Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248results about How to "Reduce the amount of dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of catalytic wet oxidation catalyst and treatment method of organic wastewater

ActiveCN103041818AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationHigh concentrationOrganic acid

The invention discloses a preparation method of a catalytic wet oxidation catalyst and a treatment method of organic wastewater. The preparation method comprises the following steps of: (1) taking a porous inert material as a carrier, and performing pre-impregnation treatment on the carrier by adopting an organic acid solution; and (2) preparing an impregnating solution with a water-soluble compound containing transition metal elements and a water-soluble compound containing auxiliary elements, impregnating the carrier after treatment in the step (1) with the impregnating solution, drying in shade for 12-48 hours in air at appropriate humidity, then drying and roasting to obtain a final catalyst. When the catalyst prepared by the method disclosed by the invention is used for high-concentration organic wastewater, the characteristics of high activity, good stability and the like are realized, and the energy consumption and the investment can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

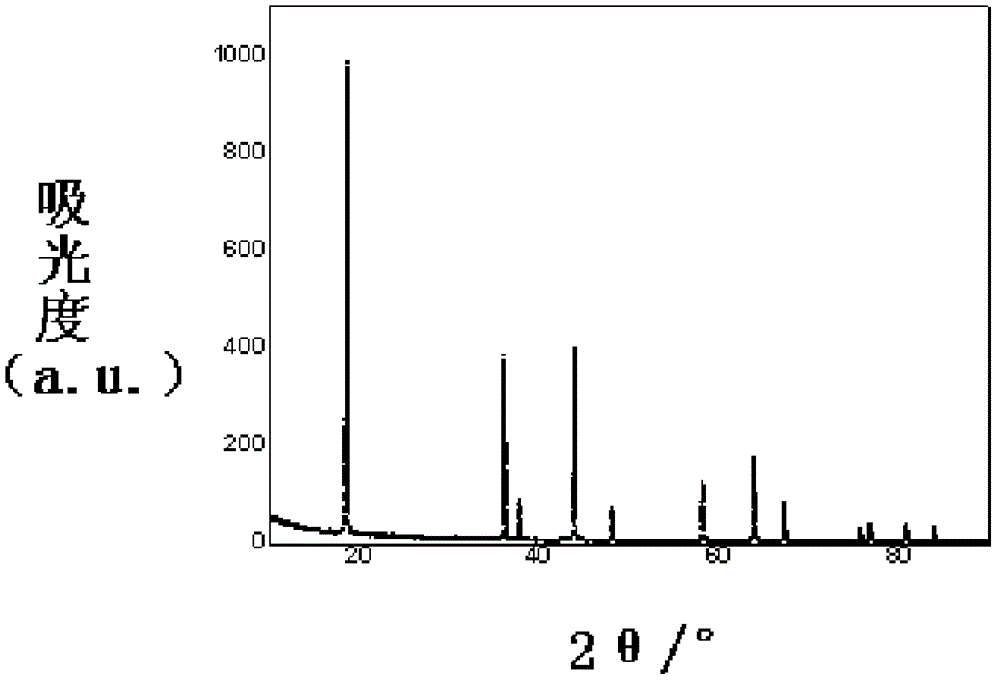

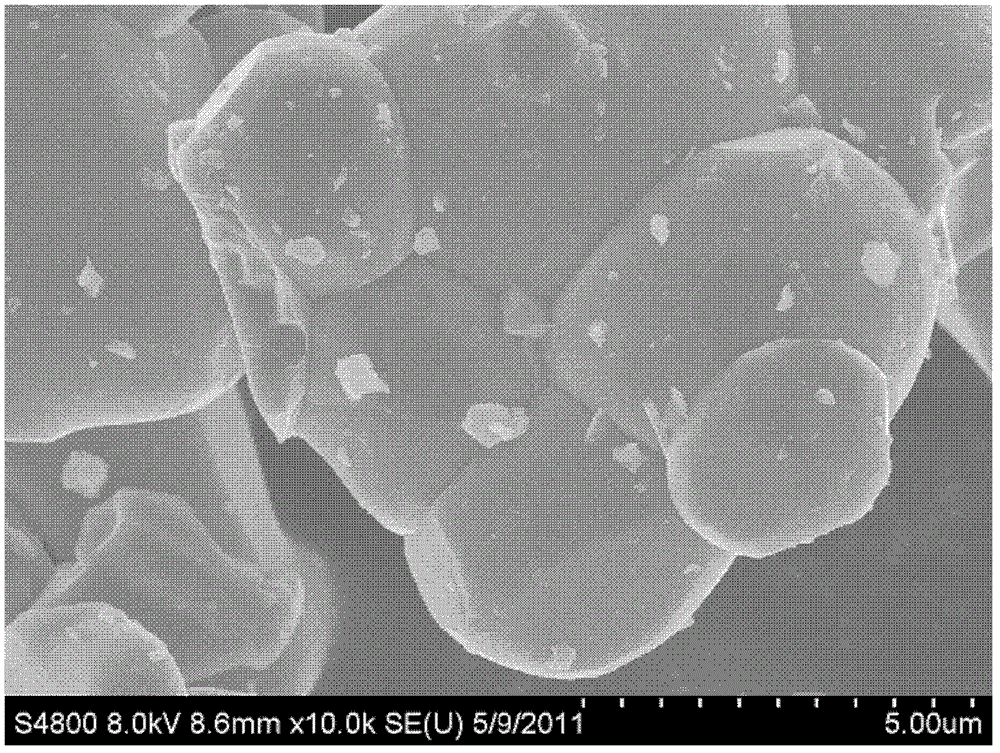

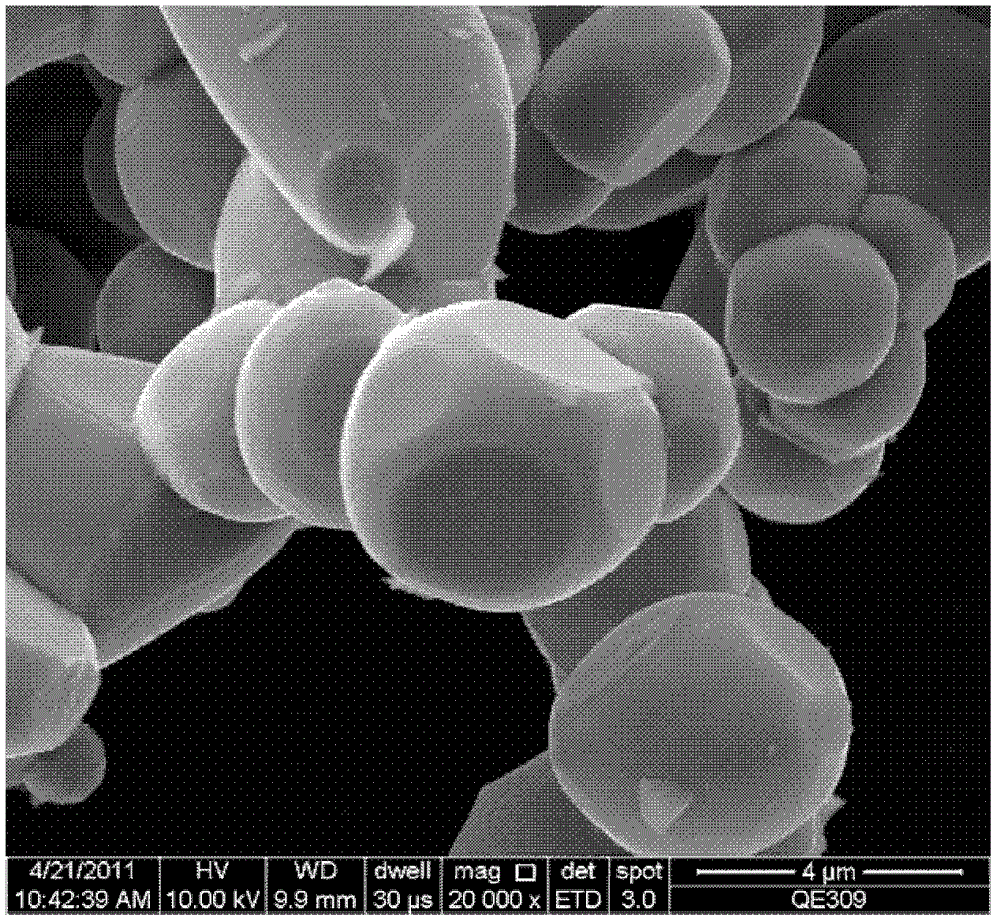

Cathode material of lithium ion battery, and preparation method thereof and lithium ion battery

ActiveCN102800840ANot easy to dissolveGood high temperature cycle performanceCell electrodesSecondary cellsTemperature cyclingLithium electrode

The invention provides a cathode material of a lithium ion battery. The cathode material is composed by the atomic ratio shown in formula (I): Lia(MxMn2-x)(O4-yZy), wherein a is greater than or equal to 0.8 and less than or equal to 1.2; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is one or more selected from Li, Na, K, Ca, Mg, Al, Ti, Sc, Ge, V, Cr, Zr, Co, Ni, Zn, Cu, La, Ce, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, Pb and Si; and Z is one or more selected from OH, halogens, N, P, S and O. Primary particles of the cathode material have sphere-like morphologies, wherein (111) face is connected with adjacent equivalent crystal face through a curved surface having no clear edges. The invention also provides a preparation method for the cathode material of the lithium ion battery and the lithium ion battery. The cathode material provided by the invention has good high-temperature cycling performance and good filling property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

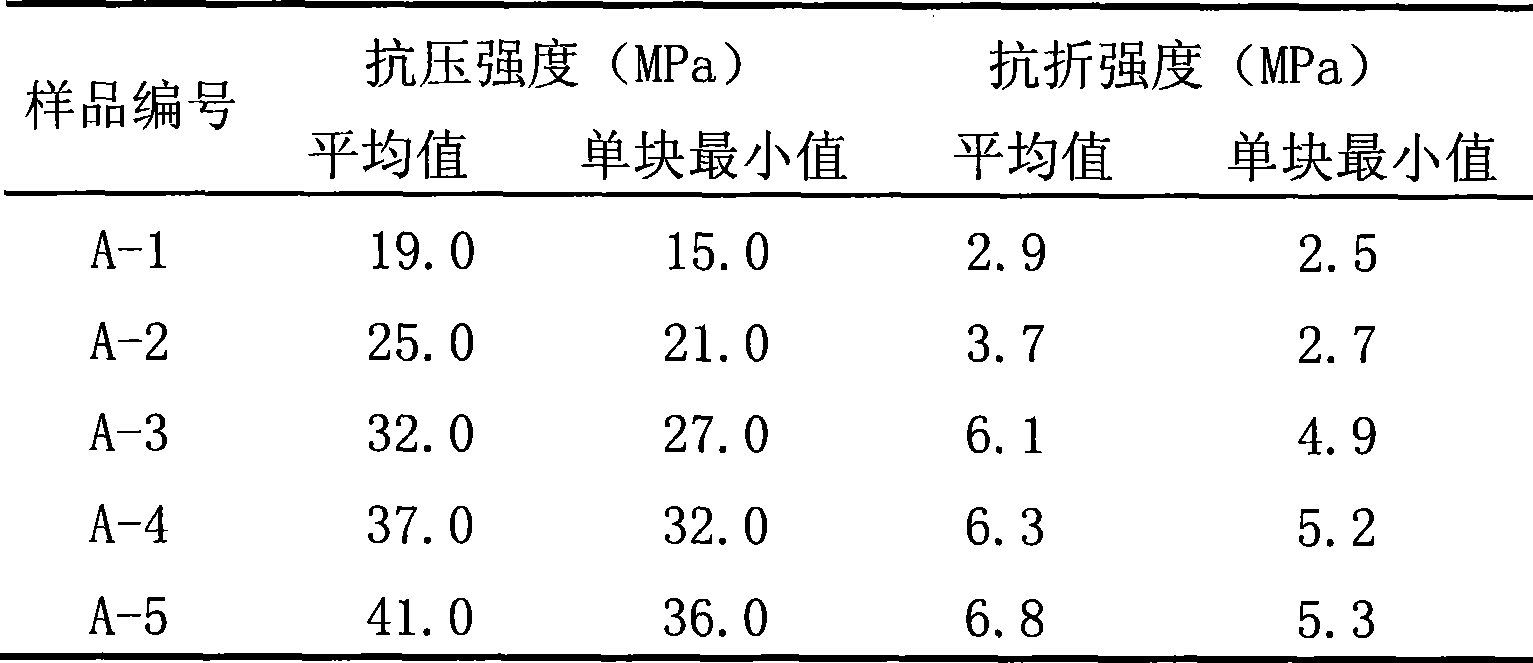

Building material based on interaction of alkali and CO2

ActiveCN101381217AWiden the range of process parametersReduce carbonization depth requirementsSolid waste managementSlagCarbonization

The invention discloses a building material product based on the synergic action between alkali and CO2 and a method for preparing the same, which belongs to the field of silicate building material and product thereof. In the building material product, the fly ash the fineness of which is controlled in the range of between 400 and 600m<2> / Kg and the slag form a mixed powder material, and an aggregate and water glass are added into the mixed powder material for forming so as to obtain a blank, and the blank is subjected to natural curing and carbonization to obtain the building material product. In the invention, the industrial waste slag is used as raw materials, the high-performance silicate product is prepared under the conditions of low alkali and not doping lime and cement clinker, so that the strength level is high, no scumming phenomenon occurs on the surface of the product, the release quantities of various toxic and harmful ions are far below the threshold value; moreover, the building material product has the advantages of good durability, strong freezeproof and weather resistance capabilities, and is suitable to be the building wall material. The invention has active effect on utilizing waste slag resources, saving energy and reducing emission.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Preparation method of active carbon loaded catalyst for electrochemically catalyzing and degrading organic wastewater

ActiveCN105457643AHighlight substantive featuresSignificant progressWater contaminantsWater/sewage treatmentActivated carbonWastewater

The invention relates to a preparation method of an active carbon loaded catalyst for electrochemically catalyzing and degrading organic wastewater and belongs to the technical field of preparation of catalysts. The preparation method comprises the following steps: preparing an active carbon solid containing a plurality of types of active metal by using a sol-gel method; adding P2O5 powder into the active carbon solid containing the active metal and roasting; sublimating the P2O5 powder into gas at a high temperature; and when the gas is expanded at the high temperature and escapes, generating a plurality of small pores in the active carbon, so that the specific surface area and adsorption capability of the active carbon are improved. According to the preparation method, rare earth metal is used in match with the other active metal so that grains on the surface of the catalyst are uniform and thinned; and meanwhile, the preparation method is combined with a method of adding the P2O5 powder to roast, so that the catalysis efficiency of the prepared active carbon loaded catalyst can be improved by more than 5%-15%. The method has a simple process, is convenient to operate and is low in cost; and in a process of electrochemically catalyzing and degrading the organic wastewater by using the prepared catalyst, other oxidants do not need to be additionally added and the large-scale industrialized application of the preparation method is facilitated.

