Method for preparing baking soda by metathesis

A metathesis, baking soda technology, applied in carbonate preparations and other directions, can solve the problems of reduced utilization rate of raw material ammonium bicarbonate, reduced ammonium bicarbonate dissolution rate, increased ammonia content of baking soda, etc. Dissolution speed and the effect of improving the degree of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

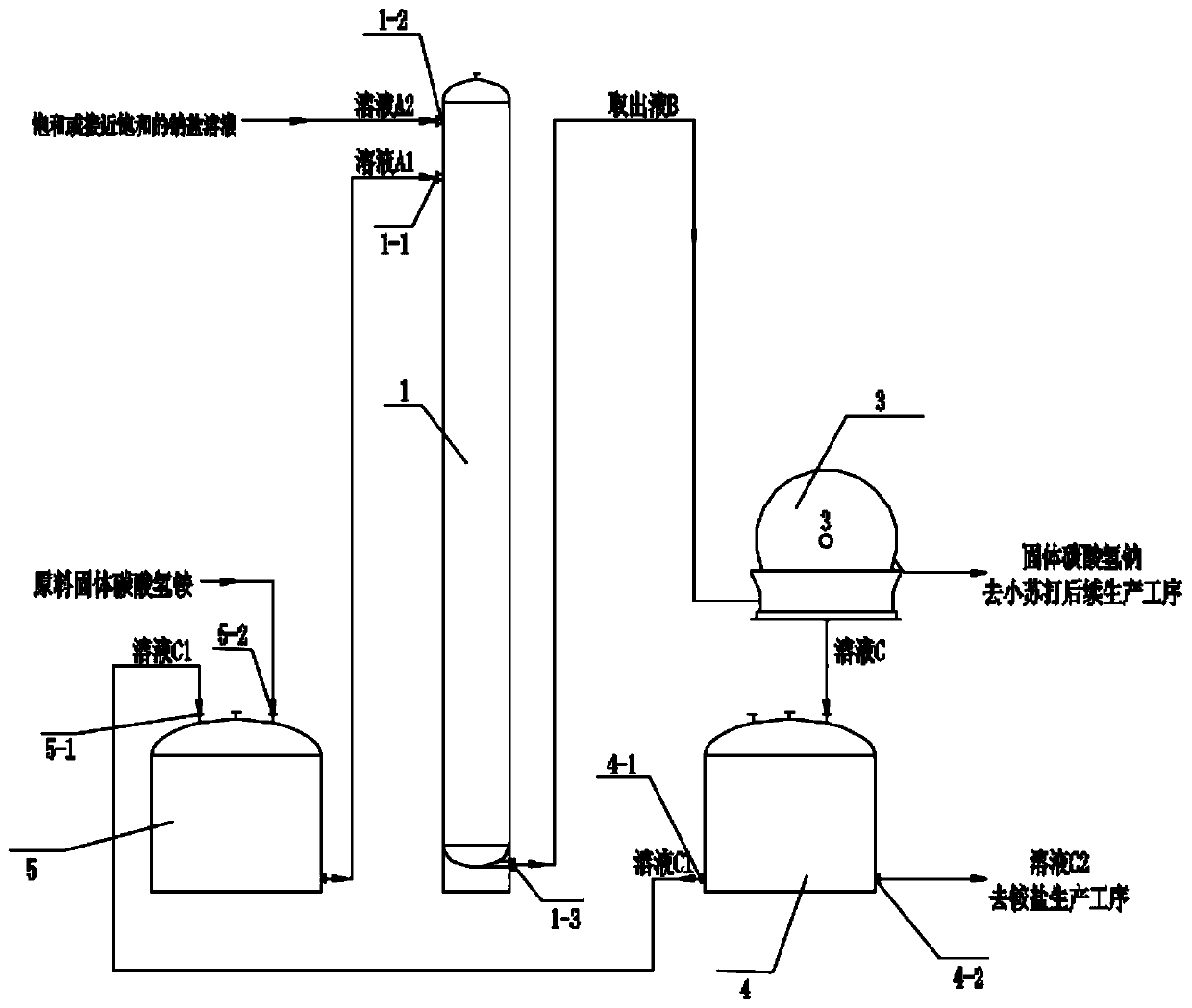

[0029] Such as figure 1 Shown is a method for preparing baking soda by metathesis, the metathesis reactor 1 takes out the liquid and enters the centrifuge 3 of the solid-liquid separator, and the solid sodium bicarbonate separated by the centrifuge 3 of the solid-liquid separator enters the subsequent production process of baking soda The solution C separated by the centrifuge 3 of the solid-liquid separator enters the filtrate storage tank 4, the solution C1 of the filtrate storage tank 4 enters the ammonium bicarbonate dissolver 5, and the solution C2 of the filtrate storage tank 4 enters the ammonium salt production process; The raw material solid ammonium bicarbonate is added to the ammonium bicarbonate dissolver 5, and the solution A1 of the ammonium bicarbonate dissolver 5 enters the metathesis reactor 1; the saturated or nearly saturated solution A2 of the raw material sodium salt enters the metathesis reactor 1; the ammonium bicarbonate and The sodium salt undergoes a ...

