Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Cause scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

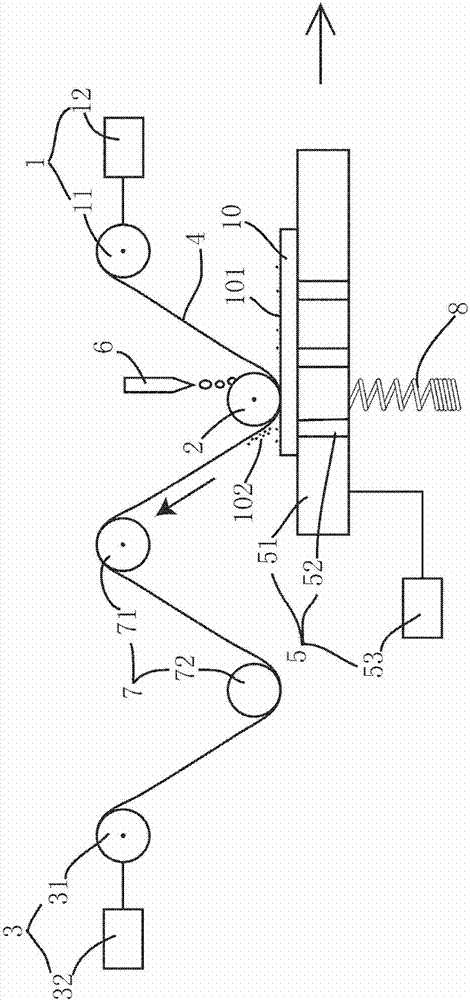

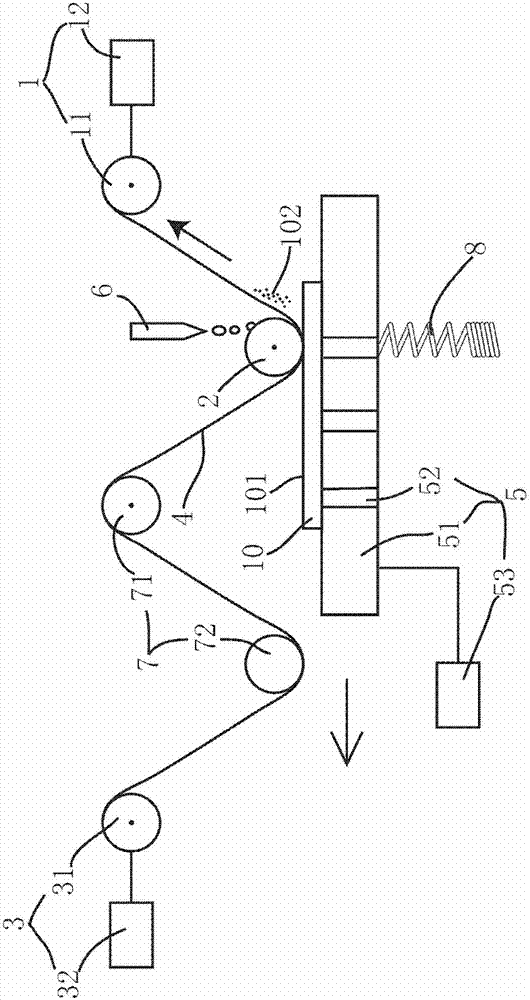

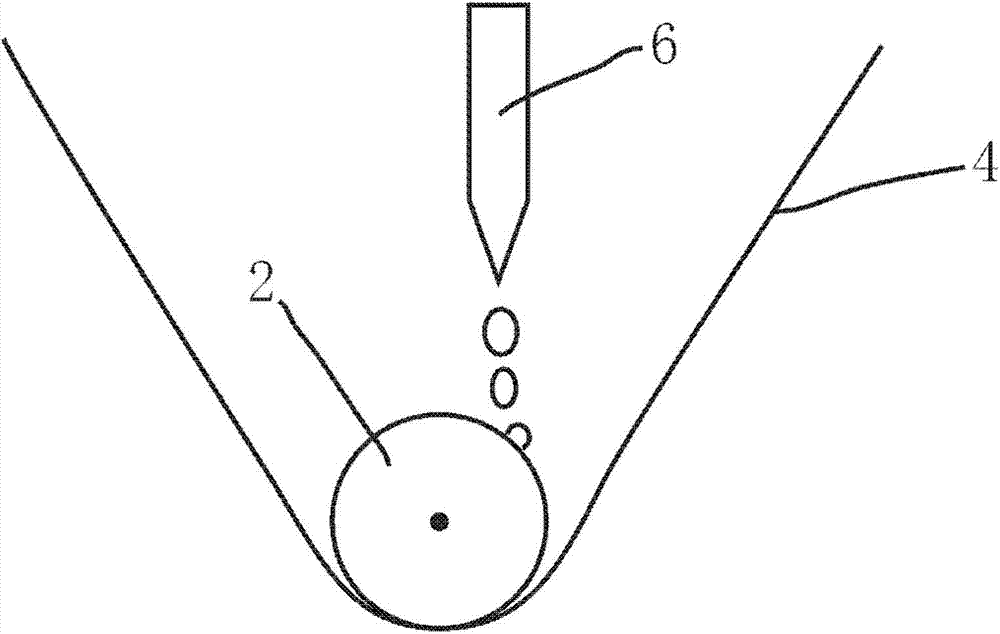

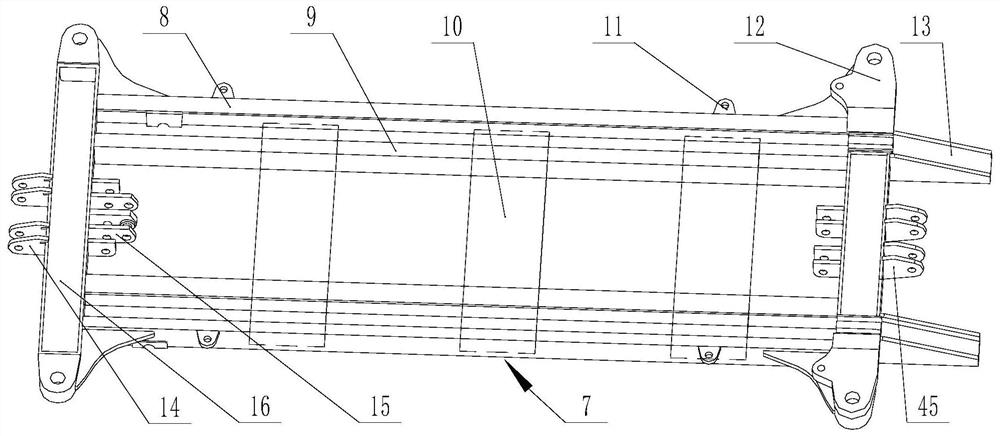

Workpiece surface wiping device and workpiece surface wiping method

InactiveCN103611694ACause scratchesQuality improvementCleaning using toolsArticle deliveryEngineeringMechanical engineering

Owner:株式会社雷恩工业

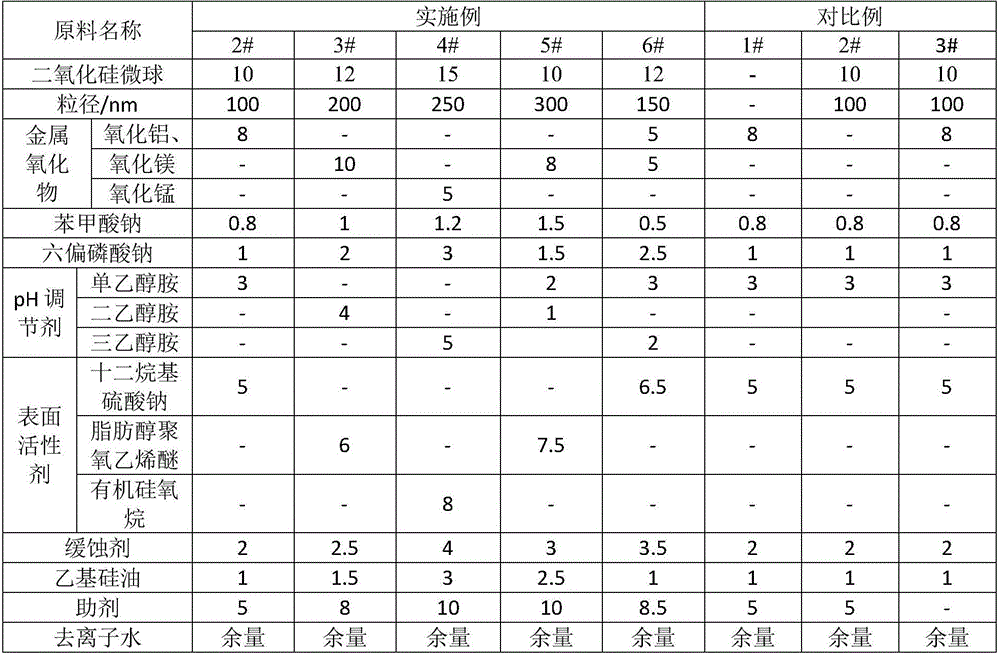

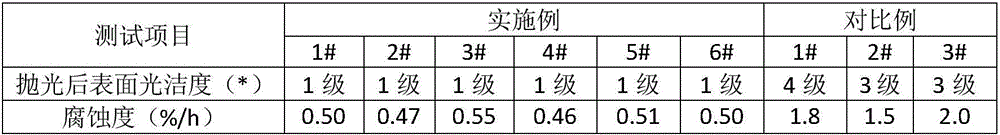

Polishing solution for stainless steel surface machining

InactiveCN106318220AModerate hardnessImprove stress resistancePolishing compositions with abrasivesSurface-active agentsSilicon dioxide

The invention belongs to the technical field of materials, and particularly relates to a polishing solution for stainless steel surface machining. The polishing solution is prepared from, by weight, 10-15 parts of modified silicon dioxide pellets, 5-10 parts of metallic oxide, 0.5-1.5 parts of sodium benzoate, 1-3 parts of sodium hexametaphosphate, 3-5 parts of a pH conditioning agent, 5-8 parts of a surface active agent, 2-4 parts of a corrosion inhibitor, 1-3 parts of ethyl silicon oil, 5-10 parts of auxiliaries and the balance deionized water. The prepared polishing solution is easy to prepare, low in cost, good in polishing effect and high in polishing precision and polishing efficiency, and has the advantages of removing oil stain, resisting rust, being easy to clean and non-toxic, doing no harm to human bodies or environment and being suitable for large-scale production.

Owner:JIANGSU JINYANG STAINLESS PROD

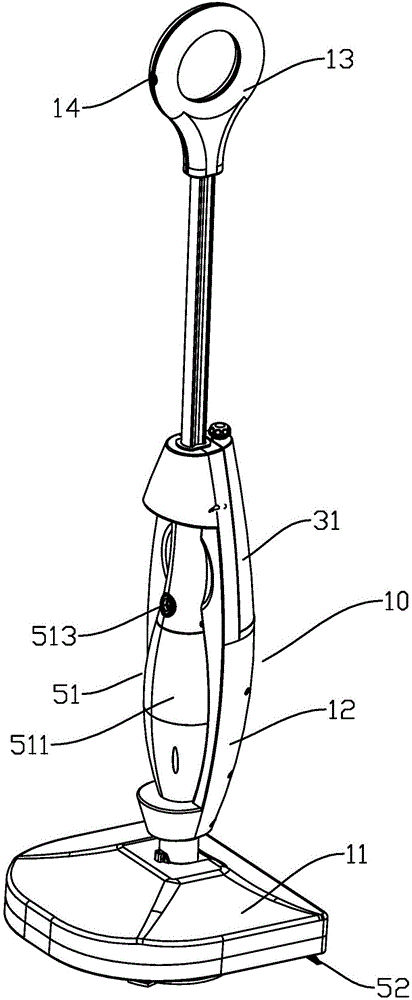

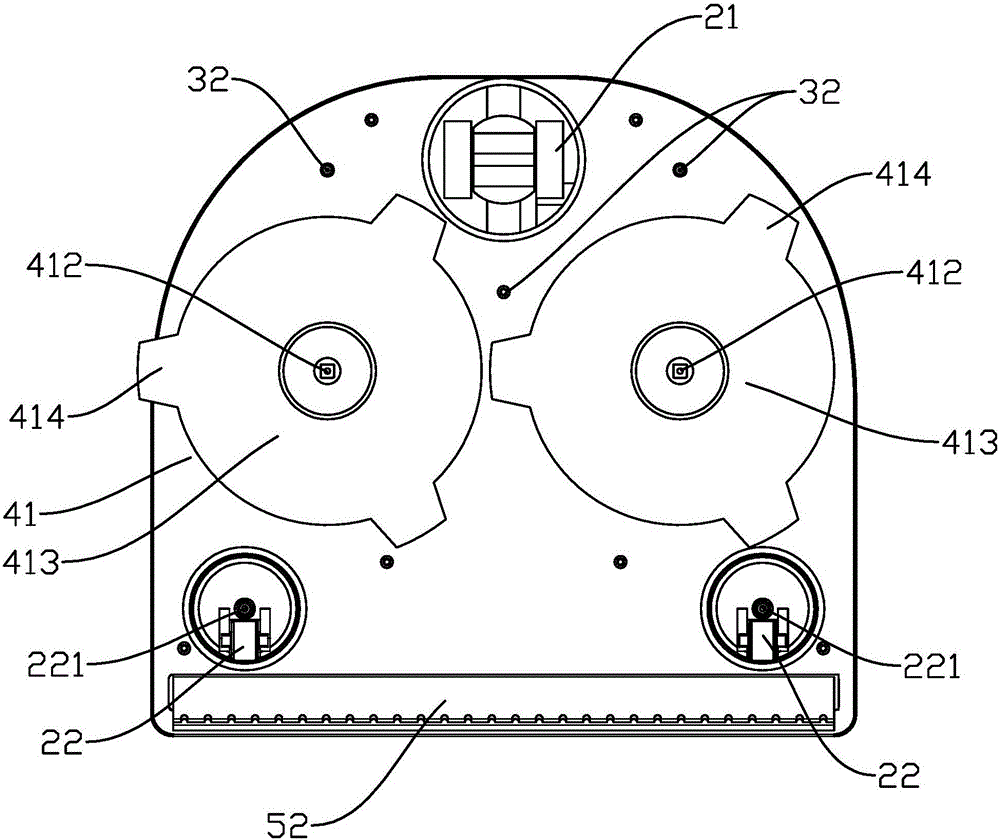

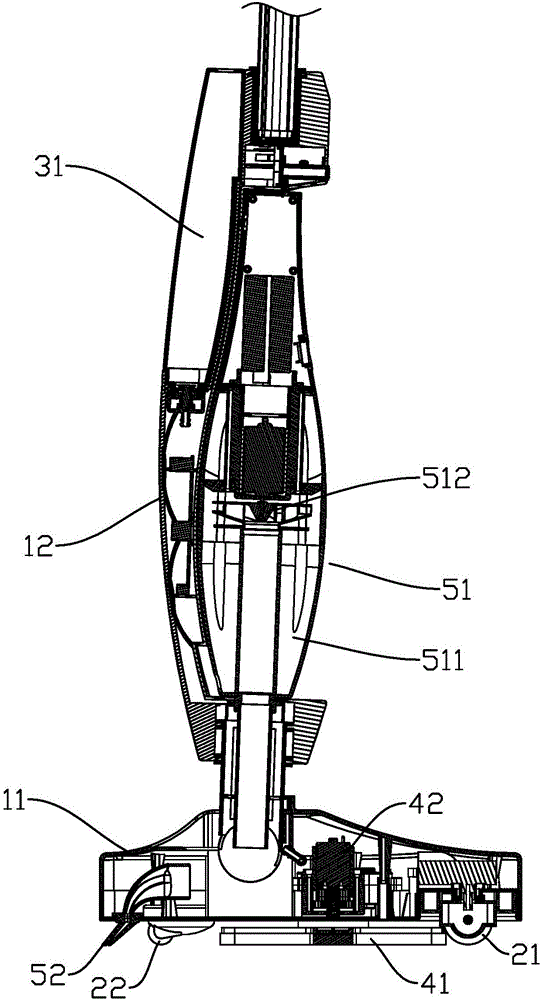

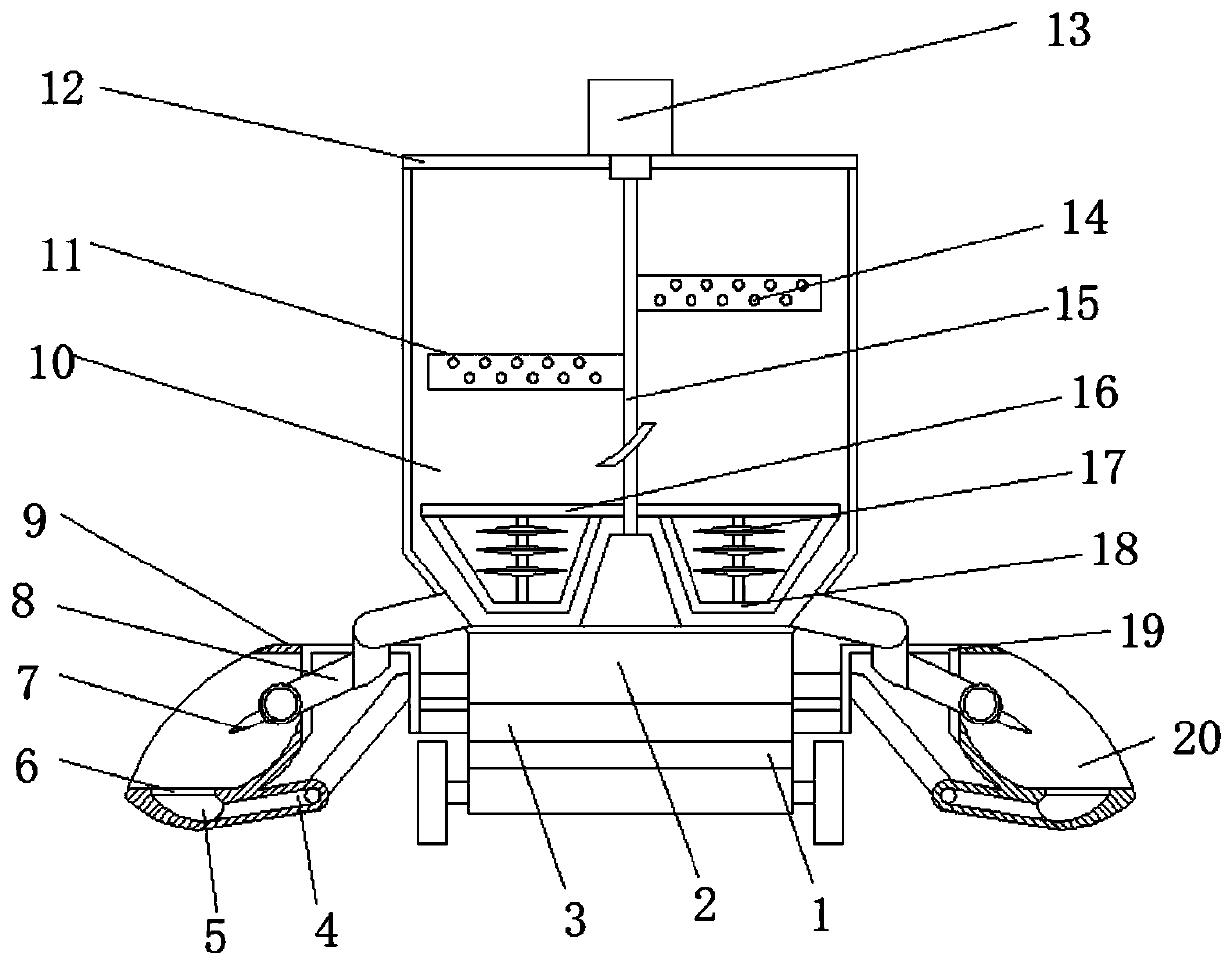

Automatic floor scrubber

InactiveCN106667382ARealize automatic wipe cleaningReduce labor intensityCarpet cleanersFloor cleanersFloor scrubberMechanical engineering

The invention discloses an automatic floor scrubber. The automatic floor scrubber comprises a basal body, a traveling device, a liquid supply device, a scrubbing device and a liquid absorbing device, wherein the traveling device is arranged on the basal body and used for driving the basal body to move forwards, the liquid supply device is arranged on the basal body and used for spraying cleaning liquid, the scrubbing device is arranged on the basal body and used for scrubbing a to-be-cleaned surface and comprises at least one cloth scrubbing part which is arranged at the bottom of the basal body and can be attached to the to-be-cleaned surface, and the liquid absorbing device is arranged on the basal body and positioned behind the scrubbing device. The automatic floor scrubber has the advantages that the automatic floor scrubber is simple in structure and is capable of achieving scrubbing cleaning automatically without being pushed by a user to move, thereby being lower in labor strength and convenient to use; with the aid of the cloth scrubbing parts, the flat to-be-cleaned surface such as wooden floor and ceramic tile floor can be scrubbed without being scratched, so that scrubbing cleanliness can be improved effectively; the automatic floor scrubber is particularly suitable for families and small commercial tenants and fills the blank of floor scrubbers in the household field.