Owner:武汉森宁开源科技有限公司

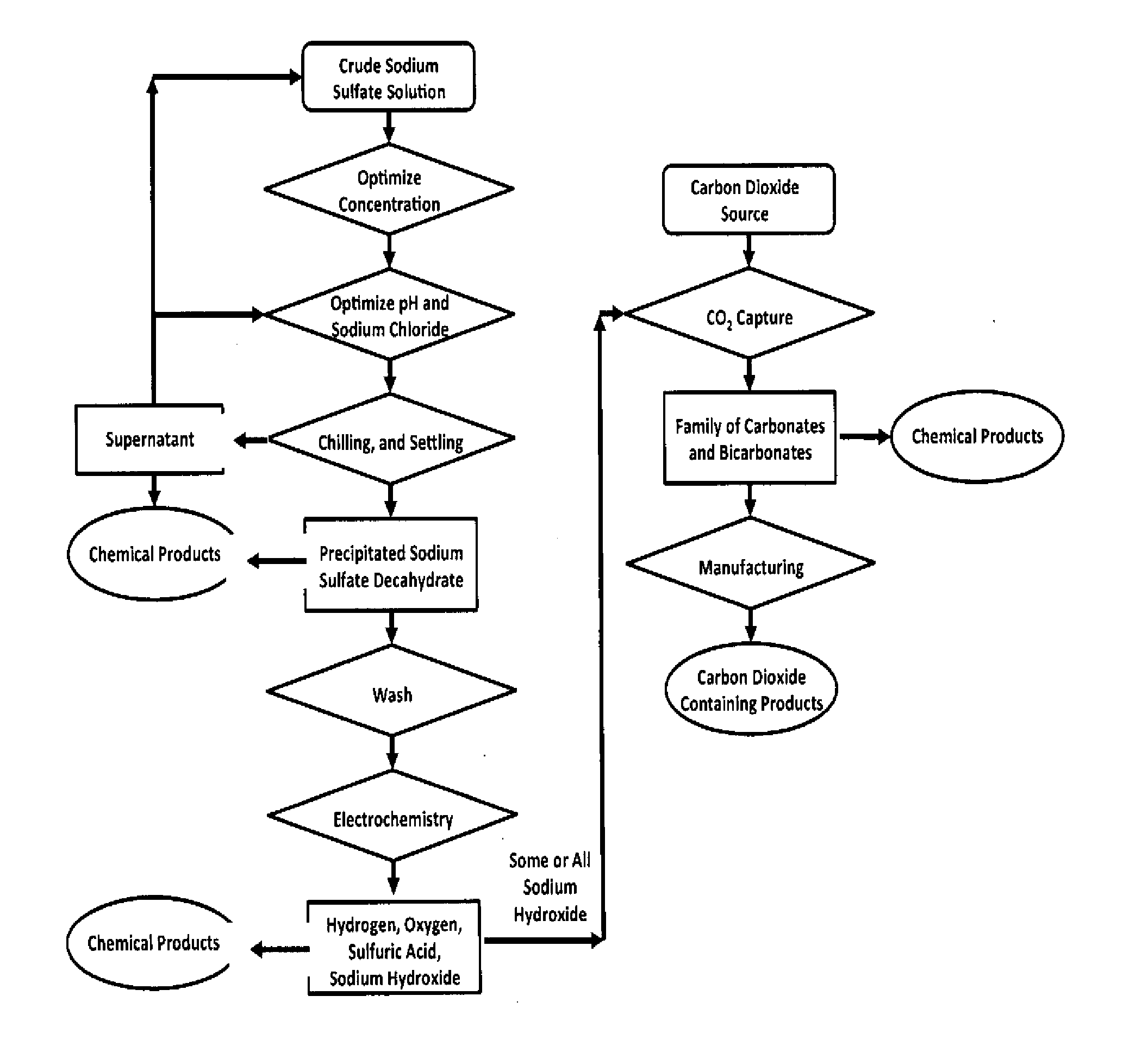

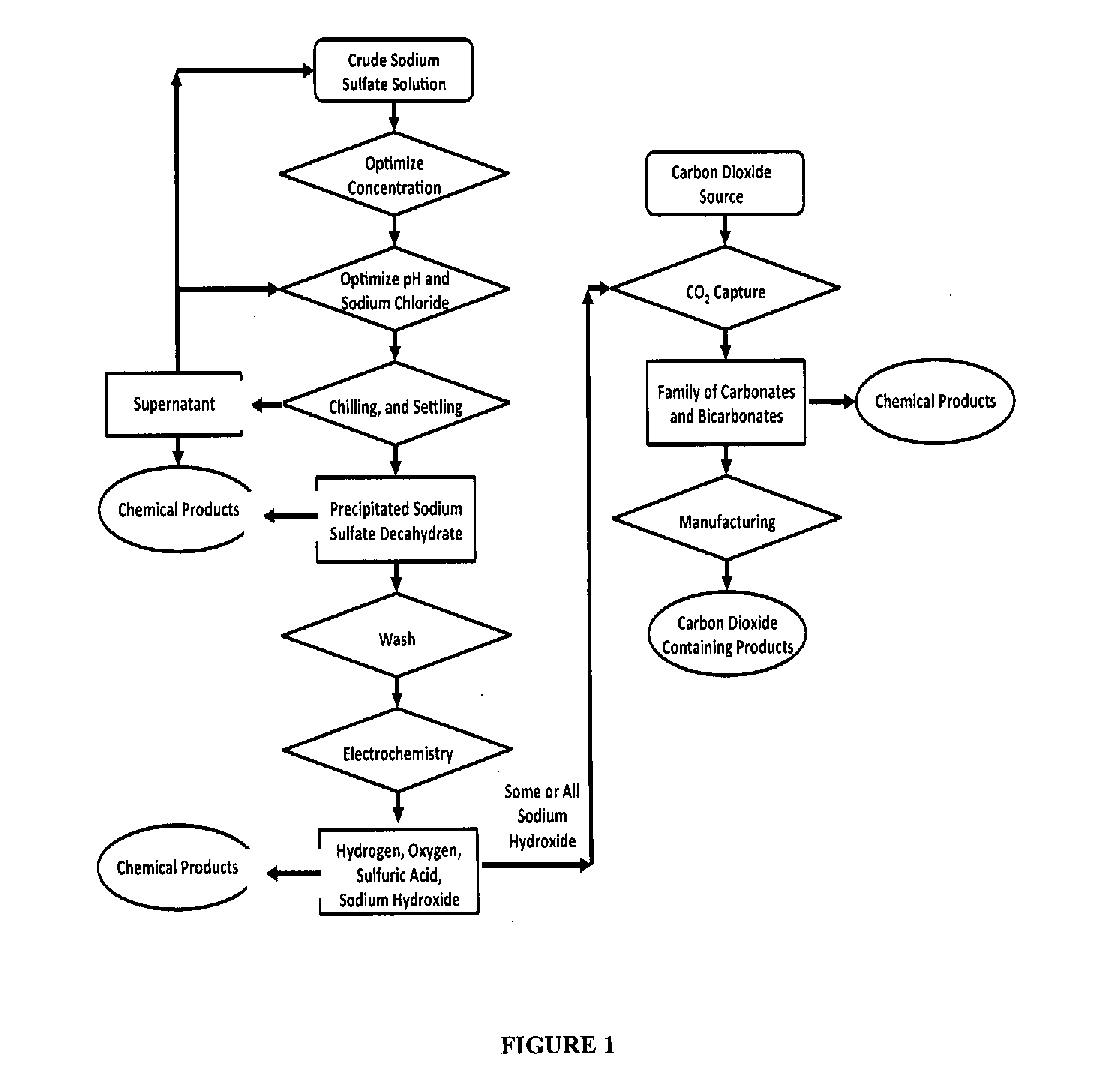

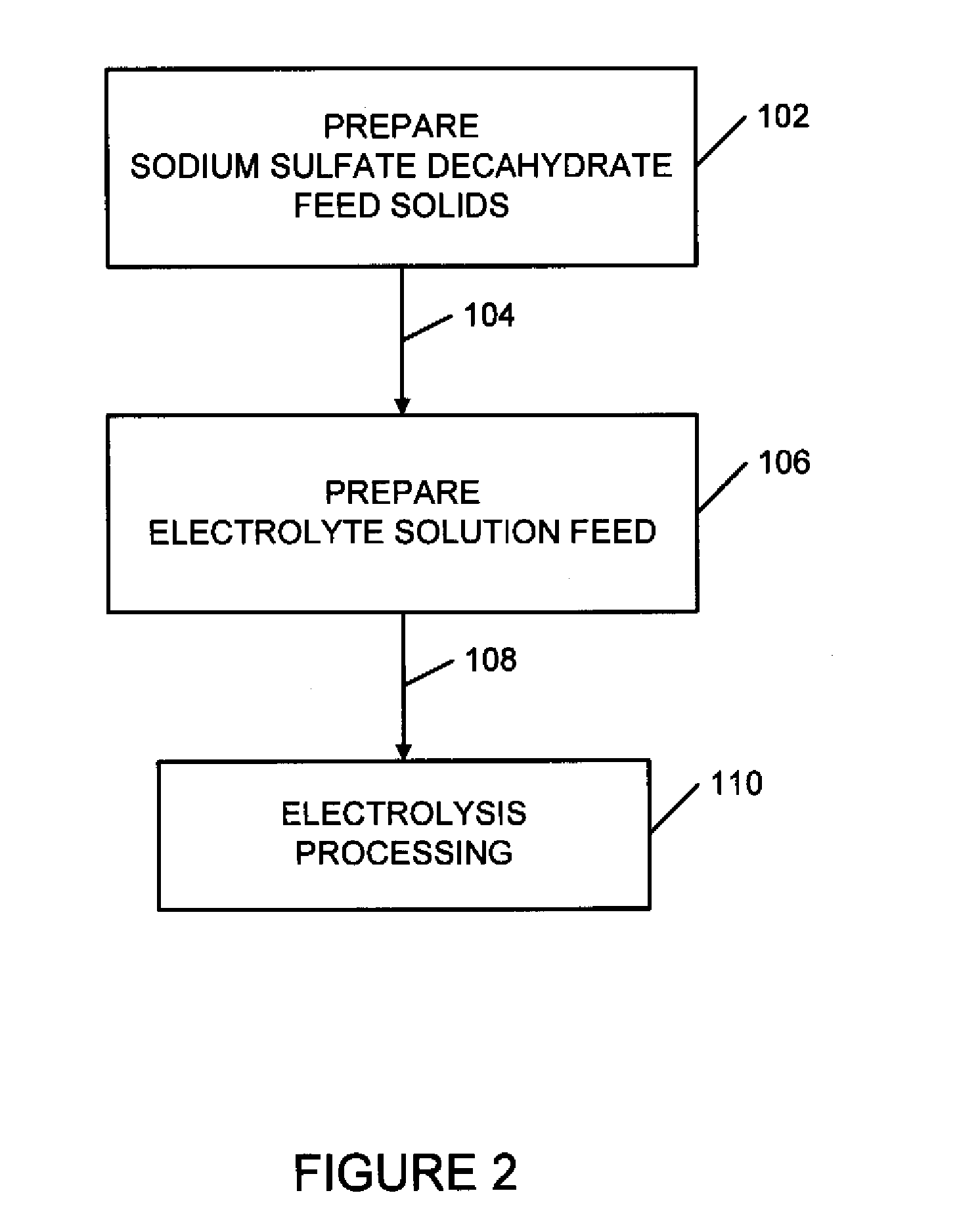

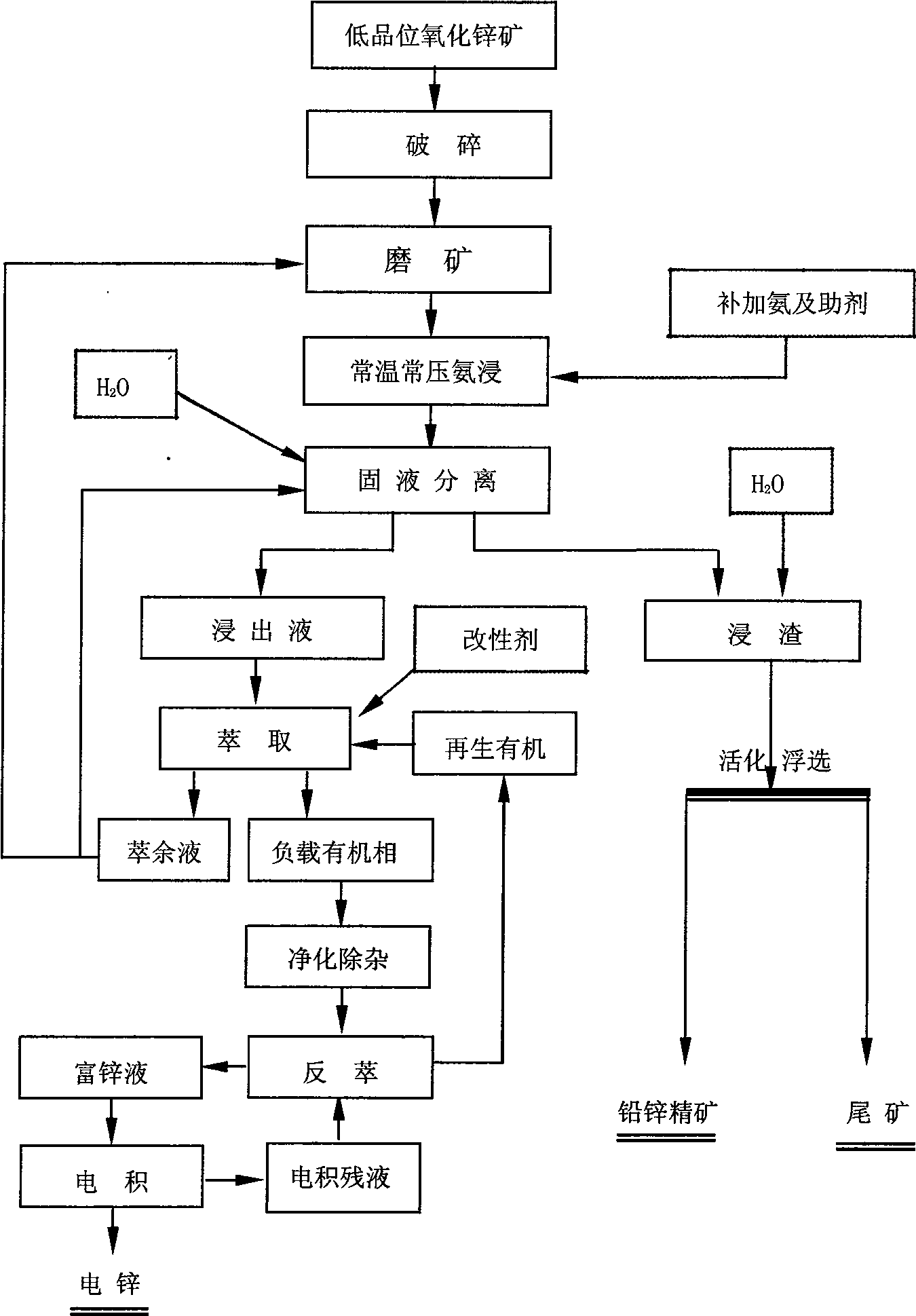

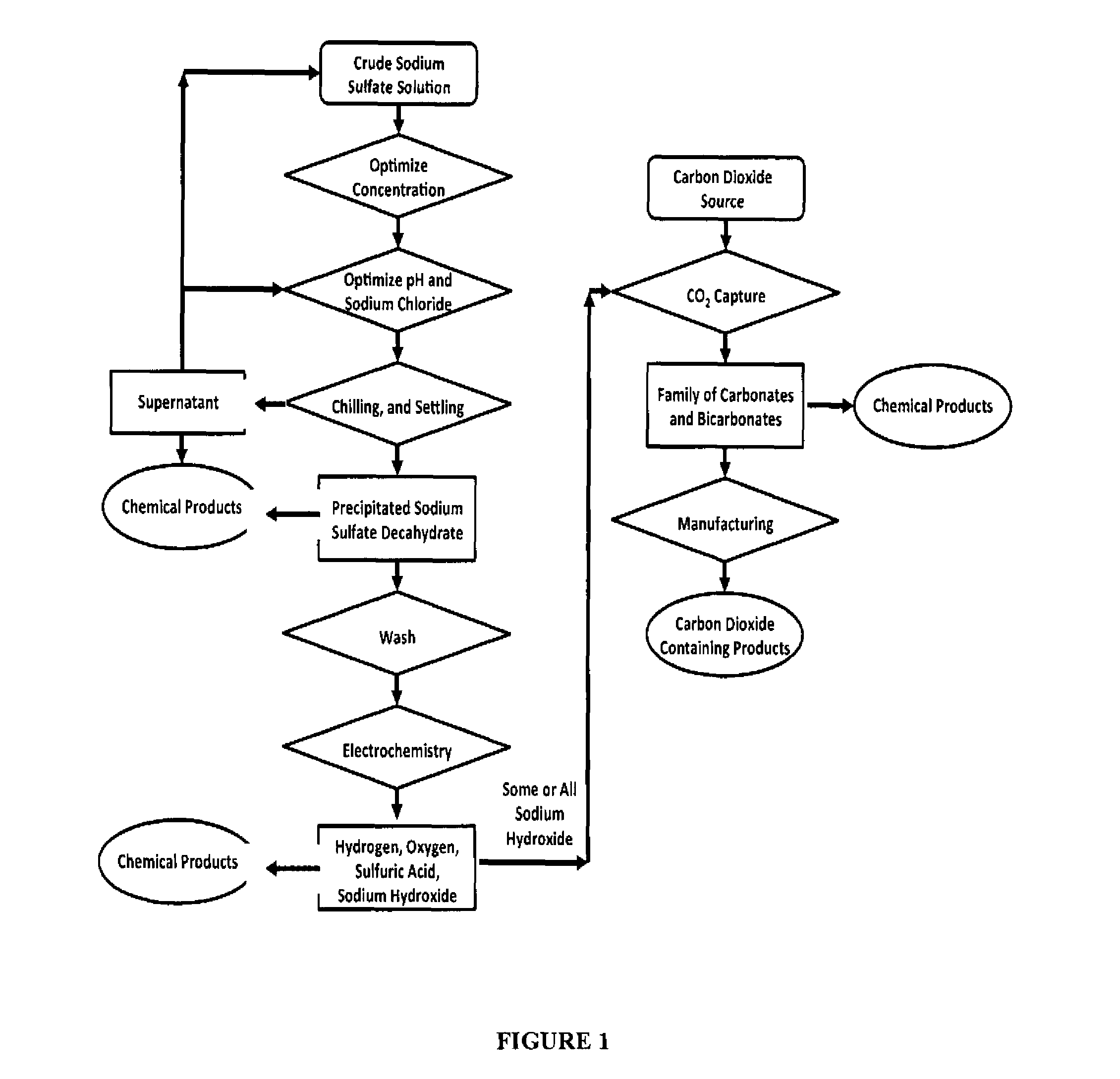

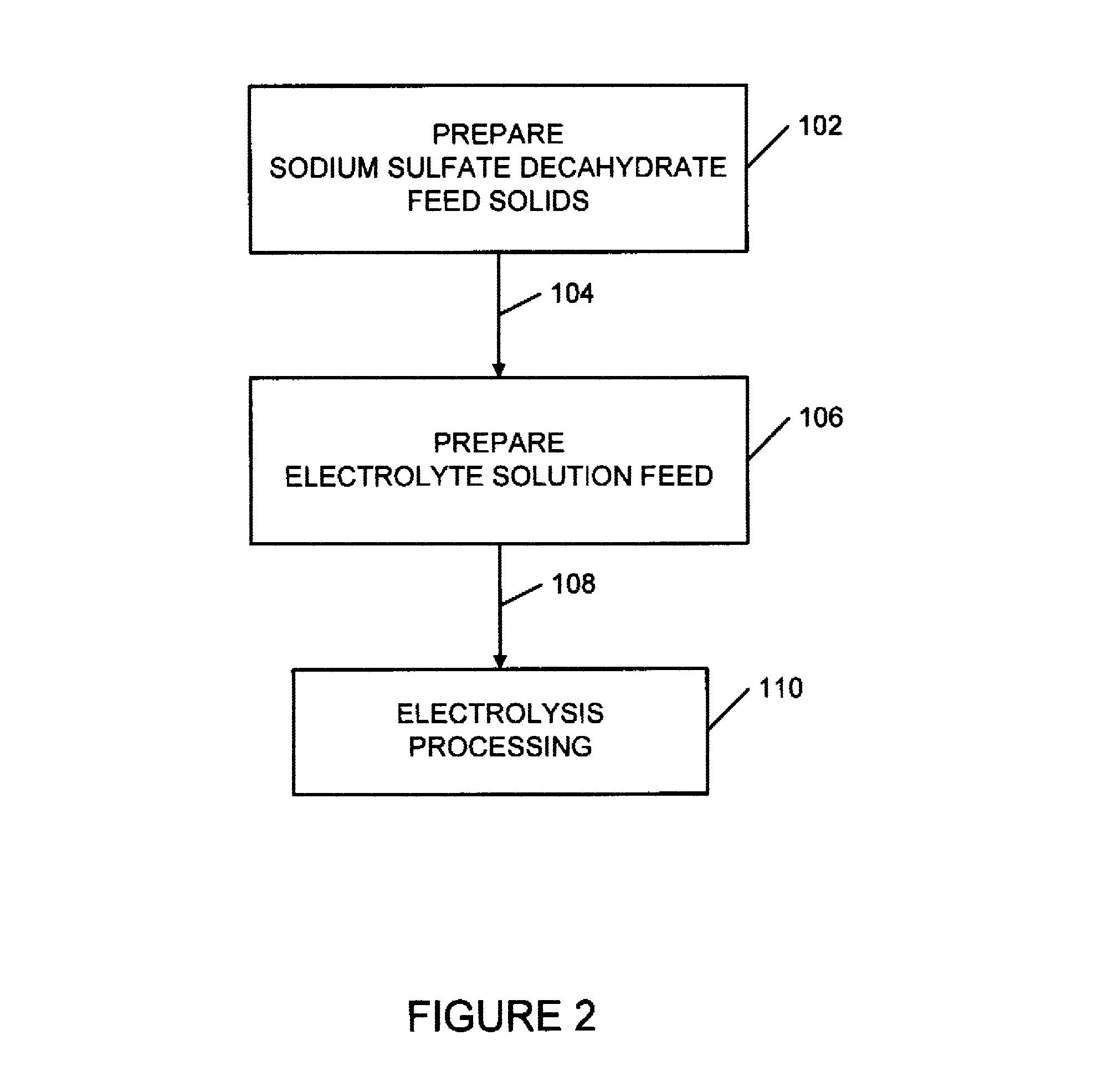

Sulfate-based electrolysis processing with flexible feed control, and use to capture carbon dioxide

ActiveUS20140010743A1Lower the temperature of the solutionProcess economyCalcium/strontium/barium carbonatesElectrolysis componentsElectrolysisSulfate

A method including electrolysis processing using sulfate-based electrolytes includes precipitating sodium sulfate decahydrate from a salt solution and then redissolving sodium sulfate decahydrate to prepare feed of electrolyte solution for the electrolysis processing. Front-end processing may be used to treat mixed salt solutions, including brine solutions. Calcium sulfate reagent may provide a sulfate source to regenerate electrolyte solution following carbon capture, and with carbon dioxide being sequestered in the form of calcium carbonate.