Embodiment 2

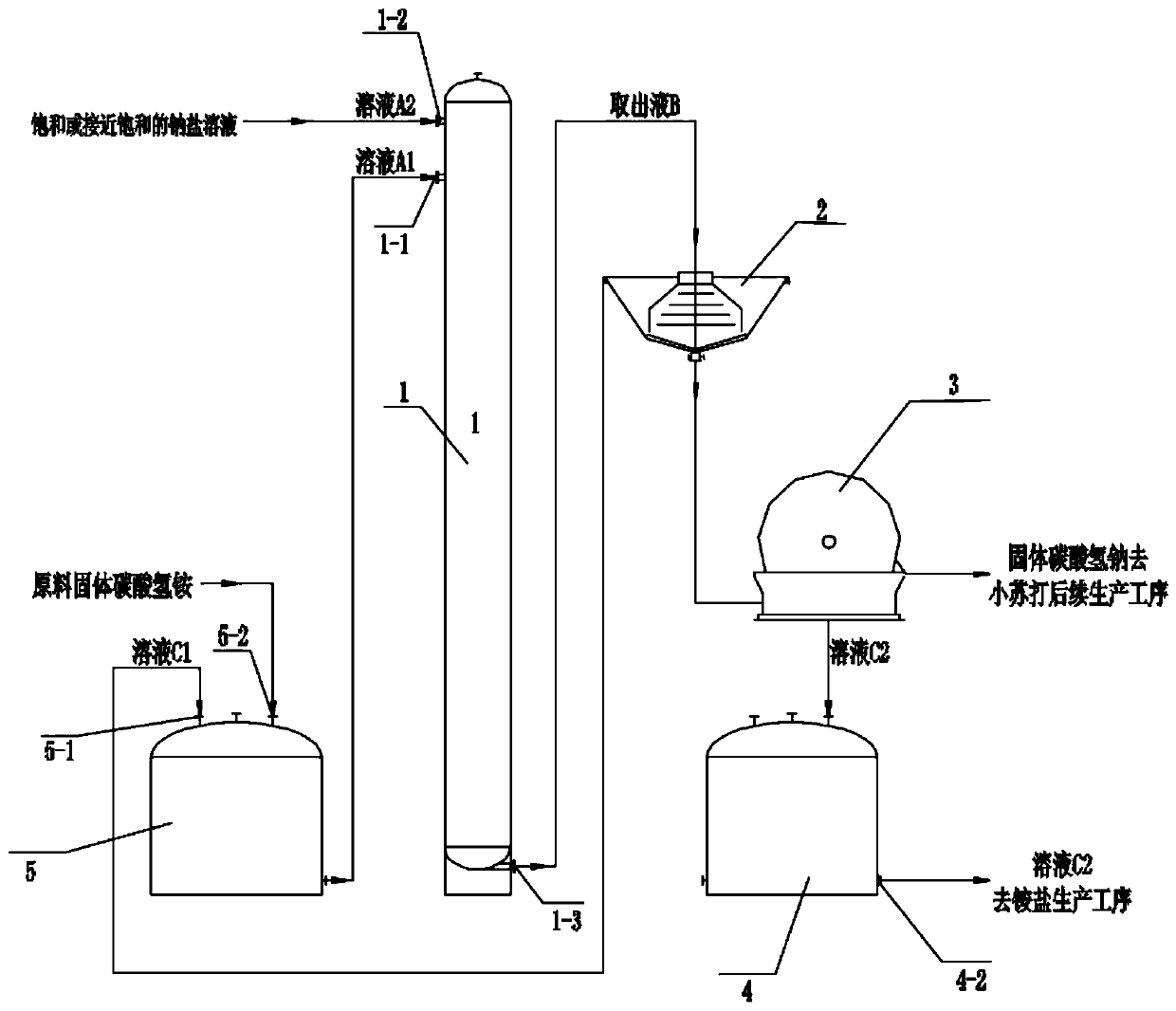

[0034] Such as figure 2Shown is a method for preparing sodium bicarbonate by metathesis, the metathesis reactor 1 takes out the liquid and enters the thickener 2 of the solid-liquid separator, and the clear solution C1 overflowing from the thickener 2 of the solid-liquid separator enters ammonium bicarbonate Dissolver 5, the crystal slurry at the bottom of the thickener 2 of the solid-liquid separator enters the centrifuge 3 of the solid-liquid separator, and the solid sodium bicarbonate separated by the centrifuge 3 of the solid-liquid separator enters the subsequent production process of baking soda; The solution C2 separated by the centrifuge 3 of the liquid separator enters the filtrate storage tank 4, and the solution C2 exiting the filtrate storage tank 4 enters the ammonium salt production process; the raw material solid ammonium bicarbonate is added to the ammonium bicarbonate dissolver 5, and the ammonium bicarbonate is dissolved Solution A1 of device 5 enters metath...