Owner:朱厚林

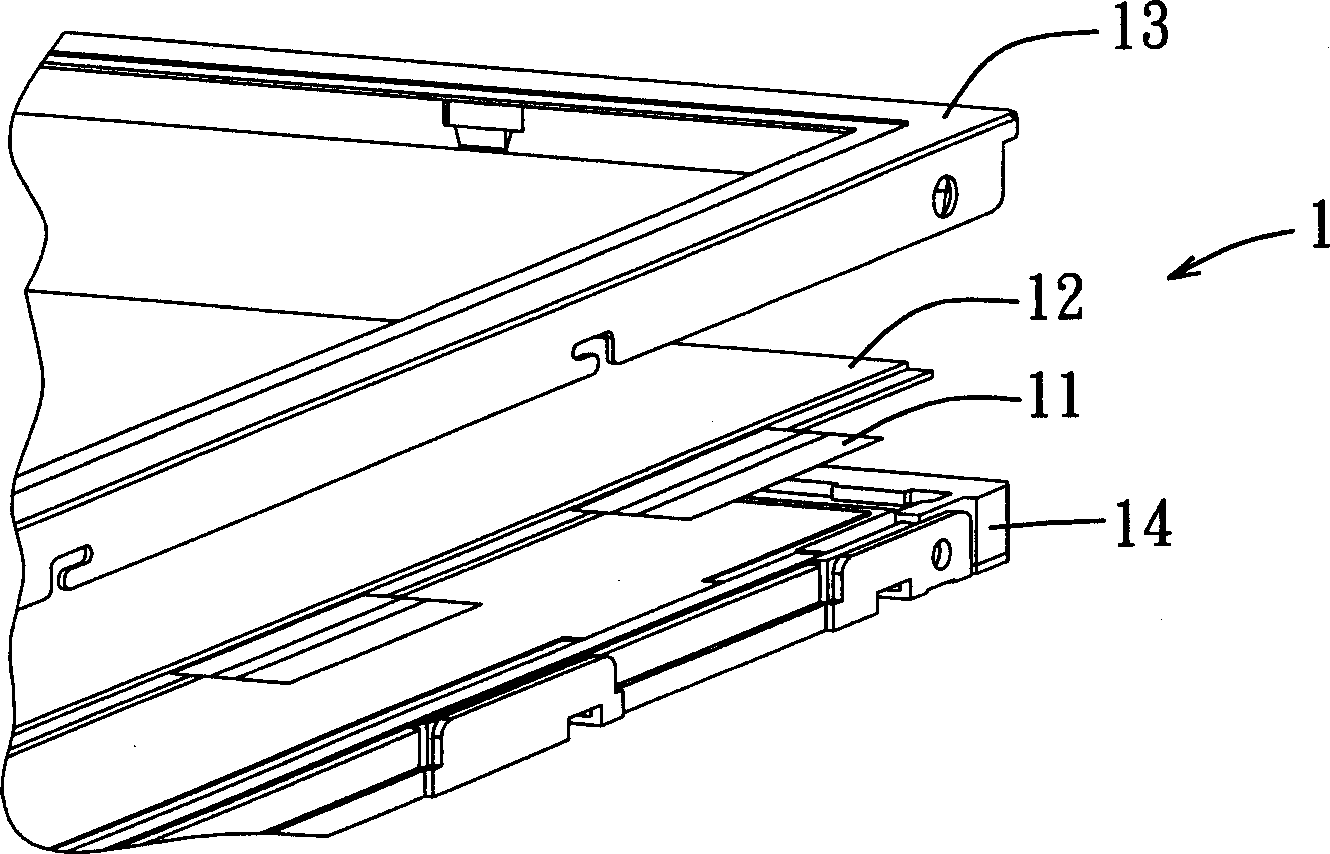

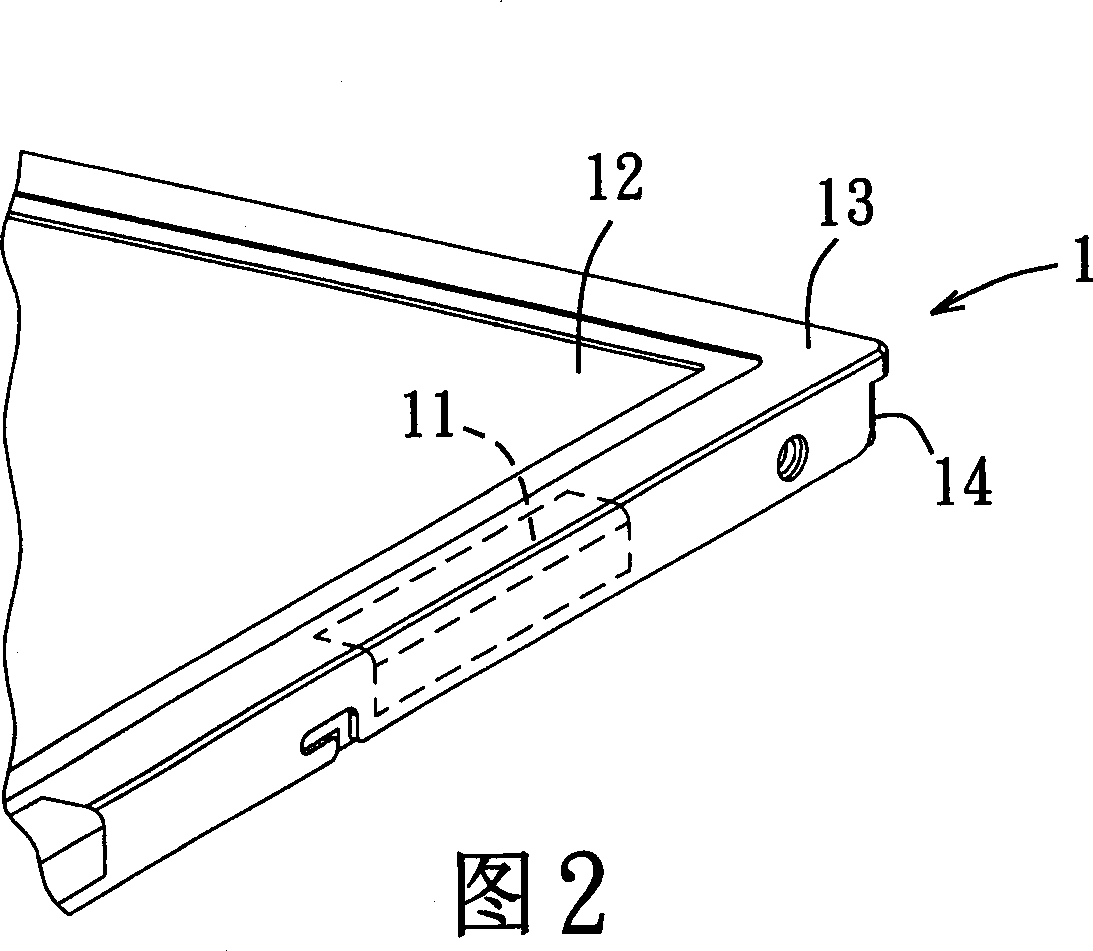

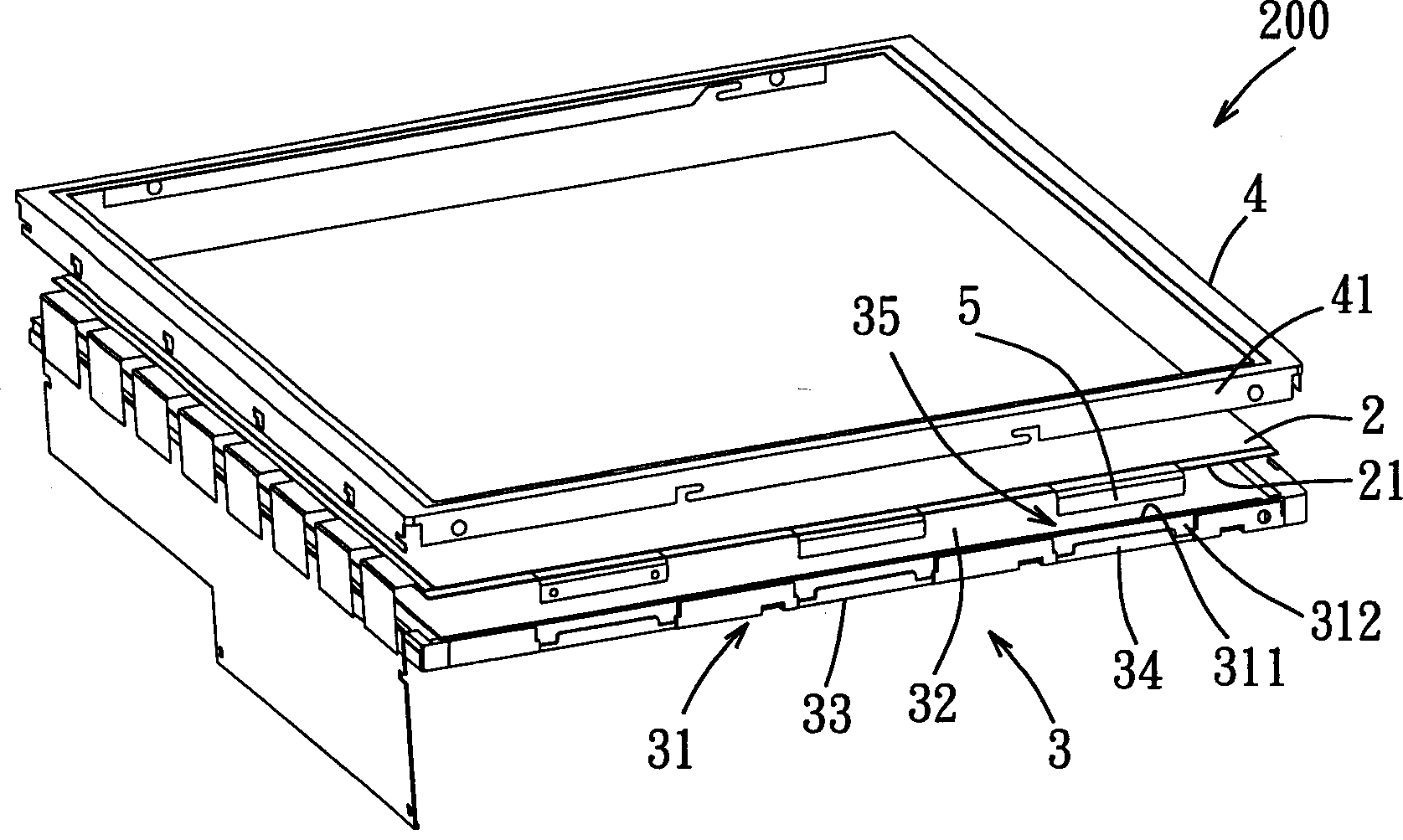

Liquid crystal panel module with coated film limiting device

InactiveCN1815307ACause scratchesNo adverse effectsStatic indicating devicesSemiconductor/solid-state device manufacturingComputer moduleEngineering

The module includes a liquid crystal faceplate, a base, and an outline border bonded the base. Multiple pieces of polycrystalline film with spacer connected electrically are installed on selected side of the liquid crystal faceplate. The base possesses accommodation space enclosed by stand-up sidewalls for the liquid crystal faceplate to be placed. Position-limited parts are setup at outside of the vertical sidewalls corresponding to places, where pieces of polycrystalline film are installed. Multiple pieces of polycrystalline film are bent and constrained on position limited parts so that in procedure of assembling module, pieces of polycrystalline film will not be scratched caused by pressing outline border together. Therefore, unflavored influence on polycrystalline film in assembled module caused by vibration of force can be avoided, so as to raise ratio of fine products.

Owner:CHUNGHWA PICTURE TUBES LTD

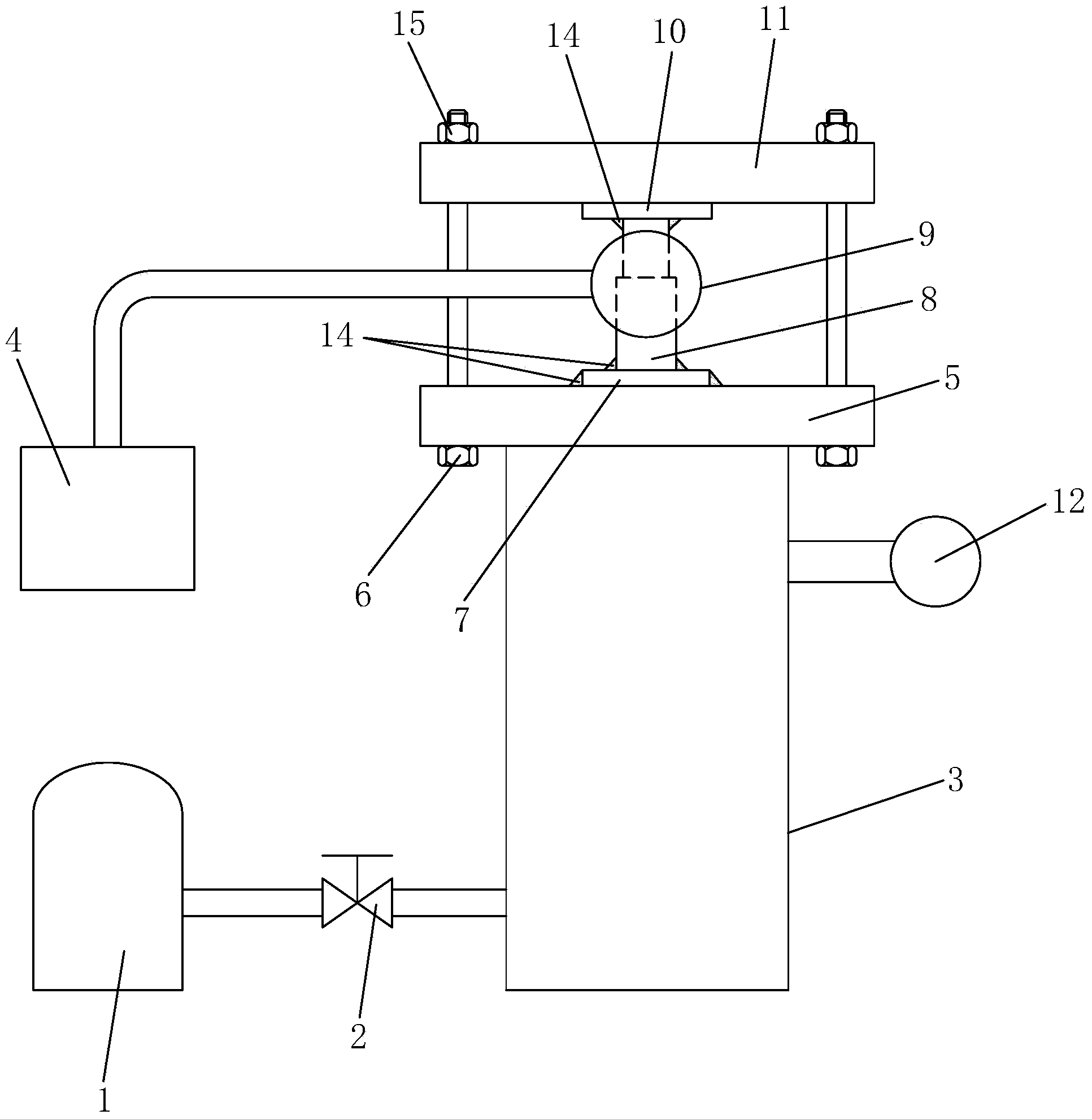

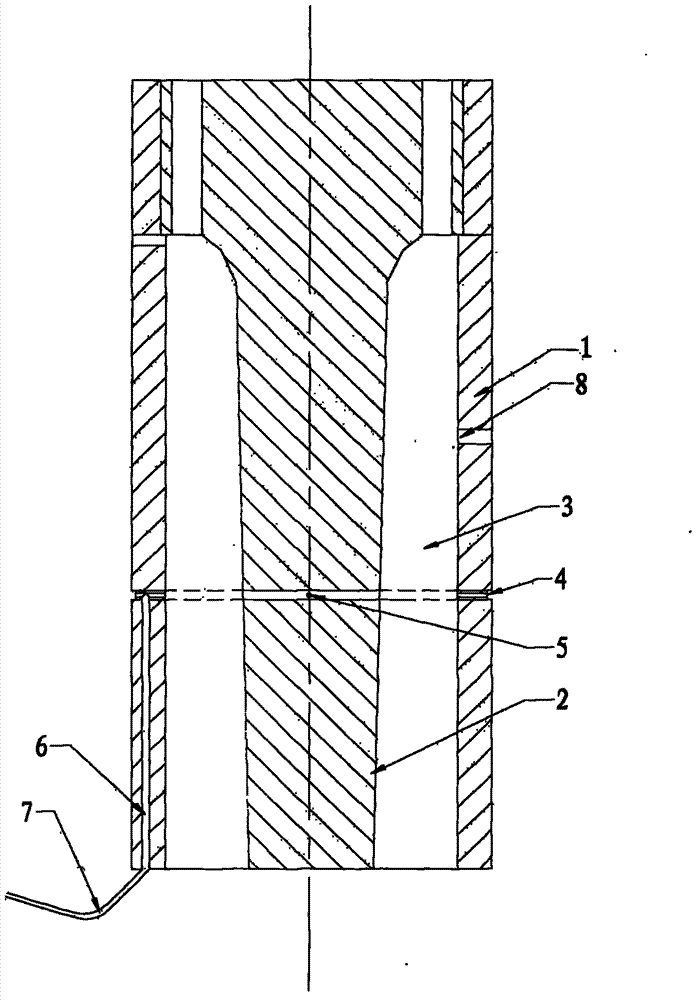

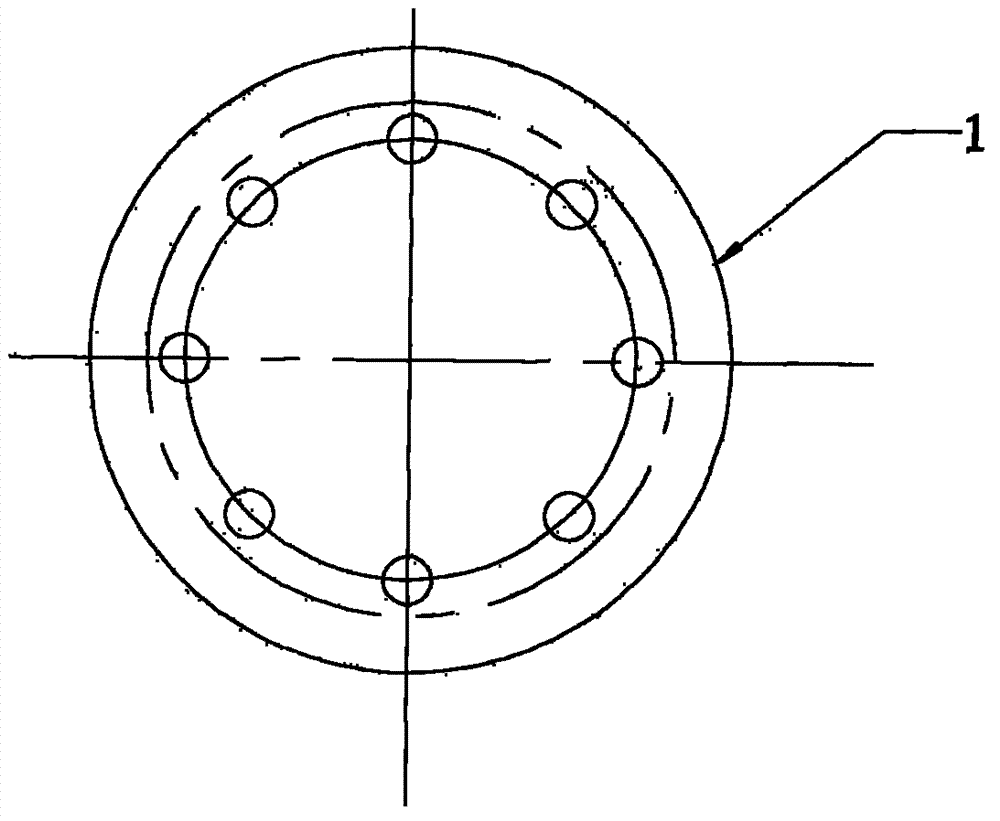

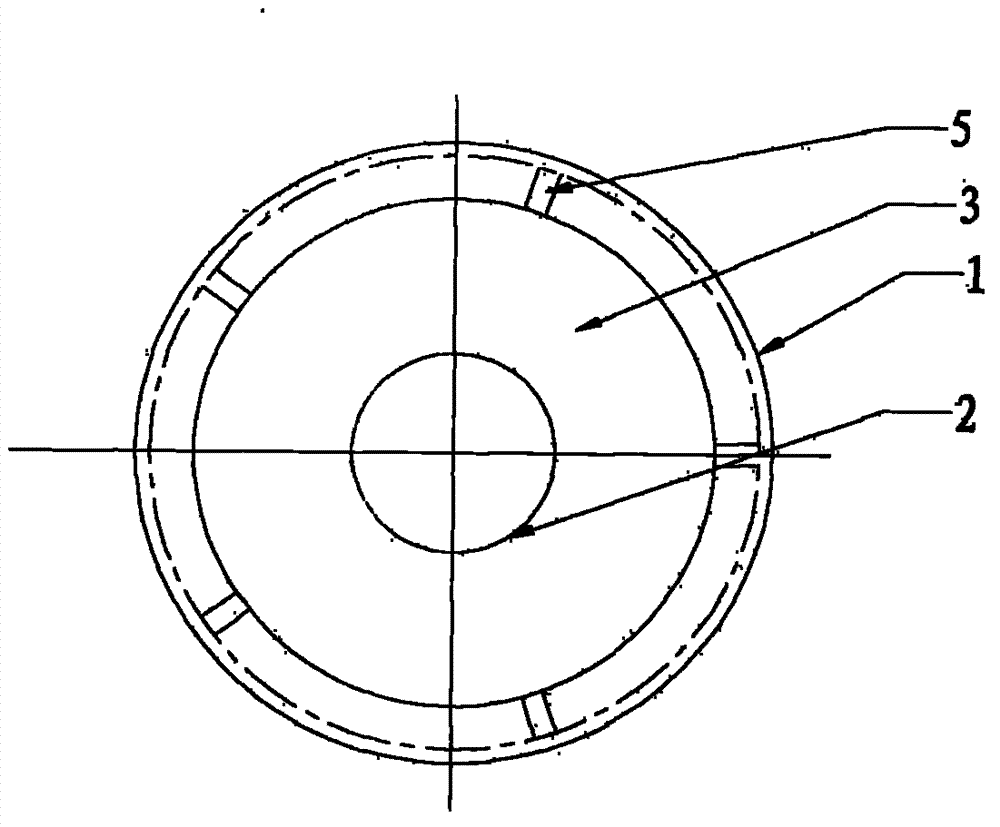

Pipe joint leakage detector

ActiveCN104075855ASimple structureReasonable designDetection of fluid at leakage pointBuffer tankMass spectrometry