Owner:NEW SKY ENERGY INC

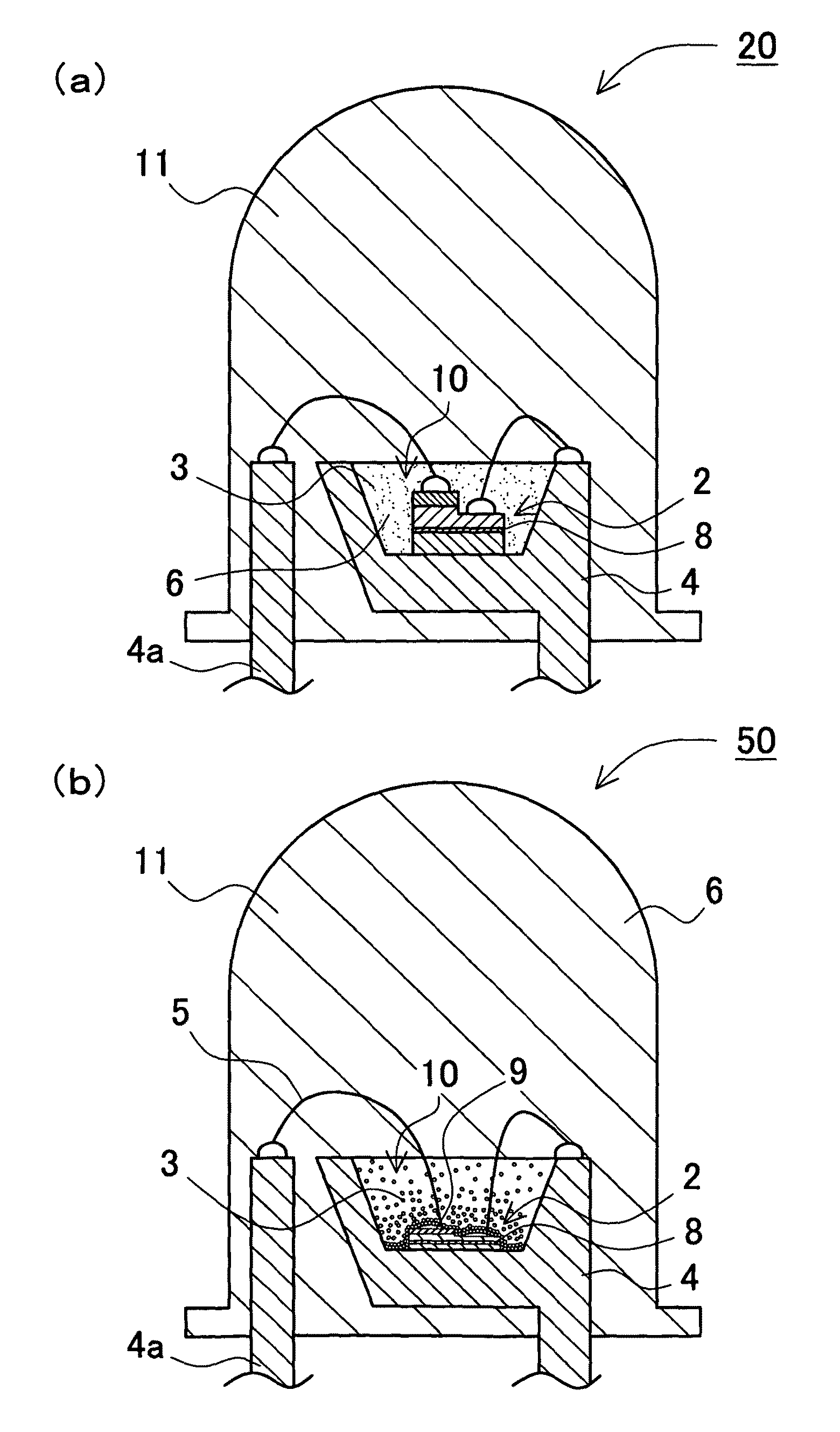

Phosphor activated with europium, light emitting device using the same and method of manufacturing the phosphor

ActiveUS8030839B2Improve life characteristicsIncrease brightnessDischarge tube luminescnet screensElectric discharge tubesGreen-lightLight emitting device

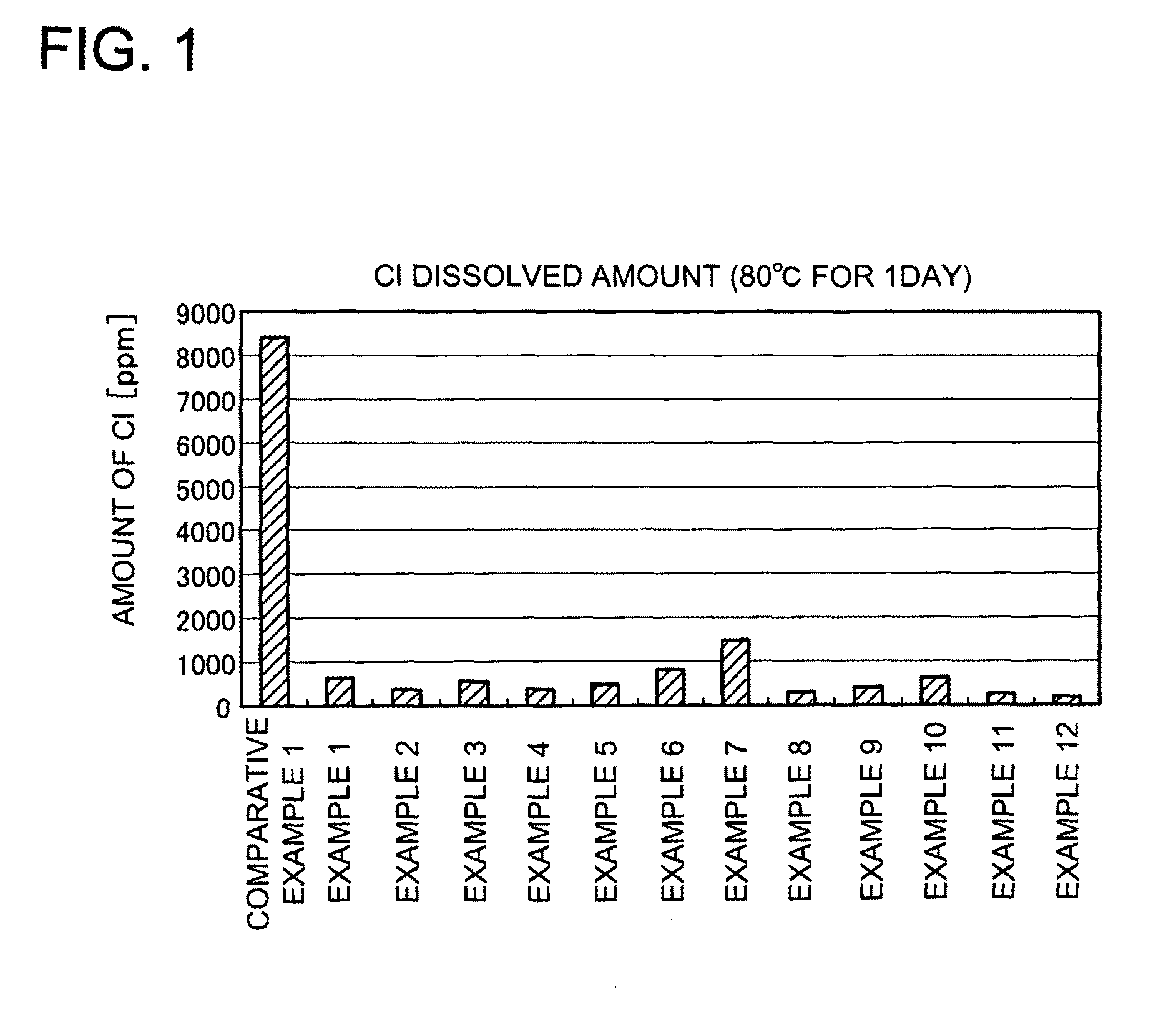

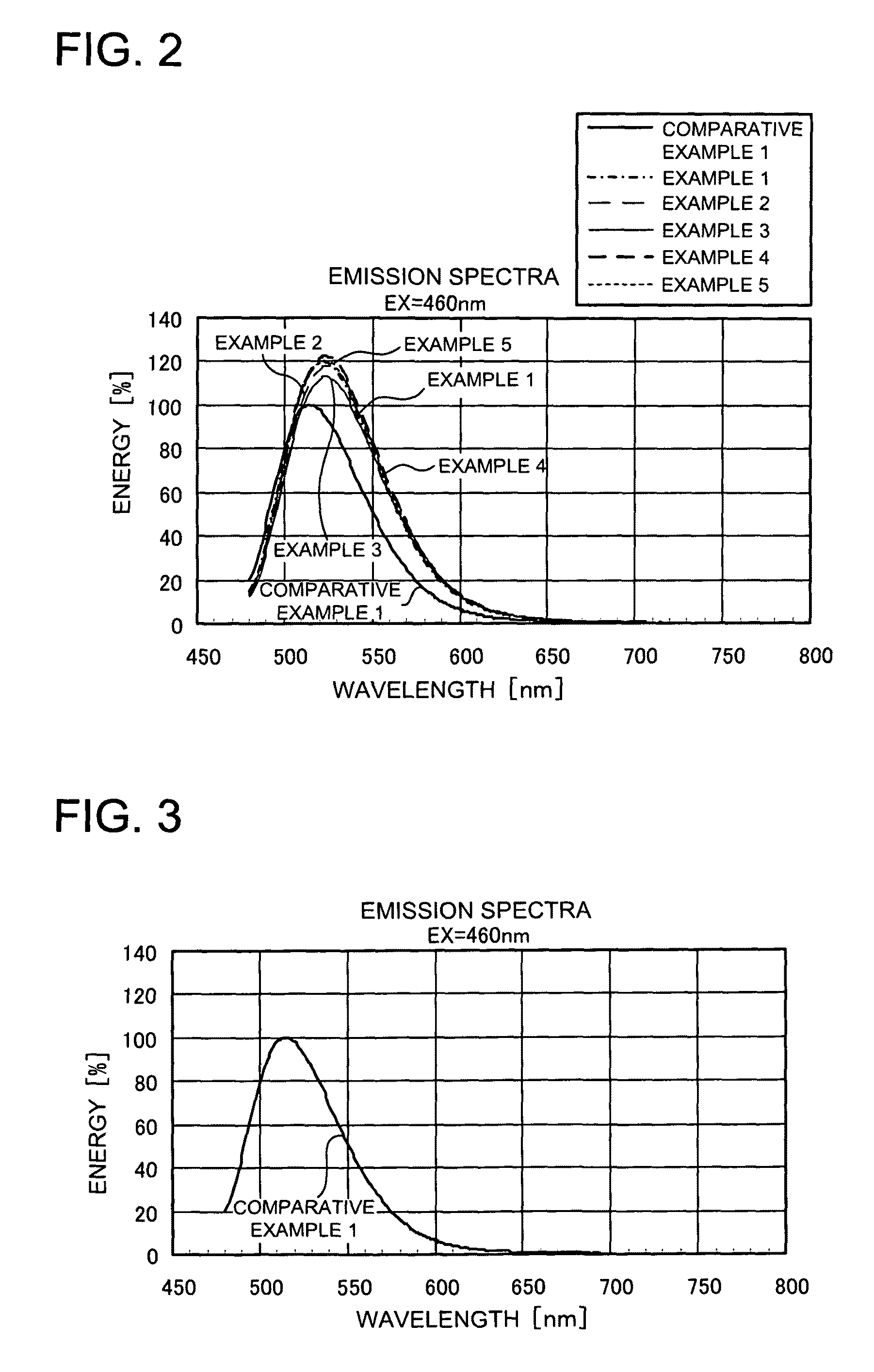

Provided are a phosphor which is capable of emitting green light of high luminance and in which unfavorable effects on other members has been reduced so as to be applicable to white light having excellent light emitting characteristics, a light emitting device using the phosphor, and a method for manufacturing the phosphor. The phosphor containing silicon, magnesium, and chlorine, and activated with europium and capable of emitting green light, in which the molar ratio of chlorine to magnesium is in a range of 1.0≦Cl / Mg≦1.9. Introduction of chlorine at such a composition ratio improves the light emitting characteristics and the amount of chlorine dissolved.

Owner:NICHIA CORP

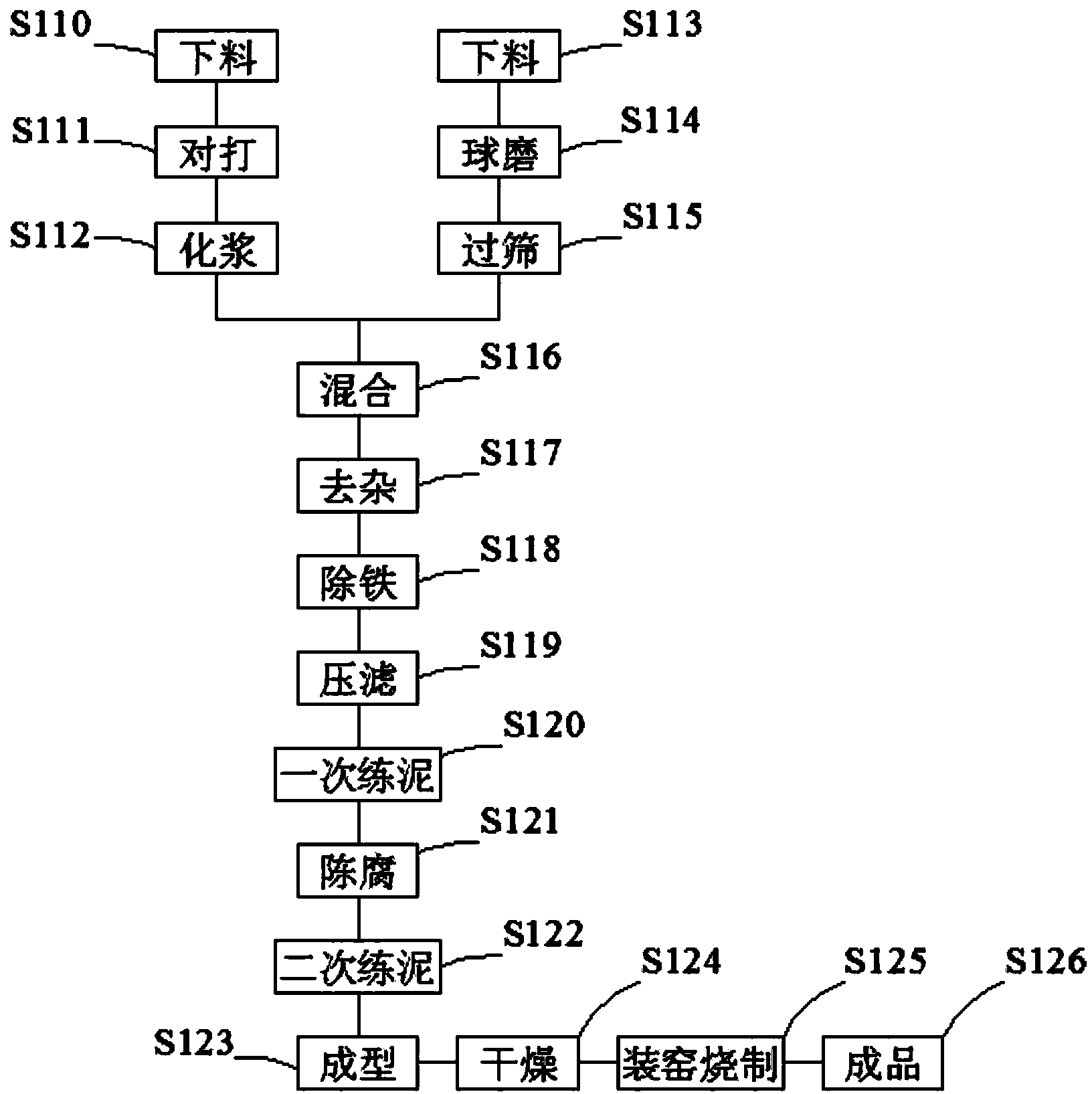

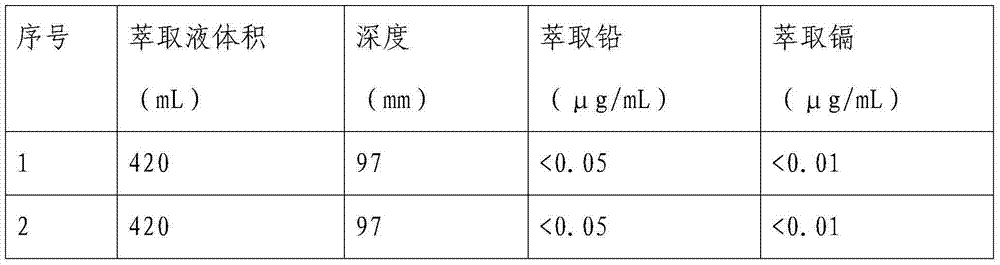

Self-forming glaze white jade porcelain pug and manufacturing method of porcelain pug product

The invention relates to self-forming glaze white jade porcelain pug and a manufacturing method of a porcelain pug product. The self-forming glaze white jade porcelain pug comprises the followings in percentage by weight: 13 to 21 percent of kaoline, 14 to 20 percent of feldspar, 2 to 7 percent of bentonite, 38 to 47 percent of quartz, 11 to 16 percent of wollostonite and 7 to 11 percent of calcite power. The manufacturing method provided by the invention comprises the steps of sparring, slurrying and the like. The method has the benefits as follows: traditional two-step firing is changed to be one-step firing, energy consumption is lowered, carbon discharge capacity is reduced, processes of glaze making and glazing are removed, the discharge capacity of three wastes is reduced, human resources are saved, the dissolving-out amount of heavy metals such as lead and cadmium and the like carried into glaze is reduced, the porcelain pug is glittering and translucent, like jade, and the section of the porcelain pug has no arrises and is shell-shaped. The porcelain pug product prepared by the invention is green, environmental-friendly and safe, can be used as dishware porcelain, daily porcelain, art porcelain, decorative porcelain, porcelain for lighting tools and the like in the ceramic industry.

