Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Glaze surface hardness is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glaze coloured decoration daily use poocelain and its production method

InactiveCN1911855AMeet technical requirementsMeet the process requirementsHigh volume manufacturingThermal stability

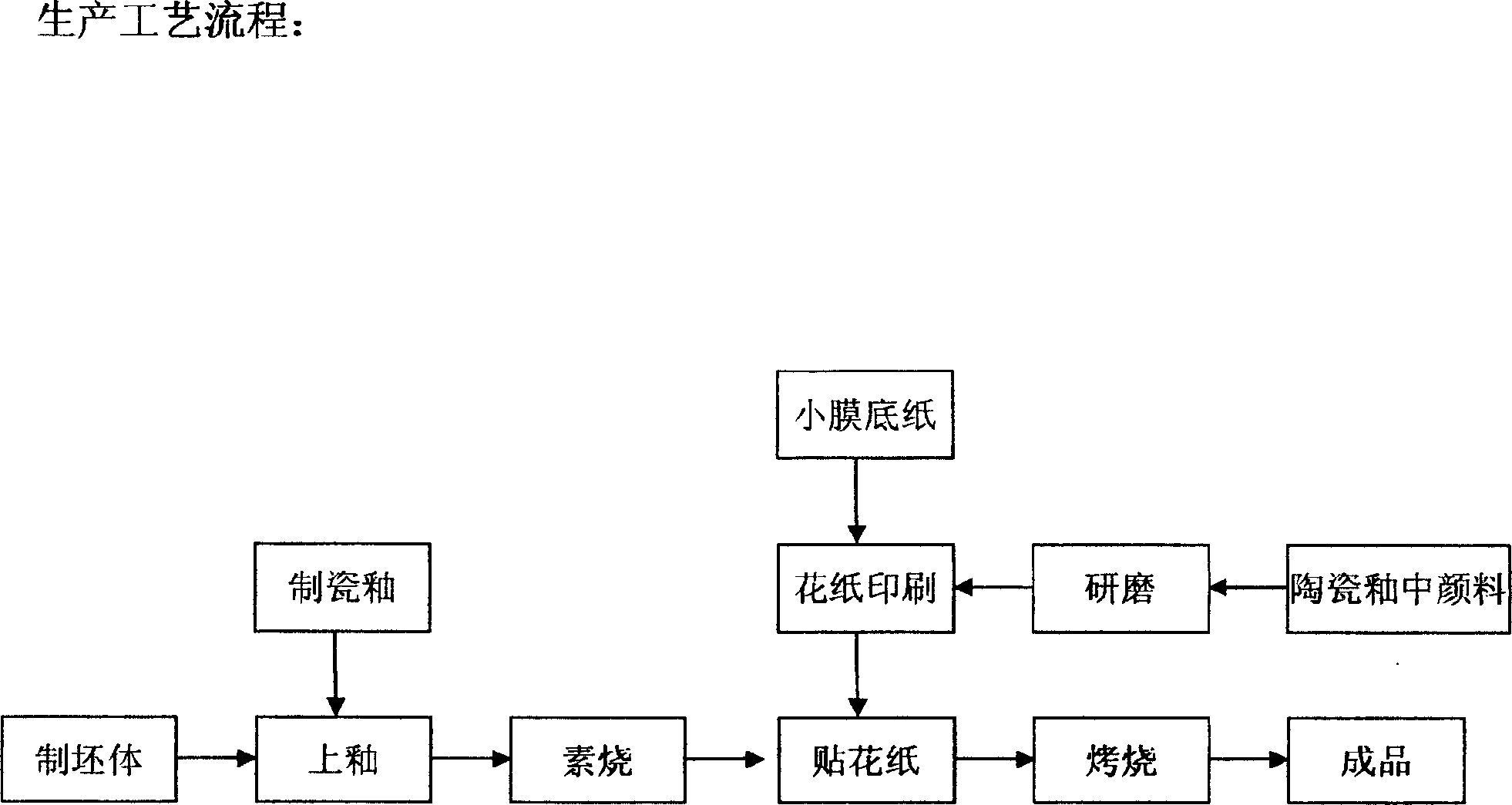

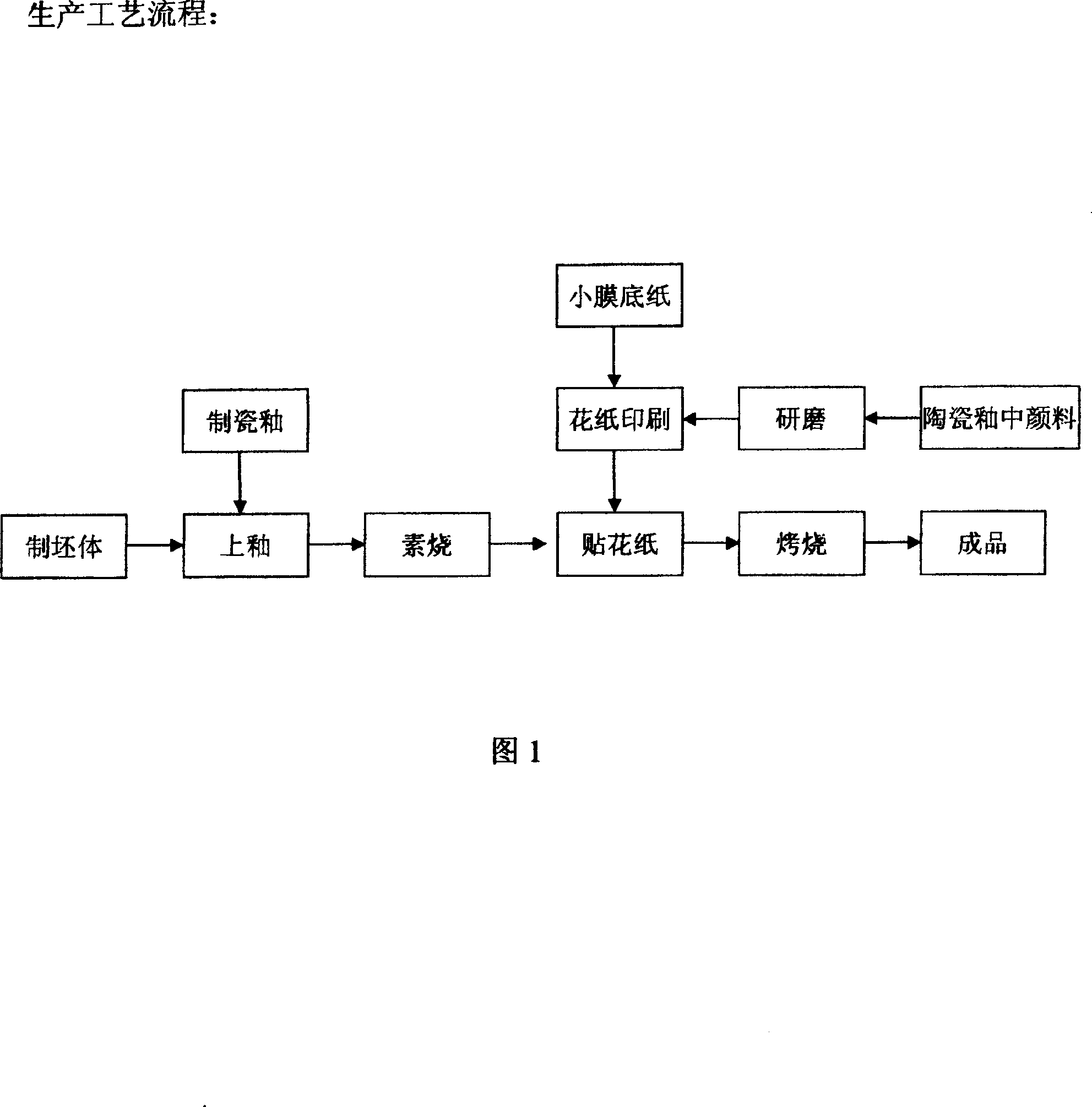

The present invention relates to ceramic product, and is especially one kind of in-glaze color decorated daily use porcelain product and its production process. The materials for the in-glaze color decorated daily use porcelain include Longyan clay, weathered potash feldspar, Jiepai clay, potash feldspar, calcined alumina, Guizhou clay and quarztz. The production process of the in-glaze color decorated daily use porcelain product includes the steps of making biscuit, preparing glaze and in-glaze color paper, glazing the biscuit, firing biscuit, adhering the in-glaze color paper, and baking to obtain the product. The in-glaze color decorated daily use porcelain has rich bright colors, smooth and fine glaze surface, low Pb and Cd leaching out amount, high strength, and other advantages.