The invention discloses a pipe joint leakage detector which comprises a helium tank, a stop valve, a buffer tank, a collecting gas bag and a helium mass spectrometer leak detector, wherein an outlet of the helium tank is connected with one end of the stop valve, and the other end of the stop valve is connected with an inlet of the buffer tank; a pressure meter is connected onto the buffer tank; a pipe joint connecting mechanism is arranged at the top of the buffer tank and comprises a connecting flange, a pressing plate, a first gasket and a second gasket; the connecting flange is fixed at the top of the buffer tank; the pressing plate is arranged above the connecting flange; the second gasket is arranged on the lower end surface of the pressing plate; the first gasket is arranged on the upper end surface of the connecting flange; a pipe joint is arranged between the first gasket and the second gasket; through holes are formed in centers of the connecting flange and the first gasket; the pressing plate is fixedly connected with the connecting flange through fastening pieces; the collecting gas bag is arranged outside the possible leaking part of the pipe joint in a sleeving manner; and a suction gun of the helium mass spectrometer leak detector is communicated with the collecting gas bag. The pipe joint leakage detector can detect leakage of the pipe joint and has high detection sensitivity, accuracy and efficiency.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

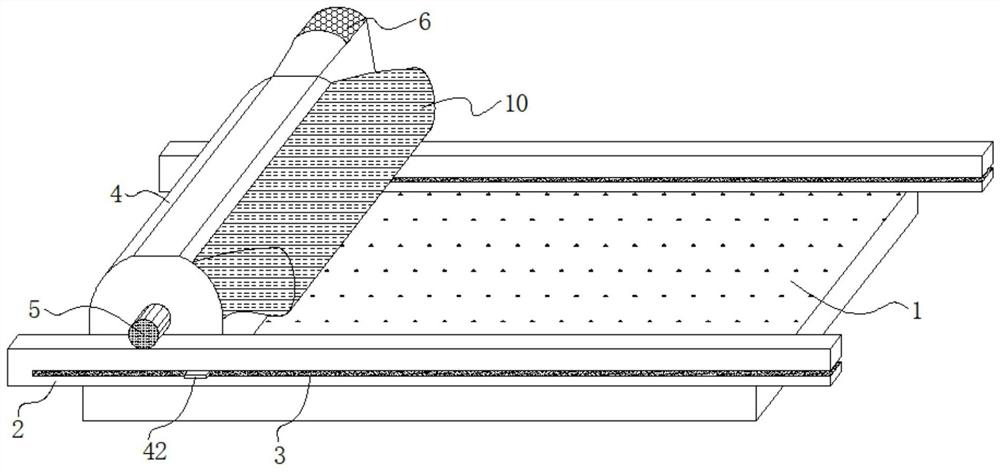

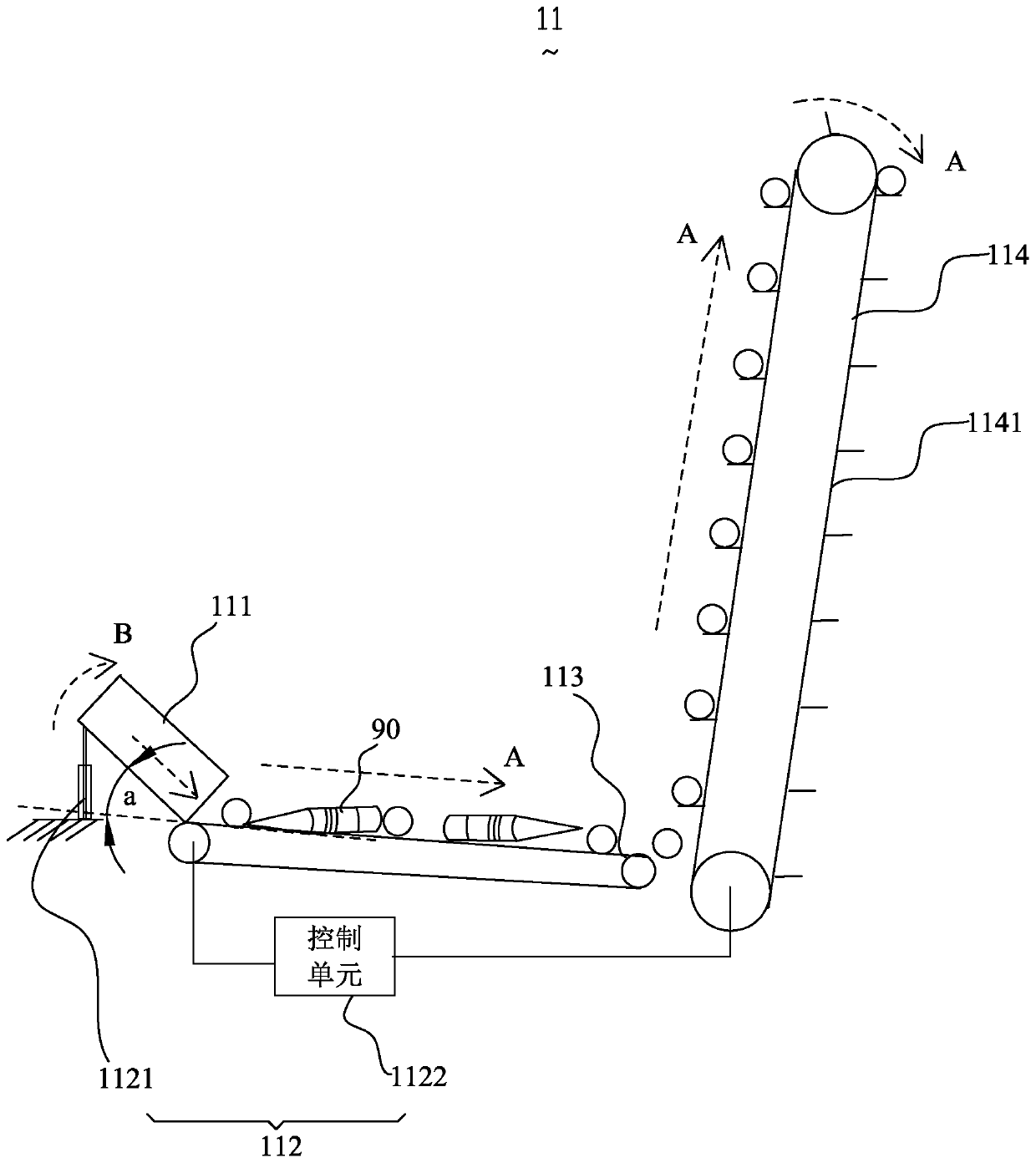

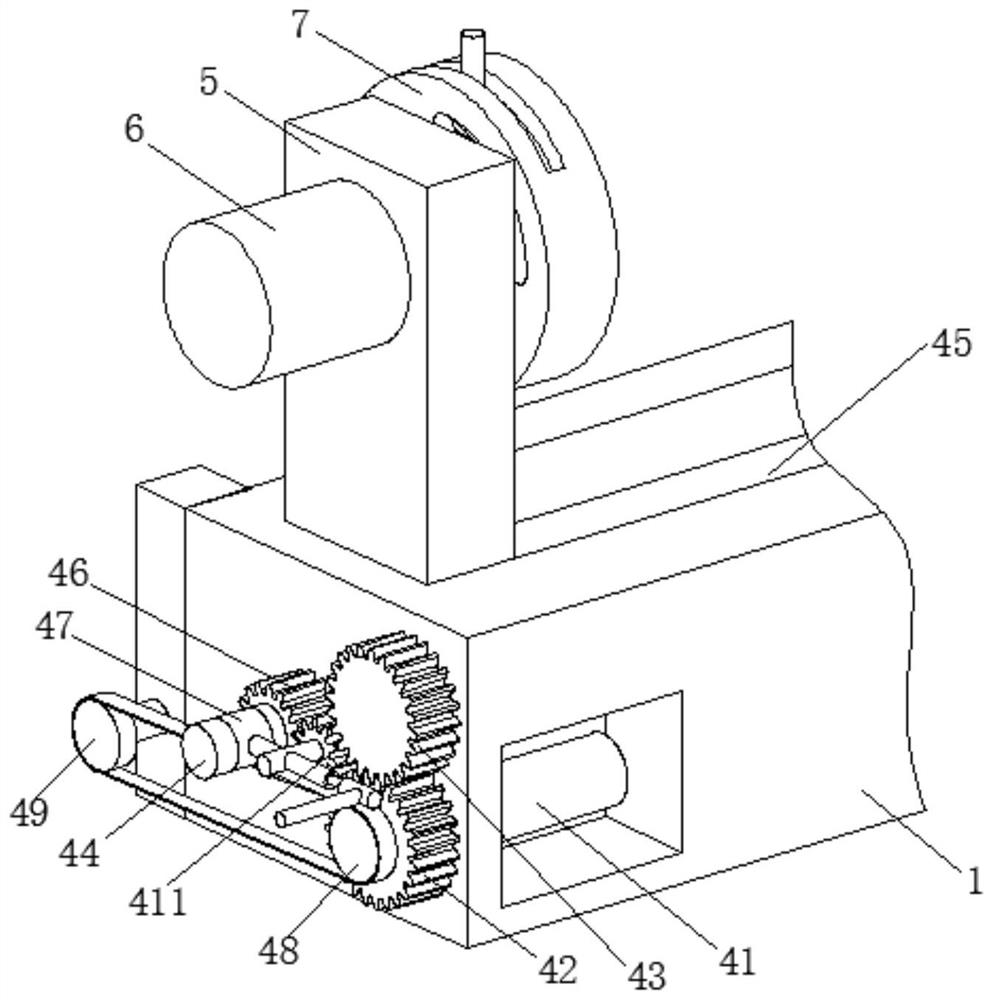

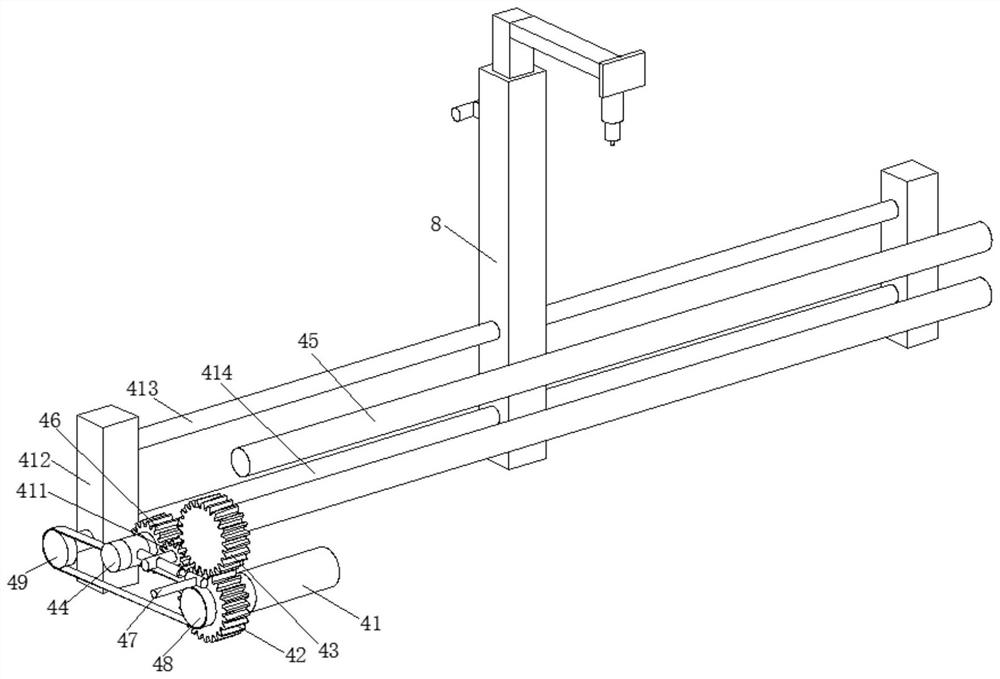

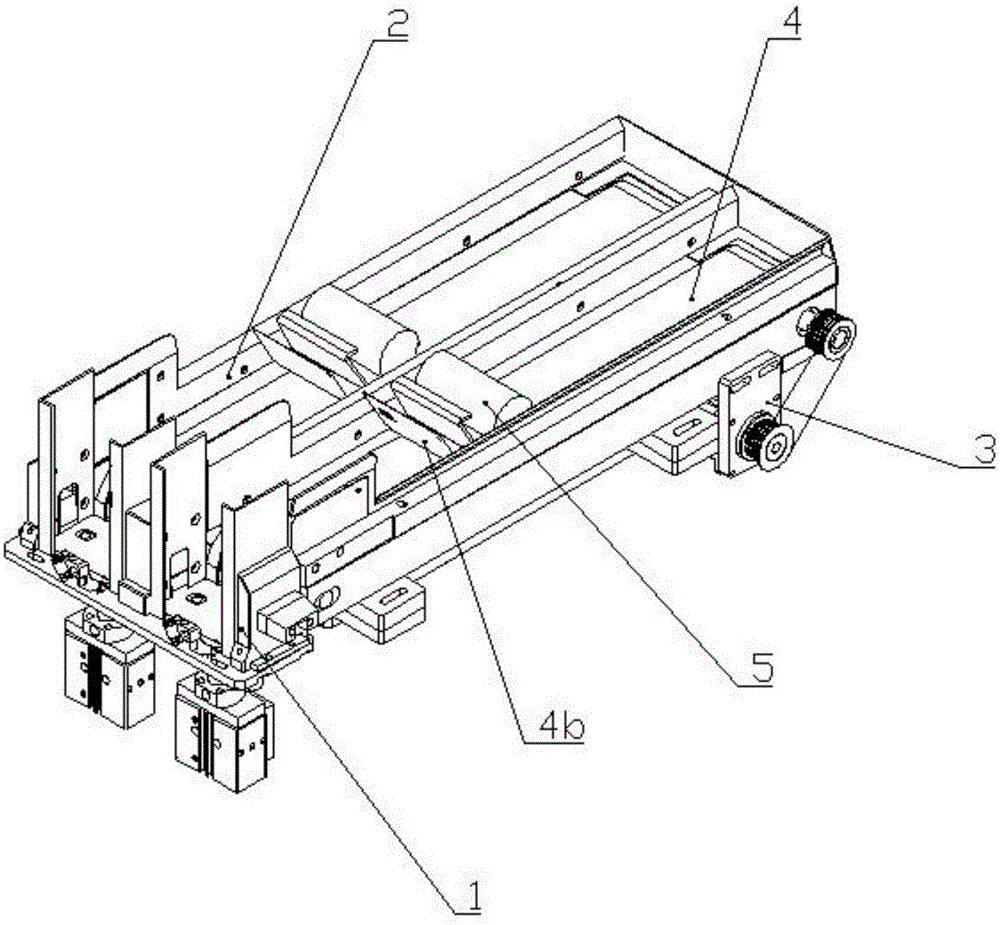

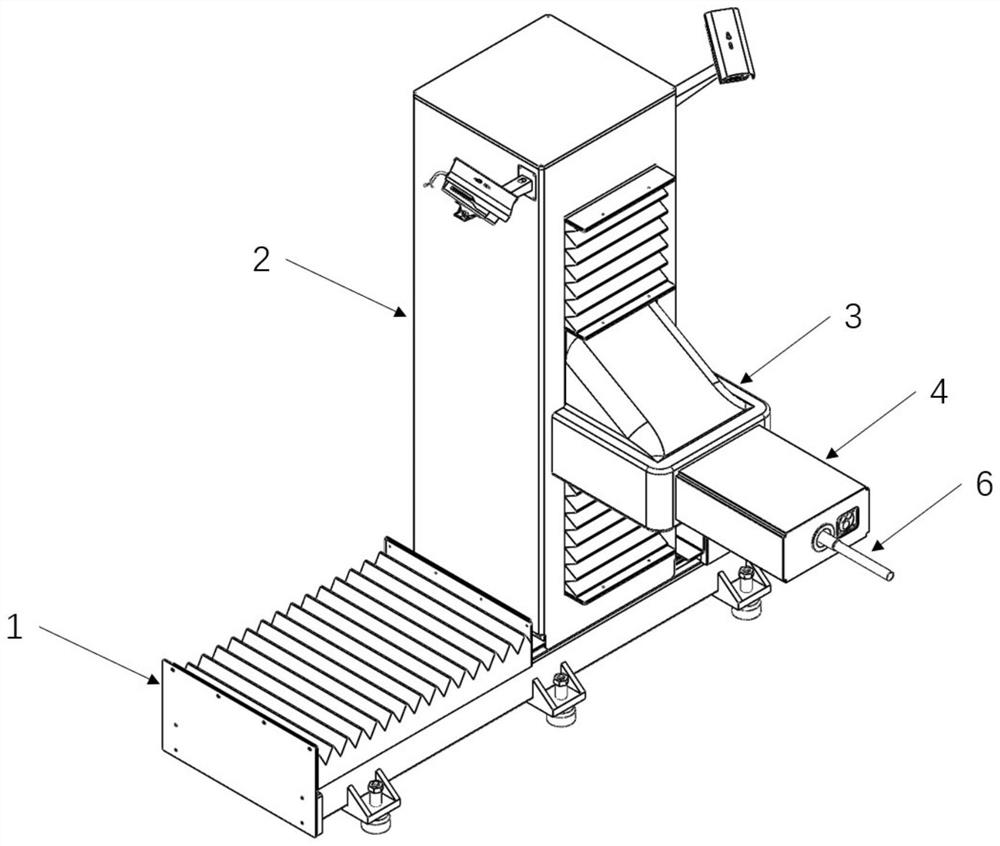

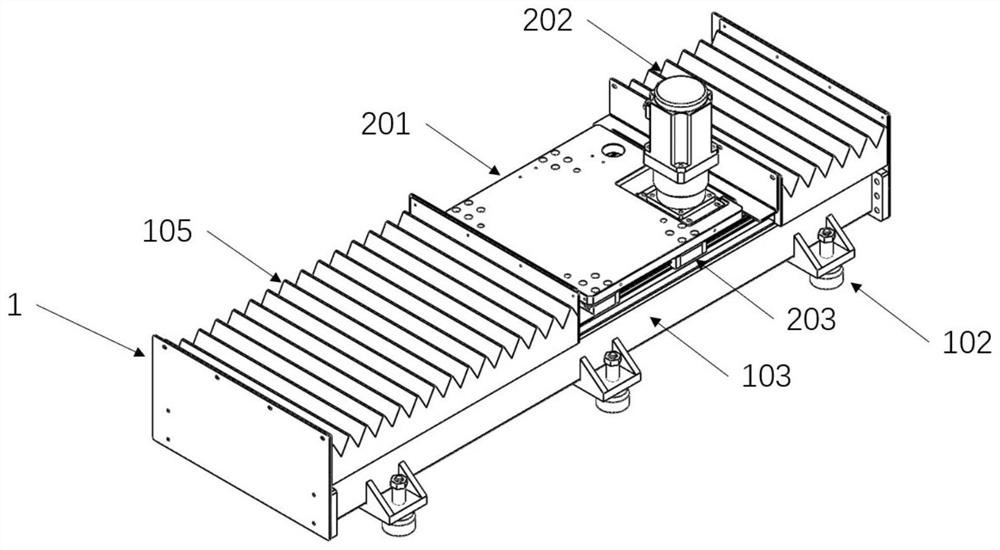

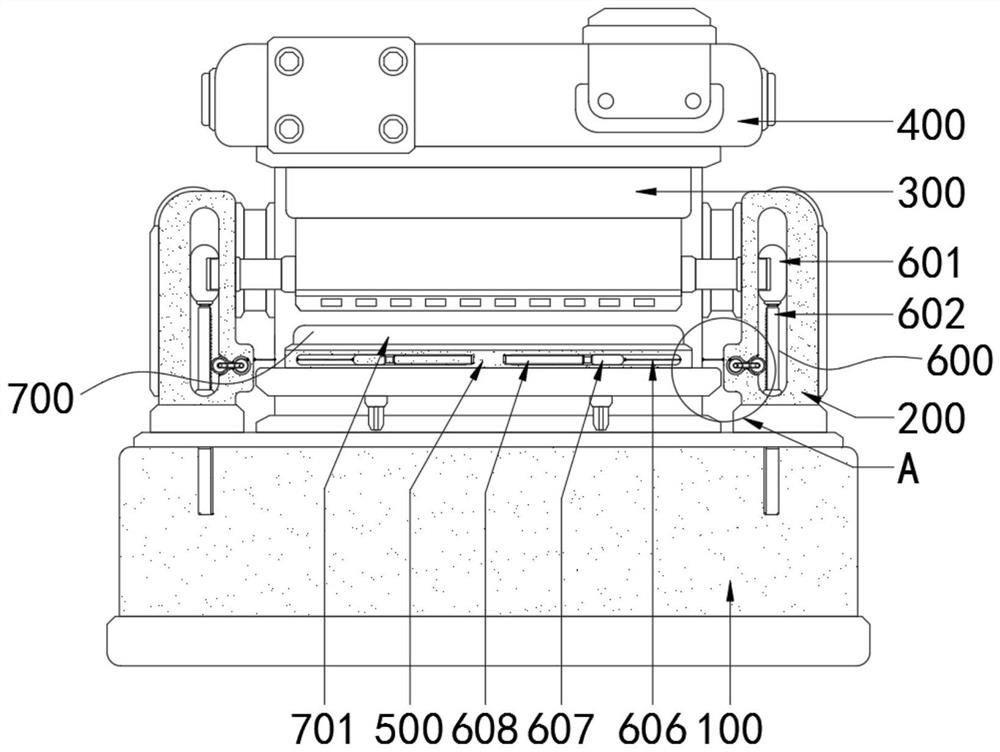

Conveying device

PendingCN108529150AEasy to adjustReduce error rateConveyor partsMechanical conveyorsEngineeringMechanical engineering

