Vertical cluster casting die for cast steel parts and cluster casting method thereof

A technology for steel castings and mold strings, which is applied to the vertical string casting molds of steel castings and the field of string casting, can solve the problems of poor product quality stability, low product qualification rate, low productivity, etc., and achieves convenient and fast installation and operation. , the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

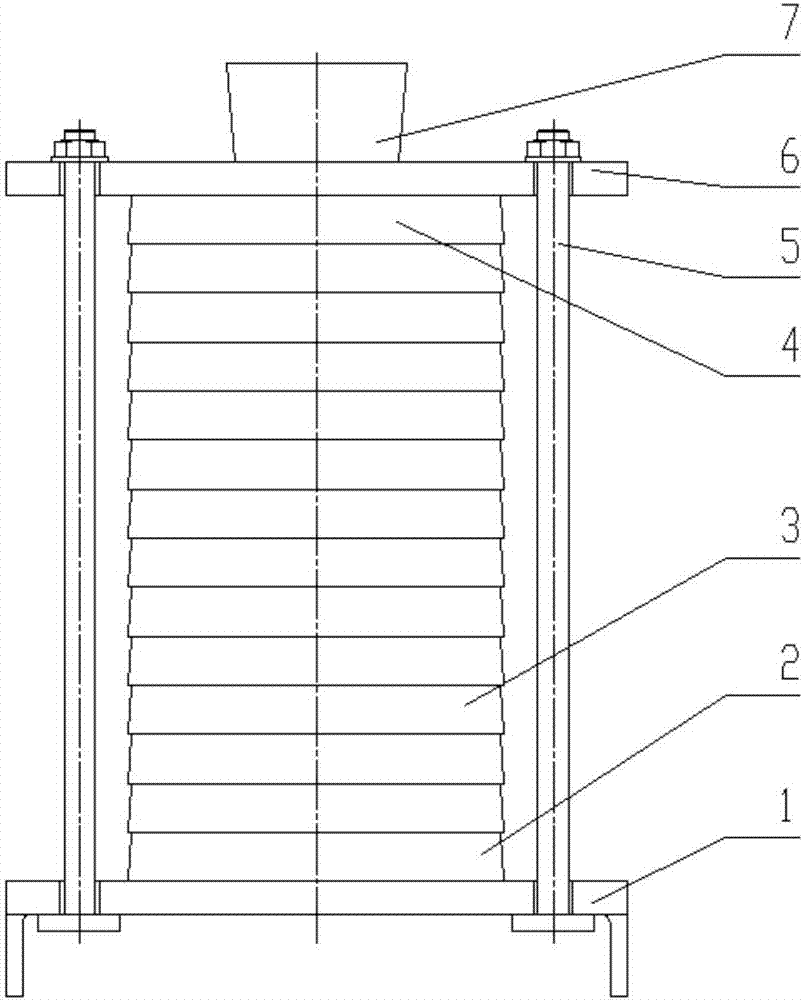

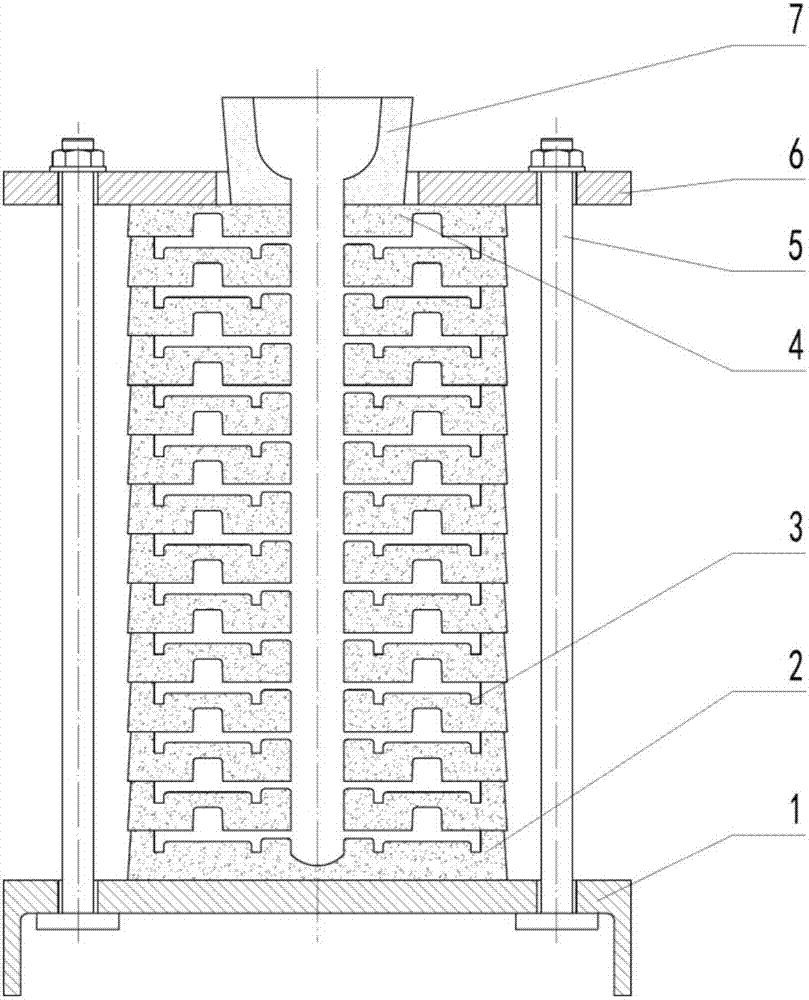

[0053] Such as Figure 1-11 As shown, a vertical series casting mold for steel castings includes a bottom plate 1 and a cover plate 6. The bottom plate 1 and the cover plate 6 are fixed by bolts 5 to form a casting cavity, and a casting module is arranged in the casting cavity.

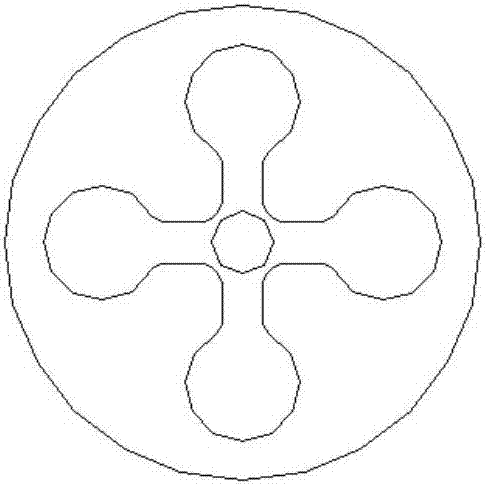

[0054] The casting module includes a bottom block 2, a middle block 3, and an upper block 4. The bottom block 2 is arranged at the bottom of the casting cavity, the upper block 4 is arranged at the top layer of the casting cavity, and several medium blocks 3 Set between the bottom block 2 and the upper block 4. The bottom block 2 has a groove in the middle, and a casting structure is provided around it. The middle block 3 is a through hole, and there are several casting structures around it. Each casting structure is provided with a through hole, and the upper block 4 is provided in the middle. There is a through hole, and a casting structure is provided around it.

[0055] The bottom block 2, the middle...

Embodiment 2