Owner:林伟河

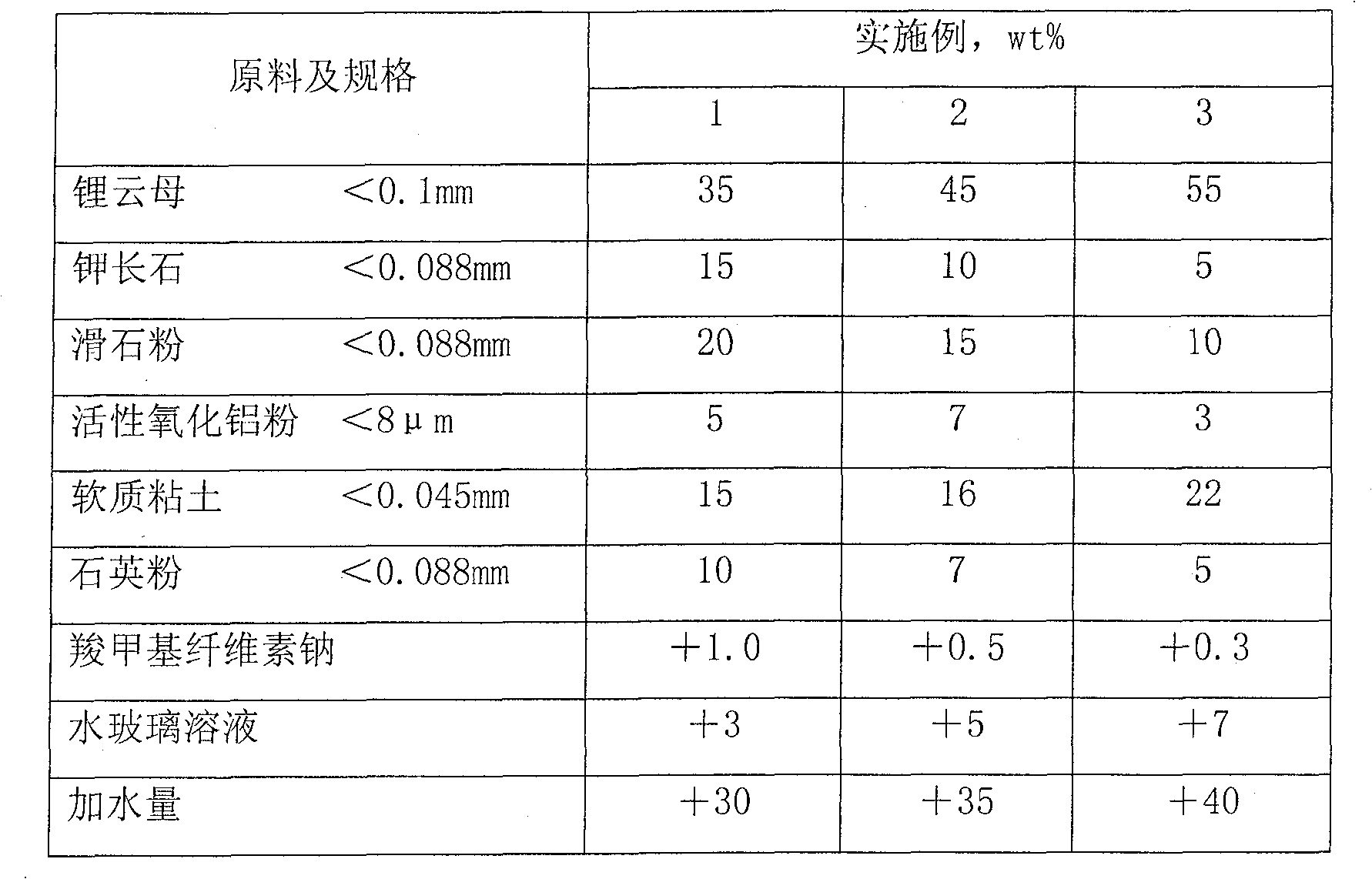

Coating material preventing carbon deposition of coke oven and method for making same

ActiveCN101134853AGood matchGlaze surface hardness is highOven incrustations prevention/removalCoatingsPotassium feldsparSoft clay

The present invention relates to one kind of refractory coating material and its preparation process. The coating material is prepared with lepidolite 35-55 wt%, potassium feldspar 5-15 wt%, talcum powder 10-20 wt%, soft clay 15-25 wt%, active alumina powder 3-7 wt%, and quartz powder 5-10 wt%, and through mixing into slurry after being added with sodium carboxymethyl cellulose 0.3-1.0 wt%, water glass solution 3-7 wt% and water 30-40 wt%, painting or spraying onto the lining of furnace, drying and sintering at 1200-1300 for 4-12 hr. The refractory coating material has obvious carbon preventing effect, high durability, heat expansion performance similar to that door material of coke oven and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

Metallic glaze and its preparation method

The invention discloses a metallic glaze. The metallic glaze comprises the following components: 5-25 parts by weight of feldspar, 10-30 parts by weight of albite, 25-40 parts by weight of quartz, 1-15 parts by weight of calcite, 5-20 parts by weight of kaolin, 15-40 parts by weight of frit powder, 0.1-5 parts by weight of titanium oxide, 0.5-5 parts by weight of vanadium pentoxide, 5-20 parts by weight of manganese dioxide, 0.1-5 parts by weight of copper oxide, 0.1-3 parts by weight of cobalt oxide and 0.1-5 parts by weight of nickel oxide, wherein the frit powder comprises potassium chloride, sodium chloride, silica, alumina, magnesia, boric acid and spodumene. The invention also discloses a preparation method for the metallic glaze. With the formula and preparation method for the metallic glaze, the prepared metallic glaze has excellent metallic luster and high glaze hardness and totally appears to be golden yellow.

Owner:湖南铜官海旭陶瓷有限公司

Processing craft of new bone china blank and glaze

The invention belongs to the technical field of ceramic product manufacturing methods, particularly relates to a new bone china blank and glaze craft, and mainly solves the problem that the production processes in the bone china are complex, the heat stability of a product is poor, the glaze hardness is low, and the production cost is high. According to the technical scheme, the new bone china blank and glaze craft comprises the following steps of preparing pug, preparing glaze, and producing a blank. The processing craft provided by the invention has the advantages that the heat stability of a once-firing product is good, the glaze hardness is high, the production cost is low, the boneblack content is less and the like.