Owner:何晓洪 +1

Soft PVC plastic in use for apparatus transfusions

A soft polyvinyl chloride plastics for blood transfusion device, such as blood bag, is proportionally prepared from PVC resin, phthalate, trimellitate, citrate, epoxy soybean oil, composite Ca-P stabilizer and silicon oil. Its advantages are no erythrocatalysis, high stability of trimellitate, and low toxin.

Owner:威海威高创新有限公司

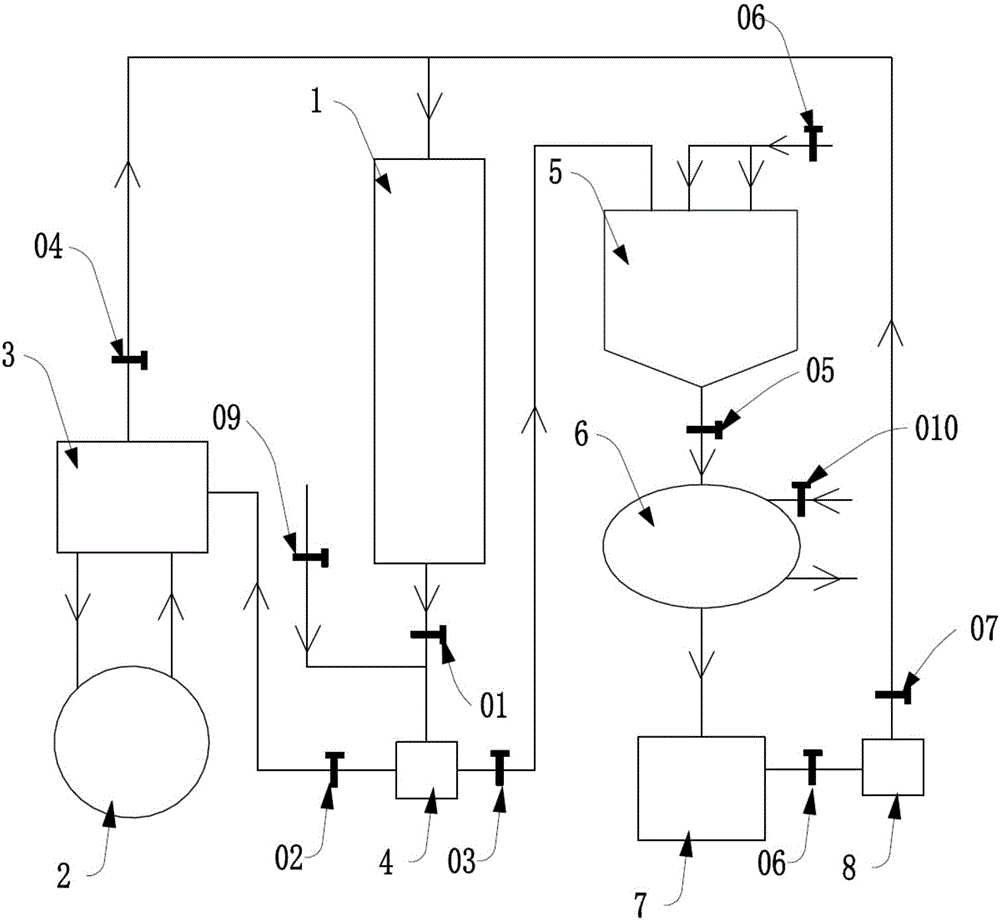

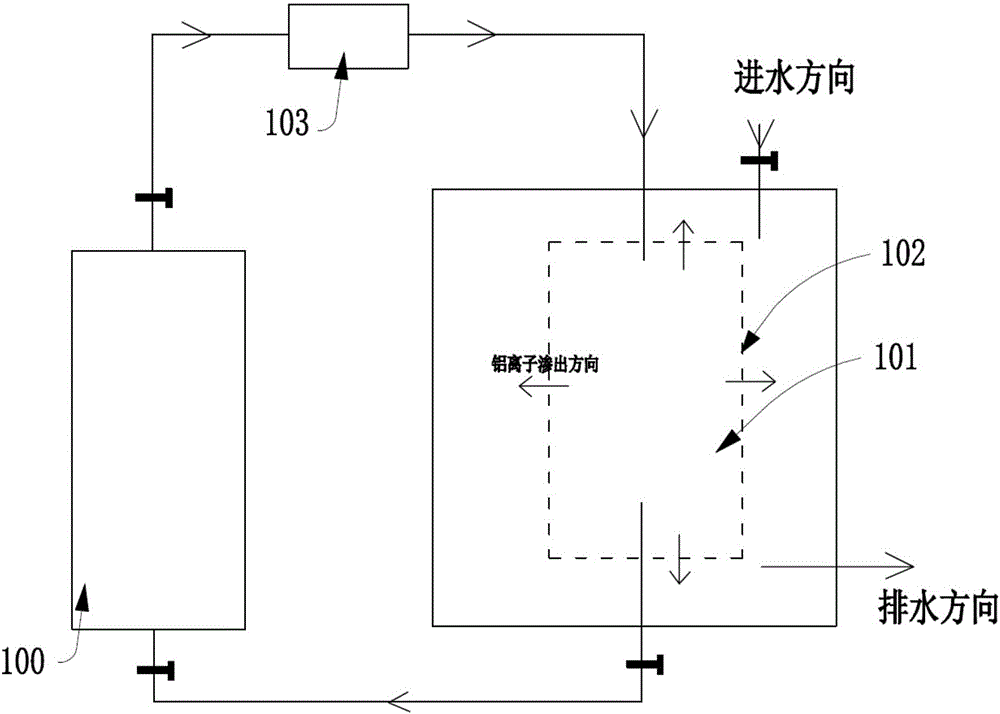

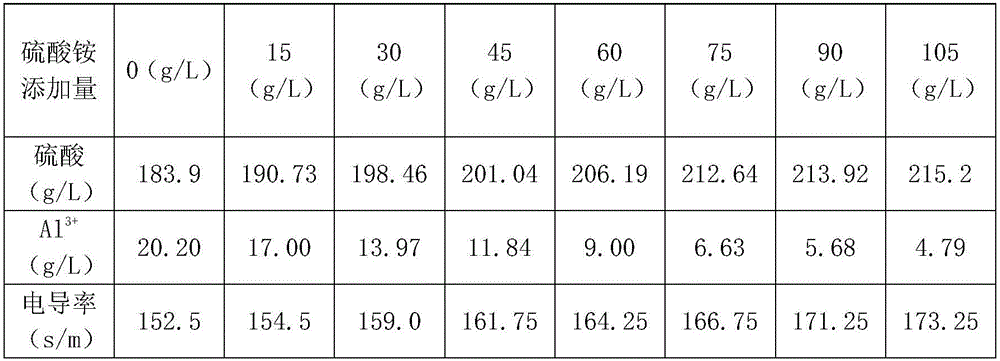

Energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition

ActiveCN106757258ALower resistanceReduce the amount of dissolutionCellsAnodisationAmmonium sulfateAluminium salts

The invention discloses an energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition. The process comprises an oxidization liquid cyclic cooling step, an aluminum ion crystal product recycling step, a sulfuric acid oxidization liquid recycling step, a gas stirring step and a defrosting step; the aluminum ion crystal product recycling step includes that oxidization liquid is guided into a reaction tank, ammonium aluminum sulfate crystals are precipitated out after ammonium sulfate is added into the reaction tank, and then materials in the reaction tank are guided into a centrifugal machine to be centrifuged so that solid and liquid after solid-liquid separation can be acquired; and the sulfuric acid oxidization liquid recycling step includes that oxidization liquid after crystallization treatment is collected, and is conveyed to an anodic oxidization tank to be cyclically used after being subjected to regeneration treatment. The energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition are provided, by extracting aluminum in the oxidization liquid, sulfuric acid is recycled, the resistance of the oxidization liquid is reduced, a corrosion inhibition agent is added in the oxidization liquid, oxidization energy conservation is achieved by reducing the dissolving amount of an oxidization film, and more than 20% of energy is saved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

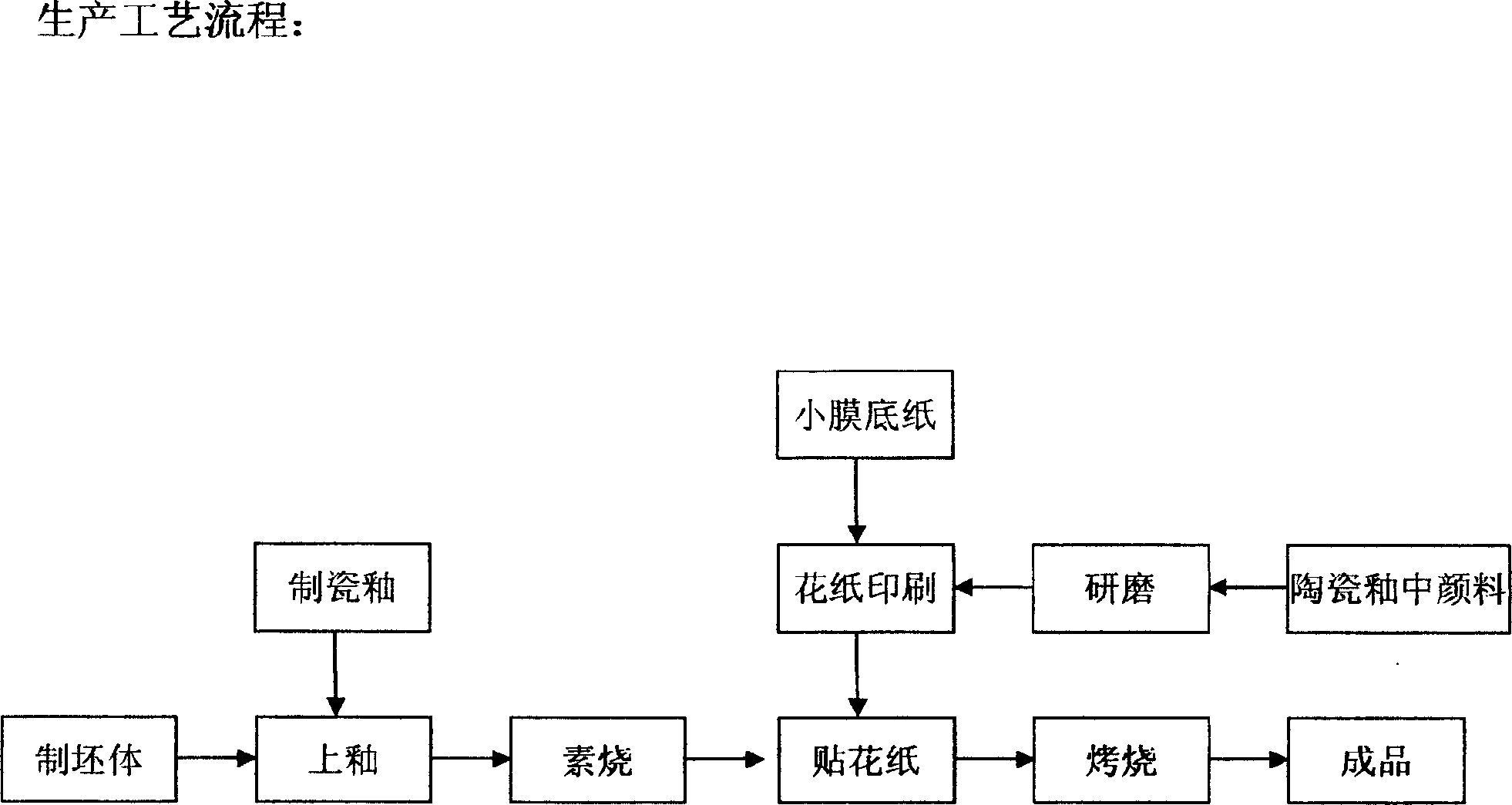

Glaze coloured decoration daily use poocelain and its production method

InactiveCN1911855AMeet technical requirementsMeet the process requirementsHigh volume manufacturingThermal stability

The present invention relates to ceramic product, and is especially one kind of in-glaze color decorated daily use porcelain product and its production process. The materials for the in-glaze color decorated daily use porcelain include Longyan clay, weathered potash feldspar, Jiepai clay, potash feldspar, calcined alumina, Guizhou clay and quarztz. The production process of the in-glaze color decorated daily use porcelain product includes the steps of making biscuit, preparing glaze and in-glaze color paper, glazing the biscuit, firing biscuit, adhering the in-glaze color paper, and baking to obtain the product. The in-glaze color decorated daily use porcelain has rich bright colors, smooth and fine glaze surface, low Pb and Cd leaching out amount, high strength, and other advantages.

Owner:林伟河

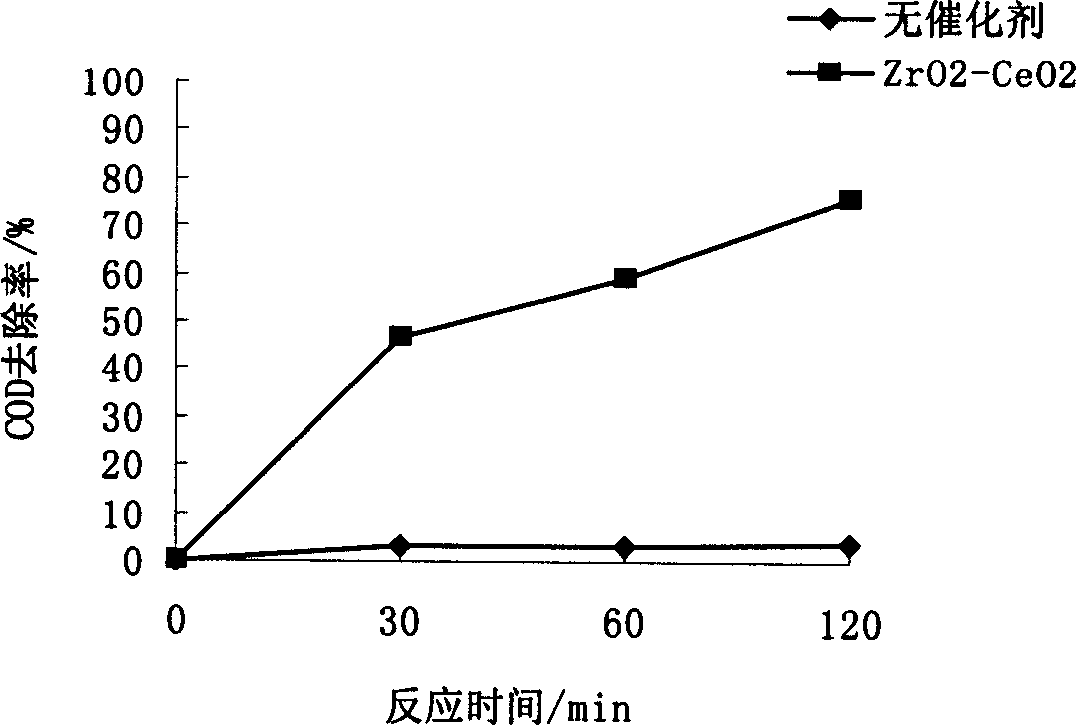

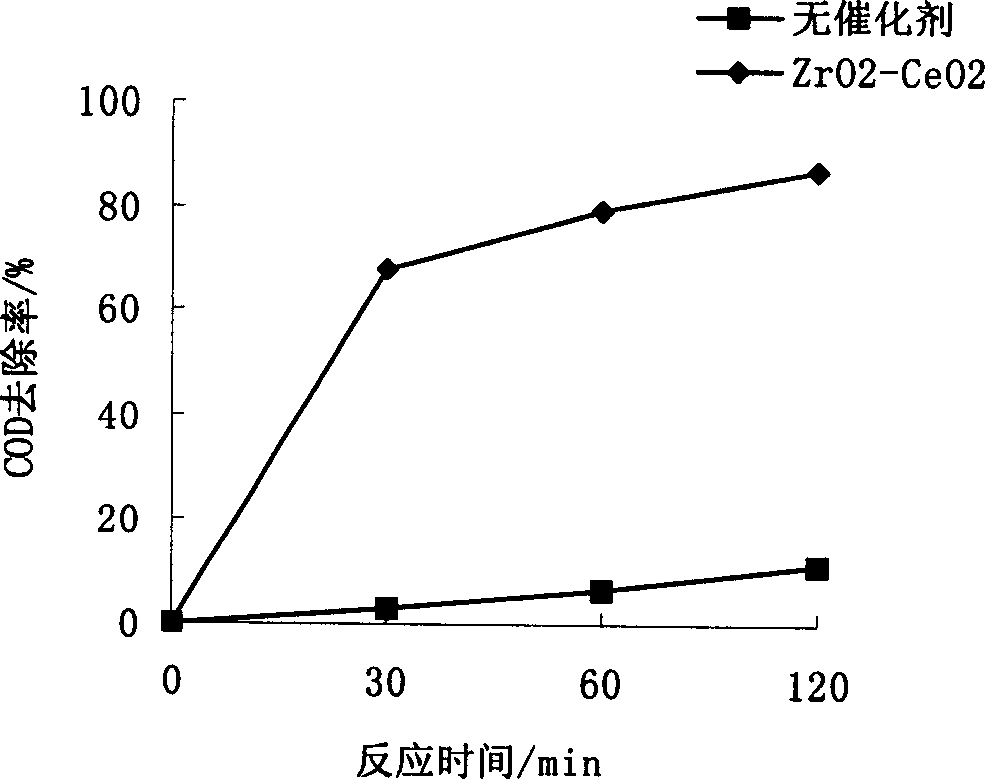

Rare earth composite oxide catalyst in catalytic wet oxidation process and preparing method thereof

InactiveCN1669643ALower operating temperatureReduce pressureMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationAlkalinityOrganic acid

The invention discloses a method for preparing the rare-earth compound oxide catalyst, wherein the component is the composite oxides of ZrO2 and CeO2, and the molar ratio of the Zr and Ce is 1:1~1:11. The preparing method comprises the following steps: a) formulating the mixed solution of zircon salt and cerium salt, b) dropping the solution slowly to the alkaline solution which has been stirred vigorously, getting the gelatin deposit and filtering, c) dispersing the deposit again into the deionized water, adjusting the PH to alkalinity, refluxing in the hot alkali liquor, drying and baking and getting the catalyst.