Owner:苏州优纳科技有限公司 +2

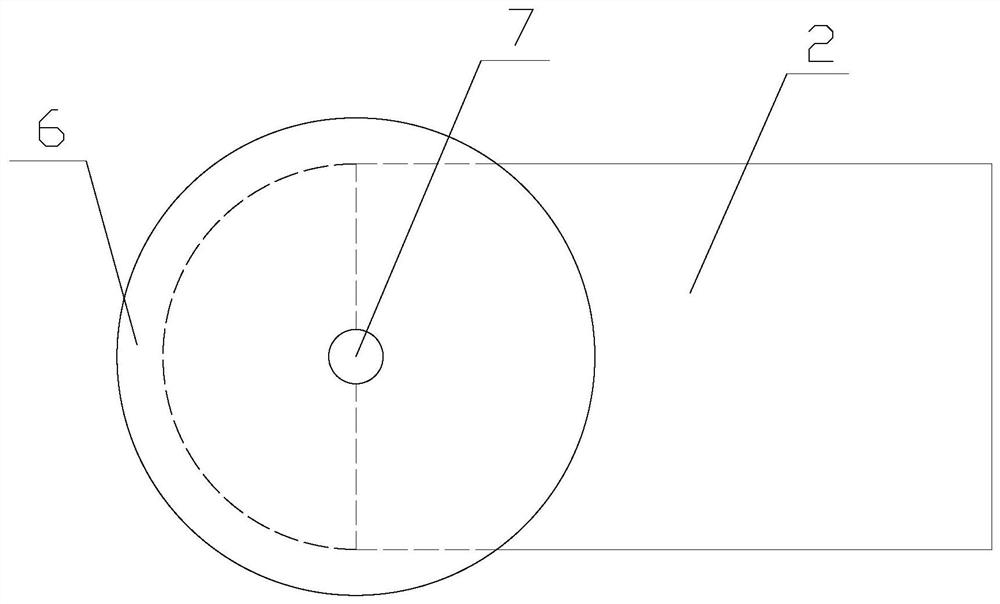

Idler wheel for conveying glass substrates

InactiveCN102689779ACause scratchesReduce defective rateSemiconductor/solid-state device manufacturingRollersEngineeringIdler-wheel

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

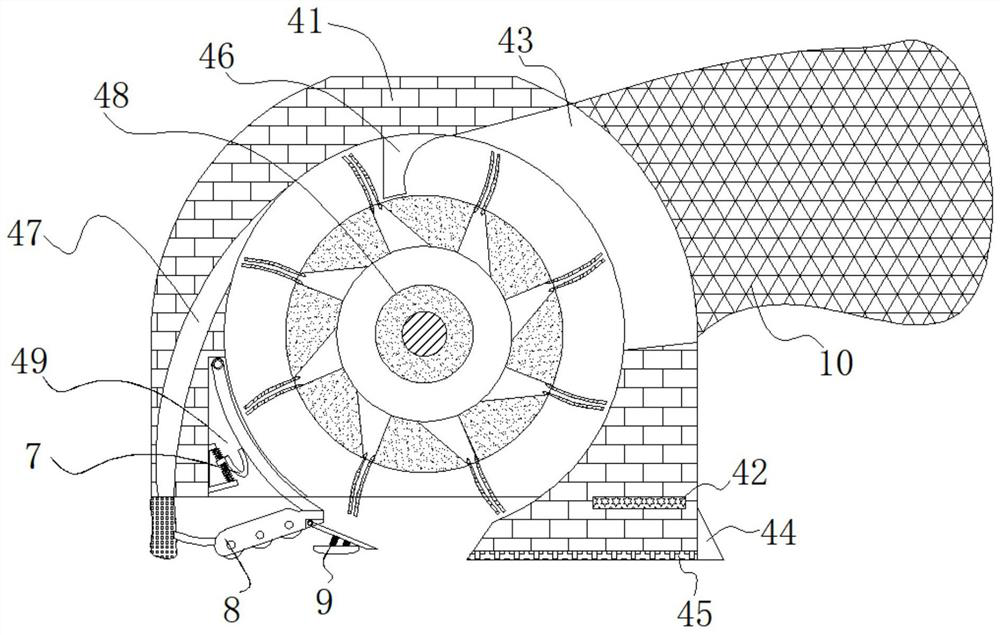

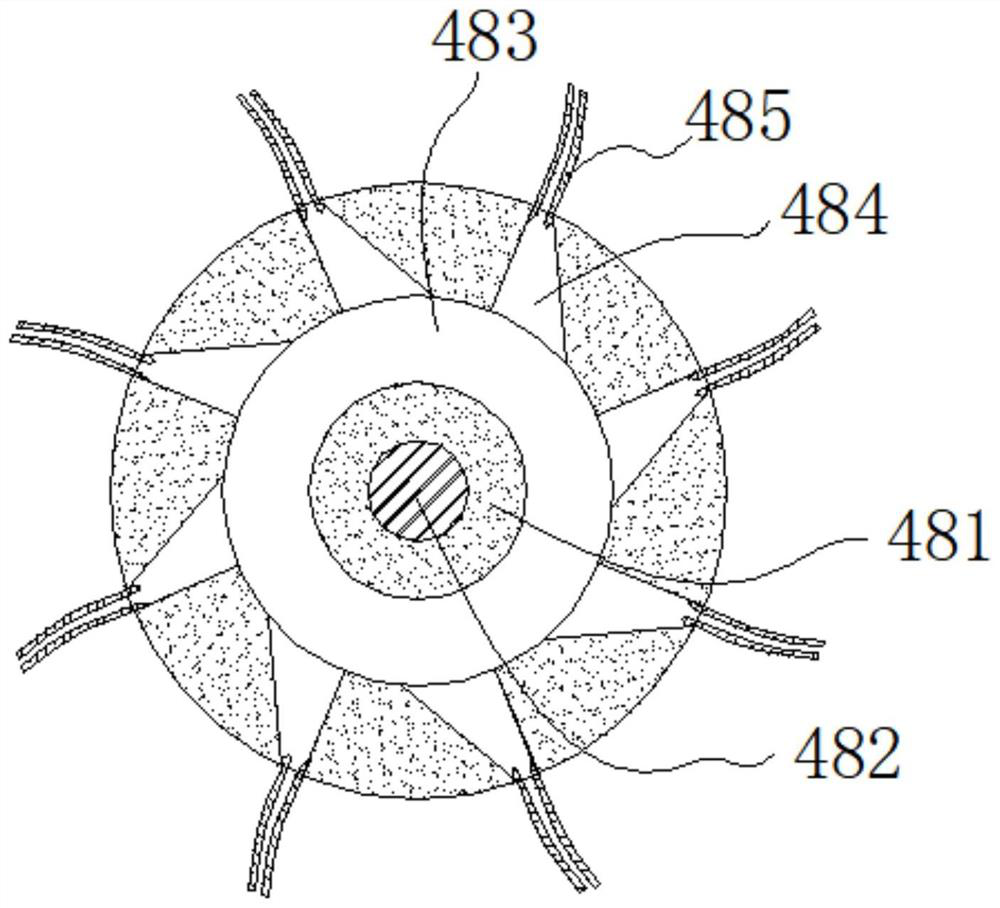

Solar photovoltaic panel dust removal device for sand and dust land

InactiveCN112620205AAvoid sand lossAvoid damageDispersed particle filtrationPhotovoltaicsEngineeringAtmospheric sciences

The invention discloses a solar photovoltaic panel dust removal device for sand and dust land, and relates to the technical field of power generation facilities. The solar photovoltaic panel dust removal device for the sand and dust land comprises a photovoltaic panel and a sand and dust removal device, wherein sliding frames are arranged at the front end and the rear end of the upper surface of the photovoltaic panel; sliding ways are formed in the front faces of the sliding frames; and the upper surface of the photovoltaic panel is in lap joint with the bottom of the sand and dust removal device. According to the solar photovoltaic panel dust removal device for the sand and dust land, a cleaning device is arranged on the sand and dust removal device, an air blower conveys strong wind power to the cavity of a rotary drum, the wind power is focused and blown into a dust removal box through air gathering holes, sand on the upper surface of the corresponding photovoltaic panel in the dust removal box can be blown up under the action of the strong wind power, the rotary drum is driven to rotate anticlockwise under the action of a motor, and sand and dust in the dust removal box are blown into a sand storage bag along with the wind direction, so that the sand and dust on the photovoltaic panel are cleaned and collected without coming into contact with the photovoltaic panel, and damage to the photovoltaic panel is avoided.

Owner:苏州波粒新能源科技有限公司

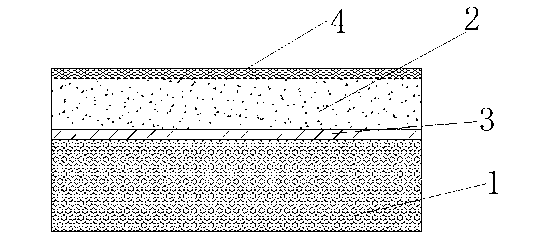

Composite leather fabric

InactiveCN103264538ACause scratchesGood hygroscopicityLayered productsTextile technologySurface layer

The invention discloses a composite leather fabric and belongs to the technical field of spinning. The composite leather fabric is formed by bonding a leather layer with a cotton fabric layer through a binder; and a PU (Poly Urethane) coating or a PVC (Poly Vinyl Chloride) coating is formed on the surface layer of the leather layer. The cotton fabric layer of the composite fabric cotton layer with the structure, provided by the invention, is fitted with the skin, and is capable of keeping warm, soft and close-fitting, and excellent in hygroscopicity and air permeability; and as the PU coating and the PVC coating is formed on the surface layer of the leather layer, the scratch of leather caused by the external environment is avoided.

Owner:KUSN ZHOUSHI TOWN JISHENG CLOTHING FACTORY

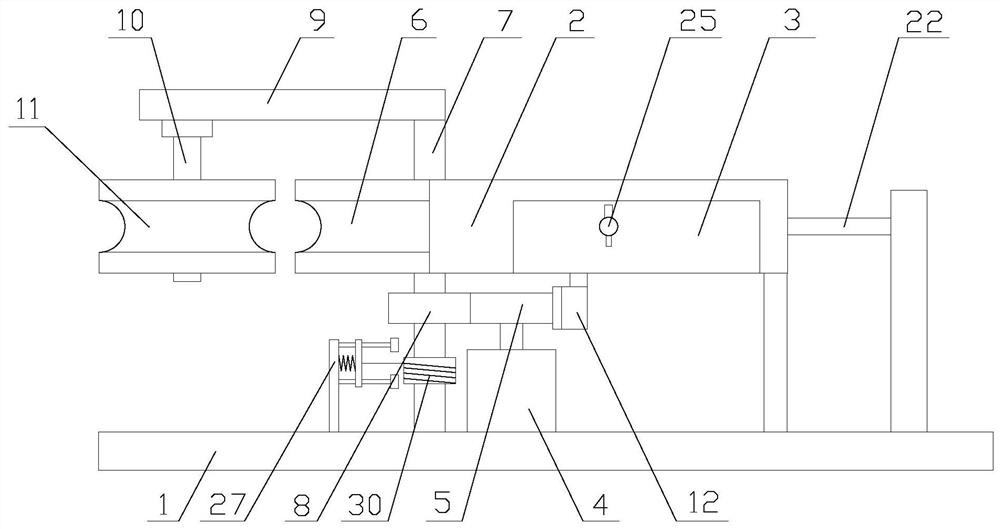

Metal pipe bending device with protection function

InactiveCN111760947AWith protective functionRealize the clamping effectMetal-working feeding devicesShaping safety devicesPipe fittingClassical mechanics

The invention relates to a metal pipe bending device with a protection function. The metal pipe bending device comprises a base, a fixing plate, a drive mechanism, a forming mechanism, a clamping mechanism and a control mechanism. According to the metal pipe bending device with the protection function, the drive assembly drives the forming mechanism to achieve bending forming of a pipe, the driveassembly drives two clamping blocks to be close to and away from each other, the workpiece is clamped and loosened, the device stops operating through the control mechanism, and operators are protected; compared with an existing bending device, according to the device, through linkage of the forming mechanism and the clamping mechanism, the pipe is more conveniently mounted and taken down; compared with an existing clamping mechanism, flexible clamping is adopted in the mechanism, and the situation that the workpiece is scratched by rigid clamping is avoided; and compared with an existing button control mechanism, a complex opening manner is adopted in the control mechanism, mis-touch is avoided, and the operators are better protected.