Owner:YING COUNTY SHENGFU CERAMICS IND CO LTD

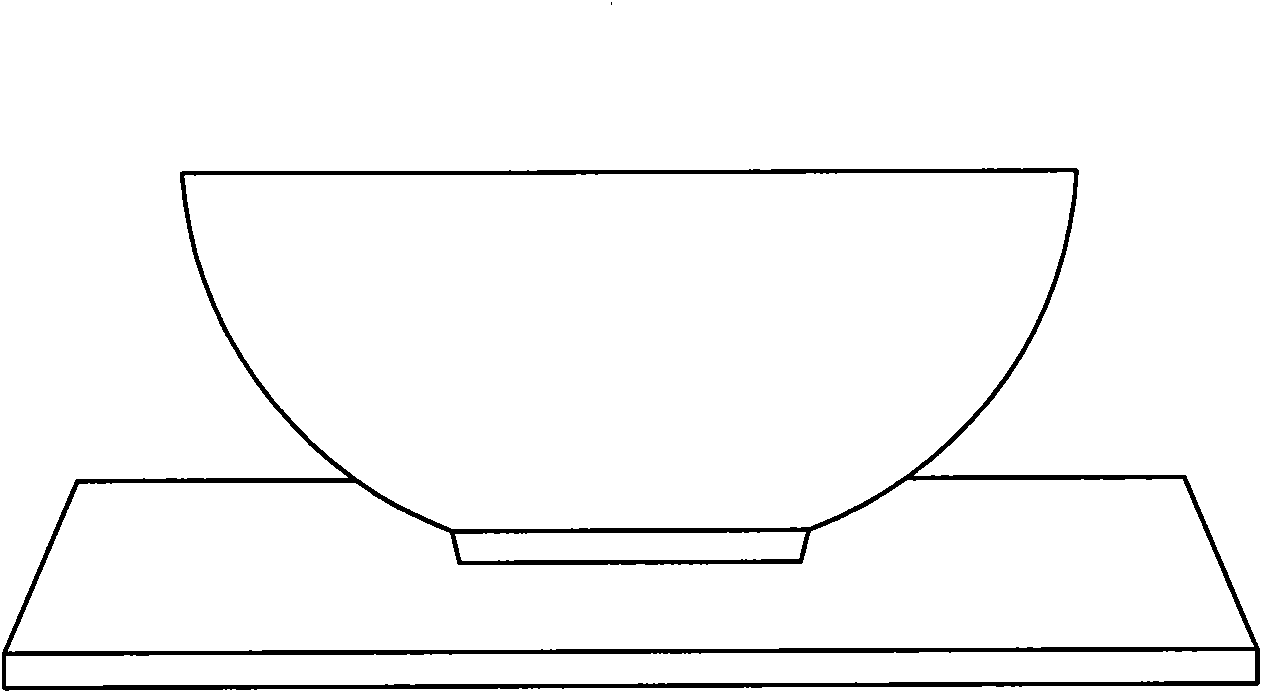

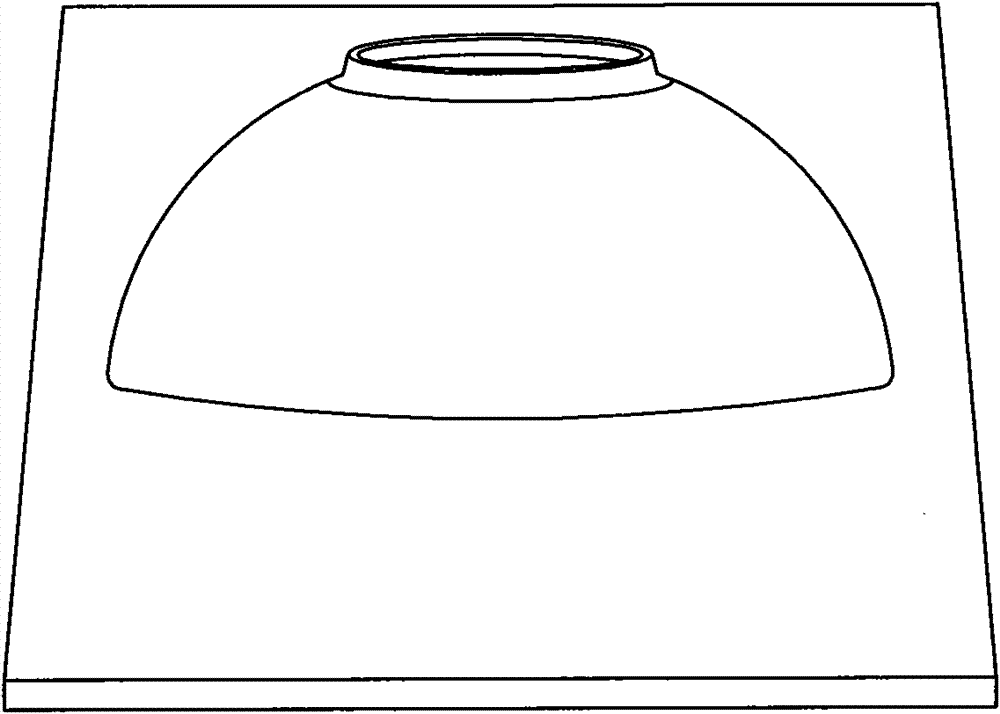

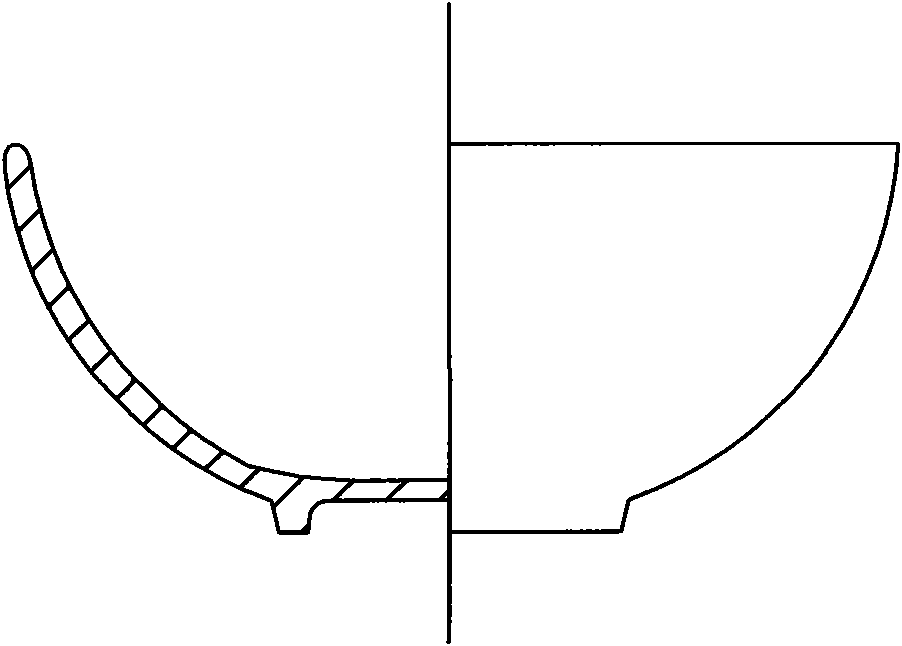

Method for firing domestic porcelain

The invention relates to a method for firing a domestic porcelain, in particular to the method for firing high-grade domestic porcelains, such as bowels and cups. The method comprises the following steps of: 1, drying a finished body, placing the body into a kiln to perform biscuit firing at the low temperature of 800 to 900 DEG C, and polishing the biscuit-fired body to smooth; 2, glazing the biscuit-fired body and removing glaze at the mouth rim and foot of the product; 3, directly placing the product on a refractory slab in a reversing way for primary high-temperature glaze firing; and 4, turning the product over, cleaning and partially glazing the mouth rim of the product, placing the product into the kiln again in an erecting way for secondary high-temperature glaze firing, and cooling the product to obtain the finished product. Compared with the conventional low-temperature biscuit-firing high-temperature glaze-firing method or high-temperature biscuit-firing low-temperature glaze-firing method, the method is convenient to operate, ensures the light weight and high superior quality rate of the fired finished product, and is very applied to the production of various high-grade domestic porcelain products, such as the bowels and the cups.