Owner:TSINGHUA UNIV

Light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition and preparation method thereof

The invention relates to a light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition, which is composed of a metal substrate, an interlayer and a composite electro-catalysis superficial layer in sequence from inside to outside, wherein the metal substrate is Al or Al base alloy (Al-M1), the interlayer is a composite layer Al2O3-(Pb-M2) composed of Al2O3 or Pb base alloy, and the composite electro-catalysis superficial layer is a composite deposite (Pb-M2)-M3Ox composed of Pb or Pb base alloy and oxide catalyst or a composite deposite PbO2-M3Ox composed of PbO2 and oxide catalyst. The preparation method of the anode comprises the following steps: preparation of the metal substrate: carrying out anodic oxidation on the metal substrate surface and prefabricating a multihole Al2O3 layer; then performing an electro-deposition Pb or Pb base alloy layer on the multihole Al2O3 layer; and plating a (Pb-M2)-M3Ox or PbO2-M3Ox composite superficial layer on the surface of the Pb or Pb base alloy layer. The anode prepared by the invention can effectively reduce production energy consumption, improve cathode product quality, lower labor intensity, is suitable for industrialized production and can replace the Pb base alloy anode applied in the existing industry.

Owner:KUNMING HENDERA SCI & TECH

Preparation process of fish scale collagen protein

ActiveCN103540635ASmall molecular weightTake advantage ofPeptide preparation methodsFermentationWaste materialImpurity

The invention provides a preparation process of a fish scale collagen protein. With the preparation process, the collagen protein can be extracted from fish scales, so that the fish scales are changed into things of value from waste material and thorough utilization of resources is realized. The preparation process comprises the following steps of pretreating, decalcifying, neutralizing and removing impurity, washing by using water, sol, solid-liquid separating and filtering, hydrolyzing, filtering and separating the collagen protein, filtering and separating the macromolecular protein, desalting, dehydrating, drying and the like to obtain collagen protein powder. The collagen protein powder prepared by the preparation process has the molecular weight of less than 5000 Daltons and can be absorbed by the human body easily.

Owner:SHISHI HAIXING FOOD +1

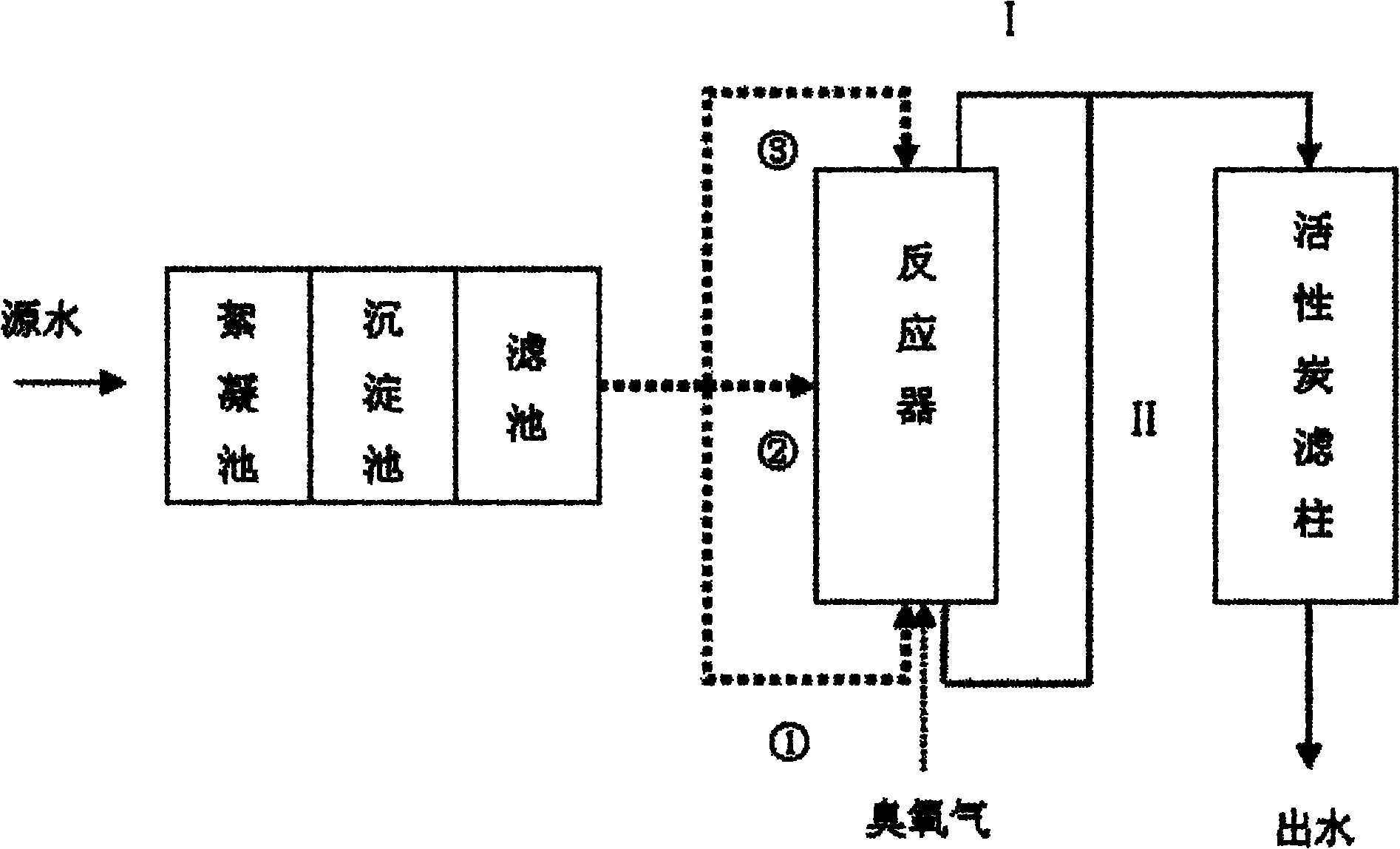

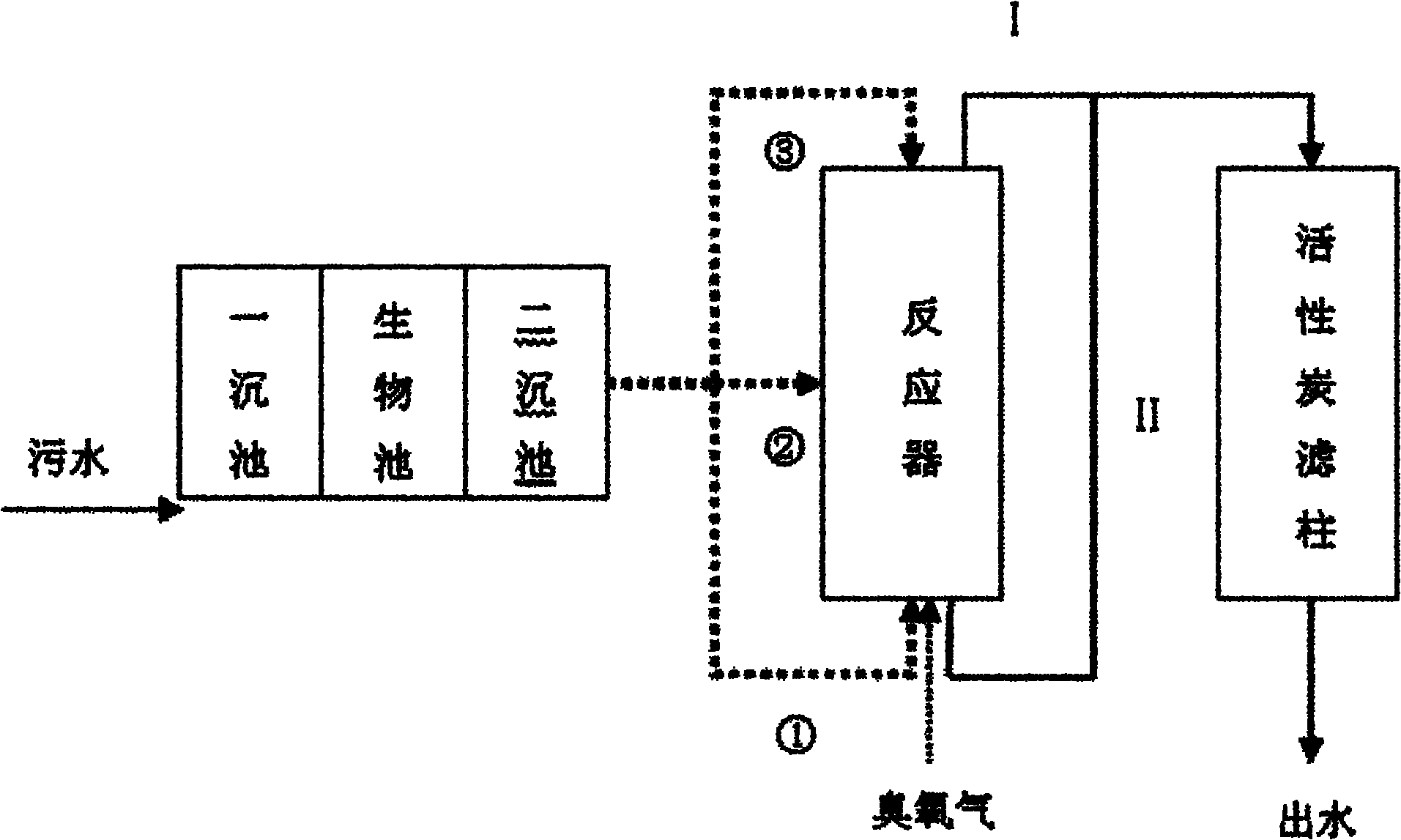

Method for preparing catalyst and water treatment method for catalyzing ozone oxidization by utilizing catalyst

InactiveCN101954297ALess investmentReduce volumeWater contaminantsCatalyst activation/preparationSludgeMuffle furnace

The invention discloses a method for preparing a catalyst and a water treatment method for catalyzing ozone oxidization by utilizing the catalyst and relates to a method for preparing a catalyst and a water treatment method. The invention solves the problem that sludge left after sewage treatment occupies vast land and causes pollution to the environment. The method for preparing the catalyst comprises the following steps of: after drying, pulverizing and screening the sludge, charging the sludge into a zinc chloride aqueous solution; standing and removing supernatant liquor; and after insulating heat of particle sludge in a muffle furnace, rinsing respectively with hydrochloric acid and deionized water and drying to obtain the catalyst. The water treatment method comprises the following step of charging water treated by a flocculating pond, a settling pond and a filter pond or sewage treated by a settling pond I, a biological pond and a settling pond II into a reactor in which ozone and the catalyst are added, for treating. The invention provides the ozonization catalyzing catalyst with the characteristics of low cost, efficient catalysis, less dissolving amount and large specific surface area while the sludge problem is solved. The catalyst of the invention can improve the removal efficiency of ozone on organic pollutants in water.

Owner:HARBIN INST OF TECH

Preparation method of modified alumina carrier, catalytic ozone oxidation catalyst, and application of catalyst

ActiveCN106732509ANot easy to loseEasy to drainCatalyst carriersHeterogenous catalyst chemical elementsFree coolingRoom temperature

The invention relates to the technical field of water treatment, and especially relates to a preparation method of a modified alumina carrier, a catalytic ozone oxidation catalyst, and an application of the catalyst. The preparation method of the modified alumina carrier comprises the following steps: providing an alumina substrate; carrying out primary modifier spray immersion, primary drying and primary calcination on the alumina substrate, and naturally cooling the obtained calcined alumina substrate to room temperature; and carrying out secondary modifier spray immersion, secondary drying and secondary calcination on the alumina substrate, and naturally cooling the secondary calcined alumina substrate to obtain the modified alumina carrier. The catalytic ozone oxidation catalyst prepared from the modified alumina carrier greatly improves the COD removal rate, so the sewage treatment cost is reduced; the dissolution rate of metal ions is greatly reduced, so the service life of the catalyst is prolonged; and the catalyst has the advantages of low cost and simple preparation method, and is very suitable for industrial production.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

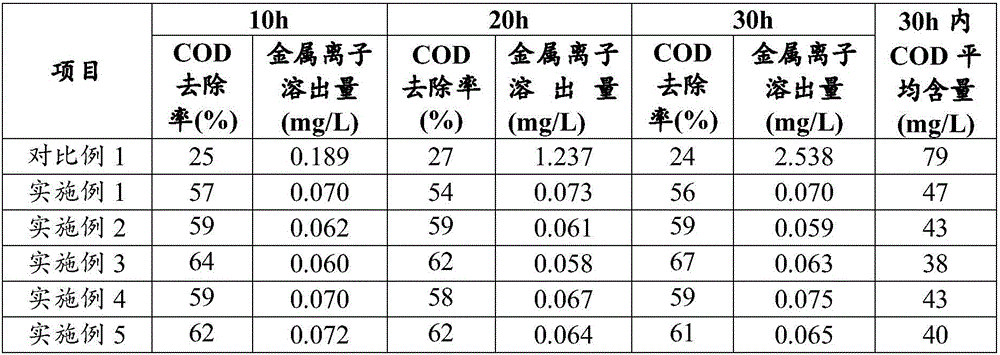

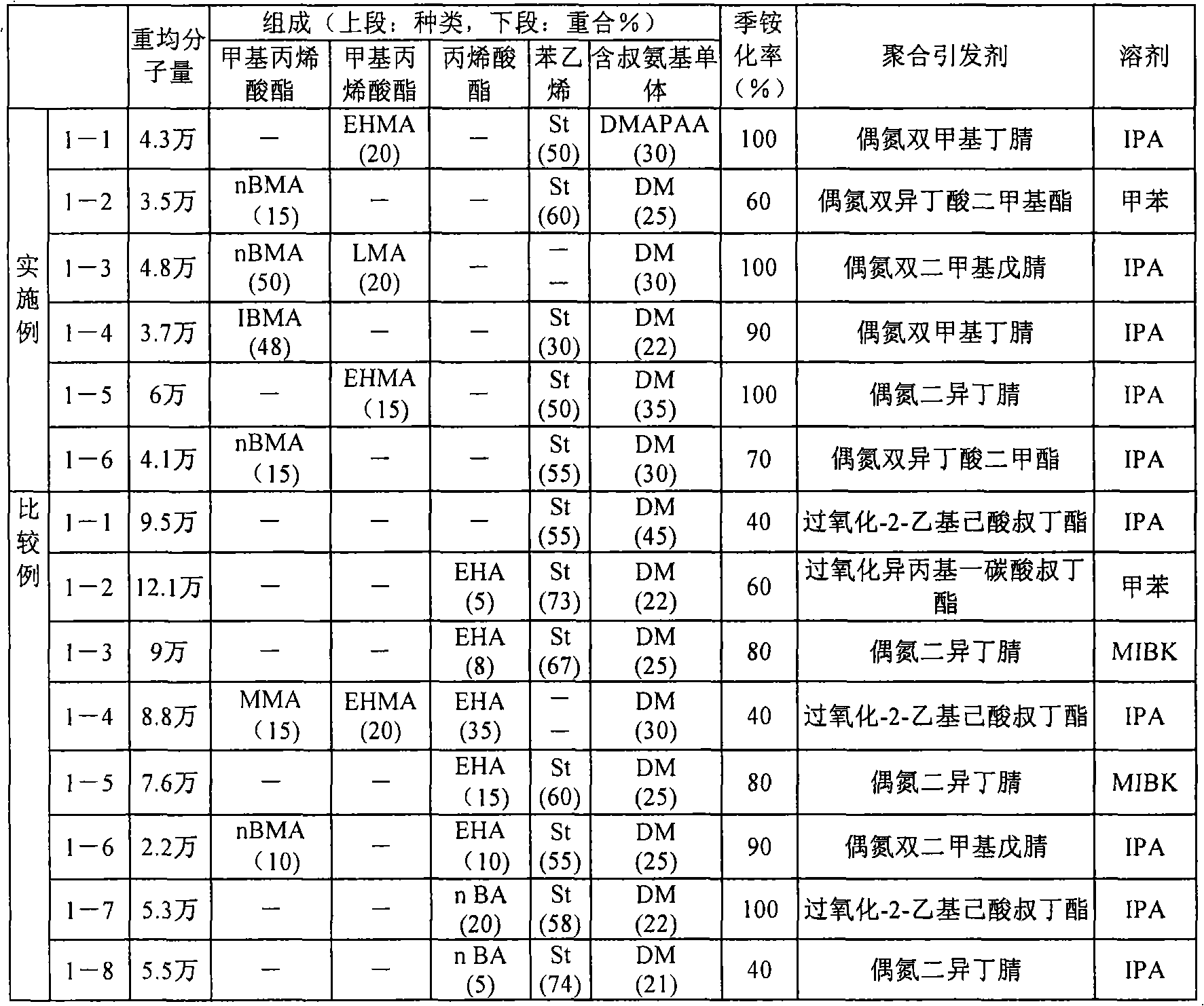

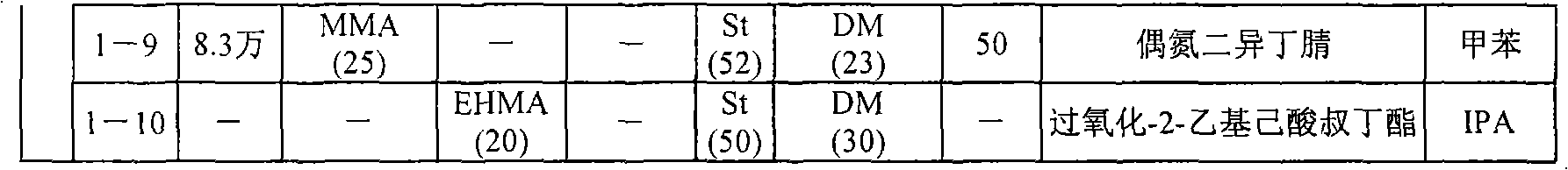

Cationic surface sizing agent and base paper for newspaper

ActiveCN101297079AModerate affinityImprove washabilityWater-repelling agents additionPaper coatingMeth-Paper sheet

Disclosed is a cationic surface sizing agent intended to be coated on a base paper for a newspaper, which can improve a sizing property and scumming resistance during offset printing. The cationic surface sizing agent is produced by quaternizing a copolymer having a weight average molecular weight of 30,000 to 60,000, wherein the copolymer is produced by polymerizing (a) 20 to 40% by weight of a monomer having a tertiary amino group, (b) 10 to 80% by weight of a C4-C18 alkyl ester of (meth)acrylic acid and (c) 0 to 70% by weight of styrene or a derivative thereof with an azo-type polymerization initiator in the presence of a chain transfer agent. The cationic surface sizing agent has an improved sizing property without causing the decrease in the level of hydrophobicity of the copolymer and can prevent the sensitization of a plate to be printed (e.g., a PS plate) by specifying the composition of the monomers, using an azo-type polymerization initiator and also specifying the molecularweight of the copolymer.

