Rare earth composite oxide catalyst in catalytic wet oxidation process and preparing method thereof

A technology that catalyzes wet oxidation and composite oxides. It is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problems of decreased catalyst activity, high catalyst cost, small The problem of low removal rate of molecular organic acids can be achieved by reducing the operating temperature and pressure, making the production process simple and easy, and promoting the promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare 0.1mol / L ZrOCl 2 ·8H 2 O and 0.9mol / L Ce(NO 3 ) 3 ·6H 2 O Mix 50ml of solution and 1000ml of 0.5mol / L ammonia water, slowly drop the salt solution into the vigorously stirred ammonia water, filter the obtained gel precipitate, and redisperse it in 400ml of deionized water, adjust the pH value to 10 , refluxed in hot lye for 24h, then dried in an oven at 100°C, then placed in a muffle furnace, and calcined at 400°C for 6h in an air atmosphere to obtain ZrO 2 -CeO 2 composite oxide catalyst.

[0024] Then utilize the catalyst prepared by the above method to catalyze wet oxidation containing high-concentration acetic acid wastewater:

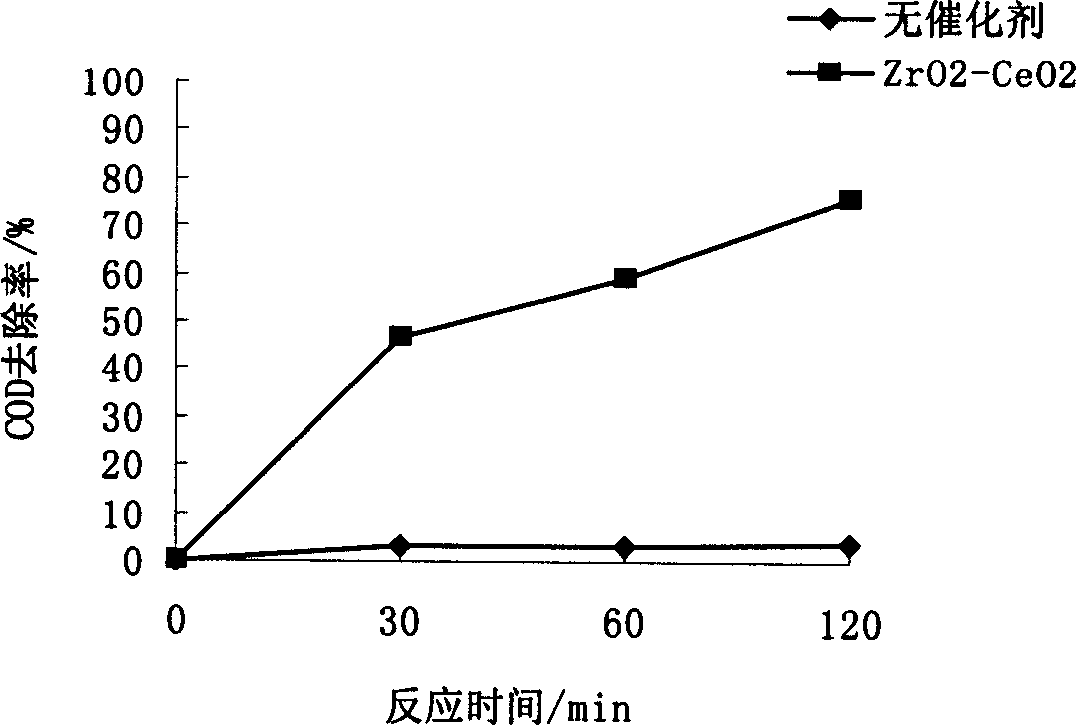

[0025] Prepare an acetic acid solution with a COD concentration of about 5000 mg / L, and add ZrO 2 -CeO 2 Put 2.7g of catalyst in the reactor and heat it up to 230°C, stop heating, feed oxygen until the total pressure is 5MPa, continue heating when the temperature drops to 230°C and keep the temperature at 230±3°C, the reactio...