Owner:FUJIAN DEHUA JIASHUN CRAFTS

Low-temperature glaze-fired ceramic product and preparing method thereof

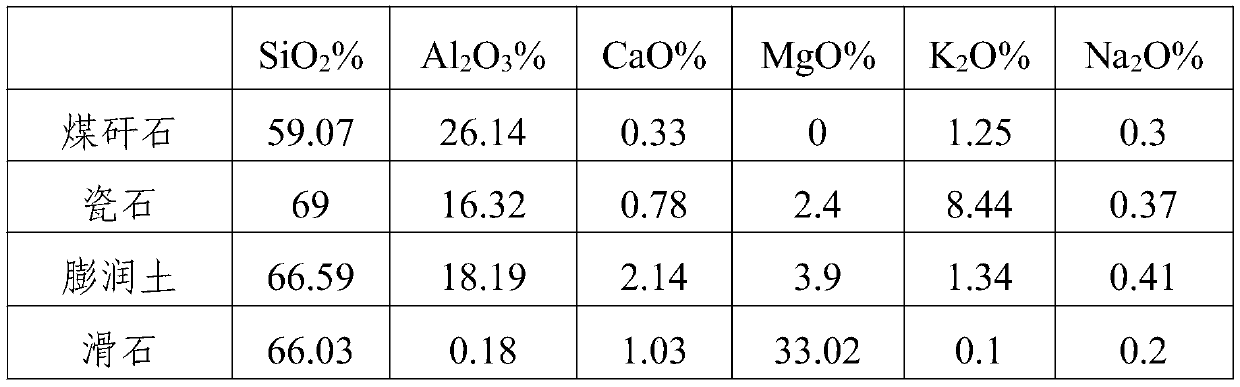

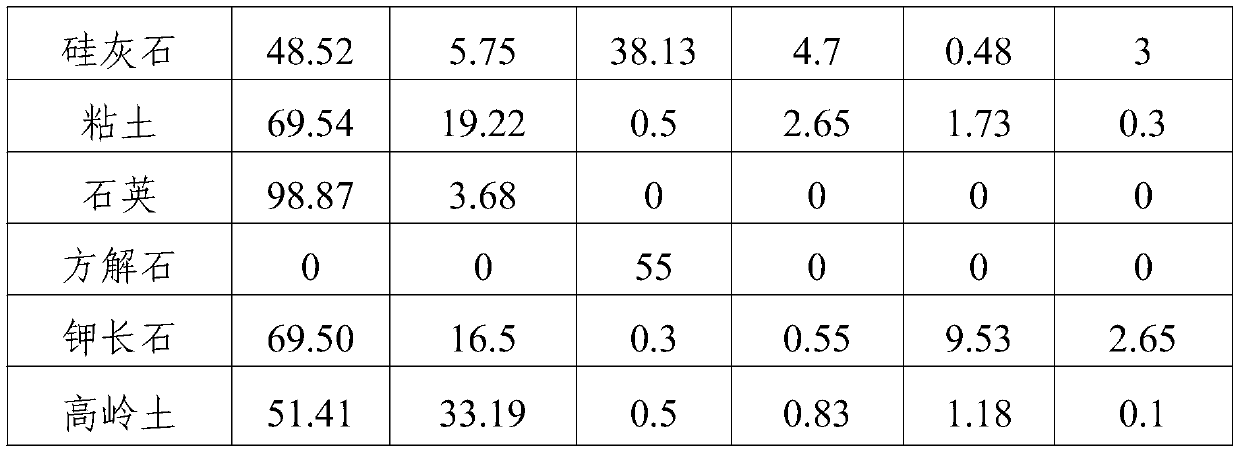

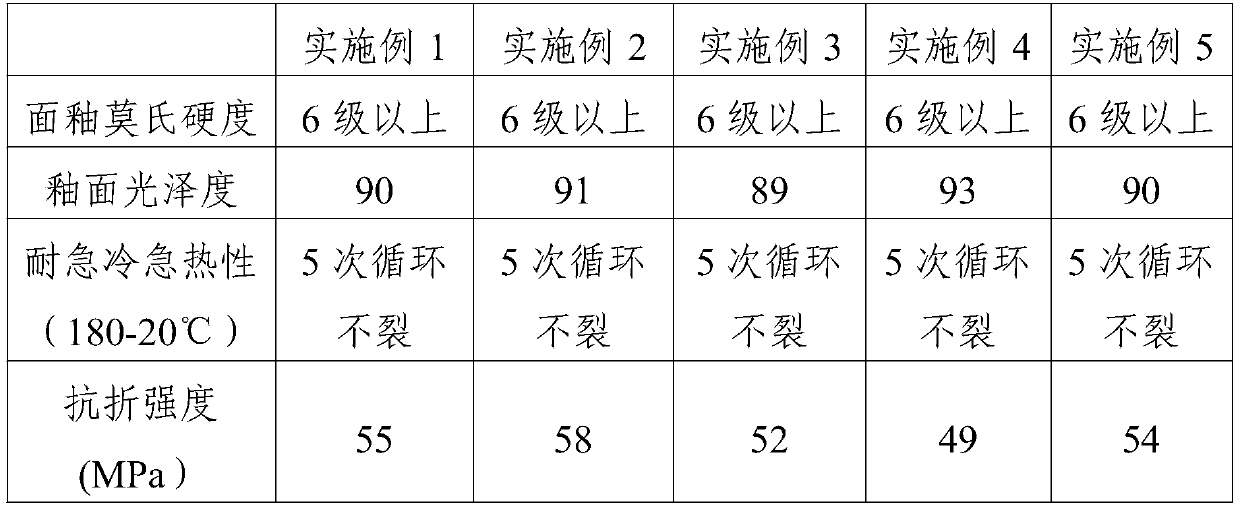

The invention provides a low-temperature glaze-fired ceramic product and a preparing method thereof, and relates to the technical field of ceramic products. The low-temperature glaze-fired ceramic product is obtained by coating a ceramic blank with low-temperature glaze and drying and firing the ceramic blank. The ceramic blank comprises, by mass, 30-40 parts of coal gangue, 40-50 parts of chinastone, 5-10 parts of bentonite, 3-8 parts of talc, 6-15 parts of wollastonite, 4-10 parts of clay, 1-3 parts of quartz and 0.2-0.6 part of sodium polyphosphate. The low-temperature glaze comprises, by mass, 5-15 parts of calcite, 30-40 parts of quartz, 10-20 parts of potassium feldspar, 9-15 parts of kaolin, 10-20 parts of talc, 15-25 parts of barium carbonate, 10-20 parts of borax, 5-10 parts of zinc oxide and 0.1-0.5 part of sodium carboxymethyl cellulose. The prepared ceramic product has high glaze surface hardness, color and luster and heat stability, the firing temperature is lowered, energy conservation and emission reduction are reduced, the adopted raw materials are easy to obtain and low in price, and production cost is reduced.

Owner:广东派陶科技有限公司

Preparation method of reinforced bone china and product prepared therefrom

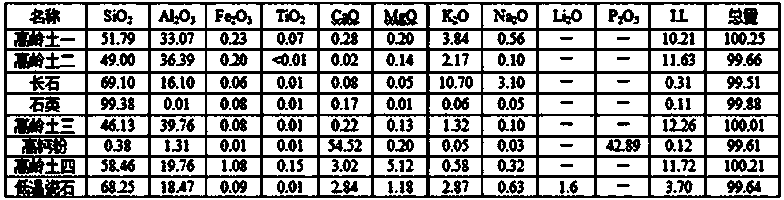

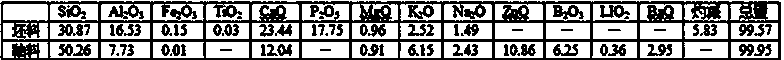

The invention relates to a preparation method of reinforced bone china and a product prepared therefrom. According to the preparation method, a green body formula comprises the following components in percentage by weight: 15 to 20% of kaolin I, 15 to 20% of kaolin II, 10 to 15% of feldspar, 5 to 10% of quartz, 8 to 10% of kaolin III, 2 to 5% of kaolin IV, 35 to 40% of high calcium powder, and 5 to 10% of low-temperature cornish stone; a glaze formula comprises the following components in percentage by weight: 10 to 15% of kaolin I, 30 to 40% of feldspar, 5 to 10% of quartz, 8 to 13% of borax, 5 to 10% of zinc oxide, 10 to 15% of cornish stone, 3 to 6% of dolomite, 8 to 12% of calcite, and 5 to 8% of barium carbonate. The production method is scientific and reasonable, advanced in process technology, high in rate of finished products, and high in product quality, realizes firing at medium and low temperatures and has the advantages that a lot of gas and fuel is saved, the defect rate caused by the glaze firing at high temperature is greatly reduced, the production cost is remarkably reduced, and thus a wide market prospect is brought.