Owner:HARIMA CHEM INC

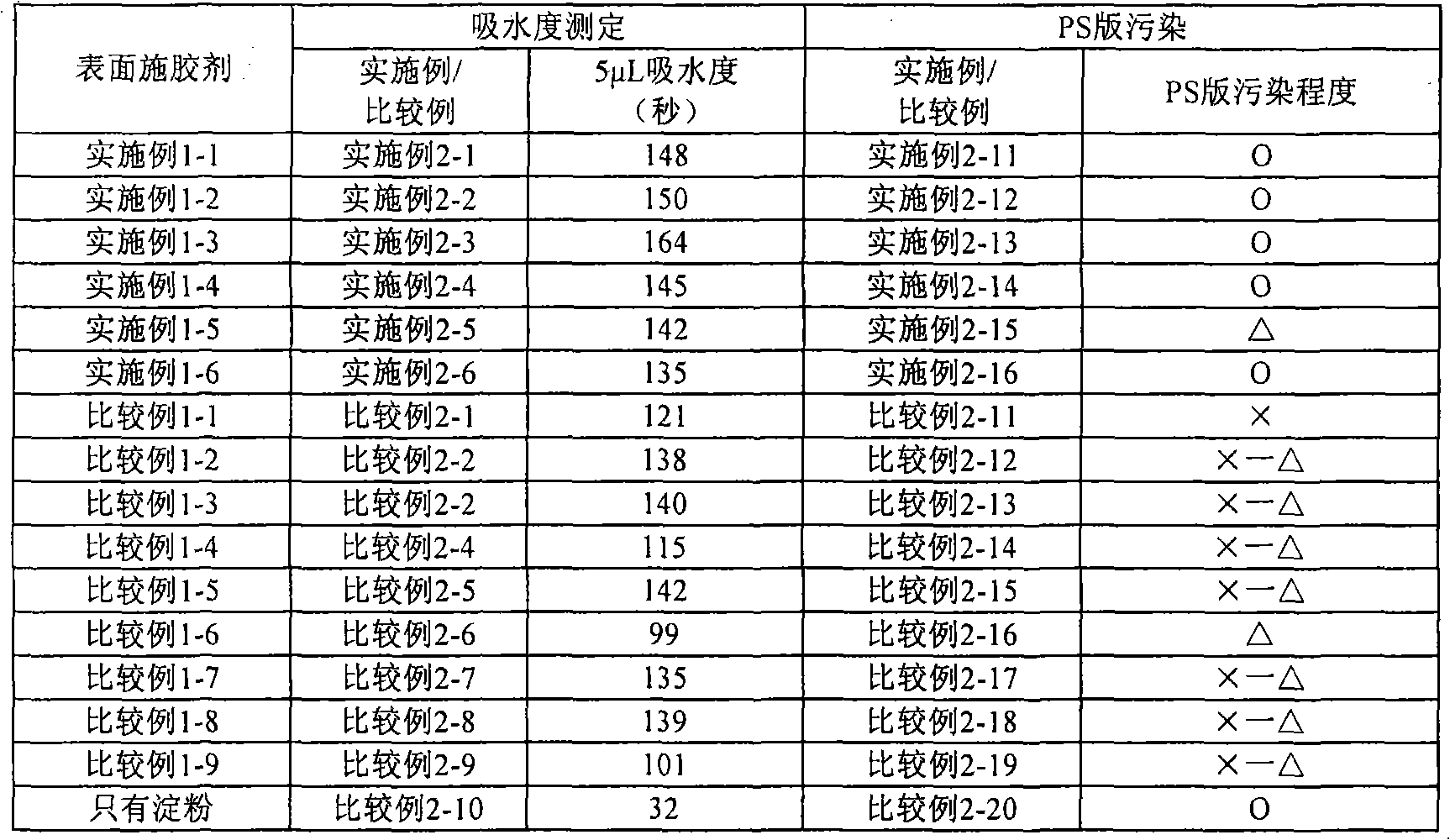

Method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration

InactiveCN101530826AHigh recovery rateReduce the amount of dissolutionWet separationZinc metalResource utilization

The invention provides a method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration, comprising the processing techniques of ammonia leaching under normal temperature and pressure-extraction-electrodeposition-leaching floatation, which not only gives full play to the advantage of wet method melting technique in recovering zinc in the oxidized lead zinc ore but also gives full play to the advantage of floatation technique in recovering vulcanized lead zinc; what is more, the advantages in the two aspects are organically combined and have shared complementary advantages, thus realizing integrated optimization of concentration technique, forming a brand-new combined process for concentration of low-grade zinc oxide ore, improving recovery rate of lead and zinc metal and achieving the effect of improving resource utilization rate and saving energy, lowering energy consumption and reducing pollutants discharge on the whole.

Owner:KUNMING UNIV OF SCI & TECH

Sulfate-based electrolysis processing with flexible feed control, and use to capture carbon dioxide

ActiveUS9493881B2Process economyReduce the amount requiredCalcium/strontium/barium carbonatesProductsElectrolysisSulfate

A method including electrolysis processing using sulfate-based electrolytes includes precipitating sodium sulfate decahydrate from a salt solution and then redissolving sodium sulfate decahydrate to prepare feed of electrolyte solution for the electrolysis processing. Front-end processing may be used to treat mixed salt solutions, including brine solutions. Calcium sulfate reagent may provide a sulfate source to regenerate electrolyte solution following carbon capture, and with carbon dioxide being sequestered in the form of calcium carbonate.

Owner:NEW SKY ENERGY INC

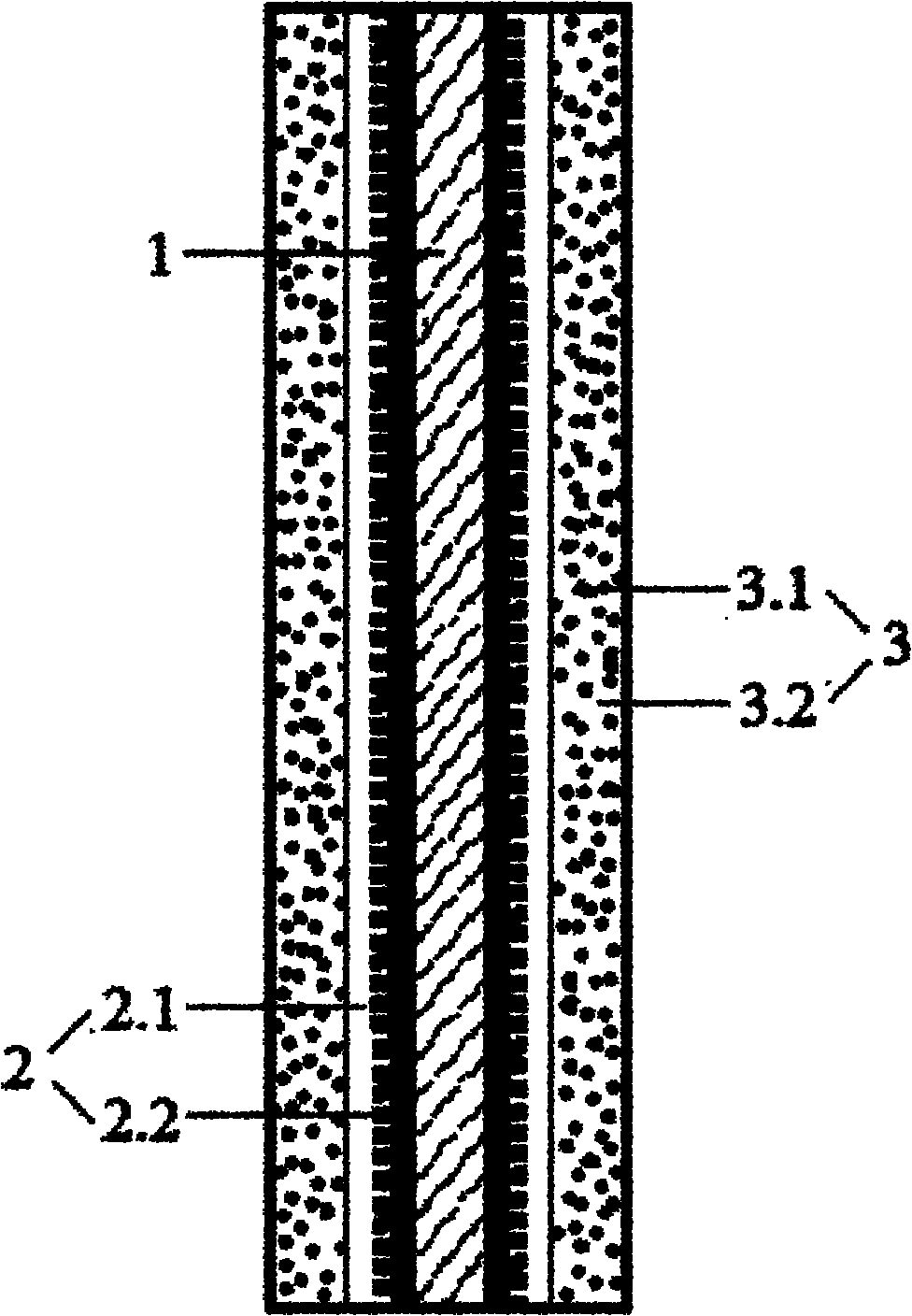

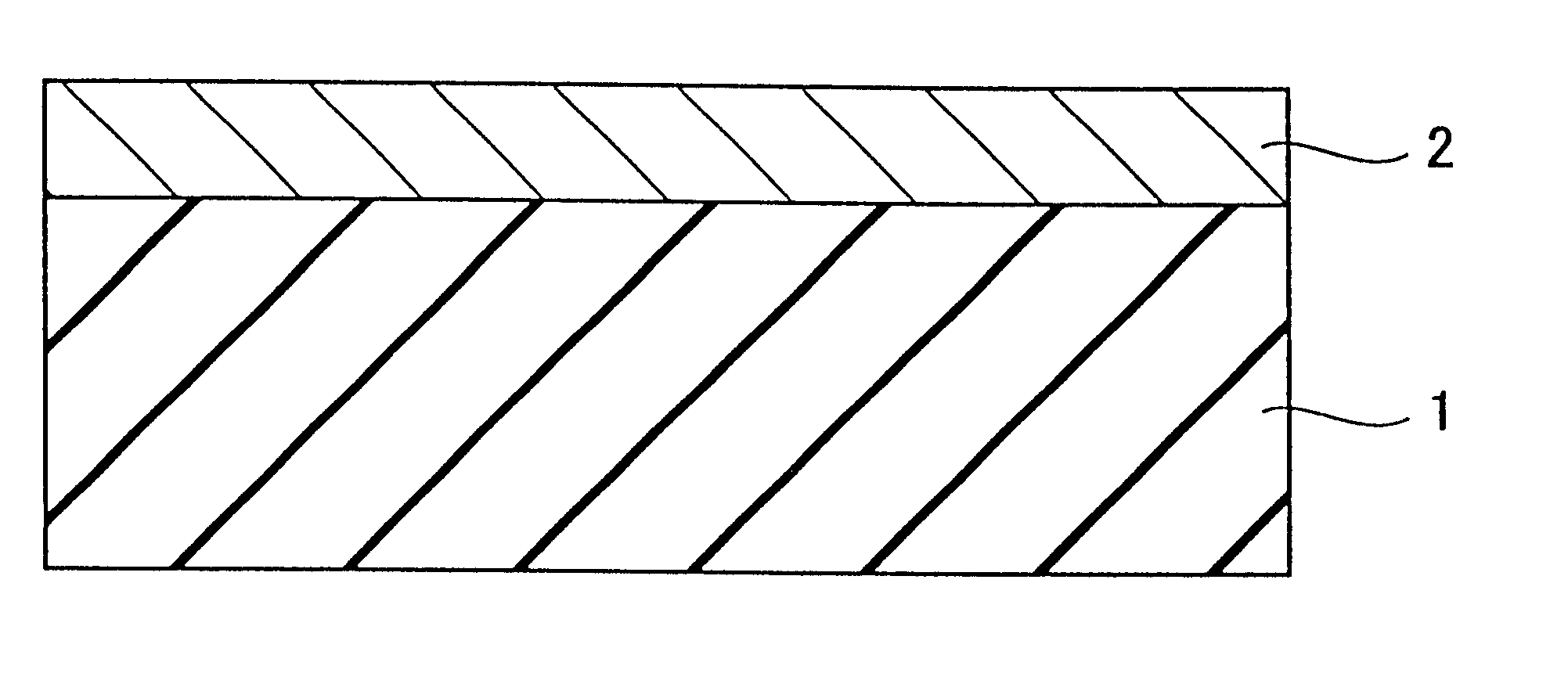

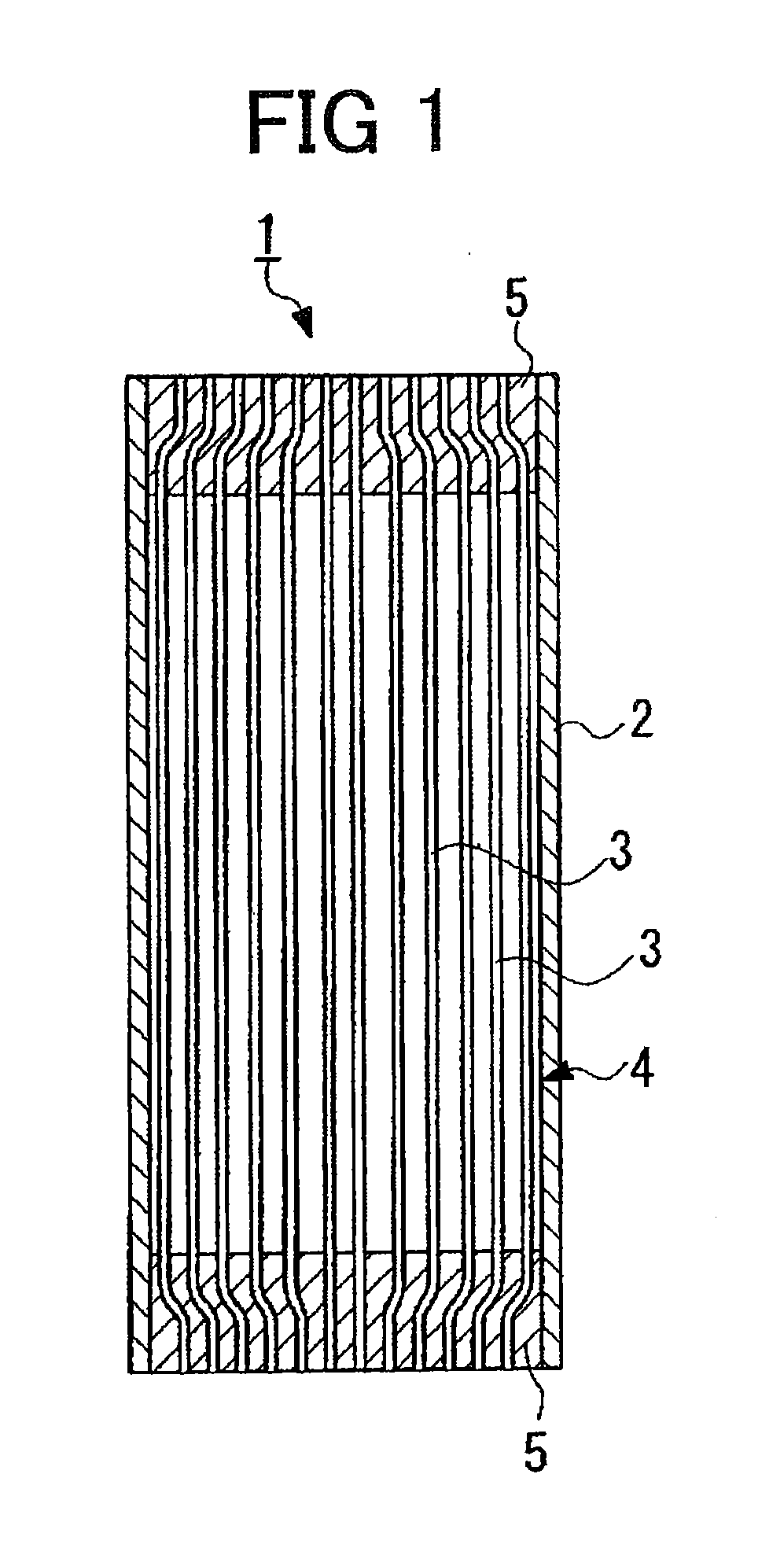

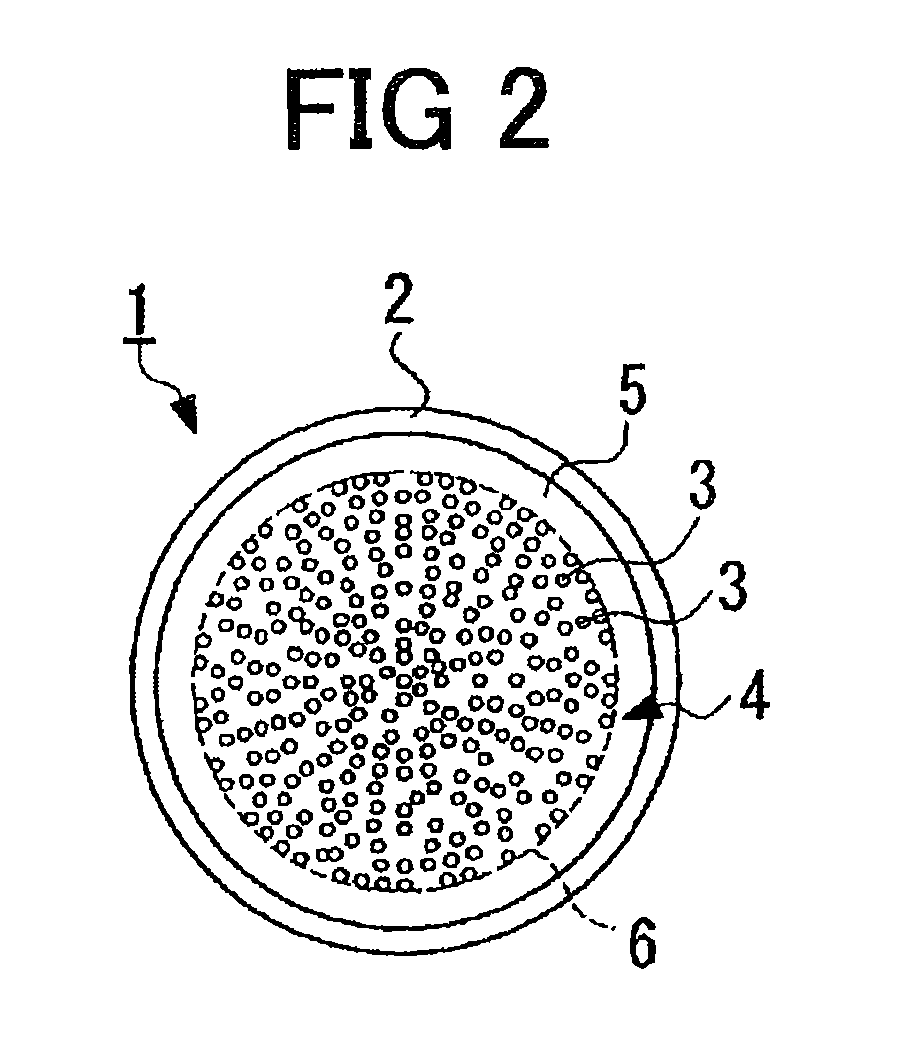

Hydrogen-permeable structure and method of manufacturing the same

InactiveUS6641647B2Reduce the amount of dissolutionDeterioration of crackingSemi-permeable membranesMembranesHydrogenGas phase