Embodiment 2

[0027] Prepare 0.1mol / L ZrOCl 2 ·8H 2 O and 0.9mol / L Ce(NO 3 ) 3 ·6H 2 O mixed solution 50ml and 0.5mol / L ammonia water 1000ml, slowly drop the salt solution into the vigorously stirred ammonia water, filter the obtained gel precipitate, and redisperse it in 400ml deionized water, adjust the pH value to 10, Reflux in hot lye for 24h, then dry in an oven at 100°C, then place in a muffle furnace and bake at 400°C for 6h in an air atmosphere to obtain ZrO 2 -CeO 2 composite oxide catalyst.

[0028] Then use the catalyst catalytic wet oxidation prepared by the above method to contain high-concentration n-butyric acid wastewater:

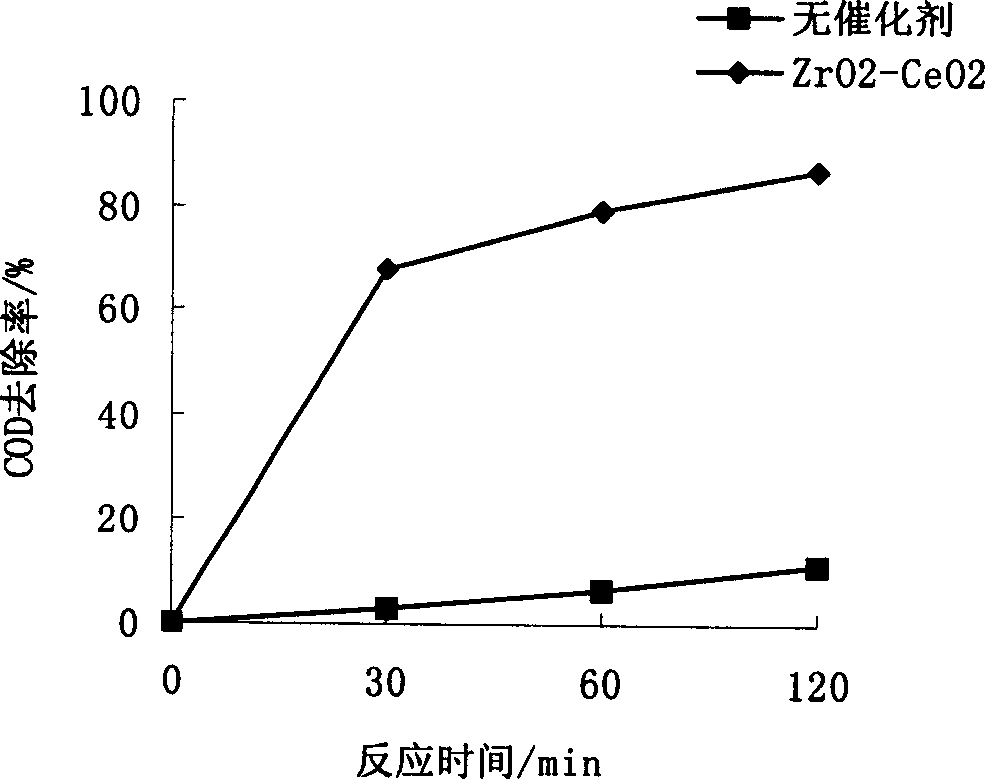

[0029] Prepare n-butyric acid solution with COD concentration of about 9000mg / L, add ZrO 2 -CeO 2 Put 2.0g of catalyst in the reactor and heat it up to 230°C, stop heating, feed oxygen until the total pressure is 5MPa, continue heating when the temperature drops to 230°C and keep the temperature at 230±3°C, the reaction time is 2h, the result is ...

Embodiment 3

[0031] Prepare 0.1mol / L ZrOCl 2 ·8H 2 O and 1.1mol / L Ce(NO 3 ) 3 ·6H 2 O mixed solution 50ml and 0.5mol / L ammonia water 1000ml, slowly drop the salt solution into the vigorously stirred ammonia water, filter the obtained gel precipitate, and redisperse it in 400ml deionized water, adjust the pH value to 11, Reflux in hot lye for 36 hours, then dry in an oven at 80°C, then place in a muffle furnace and bake at 600°C for 8 hours in an air atmosphere to obtain ZrO 2 -CeO 2 composite oxide catalyst.

[0032]Then with the catalyst prepared by the above method, carry out the test of removing acetic acid effect according to the test method in embodiment one, the result shows that can obtain better removal effect, carry out the test of removing n-butyric acid effect according to the test method in embodiment two, It can also achieve better removal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com