Owner:广州京海科技有限公司

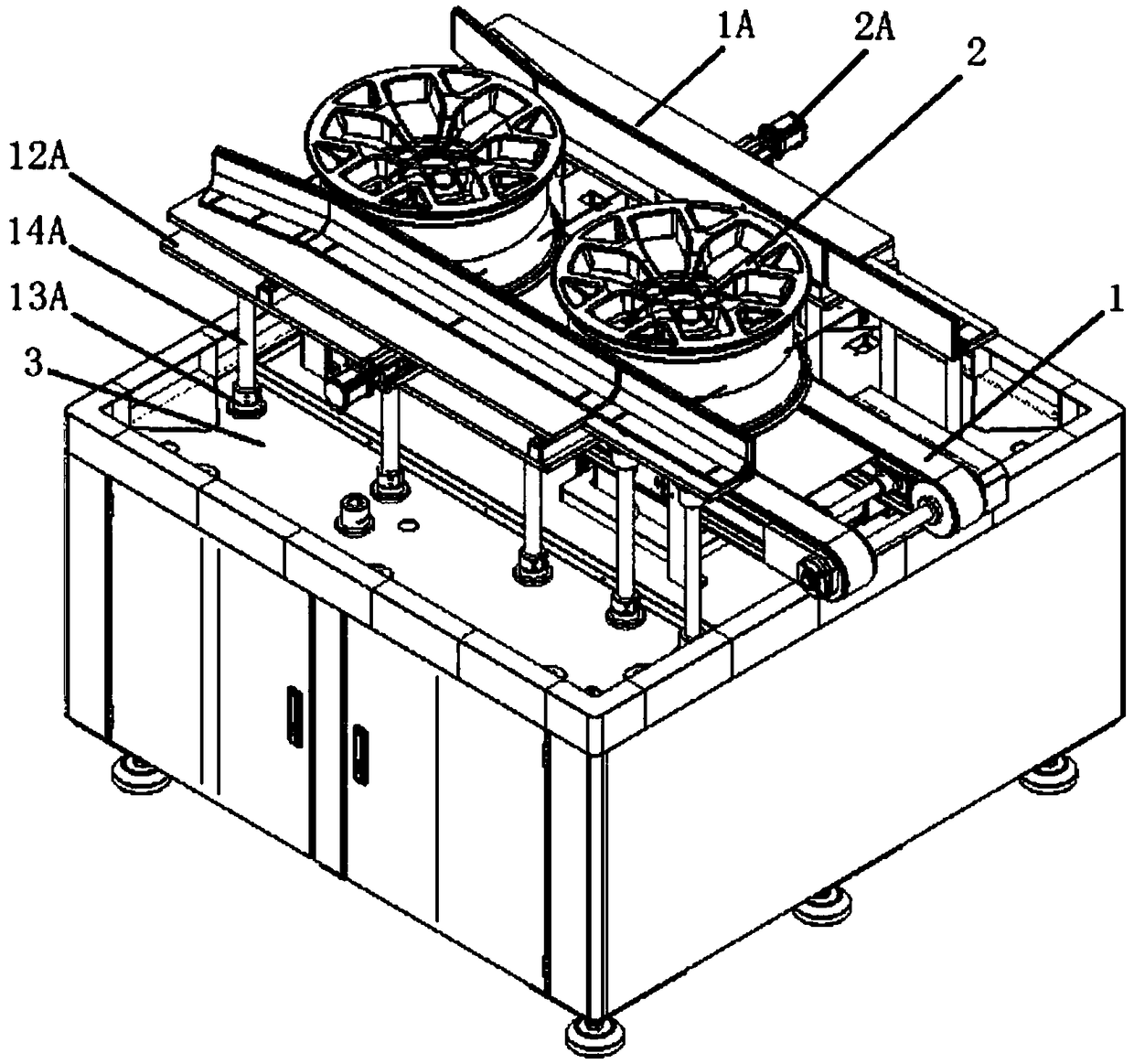

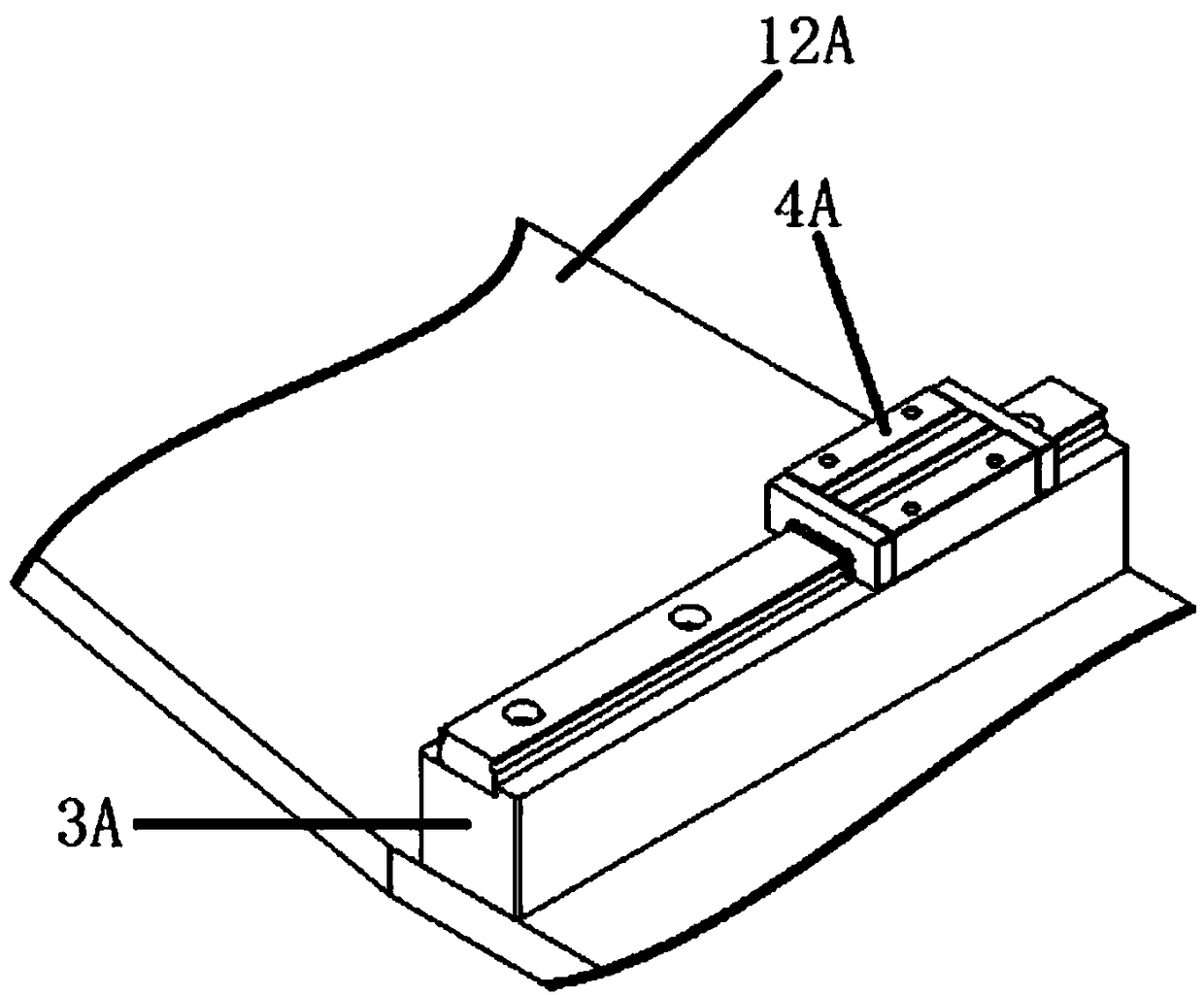

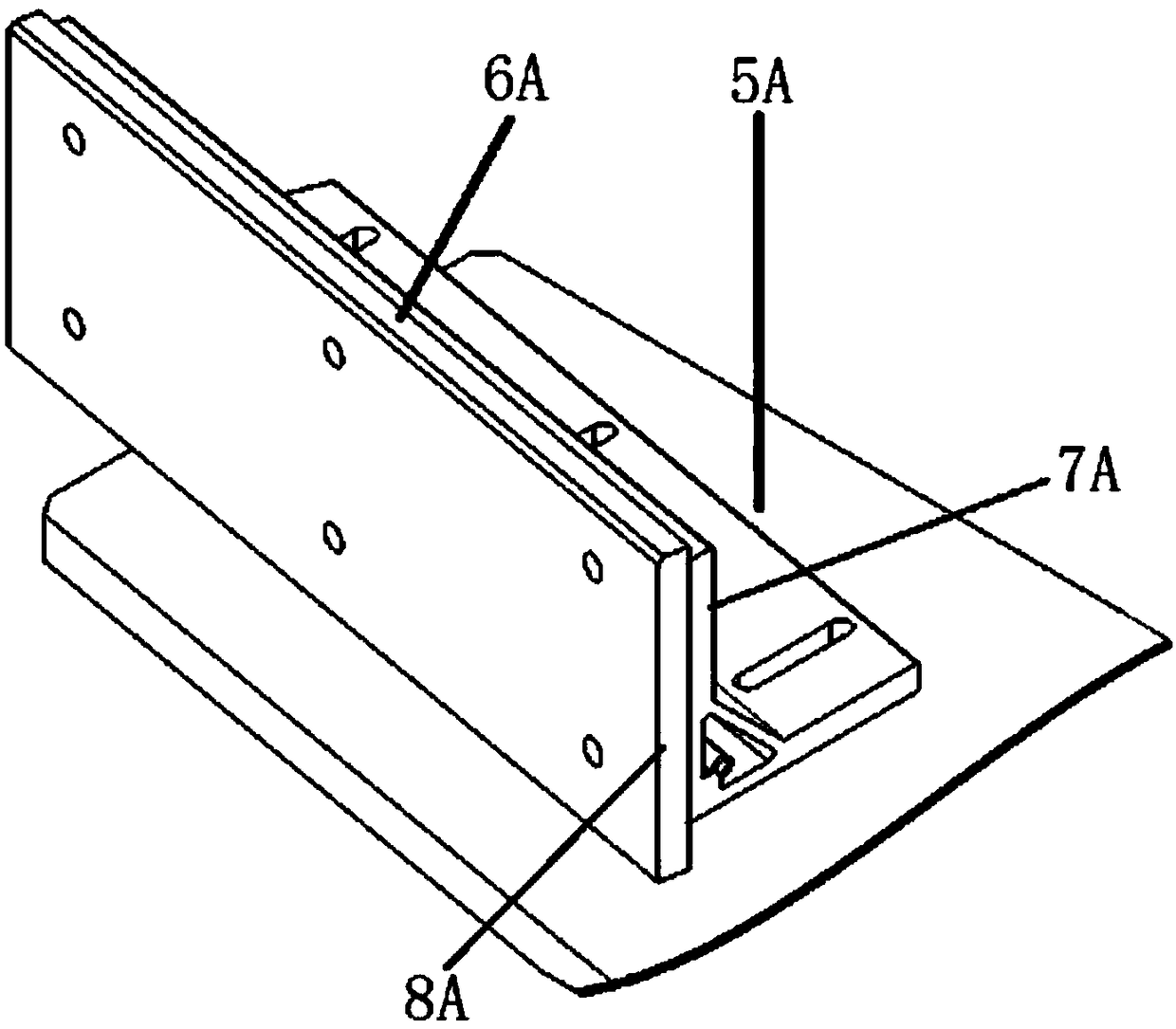

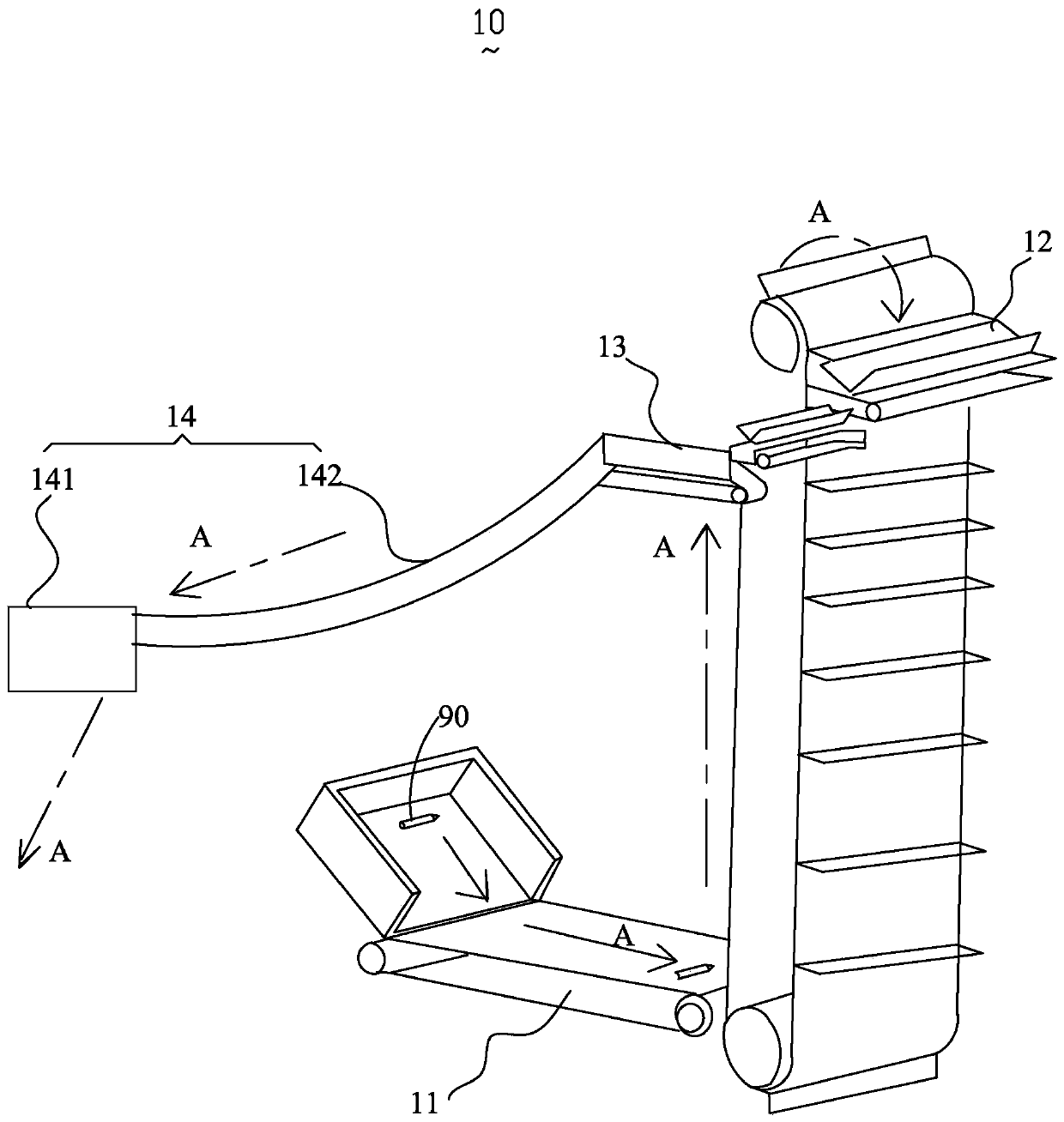

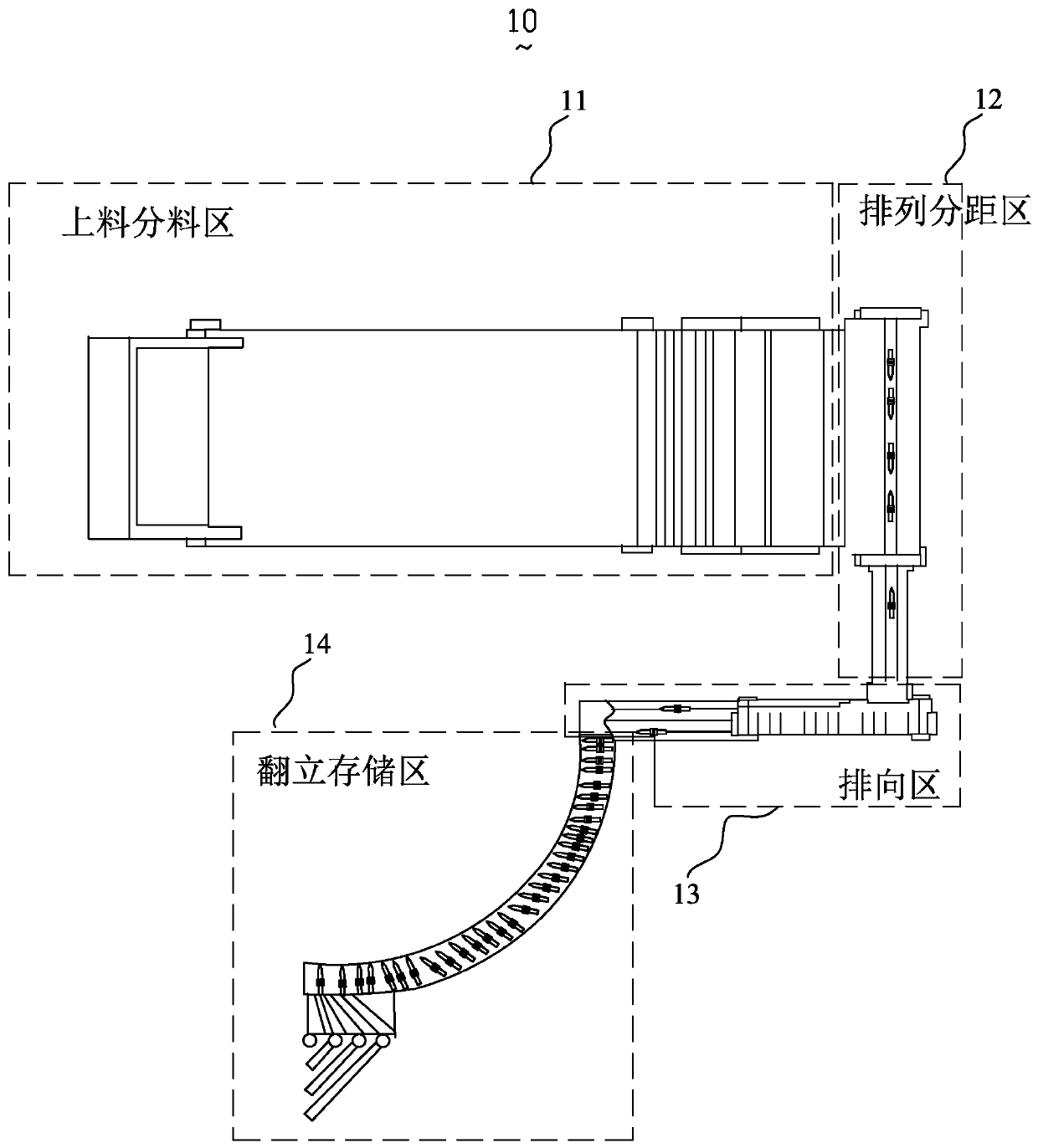

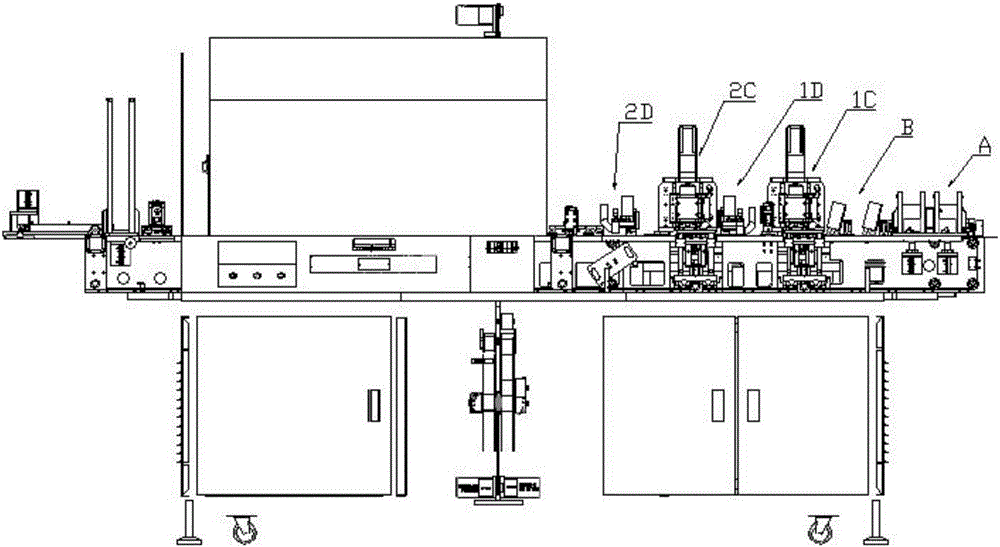

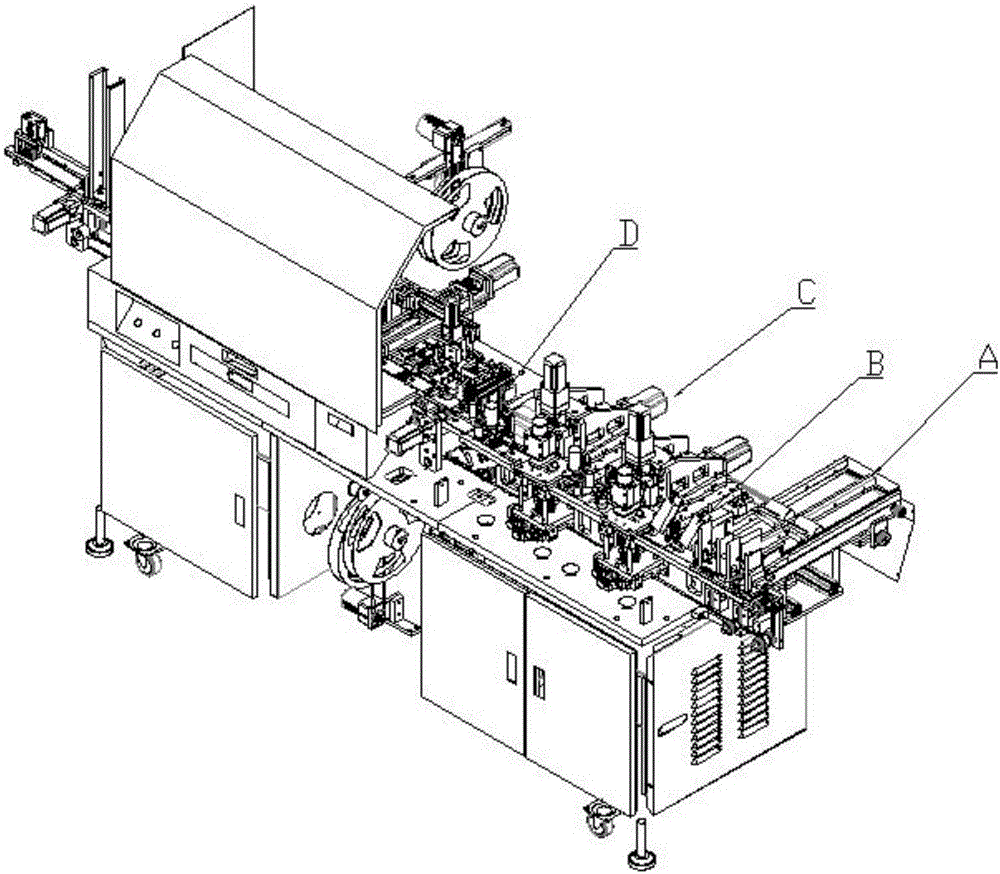

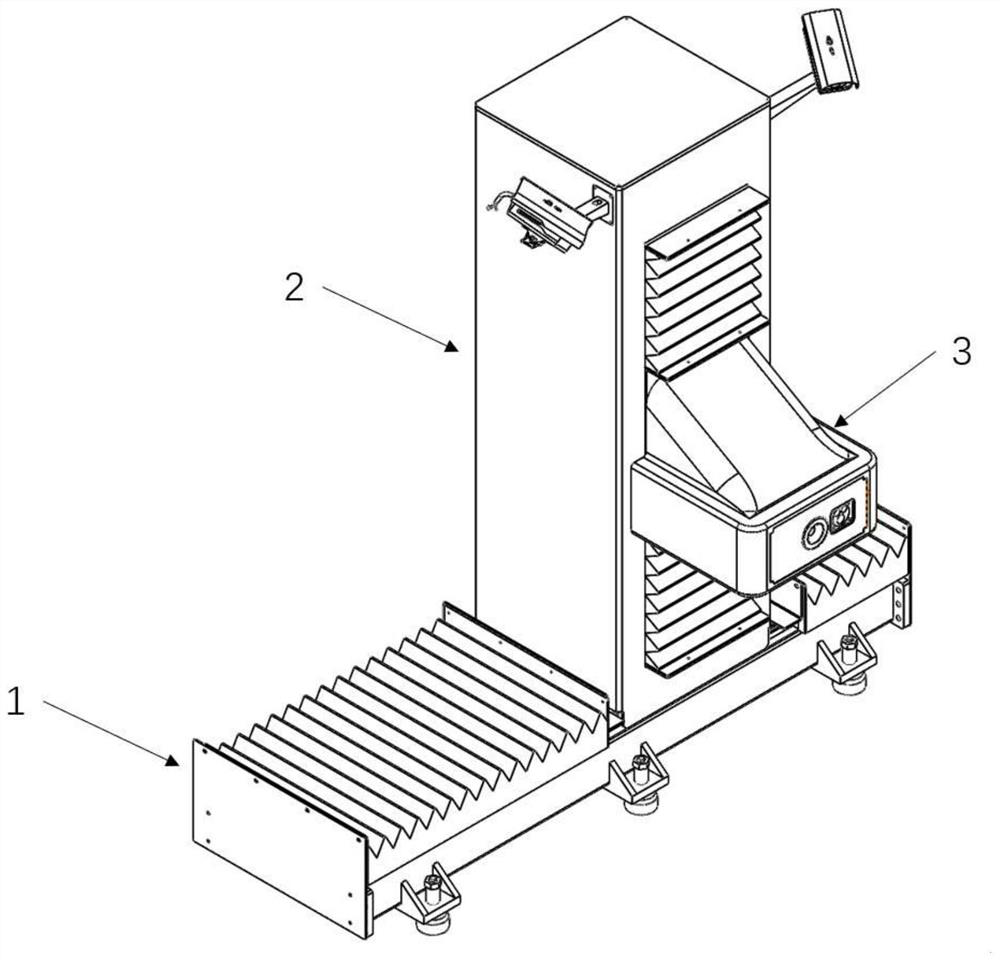

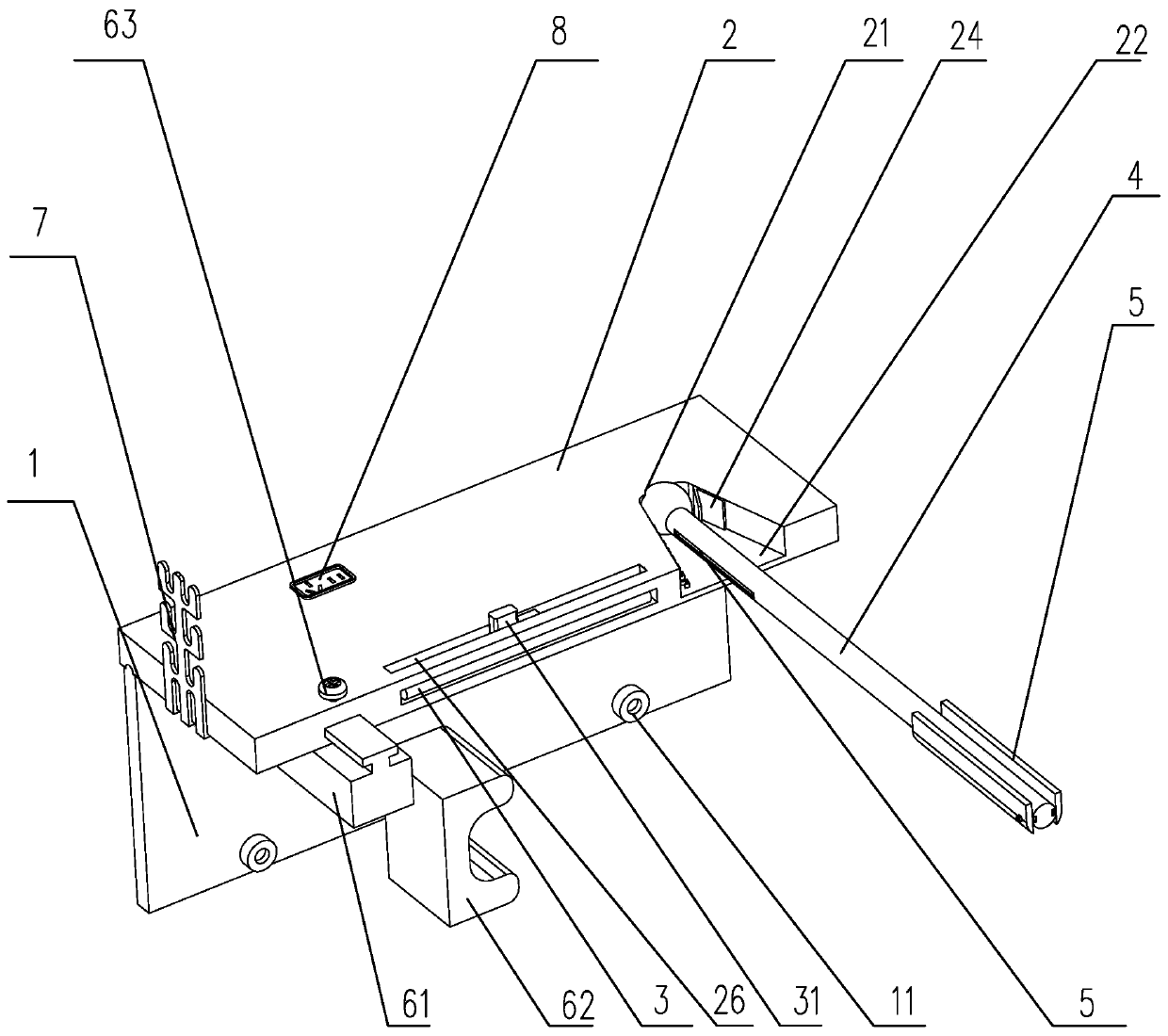

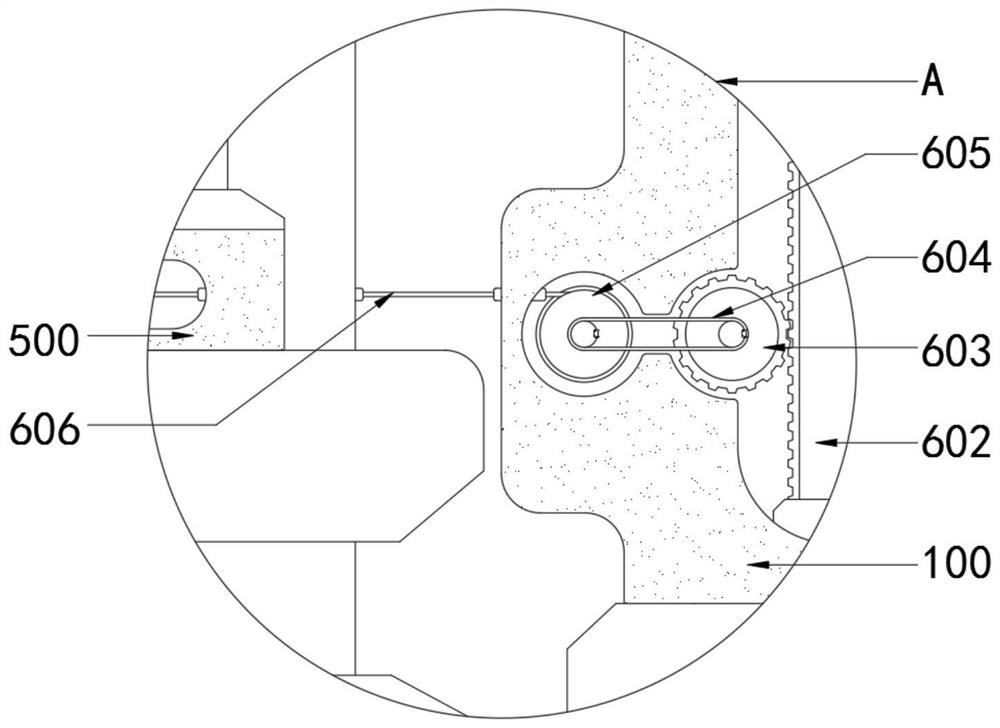

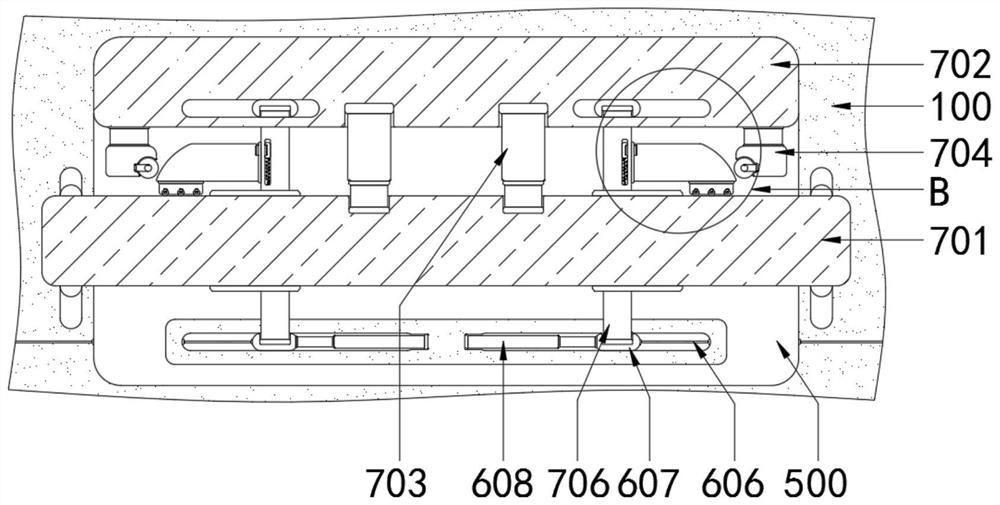

Workpiece feeding, arranging and direction arranging device and technology

Owner:SHENZHEN FUYUNDI TECH

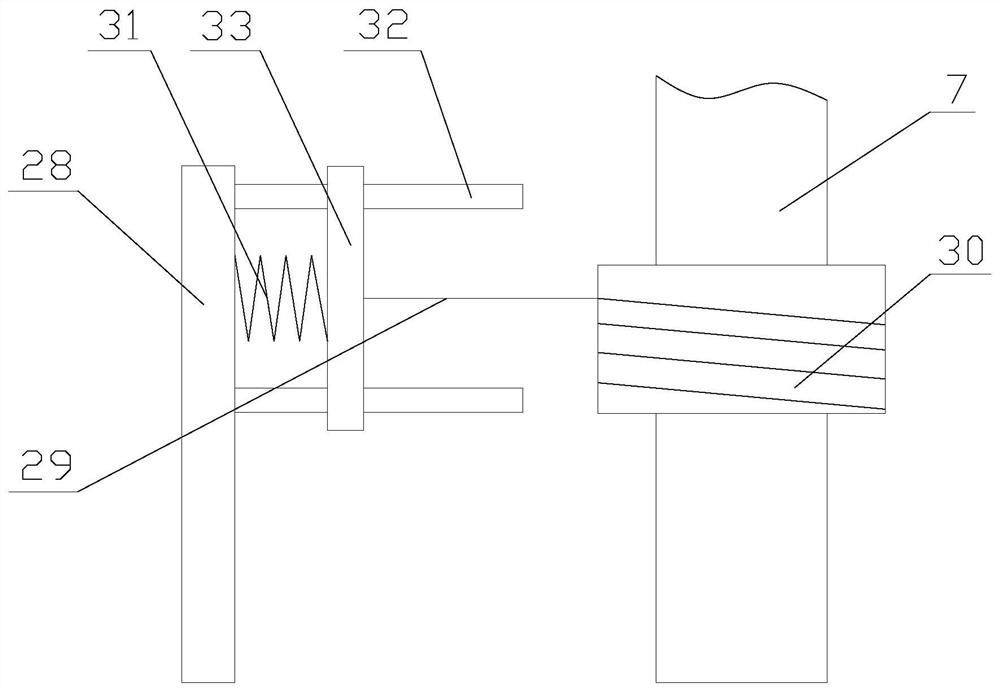

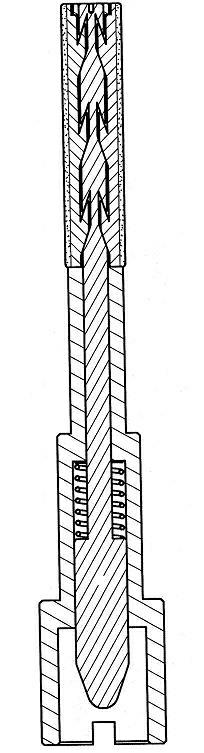

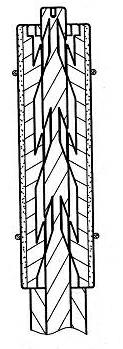

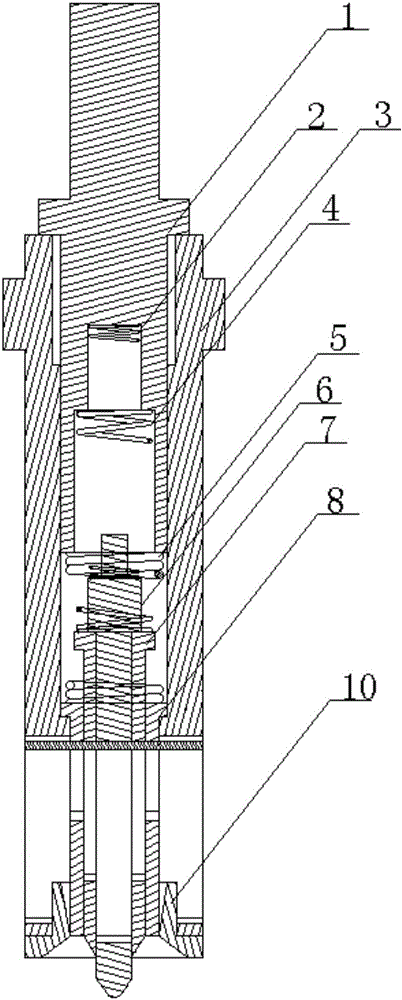

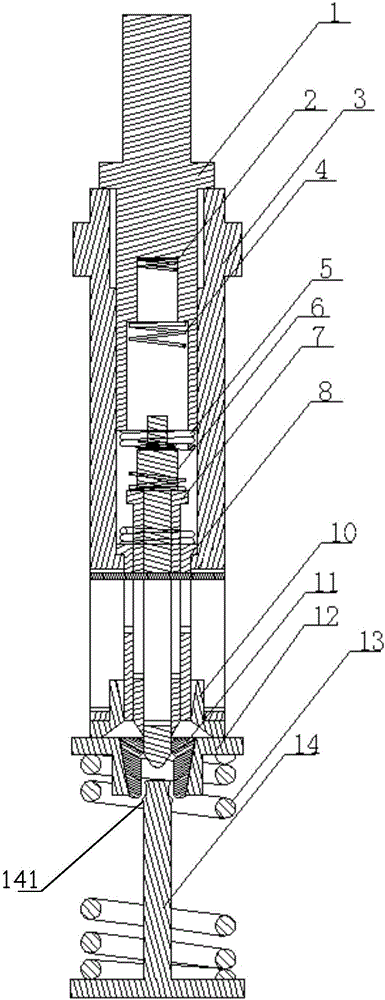

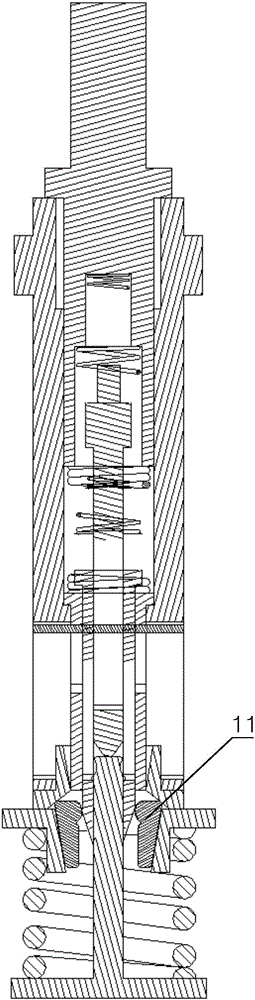

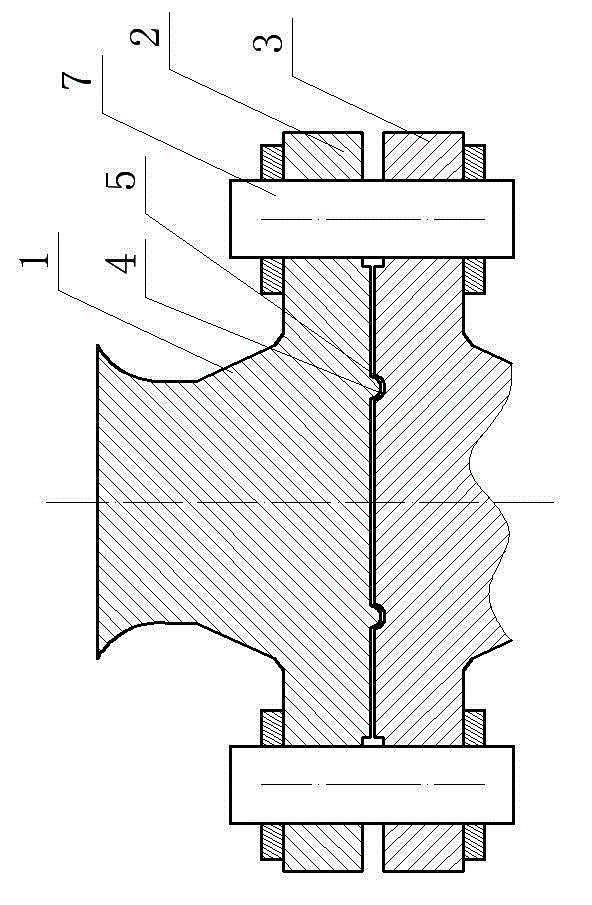

Serrated sliding automatic telescopic honing head

The invention relates to a sawtooth sliding type automatic telescopic honing head, which belongs to the honing head. The sawtooth core rod is located in the honing head