Owner:景德镇恩达陶瓷有限公司

Recipe of high temperature hard glaze for bone china and bone china producing process

The present invention is recipe of high temperature hard glaze for bone china and bone china producing process. The recipe of high temperature hard glaze for bone china consists of quartz, feldspar, talc, ceramic powder, calcium carbonate, dolomite, kaolin and clinker. The bone china producing process includes the first step of spraying high temperature hard glaze for bone china in the front face of dried biscuit, supporting the back of the biscuit with sagger to avoid deformation and sintering in kiln at 1270-1280 deg.c; and the second step of spraying low temperature glaze to the back of first sintered piece and sintering for the second time in the glaze kiln at 1050-1160 deg.c. The bone china product of the present invention has high glaze surface hardness, high strength, high heat stability and no lead contained. The present invention is suitable for produce various kinds of household china products.

Owner:赵孟冬

Zirconium-free spinel crystalline opaque glaze and manufacturing method

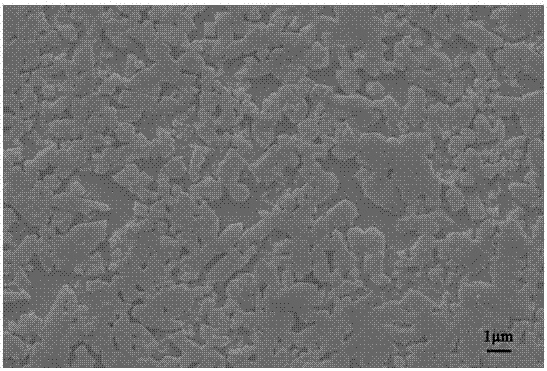

The invention discloses a zirconium-free spinel crystalline opaque glaze and a manufacturing method. The zirconium-free spinel crystalline opaque glaze comprises the following components in percentages by mass: 1-5% of Na2O, 1-5% of K2O, 20-25% of Al2O3, 2-6% of CaO, 7-15% of MgO, 5-8% of ZnO, 2-6% of B2O3, and the balance being SiO2. The glaze layer of the zirconium-free spinel crystalline opaque glaze precipitates (Mg,Zn)Al2O4 spinel crystal, the crystal grain size is 300-1000nm, the crystal has high scattering effects for visible light, in order to reach whiteness of common zirconium white fritted glaze, and improve hardness, wear resistance and mar-resistance of glaze. The product does not contain zircon sand and any radioactive elements, and has low cost and good milky white effects; the production technology is completely identical to the production technology of zirconium opaque fritted glaze, and the production cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Anorthite micro-crystal transparent glaze and preparation method thereof

The invention discloses an anorthite micro-crystal transparent glaze and a preparation method thereof, and relates to a ceramic-used glaze material. The anorthite micro-crystal transparent glaze comprises the following ingredients by mass percentage: 1%-5% of Na2O, 1%-5% of K2O, 12%-18% of Al2O3, 15%-20% of CaO, 2%-5% of MgO, 2%-7% of ZnO, 2%-7% of high-boron frit and the balance of SiO2. The fineness of the glaze material is less than 0.15% as the residue of a 250-mesh sieve; the preparation method comprises the following technological processes: testing raw materials, matching the raw materials, ball-milling, detection, milling out, sieving, adjusting the density of glaze slip to 1.35-1.4g / cm<3>, glazing, sintering and obtaining a finished product. A sintering system is described as follows: preserving heat at the temperature of 1,200-1,210 DEG C for 30-40min, cooling to the temperature of 860-880 DEG C and preserving heat for 30-40 min. Anorthite crystals grow on a glaze surface of the anorthite micro-crystal transparent glaze prepared by the invention, so that the hardness, wear resistance, mar-resistance and corrosion resistance of the glaze surface are improved, and the defect that scratches are easily caused on the glaze surface of the transparent glaze is overcome.

Owner:SOUTH CHINA UNIV OF TECH

High-permeability high-whiteness high-strength eggshell porcelain plate

ActiveCN108840665AExpand the practicalityBroaden the field of applicationCeramic materials productionClaywaresEggshellFiltration

The invention discloses a high-permeability high-whiteness high-strength eggshell porcelain plate which is characterized by comprising the following natural ore raw materials and industrial chemical raw materials in percentage by weight: 30-35% of Longyan kaolin, 10-12% of quartz, 5-8% of aluminum oxide, 30-35% of feldspar, 4-6% of talc, 1%b of calcite, 2-5% of potassium feldspar, 1-2% of albite,8% of bone meal and 3-5% of yttrium oxide, and a product of the eggshell porcelain plate is prepared through procedures of washing, blending, ball milling, addition of 4% of external porcelain powder,deironing, filtration, slurry treatment, molding, primary drying, blank trimming, biscuiting, refining, glazing, secondary drying and glaze firing. By controlling formula and molding processors, theproblems of whiteness, transparency, glaze surface hardness and flatness of the product can be solved, and the obtained high-permeability high-whiteness high-strength eggshell porcelain plate productcan be used as decorative lamp shades in families, offices, indoor places and the like, and has wide application prospects.

Owner:景德镇市华运坊陶瓷有限公司

A kind of firing process of reinforced enamel bone china

The invention belongs to the technical field of firing ceramics, in particular to a firing process for strengthening enamel bone china. Its characteristics are: after the blank is formed, it is polished smooth after biscuit firing at 780-800°C, then glazed, and then the glaze on the edge and bottom edge is removed; when loading the blank, the edge of the product with the glaze removed In the groove of the shaped pad cake, put the billets into the kiln together, and use the reduction flame for the first firing, and the firing temperature is 1330-1350°C. The shaped pad cake is made of the same mud as the product. A groove pad cake made of mud that completely matches the edge of the finished product; after firing and cooling, the porcelain is selected and graded, and the colored flowers in the glaze are pasted. Secondary firing in a weak reducing atmosphere, that is, firing the in-glaze color at the same time as the second mouth glaze firing. The strengthened enamel bone china of the invention has the characteristics of good whiteness, good translucency, good heat stability, high glaze hardness, no lead cadmium dissolution and the like.

Owner:尧忠义

Pearl glaze material, pearl glaze, manufacturing method of pearl glaze and pearl glaze ceramics

The invention relates to the technical field of researching and developing, producing and processing the formula of a pearl glaze material, and provides a pearl glaze material, a pearl glaze, a manufacturing method of the pearl glaze and pearl glaze ceramics. The method for manufacturing pearl glaze ceramics comprises: step a, applying ground graze on the surface of a ceramic green body to obtain a substrate; step b, applying a thick pearl glaze liquid to the surface of the substrate; and step c, sintering the product obtained from the step b to obtain pearl glaze ceramics. The sintering temperature is 1150-1230 DEG C and the sintering time is 80-120 min. The surface of the manufactured pearl glaze ceramics is made from a layer of random-distributed fine natural pearl particles, and the pearl glaze ceramics has a great sense of reality. The pearl glaze ceramics is high in glaze hardness and excellent in wear resistance and skid resistance. Problems in conventional technology are solved. The manufacturing method and the use method are simple, are low in cost and have great economic benefit.

