution of the environment, waste of resources, etc., to achieve the effect of improving effective utilization, eliminating pollution, and reducing fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1——Prepare 75 tons of wall bricks:

[0016] The following raw materials are used: 5 tons of high-temperature sand, 40 tons of low-temperature sand, 15 tons of talc mud, and 15 tons of ceramic polishing waste;

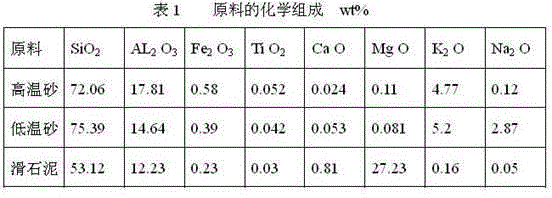

[0017] The weight percent of active ingredients of high-temperature sand, low-temperature sand and talc mud should meet the requirements of Table 1:

[0018]

[0019] The production method is:

[0020] Weigh the raw materials of the above weight and 30% water of the total amount of raw materials, add them to the ball mill for ball milling, and after the raw materials are pulverized to a fineness of 10,000 mesh sieves, use a spray drying tower to spray them into powder materials, so that the water content is 6%; The tonnage press dry-presses the above-mentioned product into a green body with a thickness of 4.1 mm; put the green body on the backing plate through a vacuum absorber, and send the green body placed on the backing plate together with the ...

Embodiment 2

[0021] Embodiment 2——preparation of 95 tons of wall bricks:

[0022] The following raw materials are used: 10 tons of high-temperature sand, 30 tons of low-temperature sand, 5 tons of talc mud, and 50 tons of ceramic polishing waste;

[0023] The percentage by weight of the effective components of high-temperature sand, low-temperature sand and talc mud is the same as in Example 1.

[0024] The production method is:

[0025] Weigh the above-mentioned raw materials and 40% water of the total amount of raw materials, and add them into a ball mill for ball milling. After the raw materials are crushed to a fineness of 10,000 mesh sieves, they are sprayed into powder by a spray drying tower, so that the water content is 8%; The tonnage press dry-presses the above-mentioned result into a green body with a thickness of 4.2 mm; put the green body on a backing plate through a vacuum absorber, and place the green body on the backing plate together with the pad The boards are sent tog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com