casing, the limit screw is fixedly connected with the serrated core rod, the limit screw is slidingly connected with the groove on the honing head casing, the spring is sleeved on the serrated core rod, and the working surface of the bottom plate is installed on the honing head casing In the long groove at the front end, the working surface of the bottom plate adopts a zigzag structure and is supported by three taper slopes. The advantages are: novel structure, long-time grinding, and no drum shape on the working surface. When the feed mechanism of the machine tool returns, the core rod will quickly pull the working surface of the bottom plate back to the original state under the force of the spring, which will not cause scratches or strains on the inner hole of the workpiece.

Owner:JILIN DONGGUANG AOWEI AUTOMOBILE BRAKE SYST

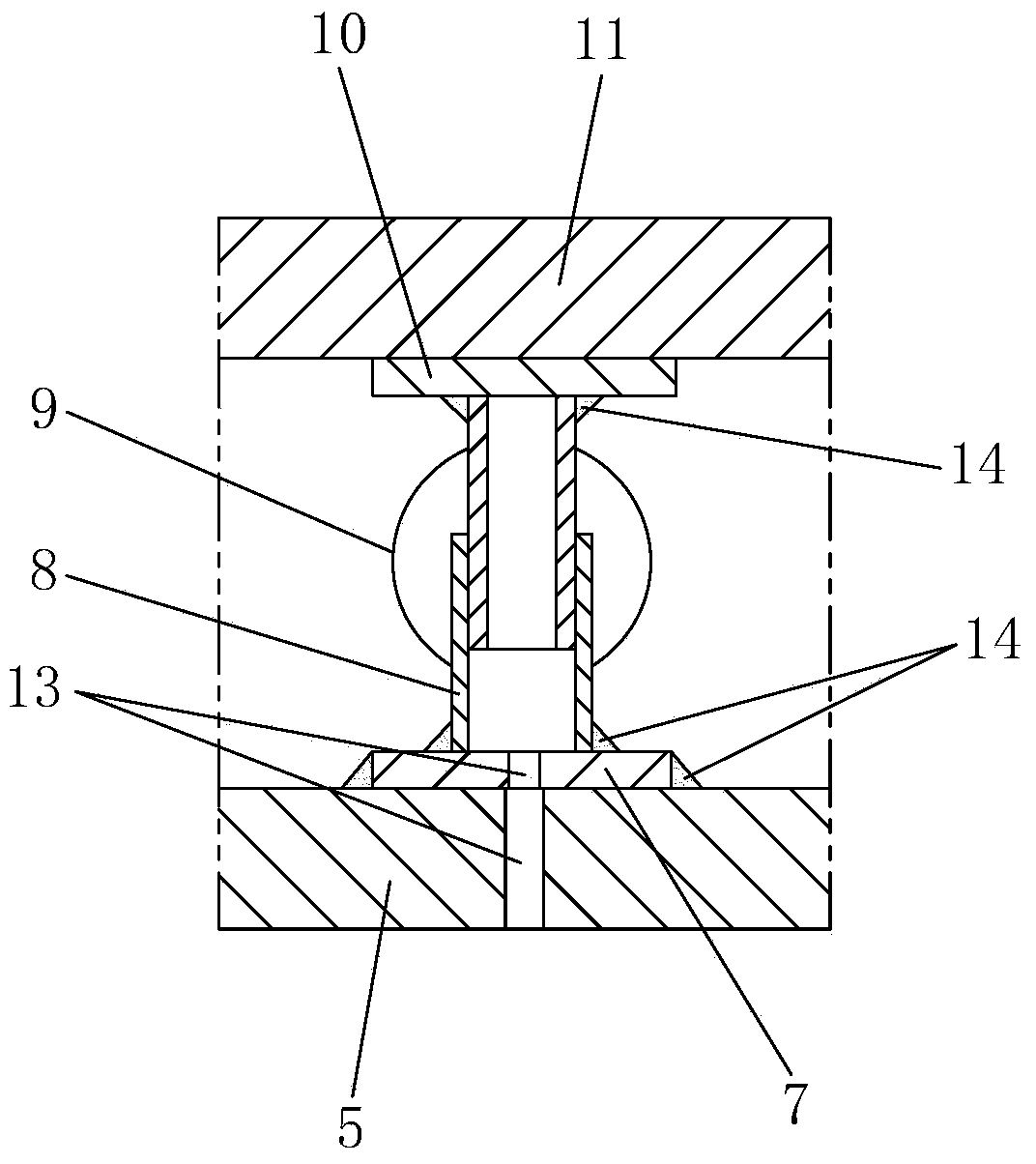

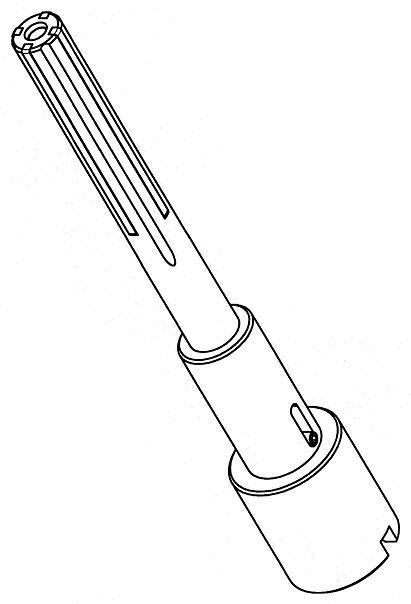

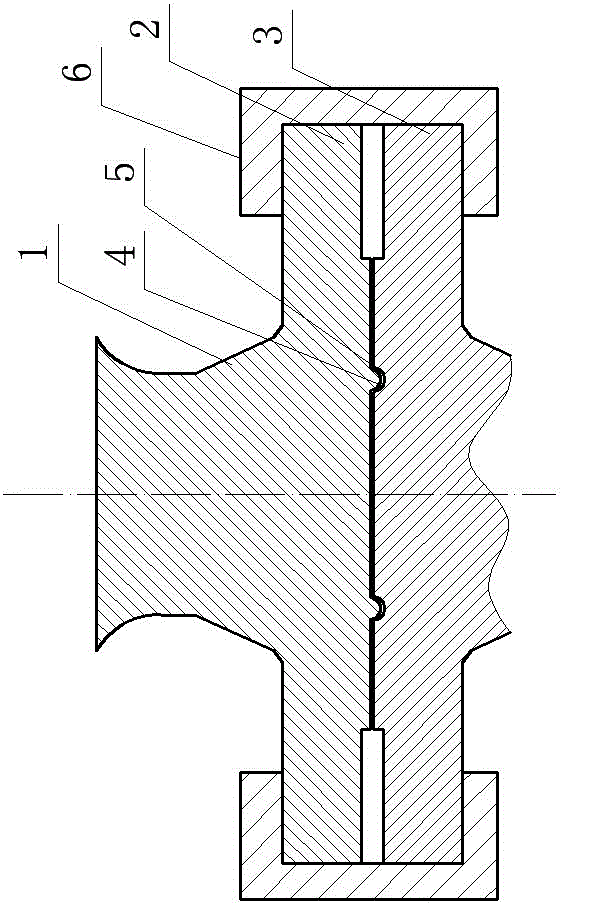

Valve collet pressure head

ActiveCN106475956AIncrease the outer diameterEasy to installMetal-working hand toolsColletEngineering