Owner:HUBEI HANGRUI CERAMIC CO LTD

Porcelain glaze and preparation method thereof

InactiveCN106495481AGlaze surface hardness is highImprove wear resistancePotassium feldsparSilica fume

The invention belongs to the field of porcelains and relates to porcelain glaze and a preparation method thereof. The porcelain glaze comprises 25 to 30 parts of potassium feldspar, 20 to 30 parts of bentonite, 5 to 8 parts of molybdenum trioxide, 5 to 10 parts of wollastonite, 0.5 to 0.8 parts of chromium oxide, 6 to 10 parts of quartz, 3 to 5 parts of dolomite, 5 to 8 parts of calcium carbonate, 4 to 8 parts of flint clay, 0.7 to 0.8 parts of sodium tripolyphosphate, and 1 to 3 parts of silicon carbide powder. The preparation method comprises pulverization, ball milling and blending. The porcelain product made by the preparation method does not contain lead, has high hardness of a glaze surface, high wear resistance and high strength, is not deformed easily, and has a good blank-glaze combination degree and good heat stability because of sintering at a high temperature.

Owner:崔松伟

High-transmittance, high-weight and high-strength large porcelain plate

ActiveCN108793966AHigh transparencyCompact body structureCeramic materials productionClaywaresCalcitePotassium

The invention discloses a high-transmittance, high-weight and high-strength large porcelain plate. The porcelain plate adopts natural raw mineral materials and industrial chemical materials, and comprises the following material components in percent by weight: 30 to 35 percent of Longyan kaolin, 10 to 12 percent of quartz, 5 to 8 percent of aluminum oxide, 20 to 25 percent of feldspar, 4 to 6 percent of talcum, 1 percent of calcite, 3 to 7 percent of potash feldspar, 1 to 3 percent of albite, 10 to 12 percent of bone meal, 5 to 6 percent of yttrium oxide, and 3 percent of zirconium oxide. Theporcelain plate is formed through the following processes: washing, compounding, ball milling, adding 8 percent of porcelain powder, deironing, filtering, mud treatment, forming, primary drying, fettling, biscuiting, truing, glazing, secondary drying and glaze firing. The porcelain plate solves the problems in terms of whiteness, transparency, glaze surface hardness of products through control ofa formula and a forming technology, can be applied to manufacture of indoor or outdoor artistic walls or artistic atmosphere lampshades with backlight effect, and has a wide application prospect.

Owner:景德镇市华运坊陶瓷有限公司

Bone china lead-free glaze

The invention relates to lead free glaze for bone china. According to the molecular percentage, the lead free glaze is composed of 50-52 percent of silicon dioxide, 9.02-10.28 percent of aluminum oxide, 8.98-10.28 percent of calcium oxide, 2.343.24 percent of magnesia, 6.28-7.65 percent of potassium oxide, 1.24-1.89 percent of sodium oxide, 13.28-16.23 percent of zinc oxide, 1.98-3.42 percent of baryta, 2.98-3.34 percent of boron trioxide and 1.17-1.67 percent of lithium oxide; the lead free glaze has the advantages that the hardness of glaze surface of the bone china is enhanced, and the frequency of use thereof is increased; the glaze surface of the bone china is moist, the brightness and the whiteness are high, and the tacticity is high; the European and American standards on the lead release (pb) of the bone china are achieved or exceeded.

Owner:SHANGHAI HENGLI PORCELAIN

High-hardness imitated yue kiln celadon daily porcelain secret colour glaze and production process thereof

InactiveCN108975708AGlaze surface hardness is highImprove easy to be scratchedClaywaresCeramic glazeOxide

The invention discloses a high-hardness imitated yue kiln celadon daily porcelain secret colour glaze and a production process thereof. A raw glaze material of the high-hardness imitated yue kiln celadon daily porcelain secret colour glaze comprises: 25 to 45% of Shaoxing glaze soil, 14 to 25% of Zijin soil, 12 to 16% of limestone, 15 to 18% of feldspar, 2 to 4% of zirconium oxide, 2 to 4% of zincoxide and 5% of plant ash. According to the application, a reinforcing and toughening material, i.e., zirconium oxide, is added into the raw glaze material of the imitated yue kiln celadon secret colour glaze, so that hardness of a glaze surface is improved, phenomena of scratches and easiness for collision and damage of existing imitated yue kiln celadon secret colour glaze daily porcelain are greatly improved, and durability of the imitated yue kiln celadon secret colour glaze daily porcelain is improved. Adding of zinc oxide not only can improve glossiness of the secret colour glaze, but also can achieve a function of improving hardness of the glaze surface, and can reduce minute bubbles caused by a limestone calcium source and reinforce a transparent feeling.

Owner:杭州景杰陶瓷科技有限公司

Domestic ceramic with anti-seismic property

InactiveCN105906312AImprove antibacterial propertiesReduce pollutionCeramic materials productionClaywaresPolyvinyl alcoholSludge

The invention discloses domestic ceramic with an anti-seismic property. The domestic ceramic is prepared from the following raw materials (by weight): 25-28 parts of spodumene, 7-9 parts of aluminium oxide, 13-15 parts of Longyan washing sludge, 11-14 parts of diatomite, 13-16 parts of zirconium phosphate, 4-6 parts of silver nitrate, 5-7 parts of sodium carbonate, 1-2 parts of potassium humate, 40-45 parts of flyash, 35-40 parts of white glaze ball, 6-8 parts of waste glass, 17-22 parts of lithium-containing porcelain stone, 10-14 parts of medical stone, 21-25 parts of green tea, 14-17 parts of orange peel, 6-8 parts of shell powder, 4-6 parts of shrimp shell meal, 0.2-0.3 part of polyvinyl alcohol, 0.2-0.3 part of tributyl phosphate and a proper amount of deionized water. The domestic ceramic has high anti-seismic property, good mechanical strength, high hardness of glaze surface and good thermal stability, has characteristics of good appearance and the like, meet people's aesthetic requirements, is simple to operate and is worthy of promotion.

Owner:方堃

Preparation method of bone china low-temperature hard glaze

The invention discloses a preparation method of bone china low-temperature hard glaze, and belongs to the technical field of ceramic production. The low-temperature hard glaze is prepared from the following raw materials in percentage by mass: 0.10 percent to 0.90 percent of Li2O, 0.50 percent to 6.00 percent of B2O3, 6.00 percent to 11.00 percent of CaO, 7.00 percent to 10.00 percent of ZnO, 3.00 percent to 6.00 percent of K2O, 3.00 percent to 6.00 percent of Na2O, 55.00 percent to 65.00 percent of SiO2 and 7.00 percent to 11.00 percent of Al2O3, wherein the sum of the mass fractions of the raw materials is 100 percent. The use amount of ZnO in the existing low-temperature glaze is reduced, a proper amount of Li2O and B2O3 are added, and the use amount of CaO is increased, so that the hardness is increased to 6.3 GPa on the premise of not increasing the glaze firing temperature, and the acid and alkali resistance of the glaze surface reaches the acid and alkali resistance level A of the domestic ceramic glaze surface.

Owner:JIANGSU GAOCHUN CERAMICS

Processing method of nitride ceramic glaze

The invention discloses a processing method of nitride ceramic glaze and relates to the field of ceramic processing. The nitride ceramic glaze is prepared by adopting a raw material which takes limestone, kaolin, silicon nitride, calcium carbonate, zirconium oxide and aluminum nitride as basic materials, and a raw material which takes borax, mica, potassium feldspar and quartz as a wear-resistingagent, has good elasticity and wear resistance and has a good melting property; the nitride ceramic glaze has no toxin and no pollution and the product performance index of the ceramic glaze is comprehensively improved. Compared with common ceramic glaze, the nitride ceramic glaze has the advantages that the rigidity of a glaze surface is improved by 38 percent, ultrahigh wear-resisting performance is realized and fatal defects that the ceramic glaze has poor wear resistance and is easy to scratch are perfectly solved.