[0058] Example 2 is basically the same as Example 1, but the difference is that the bottom block, medium block, and upper block are formed in series with a vertical runner in the middle. The runner mouth of the vertical runner can be designed from top to bottom. The lower diameter gradually increases, because the lower the casting, the greater the pressure difference between the inside and the outside, the larger the diameter can reduce the pressure, and the upper and lower pressure differences between the inside and outside ensure a balance. The casting increases smoothly when the casting is downward. Better efficiency, faster speed, guarantee product accuracy and casting efficiency. In this way, the groove of the bottom block is larger than the through hole of the upper block, and the through hole of the medium block gradually increases from top to bottom; when the product is cast, it can also ensure that the bottom connection is thicker, and it is not easy to cause the connec...

Embodiment 3

[0060] Embodiment 3 is basically the same as embodiment 1 or 2, the difference is that the bottom block, medium block, and upper block are located away from the center according to requirements, that is, the closer the casting structure is to the edge, the size is required Gradually increase in size. According to the casting characteristics of different castings, choose different enlargement coefficients. The increase coefficient is between 0.05% and 0.3% of the original size basis. The thickness of the sand coating during casting can also be gradually reduced to reduce the coefficient. Between 0.05%-0.3% of the original size. Because it is far away from the center, the inflowing casting material flows more slowly, and the pressure is reduced, and the corresponding size is gradually enlarged, which effectively ensures the consistency of the end surface level. The rate of good products increases, and the rate of good products can rise by more than 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com