The invention discloses a valve collet pressure head. The valve collet pressure head comprises a shell, a guide rod and a guide sleeve. The shell is provided with a hollow space. One end of the hollow space is a sealed end, and the other end of the hollow space is an open end. An elastic element is arranged between the guide rod and the hollow space. The guide rod is movably arranged in the hollow space in a sleeving manner. The guide rod is sleeved with the guide sleeve. The guide sleeve is in sliding fit with the guide rod. In the direction of pointing to the sealed end from the open end, the outer diameter of the outer wall of the bottom of the guide sleeve is increased gradually. By the adoption of the valve collet pressure head, mounting of a valve collet can be completed conveniently and fast, and the valve collet can be protected against scratch.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

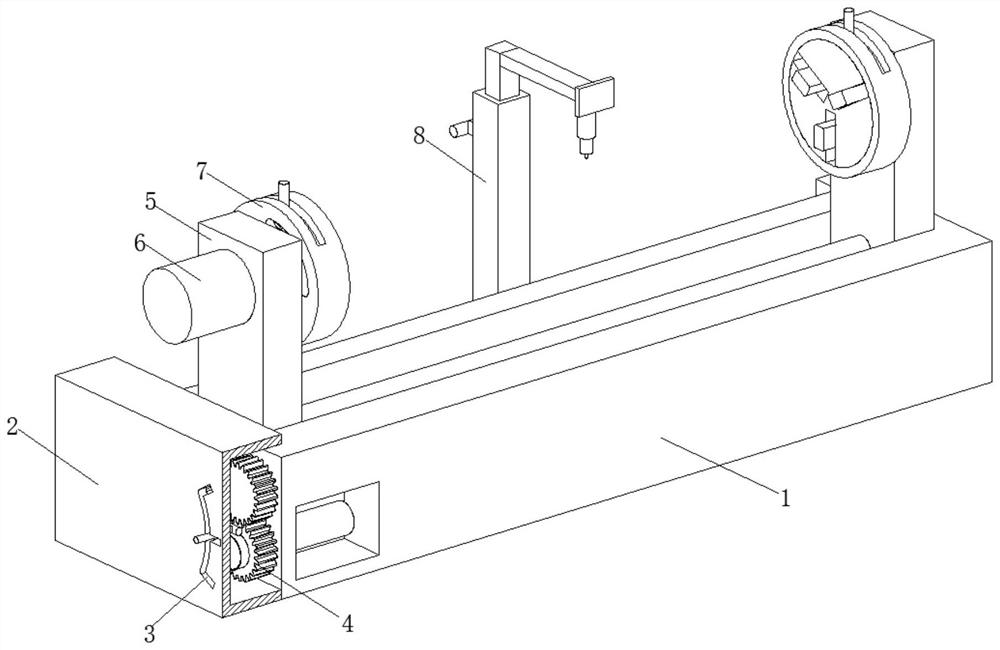

Mining machinery wheel shaft deflection measurement device

InactiveCN112484685AReduce the burden onExtended service lifeMeasurement devicesWorkbenchBolt connection

The invention relates to the technical field of deflection measurement, and discloses a mining machinery wheel shaft deflection measurement device which comprises a workbench, a protection box is connected to the front portion of the workbench through bolts, a clamping groove is formed in the front portion of the protection box, and a transmission mechanism is arranged in the protection box. Two supporting blocks are slidably connected to the inner wall of the workbench, motors are connected to the front portions of the supporting blocks through bolts, clamping mechanisms are arranged on the rear portions of the supporting blocks, and a detection mechanism is arranged on the left side of the workbench.Through cooperative use of the transmission mechanism and the supporting blocks, wheel shafts with different lengths can be clamped, so that the clamping mechanism can adapt to axles with different lengths, the application range of the clamping mechanism is widened, the axles can be clamped through the clamping mechanism, the clamping mechanism can adapt to the axles with different diameters and can be reinforced, the application range can be further widened, and the axles with largeweight can be clamped.

Owner:德清凯晶光电科技有限公司

Method for processing hollow glass with lined aluminum plate

The invention discloses a method for processing hollow glass of a lined aluminum plate, which comprises the steps of: selecting a piece of glass, and cutting the glass into glass sheets for edging, cleaning and toughening; placing the glass sheets into a coating chamber for coating; removing edge films of the coated glass sheets, cleaning the same and then putting the same into a sheet-combining chamber; gluing a hollow aluminum frame for the first time, and putting hollow aluminum frame / the same over the glass sheets for positioning; filling the hollow aluminum frame with driers; adhering double sided adhesive tapes along four internal frames of the hollow aluminum frame, and pasting an aluminum plate with the hollow aluminum frame; gluing the hollow aluminum frame for the second time, putting the second piece of coated sheet sequentially into a cleaner, the sheet-combining chamber for positioning, and a sheet presser for combination; drilling a small hole in the upper and lower edgeparts of the hollow aluminum frame, respectively, for inflation; rubberizing the butyl rubber around the hollow aluminum frame for the final sealing. The processing method has the advantages of accurate location for mounting, no scratch on film surfaces and resource saving.

Owner:江苏蓝星新材料有限公司

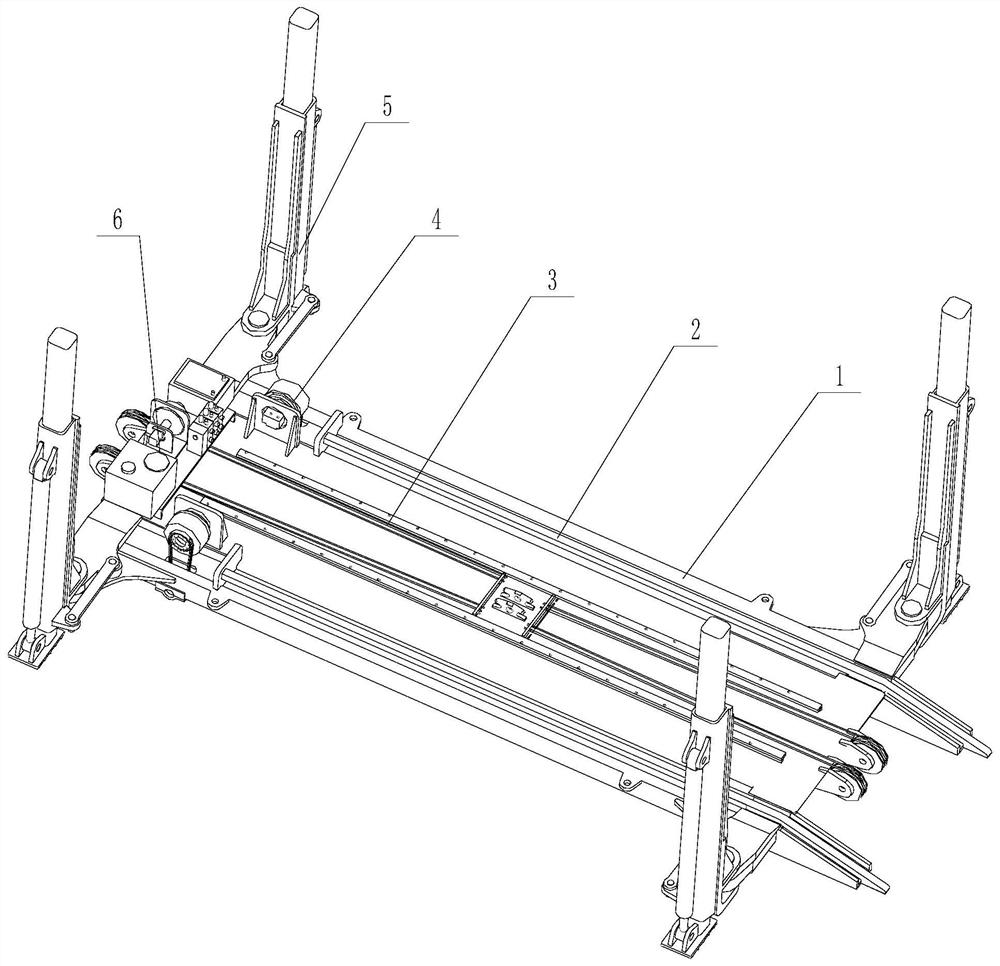

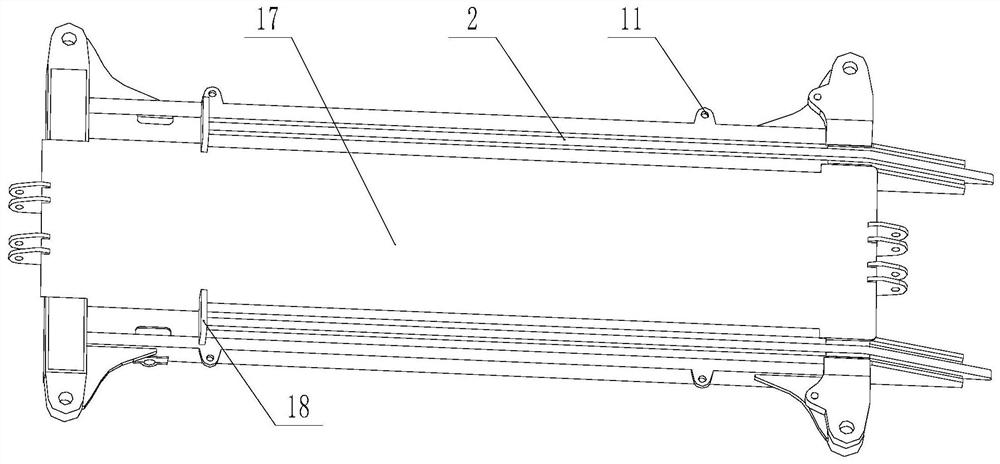

Pull lifting platform for railway rescue

PendingCN111960326ACause scratchesFast transferLifting framesCarriagesControl systemStructural engineering

The invention discloses a pull lifting platform for railway rescue, which belongs to the technical field of engineering machinery and solves the defect that inconvenience is caused to normal running on railway as a result of a poor rescue working condition while conventional construction equipment in the prior art has faults on the railway. The pull lifting platform is characterized in that a mainbody structure comprises a platform, wherein a rail, a pull mechanism, a travelling device, a folding supporting leg lifting mechanism and a control system are arranged on the platform; and the control system is separately connected to the pull mechanism, the travelling device and the folding supporting leg lifting mechanism. The pull lifting platform is mainly used for pulling down constructionequipment with faults from the railway.

Owner:SHANDONG LINGONG CONSTR MACHINERY

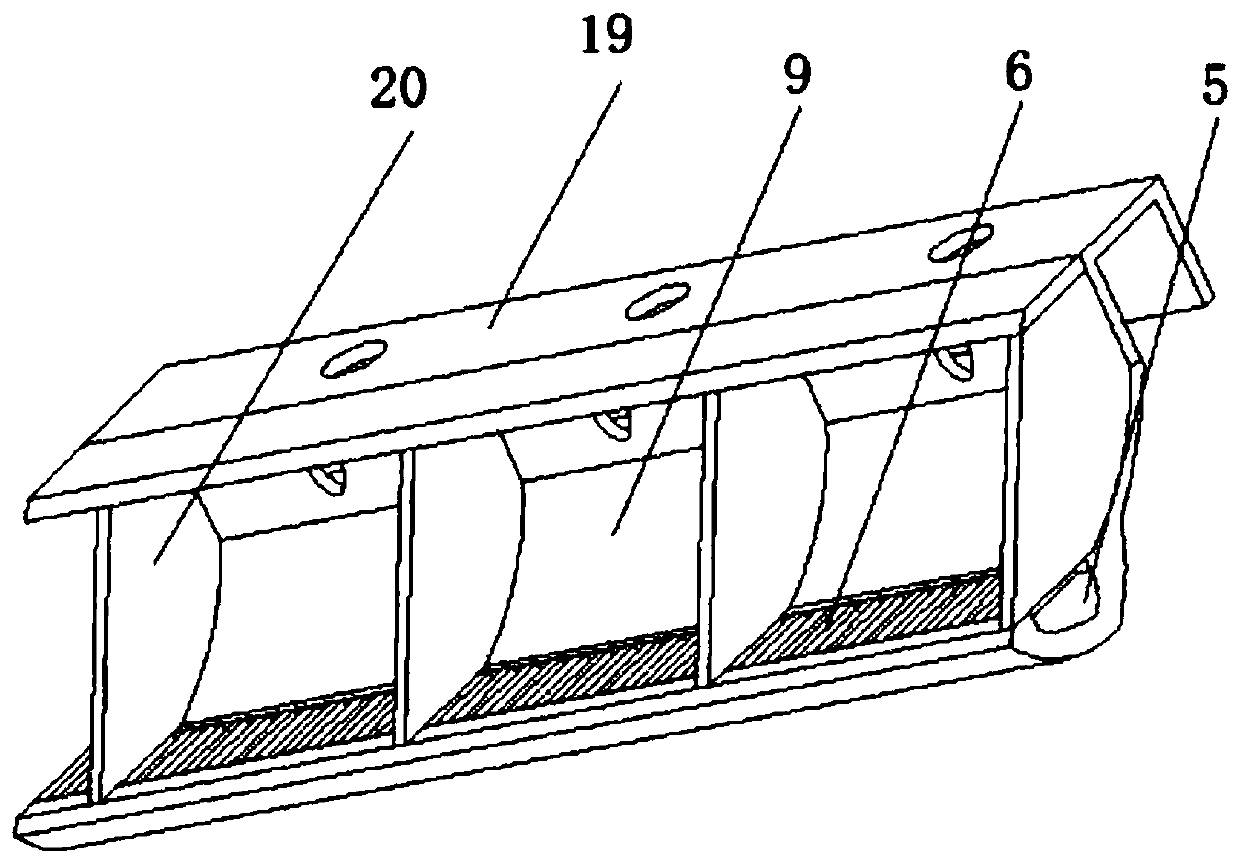

Intelligent-card groove milling device

ActiveCN106270687AIncrease the amount of single loadingAvoid frequent card loadingMilling equipment detailsMetal working apparatusEngineeringMilling cutter

The invention discloses an intelligent-card groove milling device. The intelligent-card groove milling device comprises a card feeding unit, a detection unit, groove milling devices and cleaning devices. The card feeding unit comprises a card absorbing module and an intelligent-card feeding module; the detection unit comprises a scanner and a scanning fixing plate for installing the scanner; the groove milling devices comprise milling cutters and vertical driving mechanisms for driving the milling cutters to move up and down; the cleaning devices comprise cleaning modules and driving mechanisms for driving the cleaning modules to permit vertical straight reciprocating motion. By means of the intelligent-card groove milling device, the one-time card feeding quantity can be greatly increased, and card feeding is convenient. Meanwhile, by means of the card feeding device, detection of the gestures of intelligent cards is completed, and intelligent cards which do not belong to the production batch are identified; the detection speed is high, and the accuracy is high. In addition, by means of the intelligent-card groove milling device, chips can be discharged to the designated place and uniformly collected, the problem that cleaning media are abraded can be solved, and the surfaces of the intelligent cards are not also scratched..

Owner:GUANGZHOU MINGSEN TECH CO LTD

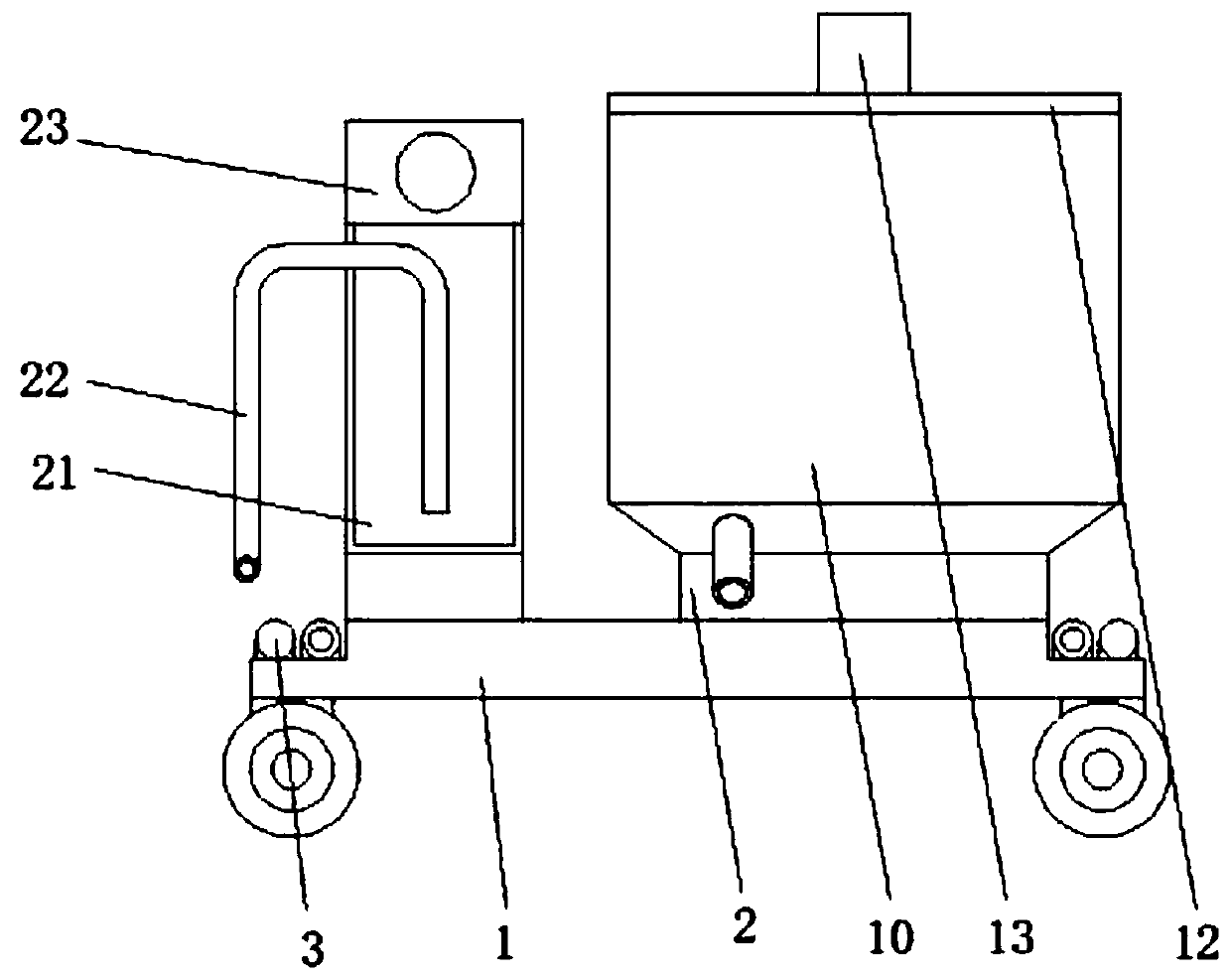

Cub feeding device for industrial breeding in animal husbandry

InactiveCN111480591AAvoid snatchingImprove protectionTransportation and packagingAnimal feeding devicesAnimal scienceElectric machinery

The invention belongs to the technical field of animal husbandry, particularly relates to a cub feeding device for industrial breeding in the animal husbandry, and aims to solve the problem that an existing cub feeding device is prone to cause food snatching in a feeding process. According to the scheme, the cub feeding device comprises a saddle; two supporting frames are fixedly mounted at the top of the saddle; a milk tank and a residual liquid tank are fixedly mounted at the top ends of the two supporting frames correspondingly; a sealing cover is mounted at the top end of the milk tank through a hasp lock and a hinge; and a driving motor is fixedly mounted at the top end of the sealing cover. When cubs are fed, feeding troughs are pushed out into a breeding fence through electric pushrods installed on the side surfaces, so that the cubs can be attached into the feeding trough for eating; the feeding troughs are separated through separation plates, so that the cubs are prevented from snatching for food, and the feeding quality is improved; and meanwhile, the flexible feeding troughs and the separation plates can prevent skin scratches of the cubs during eating and moving, so that the protection effect on the cubs is improved.