Owner:TIANJIN ZHONGYI HIGH TECH CO LTD

Tech. for mfg. multicrystal strengthening porcelain

InactiveCN100355696CGlaze surface hardness is highImprove wear resistanceManufacturing technologyNano sio2

The invention relates to polycrystal intensified ceramic manufacturing technology that belongs to ceramic manufacturing technology field. It adopts common kaolin as main raw material. The main constituents of the ingot is 52-60% SiO2, 15-22% Al2O3, 15-21% MgO, 0.5-2% ZnO, 3-5% ZrO2, 0.5-3% BaO, and the other 1-3%. 3-5% Al2O3 crystal whisker and 1-2% ZrO crystal whisker are induced into the ingot, and 5-10% nm SiO2 and 1-2% ZnO are induced into glaze material. After the process of modifying the raw material, mixing and grinding, filtering to remove iron, filtering mire, drilling mire, banalitying, molding, drying, glazing, drying, sintering, checking and packaging, the common kaolin is modified to have 43-52% SiO2, 32-38% Al2O3. The invention could produce high level ceramic.

Owner:詹振明

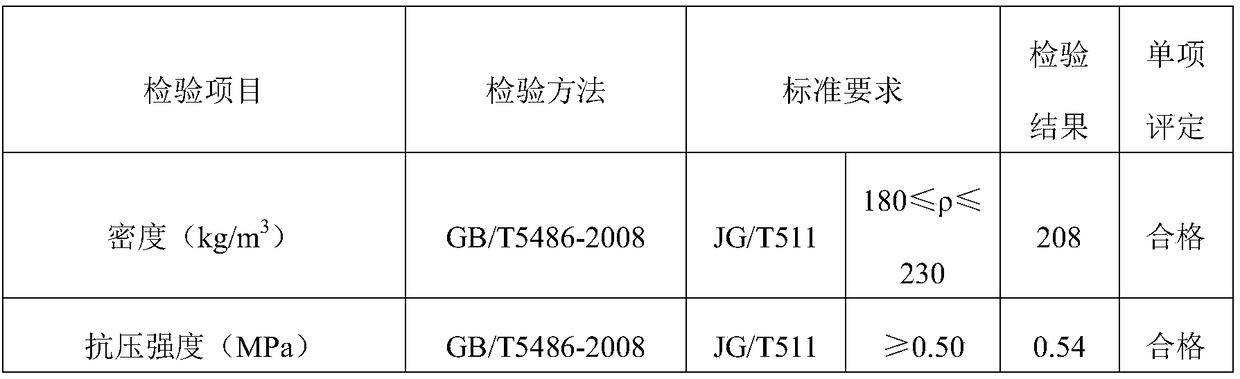

Preparation method of ceramic glaze layer of foamed ceramic thermal insulation and decorative integrated board

The invention discloses a method for preparing a ceramic glaze layer of a foamed ceramic thermal insulation and veneer integrated board, which belongs to the technical field of energy saving and environmental protection. The preparation method comprises the following steps: 1) cutting the foamed ceramic thermal insulation thick plate prepared by high-temperature foaming in the kiln into foamed ceramic thermal insulation veneers; The single surface of the foamed ceramic thermal insulation veneer is baked at a temperature of 220-420 °C to obtain the decorative base layer of the foamed ceramic thermal insulation veneer integrated board, and the thickness of the decorative base layer is 1.2-1.8mm; 3) Then Spray or roller coat the finishing glaze layer material on the surface of the facing base layer, and bake at a temperature of 80-220° C.; the thickness of the finishing glaze layer of the foamed ceramic thermal insulation and facing integrated board is 30-60 μm. The preparation method avoids the deformation of the ceramic thermal insulation veneer; and increases the adhesion between the decorative surface and the foamed ceramic thermal insulation substrate, and also saves energy and increases production capacity.

Owner:武汉依德创拓科技发展有限公司

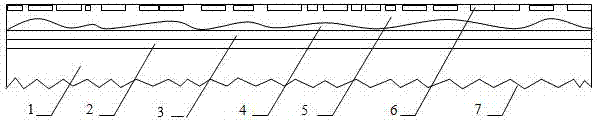

Preparation method of ceramic glaze layer of foamed ceramic insulating veneer integral plate

The invention discloses a preparation method of a ceramic glaze layer of a foamed ceramic insulating veneer integral plate, and belongs to the technical field of energy saving and environmental protection. The preparation method comprises the following steps: 1) cutting a foamed ceramic insulating thick plate prepared by high temperature foaming in a kiln into a foamed ceramic insulating single plate; 2) spraying and rolling a ceramic material of the veneer base layer on single surface of the foamed ceramic insulating single plate in the step 1), and baking at the temperature of 220-420 DEG Cto obtain a veneer base layer of the foamed ceramic insulating veneer integral plate, wherein the thickness of the veneer base layer is 1.2-1.8 mm; and 3) spraying or roll-coating the surface of the veneer base layer with a veneer glaze layer material, and baking at the temperature of 80-220 DEG C, wherein the thickness of the obtained ceramic glaze layer of the foamed ceramic insulating veneer integral plate is 30-60 [mu]m. The preparation method avoids the deformation of the ceramic insulating single plate, the adhesion force between the veneer and the foamed ceramic insulating substrate isincreased, the energy is saved and the production capacity is increased.

