Preparation method of high-speed polyester POY (Pre-Oriented Yarn) spinning oil agent

A high-speed spinning and oiling technology, applied in textile and papermaking, fiber processing, fiber type, etc., can solve the problems of sudden viscosity, increased filaments and broken ends, uneven oiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

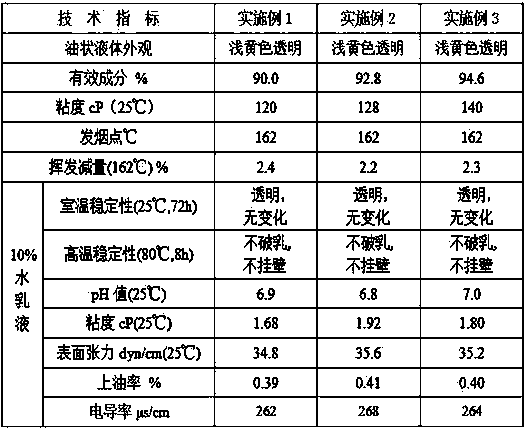

Embodiment 1

[0034] The active ingredients in the oil formula The pure oil is composed of the following components and contents:

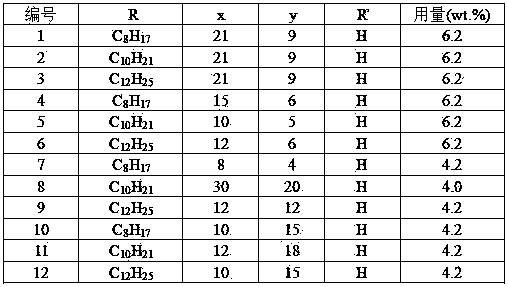

[0035] Smoothing agent accounts for 76.0% of the total mass of pure oil agent. Among the polyether smoothing agents, 11 kinds of random polyethers are selected, and the usage amount accounts for 67.4% of the total mass of the pure oil agent. The specific compounds and their dosages are as follows:

[0036]

[0037] In the polyether smoothing agent, polyoxyethylene ricinoleate EL20 (2.4%) and block polyether C 12 h 25 O(PO) 6 (EO) 10H (2.4%). In addition, 3 kinds of non-polyether smoothing agents were selected, the amount used accounted for 3.8% of the total mass of the pure oil agent, the specific compounds and their amounts are as follows: octyl stearate (1.6%), dioctyl adipate (1.6%) and 18 # White oil (0.6%).

[0038] The emulsifier accounts for 9.6% of the total mass of the pure oil, and the polyether is nonylphenol polyethylene oxide - 4 ether (...

Embodiment 2

[0045] The active ingredients in the oil formula The pure oil is composed of the following components and contents:

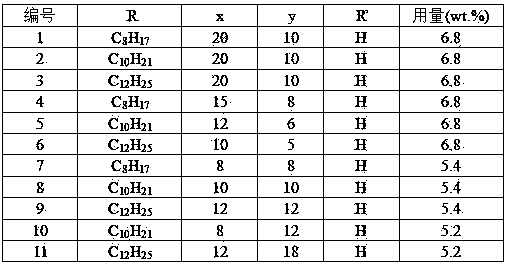

[0046] Smoothing agent accounts for 73.8% of the total mass of pure oil agent. Among the polyether smoothing agents, 12 kinds of random polyether compounds are selected, and the usage amount accounts for 62.2% of the total mass of the pure oil agent. The specific compounds and their dosages are as follows:

[0047]

[0048] In the polyether smoothing agent, oleic acid amide polyoxyethylene ether OAE (3.6%), block polyether L-305 (1.6%) and C 4 h 9 O(PO) 10 [(EO) 10 / (PO) 5 ]H (1.8%). In addition, three non-polyether smoothing agents were selected, lauryl oleate (2.0%), dioctyl sebacate (2.0%) and 26 # White oil (0.6%).

[0049] The amount of emulsifier used accounts for 10% of the total mass of the pure oil, and the polyether is polyoxyethylene laurate - 5-ester (3.4%) and polyoxyethylene laurate - 15 esters (3.4%); non-polyether emulsifiers are sel...

Embodiment 3

[0055] The active ingredients in the oil formula The pure oil is composed of the following components and contents:

[0056] Smoothing agent accounts for 74.8% of the total mass of pure oil agent. Among the polyether smoothing agents, 13 kinds of random polyether compounds were selected, and the usage amount accounted for 65.0% of the total mass of the pure oil agent. The specific compounds and their dosages are as follows:

[0057]

[0058] The polyether smoothing agent also uses polyoxyethylene-9 dilaurate DLE (2.8%) and block polyether C 8 h 17 O(PO) 8 (EO) 10 H (3.0%). In addition, three non-polyether smoothing agents were selected: lauryl oleate (1.4%), dioctyl sebacate (2.0%) and 15 # White oil (0.6%).

[0059] The amount of emulsifier accounts for 9.8% of the total mass of the pure oil, and the polyether is ricinoleic acid polyoxyethylene - 4 esters (3.2%) and polyoxyethylene ricinoleate - 15 ester (3.2%); the non-polyether emulsifier is propylene glycol mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com