A hydrogen permeable structure includes a base material (1) including porous ceramic, and a hydrogen permeable film (2) formed on the base material (1), including palladium (Pd) and at least one element other than palladium and having an amount of hydrogen dissolution at a prescribed temperature smaller than that of palladium alone. The hydrogen permeable film (2) is formed on the surface of the porous ceramic base by a physical vapor deposition technique after any pin holes in the surface of the base have been filled with a porous oxide material.

Owner:SUMITOMO ELECTRIC IND LTD

High-gloss transparent glaze formula for daily-use ceramics, as well as preparation method and using method of high-gloss transparent glaze formula

The invention belongs to the field of manufacturing of ceramics and specifically relates to a high-gloss transparent glaze formula for daily-use ceramics, as well as a preparation method and a using method of the high-gloss transparent glaze formula. The high-gloss transparent glaze formula for the daily-use ceramics provided by the invention is prepared by taking feldspar powder, heavy calcium carbonate, limestone, talcum, dolomite, kaolin, silicon oxide, zinc oxide, barium carbonate and water as raw materials and performing a production process with reasonable formula and appropriate control. A ceramic device produced by a transparent glaze is detected to have high gloss and low dissolution of lead and cadmium, is suitable for production of the daily-use ceramics, such as bowls, spoons, basins and the like, has the characteristics of aesthetic shape, health, environmental friendliness and the like, and has great popularization value and social and economic benefits.

Owner:福建省德化县宏达陶瓷有限公司

Daily use ceramics and preparation method thereof

The invention relates to the field of daily use ceramics, in particular to daily use ceramics and a preparation method thereof, wherein, the blank for the daily use ceramics comprises 7-10wt% Li2O, 30-33wt% Al2O3, and 58-62wt% SiO2; the glaze comprises 48-52% SiO2, 28-31wt% Al2O3, 6-9wt% Li2O, 1-2wt% ZrO2, 2-3wt% P2O5, 2-3wt% TiO2, 0.5-1.5wt% Na2O, 0.5-1.5wt% K2O, 2-4wt% B2O3, and 0.5-1.5wt% PbO;and 4-6 wt% clay is added into the glaze in addition before glazing. Compared with the prior art, the preparation method in the invention, by improving the formulas of the blank and the glaze and thefiring process, allows the water absorption to be changed from 3.5% to less than 15%, meeting the requirement of users, improving the heat preservation of the products, reducing the sintering temperature to about 40 DEG C, and reducing the cost greatly.

Owner:福建省德化县全丰陶瓷有限公司

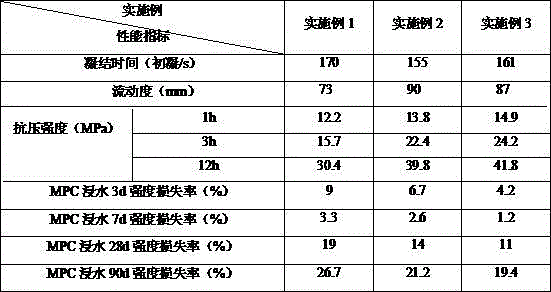

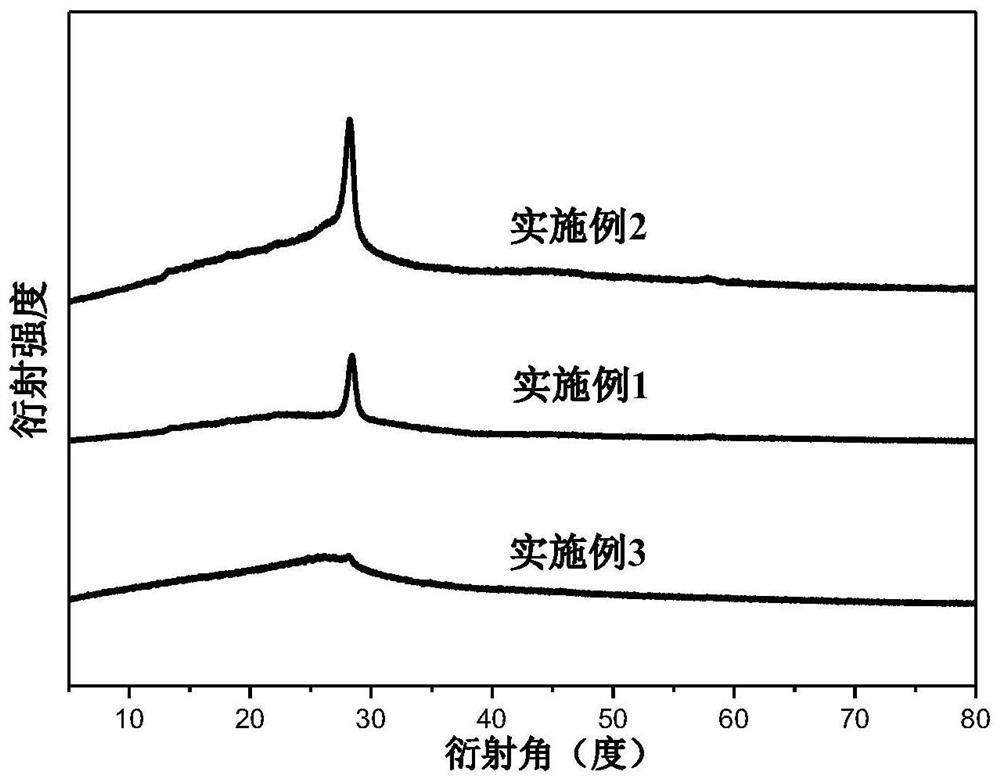

Magnesium phosphate cement with good hydrolytic resistance and using method thereof

InactiveCN105800979AImprove water resistanceIncreases the degree of hydrationMagnesium phosphateSlag

The invention belongs to the technical field of building materials, and particularly relates to preparation of magnesium phosphate cement with good hydrolytic resistance and a using method thereof. The magnesium phosphate cement is prepared from calcined magnesia, monopotassium phosphate, retarder, desulphurization gypsum, coal ash, steel slag powder, limestone flour, a water reducing agent and a defoaming agent. The defects that traditional magnesium phosphate cement is insufficient in early strength, low in later strength, poor in water resistance, high in cost and the like can be overcome, and the additional value of the industrial byproducts such as the coal ash, the steel slag powder and the desulphurization gypsum can be improved. The magnesium phosphate cement with good hydrolytic resistance can be used as a rapid repair material, has the excellent properties that preparation technology is simple, fluidity is good, early strength development is fast, later strength is not reduced and permeability and erosion resistance is good, is applicable to rapid repair engineering of bridges, wharfs, municipal engineering and the like, and has good economic benefits and social benefits.

Owner:TONGJI UNIV

Method for preparing diisopropyl phosphite

ActiveCN101250199AHeat dissipation fastLess side effectsGroup 5/15 element organic compoundsBenzenePhosphate product

The invention relates to a method for preparing diisopropyl phosphate via the esterification of phosphorus trichloride and isopropanol, which comprises adding phosphorus trichloride into benzene solvent to form a first mixture, adding benzene, isopropanol and weak alkaline organic catalyst into a reactor to form a second mixture, slowly adding the first mixture into the second mixture to form a reaction system, increasing and controlling temperature, reacting for 4.5-9h to obtain the mixture containing diisopropyl phosphate, deacidifying the mixture via pure alkali, filtering, distilling, depressurizing and distilling to obtain final diisopropyl phosphate product. The preparation method has low cost and high yield.

Owner:太仓市茜泾化工有限公司

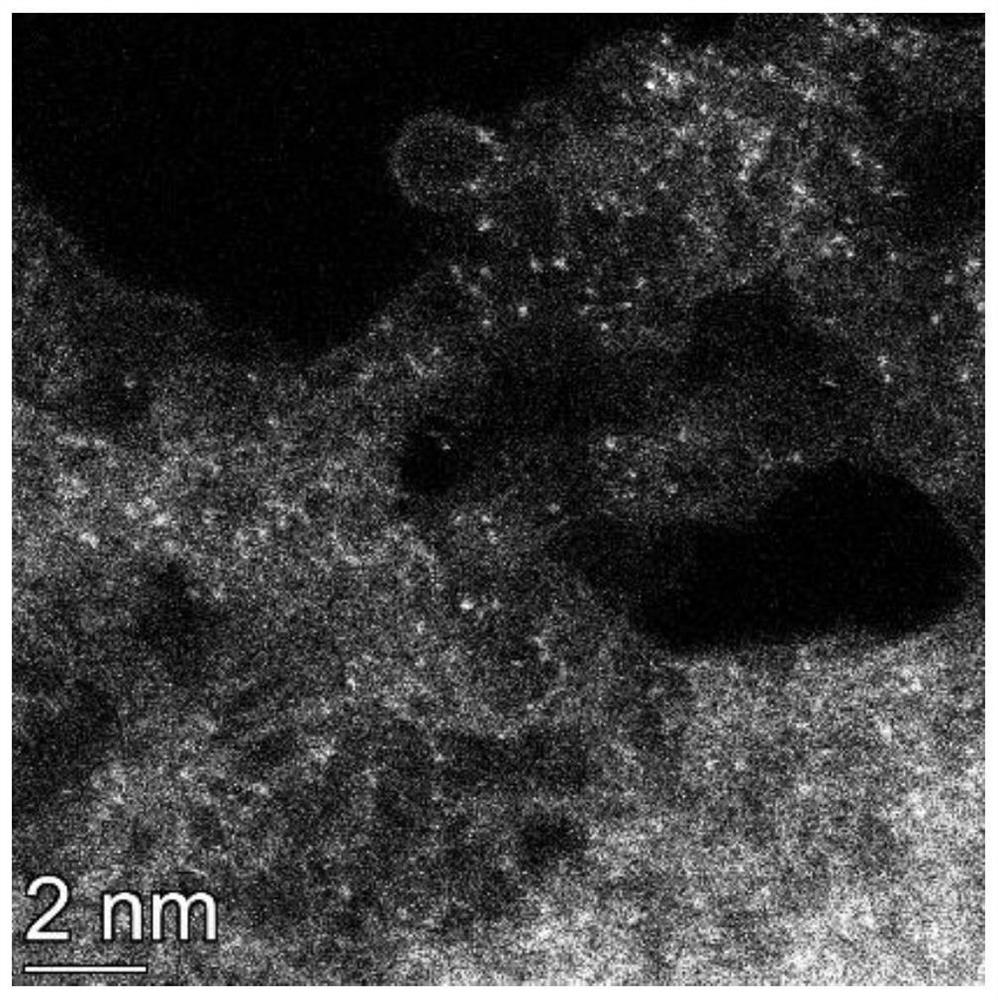

Iron-nitrogen-carbon composite material containing monatomic active sites as well as preparation and application methods of iron-nitrogen-carbon composite material

ActiveCN113042081AImprove degradation efficiencyLow dissolution ratePhysical/chemical process catalystsWater/sewage treatment by oxidationCarbon compositesIron phthalocyanine

The invention provides an iron-nitrogen-carbon composite material containing monatomic active sites, which comprises a carrier containing graphite-like carbon nitride and iron monatomic combined with the carrier, so that the catalytic activity to peroxymonosulfate is improved, and a large amount of metal ions are prevented from being dissolved out. The preparation method comprises the following steps: S1, dissolving a nitrogen-containing carbon source in an ethanol solution to obtain a solution A; wherein the nitrogen-containing carbon source is prepared from one or more of melamine, dicyandiamide and urea; S2, dispersing an iron-containing metal precursor in the solution A, and then performing evaporation to dryness treatment to obtain a mixed substance B; wherein the iron-containing metal precursor comprises one or two of chlorhematin and iron phthalocyanine; and S3, sequentially performing grinding and mixing treatment, pyrolysis treatment and cooling treatment on the mixed substance B, sequentially performing acid pickling treatment, water washing treatment and drying treatment on a substance obtained after cooling treatment, and obtaining the iron-nitrogen-carbon composite material.

Owner:CENT SOUTH UNIV

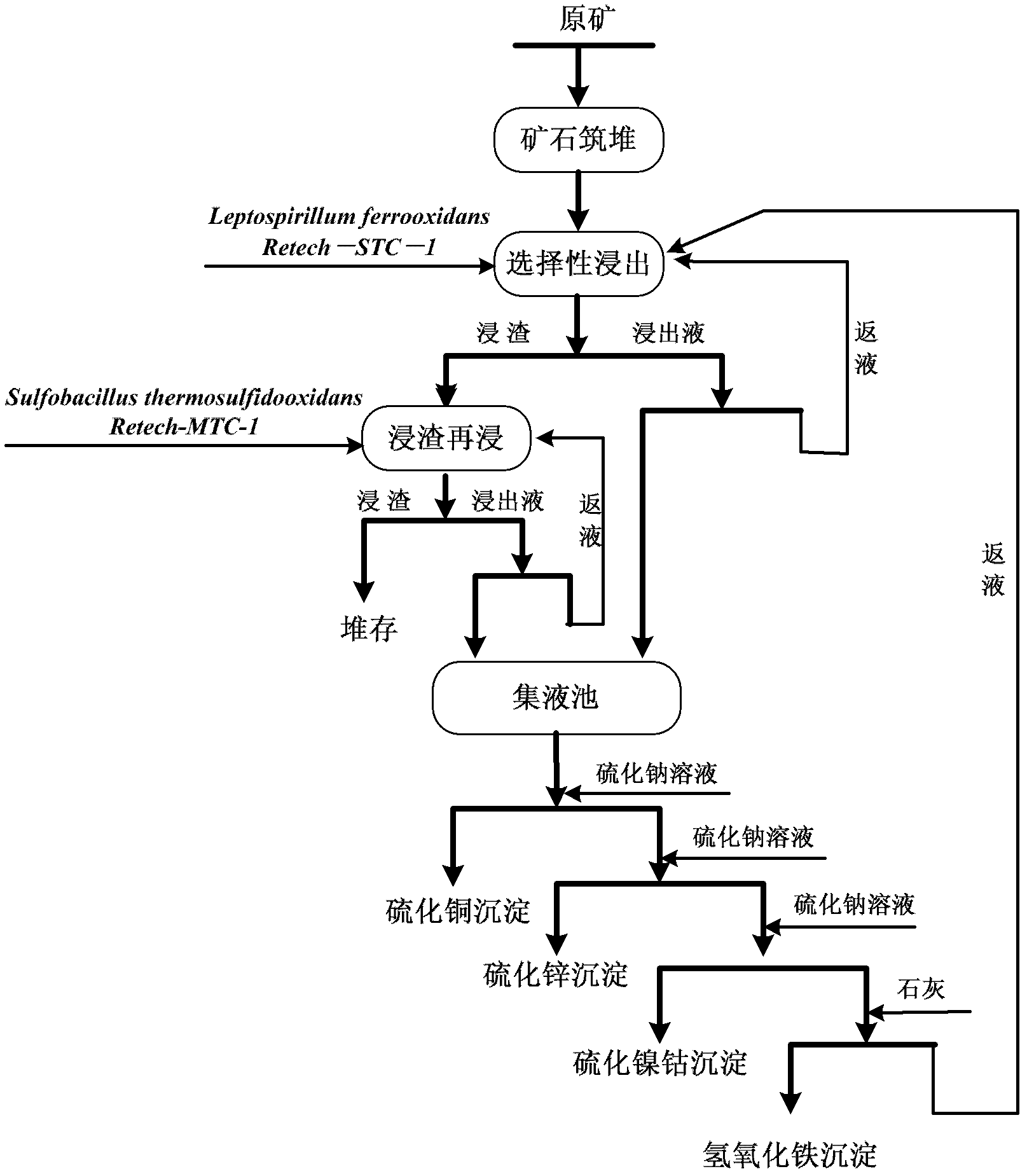

Low-grade multi-metal sulfide mineral selective bioleaching technology

ActiveCN103184335ALow impurity contentReduce the amount of sedimentProcess efficiency improvementSulfide mineralsContamination

The invention provides a low-grade multi-metal sulfide mineral selective bioleaching technology. The process is as follows: pile building is performed on the raw mineral materials, dilute acid solution is adopted for presoaking, and efficient mineral leaching bacteria are led in for leaching after the acidity of the mineral pile is basically stable; pile unloading is performed when the leaching of nickel reaches more than 80 wt%, then pile building is performed again on the leaching residue, and thermophilic bacteria are led in for leaching; and when the concentration of nickel in the leaching agent is more than 2.0 g / L, open-cycle is performed on the partial leaching agent, sodium sulfide is added into the leaching agent for fractional precipitation, so as to obtain copper sulphide, zinc sulphide and nickel and cobalt sulphide products, after precipitation is completed, lime is added into the leaching agent for neutralization, wherein concentration of iron in the neutralized leaching agent is less than 1.0 g / L, and the neutralized leaching agent can be reused at the leaching stage. According to the invention, technological process is short, equipment is simple, investment conservation and zero contamination are realized, cost is low, recovery rate of valuable metal is improved, the purpose of comprehensively utilizing low-grade multi-metal sulfide mineral resources is realized, and greater economic benefits can be achieved.