Embodiment 3

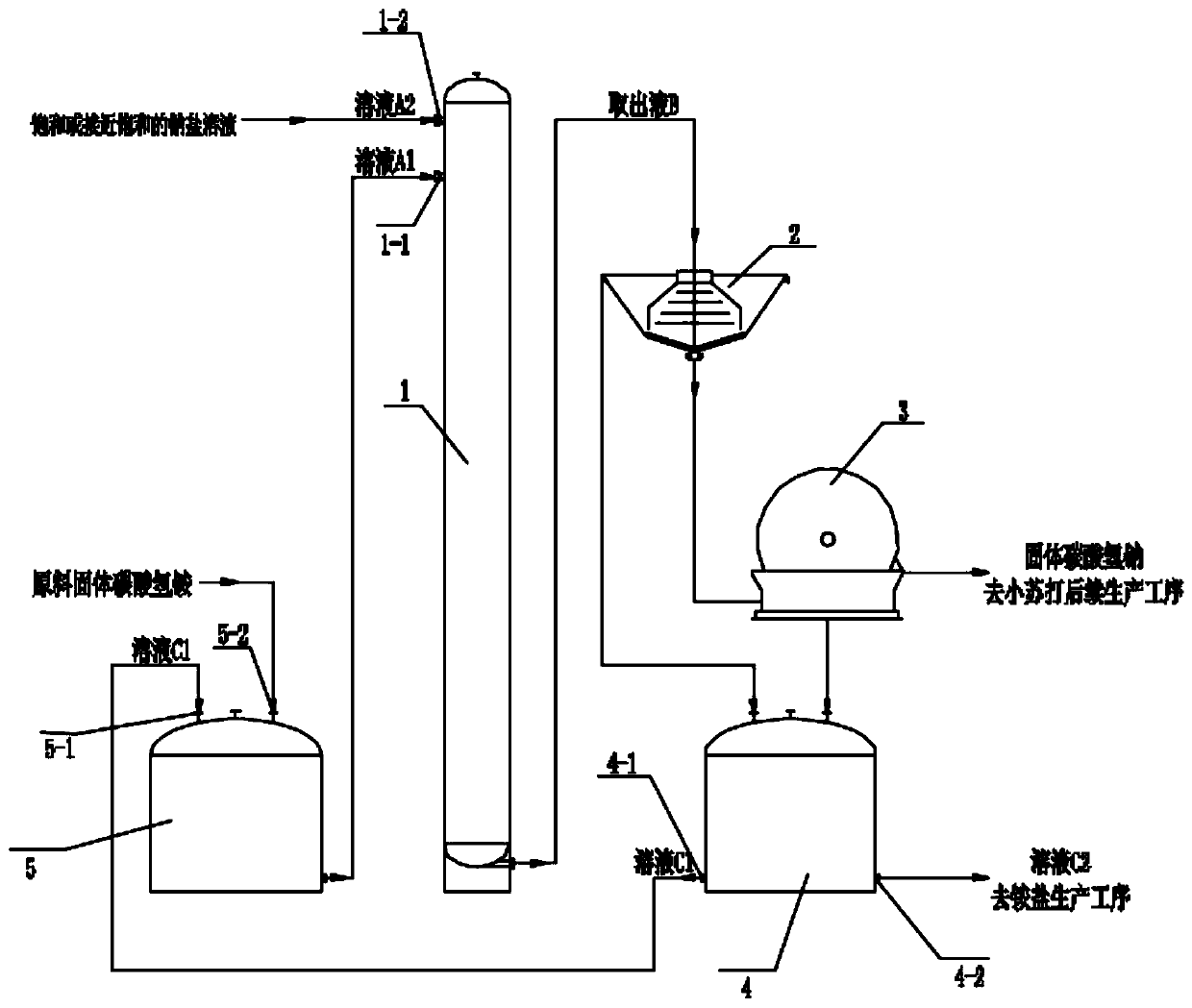

[0039] Such as image 3 Shown is a method for preparing baking soda by metathesis, the metathesis reactor 1 takes out the liquid and enters the thickener 2 of the solid-liquid separator, and the clear solution overflowing from the upper part of the thickener 2 of the solid-liquid separator enters the filtrate storage tank 4 , the crystal slurry at the bottom of the thickener 2 of the solid-liquid separator enters the centrifuge 3 of the solid-liquid separator, and the solid sodium bicarbonate separated by the centrifuge 3 of the solid-liquid separator enters the subsequent production process of baking soda; the solid-liquid separator The solution separated by the centrifuge 3 enters the filtrate storage tank 4, the solution C1 that goes out of the filtrate storage tank 4 enters the ammonium bicarbonate dissolver 5, and the solution C2 that goes out of the filtrate storage tank 4 enters the ammonium salt production process; the raw material solid ammonium bicarbonate is added A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com