Owner:武汉依德创拓科技发展有限公司

A high-transparency, high-white, high-strength thin-bodied porcelain plate

Owner:景德镇市华运坊陶瓷有限公司

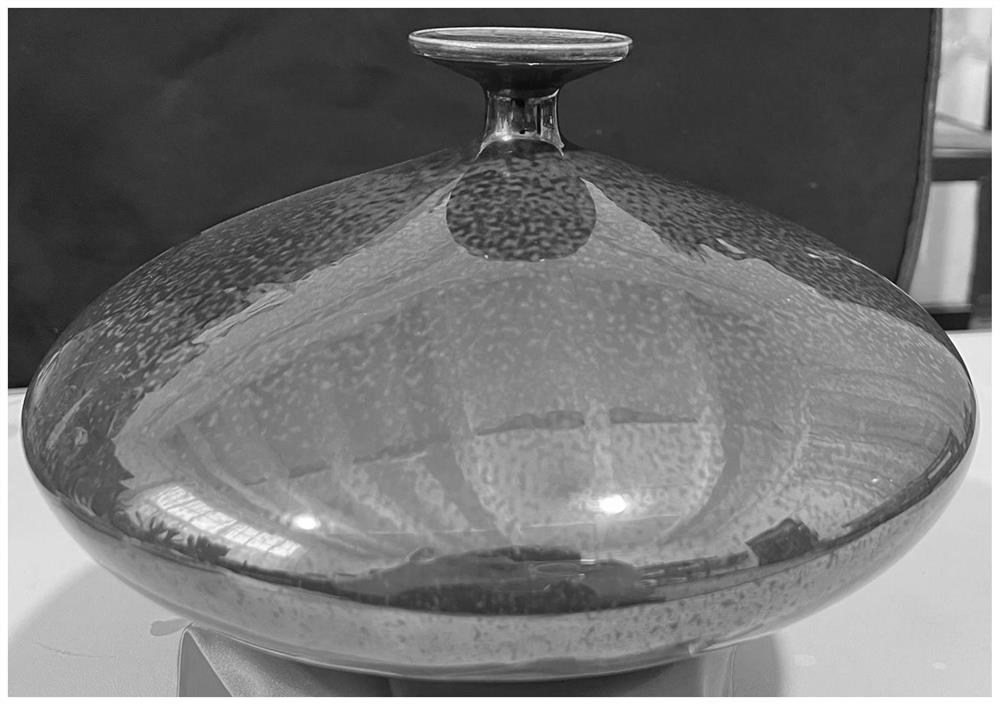

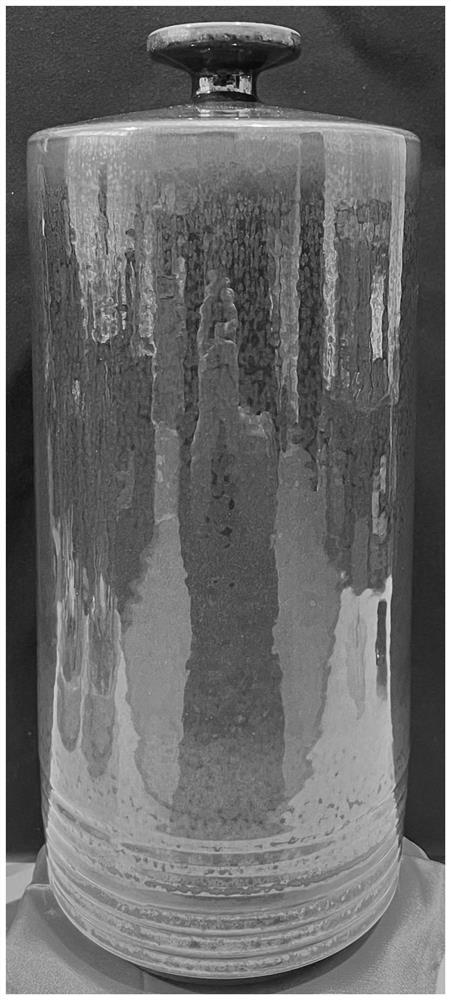

Preparation method of carbon-golden metallic luster crystalline glaze

A method for preparing a carbon-golden metallic luster crystalline glaze. The source and composition of the glaze are (parts by mass): 25-30 parts of MnO2 are used as crystallization agents, 0.5-1.5 parts of MoO2 and 0.5-1.5 parts of V2O5 are used as crystals Accelerator, 2-4.5 parts of CuO, 2.5-5 parts of Fe2O3, 3-7 parts of ZnO and 0.5-2.5 parts of NiO and various metal oxides are used as colorants, and other ingredients are 30-38 parts of Pingjiang Potassium Feldspar, 5-12 parts of quartz produced in Fengyang, 5-10 parts of talc powder produced in Wuxi and 5-12 parts of boron frit produced in Yixing. After the glaze slurry is prepared and applied to the biscuit body, the temperature curve of the present invention is used for glaze firing. With a charcoal gold metallic luster and iridescent effect and crystal beauty. In addition, it has low cost, high glaze hardness, good wear resistance and corrosion resistance. It is a brand-new ceramic art glaze and can be used to decorate ceramic handicrafts.

Owner:山西高陶瓷业有限责任公司 +1

A kind of far-infrared self-generated glazed porcelain with high utilization of desert materials and its preparation process

The invention relates to a far-infrared autogeneous glazed bone china with high utilization of desert materials and a preparation process thereof, which comprises the following raw materials in weight percentage: sand grains taken from desert: 50%-60%; pyrophyllite: 10%-20% ; Purple wood knot: 8%~15%; Coal gangue: 10%~18%; Magnesium-based bentonite: 2%~4%; Potassium feldspar: 4%~8%; Albite feldspar: 4%~8%; Spodumene: 2%~5%; zirconium silicate: 3%~5%; wollastonite: 4%~6%; the production process of the bone china includes the following steps: formula ingredients, ball milling, sieving, Iron removal, pressure filtration, first mud refining, second mud refining and finalized firing; the autogenous glazed bone china prepared by the invention has good toughness and high strength, good thermal stability, and is suitable for rapid cooling and rapid drying. In a hot environment, it has better emissivity and wide frequency spectrum.

Owner:温克仁

Method for firing domestic porcelain

The invention relates to a method for firing a domestic porcelain, in particular to the method for firing high-grade domestic porcelains, such as bowels and cups. The method comprises the following steps of: 1, drying a finished body, placing the body into a kiln to perform biscuit firing at the low temperature of 800 to 900 DEG C, and polishing the biscuit-fired body to smooth; 2, glazing the biscuit-fired body and removing glaze at the mouth rim and foot of the product; 3, directly placing the product on a refractory slab in a reversing way for primary high-temperature glaze firing; and 4, turning the product over, cleaning and partially glazing the mouth rim of the product, placing the product into the kiln again in an erecting way for secondary high-temperature glaze firing, and cooling the product to obtain the finished product. Compared with the conventional low-temperature biscuit-firing high-temperature glaze-firing method or high-temperature biscuit-firing low-temperature glaze-firing method, the method is convenient to operate, ensures the light weight and high superior quality rate of the fired finished product, and is very applied to the production of various high-grade domestic porcelain products, such as the bowels and the cups.

Owner:FUJIAN DEHUA JIASHUN CRAFTS

Copper-based golden red glaze and preparation method thereof

The invention belongs to the technical field of preparation of jun porcelain glaze, and particularly relates to copper-based golden red glaze and a preparation method thereof.The copper-based golden red glaze is prepared from, by weight, 48%-50% of melilite, 16%-20% of white feldspar, 16%-18% of calcite, 8%-10% of quartz, 2%-4% of copper ore, 2%-4% of ZnO, 0.5%-1.5% of SnO2 and 0.4%-0.6% of CuO; the preparation method of the copper-based golden red glaze comprises the following steps: (1) burdening: weighing various raw materials according to the proportion; (2) preparing glaze slip: adding various raw materials into a ball mill, and adding water for ball milling to obtain the glaze slip; (3) glazing: uniformly stirring the glaze slip, and putting a green body which is subjected to biscuit firing and has a clean surface into the glaze slip for glaze dipping; and (4) firing: firing the glazed green body in a kiln. The prepared copper-based golden red glaze is full in glaze color, good in glossiness, high in artistic ornamental value, high in glaze surface hardness, free of cracks, high in yield, low in raw material price and simple in preparation process, large-scale production can be achieved, and the commercial value of the copper-based golden red glaze is improved.

Owner:禹州市神后镇孔家钧窑有限公司

Coating material preventing carbon deposition of coke oven and method for making same

ActiveCN100567412CWide variety of sourcesImprove matchOven incrustations prevention/removalCoatingsSoft clayLong term durability

The invention relates to a refractory coating material and a preparation method thereof. The main raw material weight ratio of the coating material is: lepidolite 35-55%, potassium feldspar 5-15%, talcum powder 10-20%, soft clay 15-25%, activated alumina powder 3-7%, quartz powder 5-10%. When preparing this coating material, add sodium carboxymethyl cellulose + 0.3-1.0%, water glass solution + 3-7%, water + 30-40%, stir the above mixture into a uniform slurry, smear or spray On the lining material of the furnace door, after drying, it can be obtained by firing at 1200°C to 1300°C for 4 to 12 hours. The invention provides a coke oven door refractory coating material with remarkable anti-carbonization effect and long-term durability and its preparation method. The coating material is close to the matrix material in composition and has similar thermal expansion performance, so it is not easy to use in use. Flaking can be pre-fired in advance or directly form a glaze during use, which reduces the labor intensity of workers and environmental pollution during carbon removal.

Owner:BAOSHAN IRON & STEEL CO LTD

Glaze coloured decoration daily use poocelain and its production method

The present invention relates to ceramic product, and is especially one kind of in-glaze color decorated daily use porcelain product and its production process. The materials for the in-glaze color decorated daily use porcelain include Longyan clay, weathered potash feldspar, Jiepai clay, potash feldspar, calcined alumina, Guizhou clay and quarztz. The production process of the in-glaze color decorated daily use porcelain product includes the steps of making biscuit, preparing glaze and in-glaze color paper, glazing the biscuit, firing biscuit, adhering the in-glaze color paper, and baking to obtain the product. The in-glaze color decorated daily use porcelain has rich bright colors, smooth and fine glaze surface, low Pb and Cd leaching out amount, high strength, and other advantages.

Owner:林伟河

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com