Owner:有研资源环境技术研究院(北京)有限公司

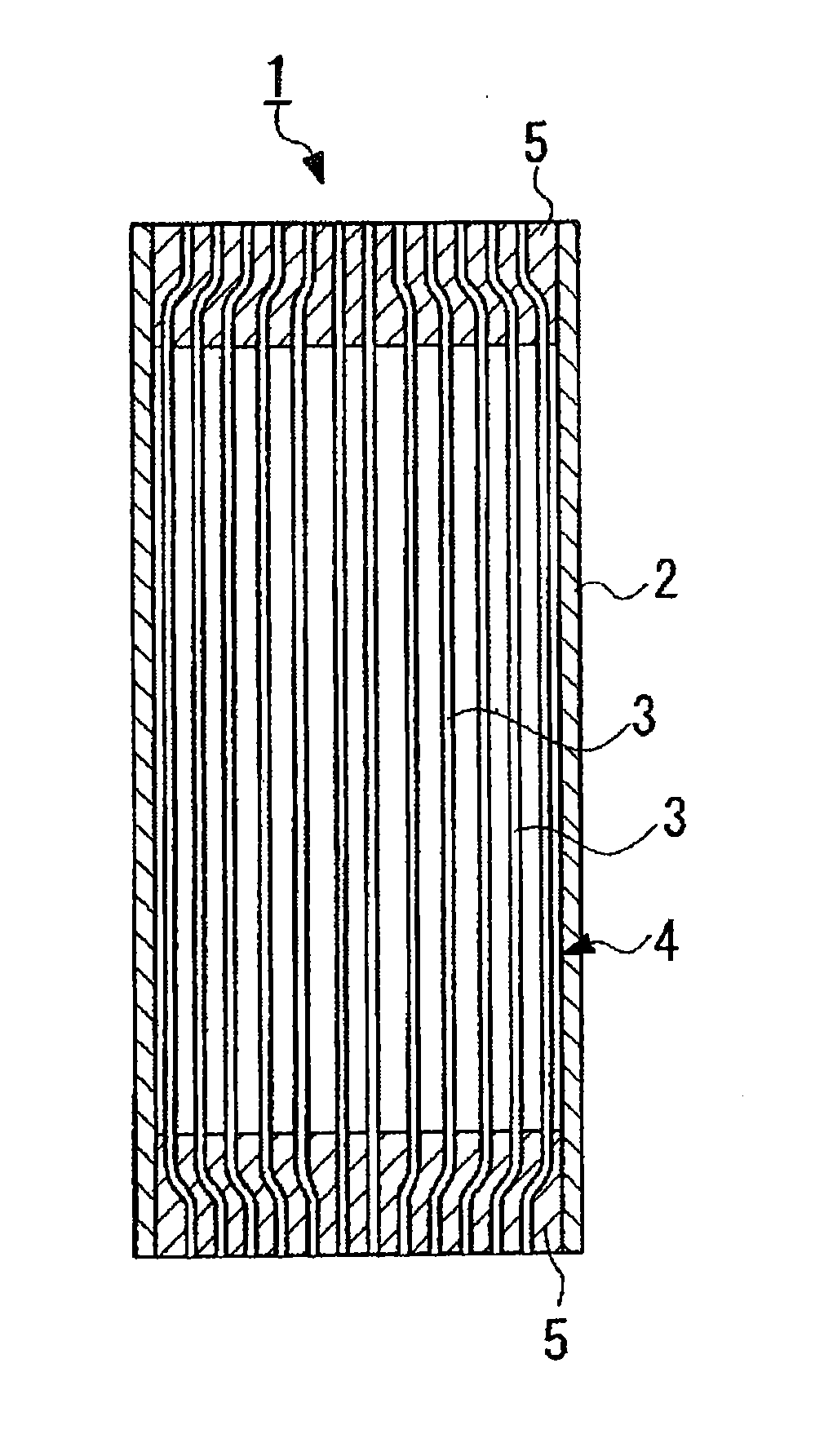

Polyolefin-composite hollow-fiber membrane and manufacturing method for same, and hollow-fiber membrane module

InactiveUS20130255498A1Suppress leakageExcellent solvent resistance and gas permeabilityMembranesHollow filament manufactureSolventPorous membrane

The present invention pertains to a polyolefin-composite hollow-fiber membrane and a manufacturing method for the same, said polyolefin-composite hollow-fiber membrane having: a homogenous membrane layer formed from polyolefins having a metal flow rate measured in accordance with JIS K7210 code D of 1.0 g / 10 minutes, or less, and an Mw / Mn ratio of not more than 4.0; and a porous membrane layer which is formed from polyolefins having an Mw / Mn ratio of 8.0-12.0. The present invention also pertains to a hollow-fiber membrane module which is equipped with the polyolefin-composite hollow-fiber membrane. The present invention enables the provision of a polyolefin-composite hollow-fiber membrane, a manufacturing method for the same and a hollow-fiber membrane module; the polyolefin-composite hollow-fiber membrane has excellent solvent resistance and gas permeability, and when used in the deaeration of dissolved gas in a drug solution, can suppress leakage of the drug solution to a high degree, and can efficiently reduce the amount of dissolved gas.

Owner:MITSUBISHI RAYON CO LTD

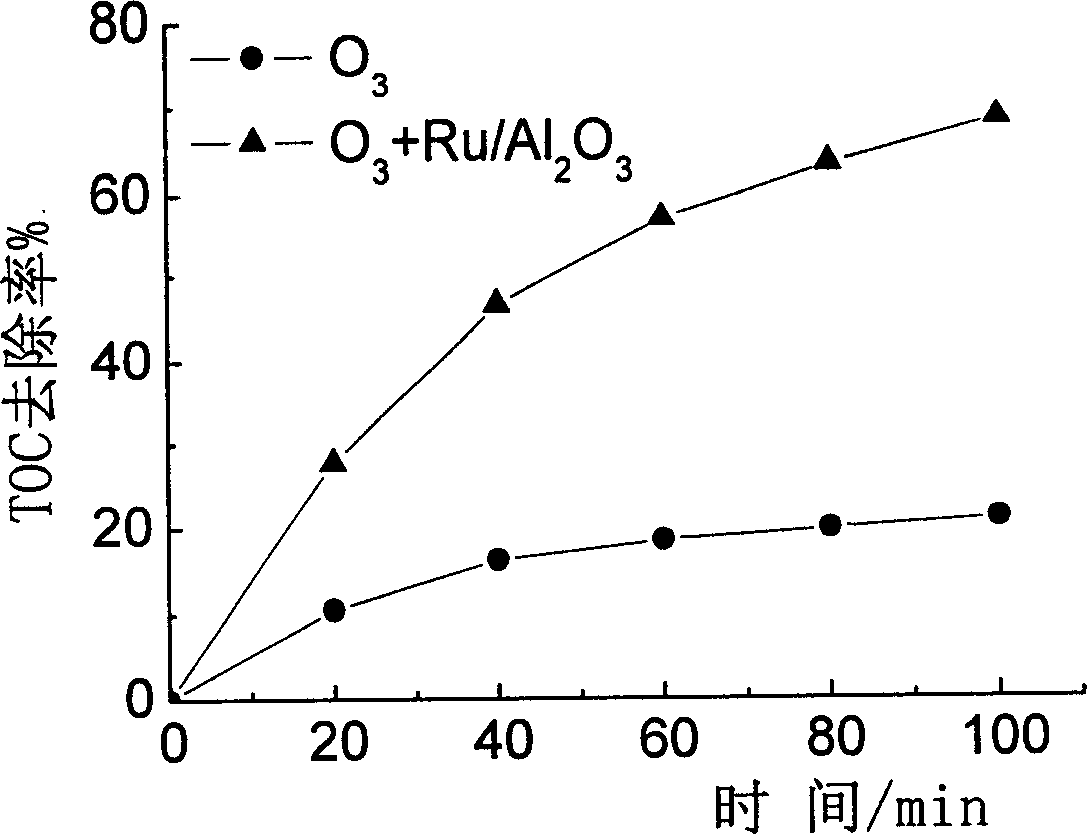

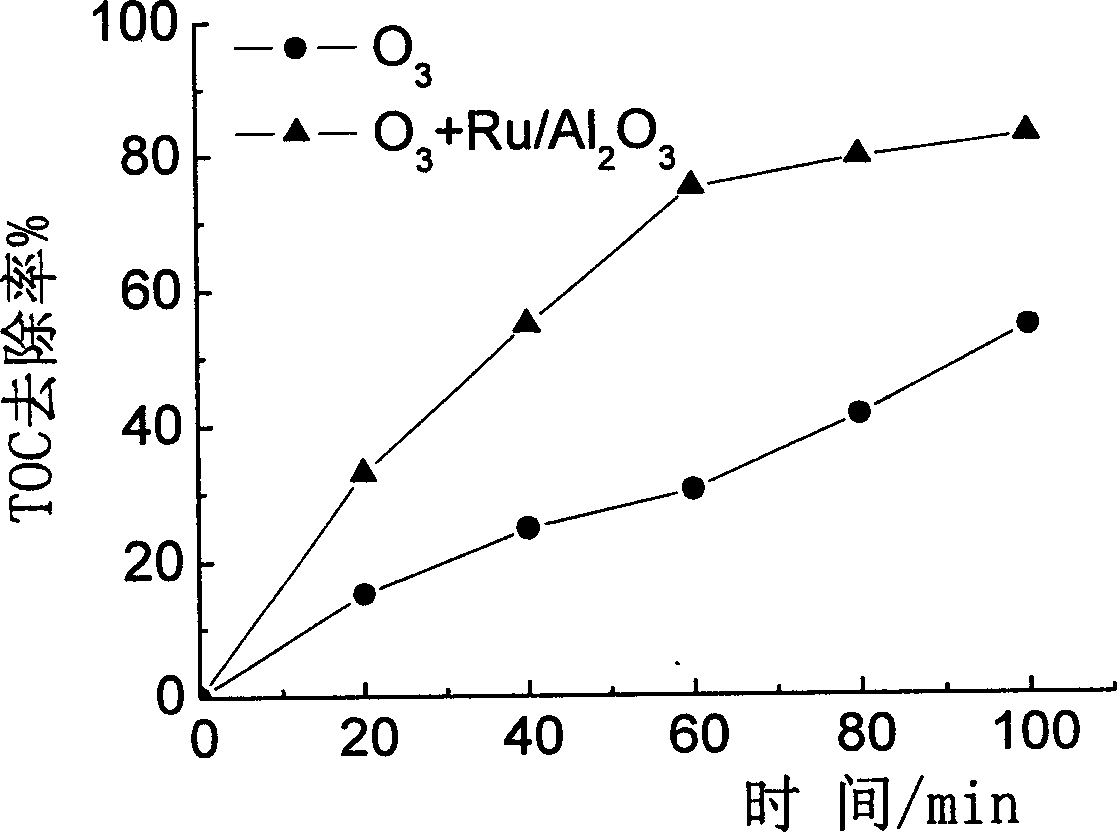

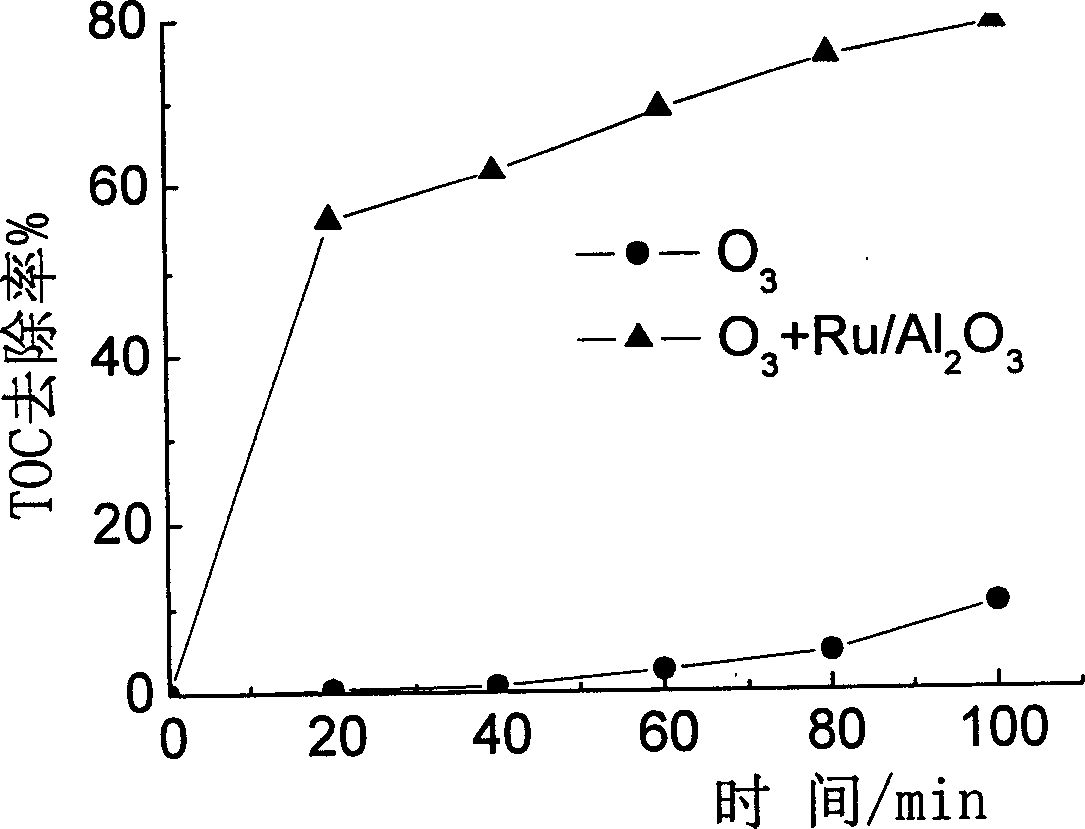

Ru/Al2O3 catalytic ozone oxidation catalyst and its microwave synthesis method

InactiveCN1785511AHigh activityLow powerCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPerturbateurs endocriniensSynthesis methods

A Ru / Al2O3 catalyst for the catalytic oxidization of ozone is composed of Al2O3 as carrier and RuO2 as active component proportionally. Its preparing process includes such steps as equivolume mixing between RuCl3 solution and Al2O3 carrier, impregnating in shaker, drying and microwave heating. It has high effect to remove ozone, interference substance to internal secretion, phenols and micro-molecular acids.

Owner:TSINGHUA UNIV

Method for reducing dissolution of noxious heavy metal components

ActiveCN101337732AReduce the amount of dissolutionReduce solubilityWater/sewage treatmentAluminateLiquid waste

The invention provides a method for reducing environmental pollution caused by hazardous heavy metals, and relates to the treatment of hazardous heavy metals in waste liquor and waste material. The method adopts hydrated calcium aluminate sulfate to solidify hazardous heavy metal components in liquid and solid waste material. Through mixing fresh calcium oxide, aluminium sulphate and silicon dust as raw materials for preparing hydrated calcium aluminate sulfate into the incineration ash of the liquid and solid waste material containing the heavy metal components, the method effectively solidifies and inhibits the hazardous heavy metals from being dissolved out; through the treatment, the reduced amount of dissolved-out hazardous heavy metal components reaches 90%; the method has the characteristics of simple implementation and prominent treatment effects, and is not easy to cause secondary pollution.

Owner:CHINA BUILDING MATERIALS ACAD

Carbide residue and waste water treating process

InactiveCN1986458AHighlight substantiveSignificant progressMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationIndustrial waste waterCarbide

The carbide residue and waste water treating process includes the following steps: pumping carbide residue with a slurry pump from acetylene producing shop to a settler, standing and separating water and precipitate; pumping the precipitate to wet ball mill and milling into 300 mesh below slurry; pressure filtering the slurry, water washing the filter cake to eliminate soluble impurity and collecting water; treating water through adding desulfurizing agent and returning to the acetylene producing shop for reuse; and pulping the filter cake to form slurry, which may be used as slaked lime for treating acid industrial waste water or sulfur containing boiler fume, building lime paste or material for producing high quality calcium carbonate.

Owner:梁永洪 +1

Preparation method for acquiring spherical activated carbon of carbon dioxide

InactiveCN102502624AHigh nitrogen contentReduce the amount of dissolutionCarbon compoundsActivated carbonNitrogen

Provided is a preparation method for acquiring spherical activated carbon of carbon dioxide. Linetype phenolic resin, nitrogenous compounds and industrial alcohol are mixed to be prepared to pulp, and the pulp is directly added to a reaction kettle which contains a surface active agent and water. After being tightly closed, the reaction kettle is turned on for mixing, heating rate is increased to100 to 170 DEG C, and then the temperature is constant for 0.5 to 3 hours. After natural cooling, resin spheres are obtained. The resin spheres are placed in a carbonization activation furnace, inertgases are led in, proportion by weight of gas flow rate to the resin spheres is 300 to 1,000 L / min: 1kg, then the temperature is increased to 700 to 1,000 DEG C with the heating rate of 0.1 to 4 DEG C / min, the gases are changed to active gases, proportion of the active gases to the resin spheres is 100 to 300L / min: 1kg, after 0.5 to 2 hours of activation, the gases are changed to inert gases, the temperature is lowered to below 50 DEG C, and the final products are obtained. The preparation method for acquiring spherical activated carbon of carbon dioxide has the advantages of being low in cost and high in nitrogen content.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com