Owner:胡锦强

Cleaning device of smart card slot milling equipment

ActiveCN106311678AEfficient removalProtect your healthDirt cleaningCleaning using gasesReciprocating motionSmart card

The invention discloses a cleaning device of smart card slot milling equipment. The cleaning device of the smart card slot milling equipment comprises a cleaning module and a driving mechanism, wherein the driving mechanism drives the cleaning module to conduct vertical straight reciprocating motion. The cleaning module comprises a dust removal hood, air blowing shafts and an exhaust pipe. One end of each air blowing shaft is connected with an air pipe, and the other end of each air blowing shaft is fixed into the dust removal hood. The side wall of the dust removal hood is provided with an opening, and the opening is connected with the exhaust pipe. The other end of the exhaust pipe is connected with a negative pressure device. According to the cleaning device of the smart card slot milling equipment, in the process of cleaning a chip slot, chips can be discharged to a designated place to be collected uniformly; and besides, air is used as the cleaning medium of the cleaning device, the problem that the cleaning medium is worn is avoided, and the surface of a card is protected against scratches.

Owner:SHENZHEN CHENGTIAN WEIYE TECH

PVC decorative sheet drying device

PendingCN108044848APrevent high temperature burntTimely coolingFlat articlesEngineeringMechanical engineering

The invention relates to a PVC decorative sheet drying device. The PVC decorative sheet drying device comprises a substrate, a protective cover and heaters; the protective cover is a cavity of which the bottom is opened; the protective cover is connected to the upper portion of the substrate in a covering manner; a plurality of heaters are arranged inside the cavity of the protective cover; a transporting structure for moving a PVC decorative sheet is arranged inside the substrate; a cooling structure is arranged inside the protective cover; one side of the protective cover is provided with afeeding opening for the PVC decorative sheet to enter the protective cover; and the other side of the protective cover is provided with a discharging opening for the PVC decorative sheet to leave awayfrom the protective cover. The PVC decorative sheet drying device provided by the invention has the beneficial effects that the cooling structure is arranged inside the protective cover so that the PVC decorative sheet can be effectively prevented from being damaged due to baking at a high temperature.

Owner:湖北银座新材料股份有限公司

Macroscopic inspection machine capable of automatically positioning and measuring luminance

InactiveCN105353537AReasonable designEasy to usePhotometryNon-linear opticsVertical planeIlluminance

The invention discloses a macroscopic inspection machine capable of automatically positioning and measuring luminance. The macroscopic inspection machine comprises a machine table, support rods, vacuum chucks, clamps and a working table. The machine table and the support rods are used for supporting glass. The vacuum chucks are arranged on the support rods and used for absorbing glass. The clamps are arranged inside of the machine table and used for clamping glass. The working table is used for operating the machine table to operate. The machine table is a frame body made up of a first horizontal plane, a second horizontal plane, a first vertical plane and a second vertical plane. A horizontal ruler is arranged on the first horizontal plane. A vertical ruler is arranged on the first vertical plane. Luminance measuring devices are arranged below the support rods. The macroscopic inspection machine capable of automatically positioning and measuring luminance has following beneficial effects: the macroscopic inspection machine can perform luminance measure and macroscopic false orientation in a safe and rapid manner.

Owner:张笑多

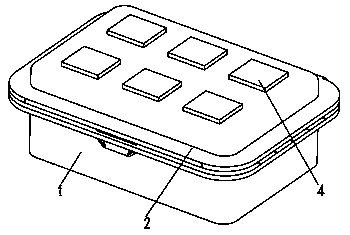

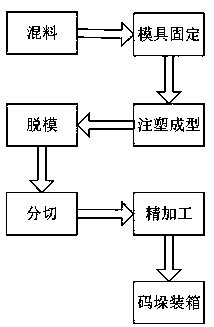

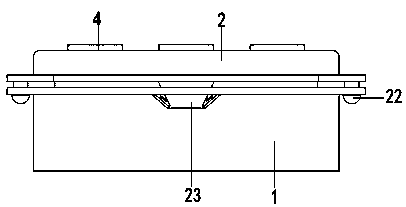

A production process of plastic packaging box

ActiveCN110015495BImprove stabilityCause scratchesNon-removalbe lids/coversTray containersPlastic packagingInjection moulding

Owner:JILIN LONGYUN CHEM IND

Reactive dyeing assistant for polyester fibers

The invention relates to the field of dyeing assistants, in particular to a reactive dyeing assistant for polyester fibers. The reactive dyeing assistant comprises a surfactant, sodium sulfate, a water softener, branched heterogeneous alcohol ether, rare earth chloride, 3-chloro-2-hydroxypropyltrimethyl ammonium chloride and goose feather protein extracted from goose feather. According to the reactive dyeing assistant for the polyester fibers, the degree of dyeing and the degree of fixation of the polyester fibers can be increased effectively by the aid of addition of a small amount of sodium sulfate and cooperation of the goose feather protein, only a small amount of sodium sulfate is added, so that scratching of polyester fiber textiles can be avoided, the quality of polyester fibers in a dyeing process is guaranteed, and the usability is improved; meanwhile, the utilization rate and the dyeing efficiency of a dye can be increased effectively by the aid of the assistant, water used in the dyeing process of unit textile can be reduced, the production cost is reduced, and environmental safety is guaranteed.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

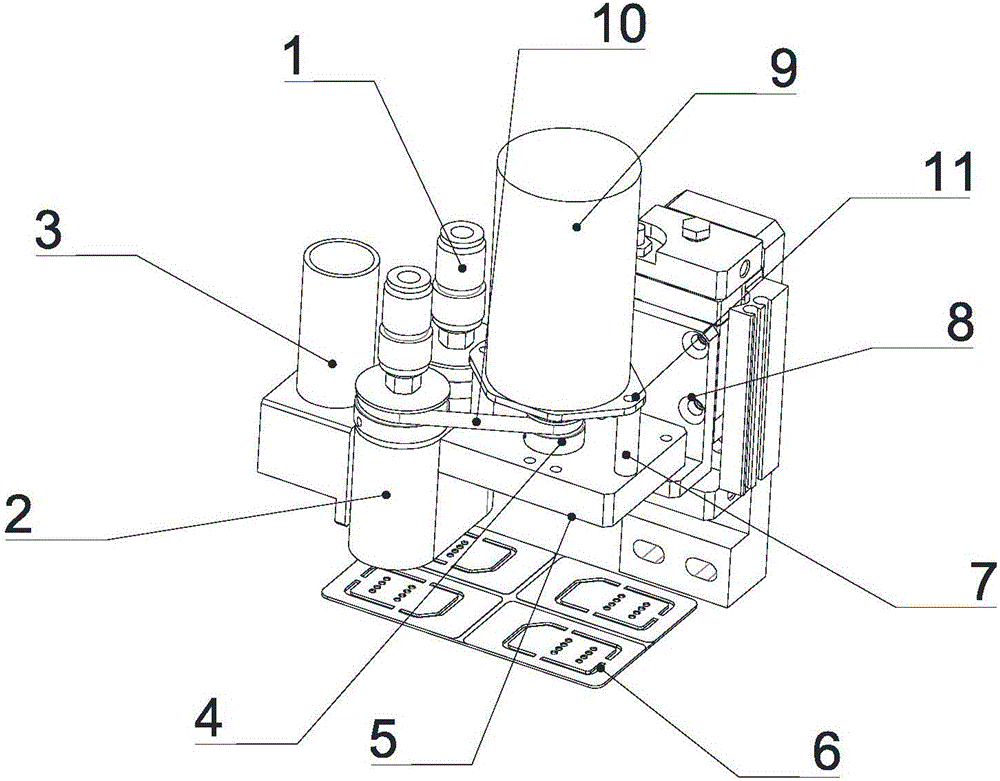

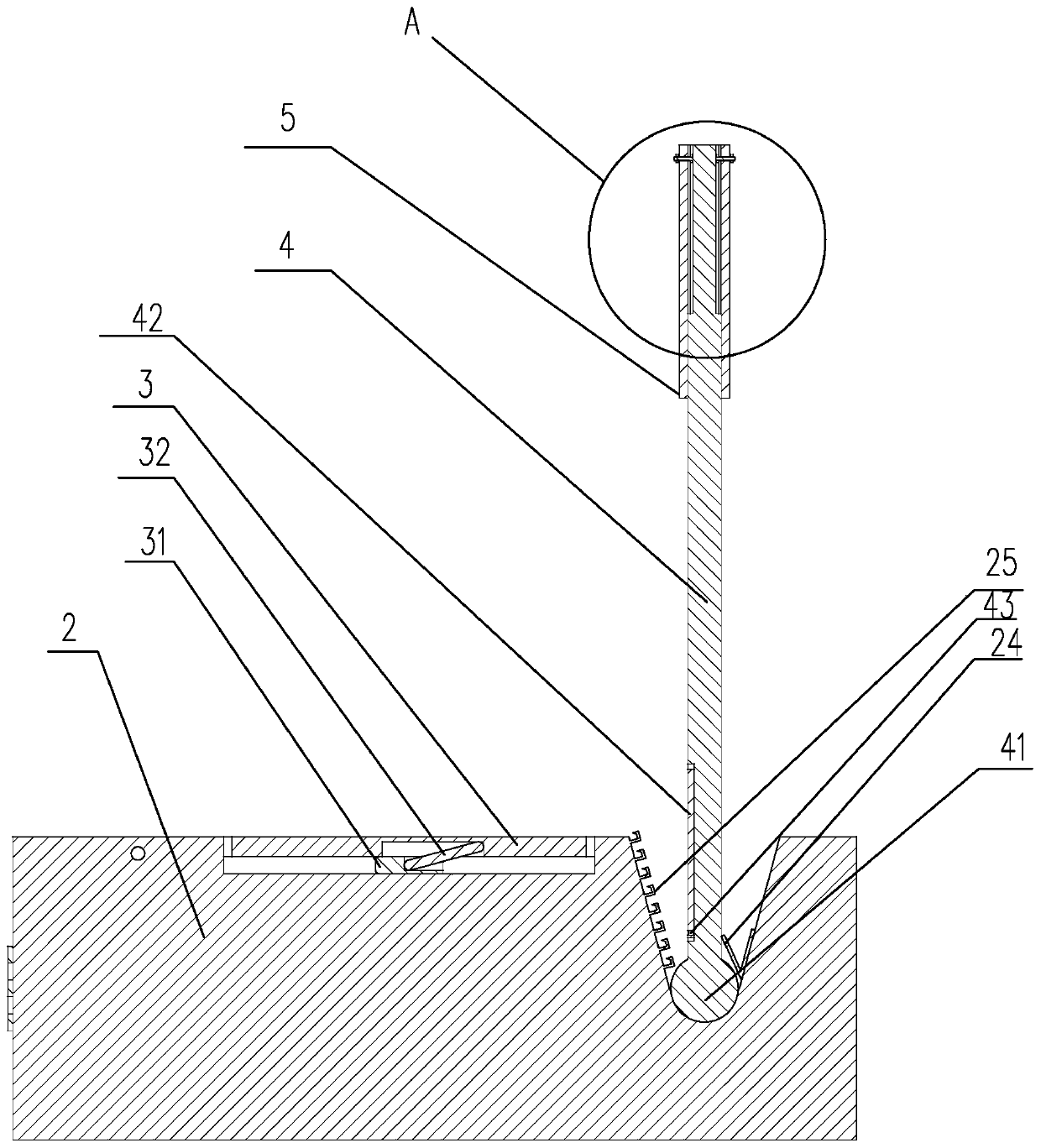

Automatic automobile refueling robot

The invention discloses an automobile refueling robot, which can realize automatic refueling of an automobile in an unattended environment. Before and during refueling, sensors such as a camera detectthe position of an automobile, the position of an automobile owner, the posture of the automobile owner as well as suspectable objects (such as own containers) prohibited in the environment and the like in real time, the refueling robot stops refueling and sound an alarm immediately if a dangerous factor is detected, and a remote alarm is sounded if the dangerous factor cannot be eliminated all the time. In the refueling process, the sensors such as the camera detect the position of a tank filler opening of the automobile and the distance from the side face of the automobile in real time, andmovable shafts move in a matching way to ensure that the mouth of an oil gun can enter the tank filler opening of the automobile accurately, so that high-speed, high-accuracy and low-cost refueling is realized.

Owner:XI AN JIAOTONG UNIV

Anesthetic head frame

The invention discloses an anesthetic head frame. The anesthetic head frame comprises a positioning frame and a connecting frame which is slidably arranged on a bed body in the width direction of thebed body, the connecting frame comprises a sliding base and a storage plate, wheels are arranged at the bottom of the sliding base, the storage plate is slidably arranged on the sliding base in the width direction of the bed body, and a containing groove is formed in the side wall of the storage plate; a hanging rod used for hanging a sterile towel is rotationally arranged in the containing groove, and a mounting groove is formed in the storage plate; the positioning frame comprises a connecting rod and a positioning rod used for abutting against the popliteal space of a patient, the positioning rod is movably connected with the connecting rod, and the connecting rod is rotationally arranged in the mounting groove; the mounting groove extends out of the storage plate to form a swing grooveso that the connecting rod can swing in the horizontal direction of the storage plate, and a back cushion used for pushing the cervical vertebra of the patient is further arranged on the bottom faceof the storage plate. The anesthetic head frame has more comprehensive functions, and also has an assisting effect on anesthesia operations.

Owner:WENZHOU PEOPLES HOSPITAL

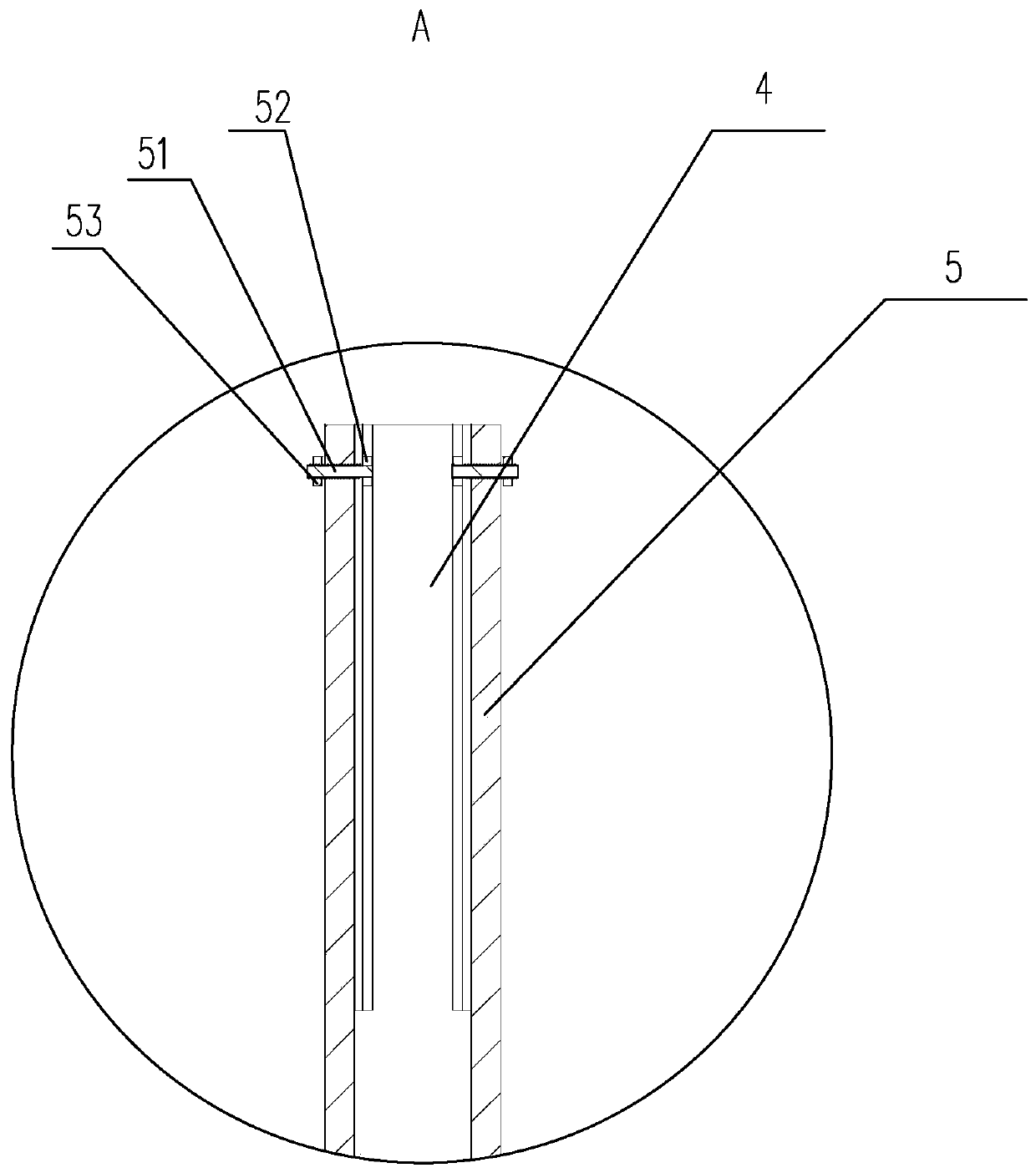

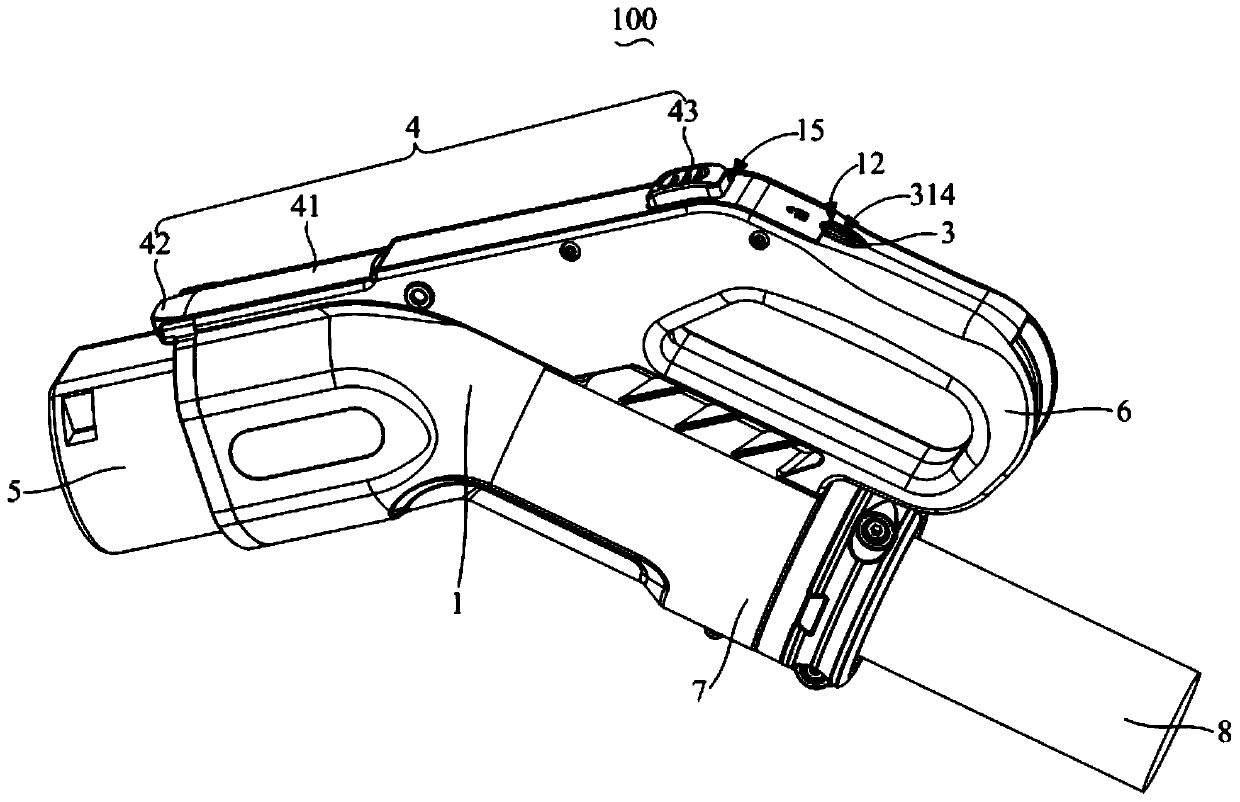

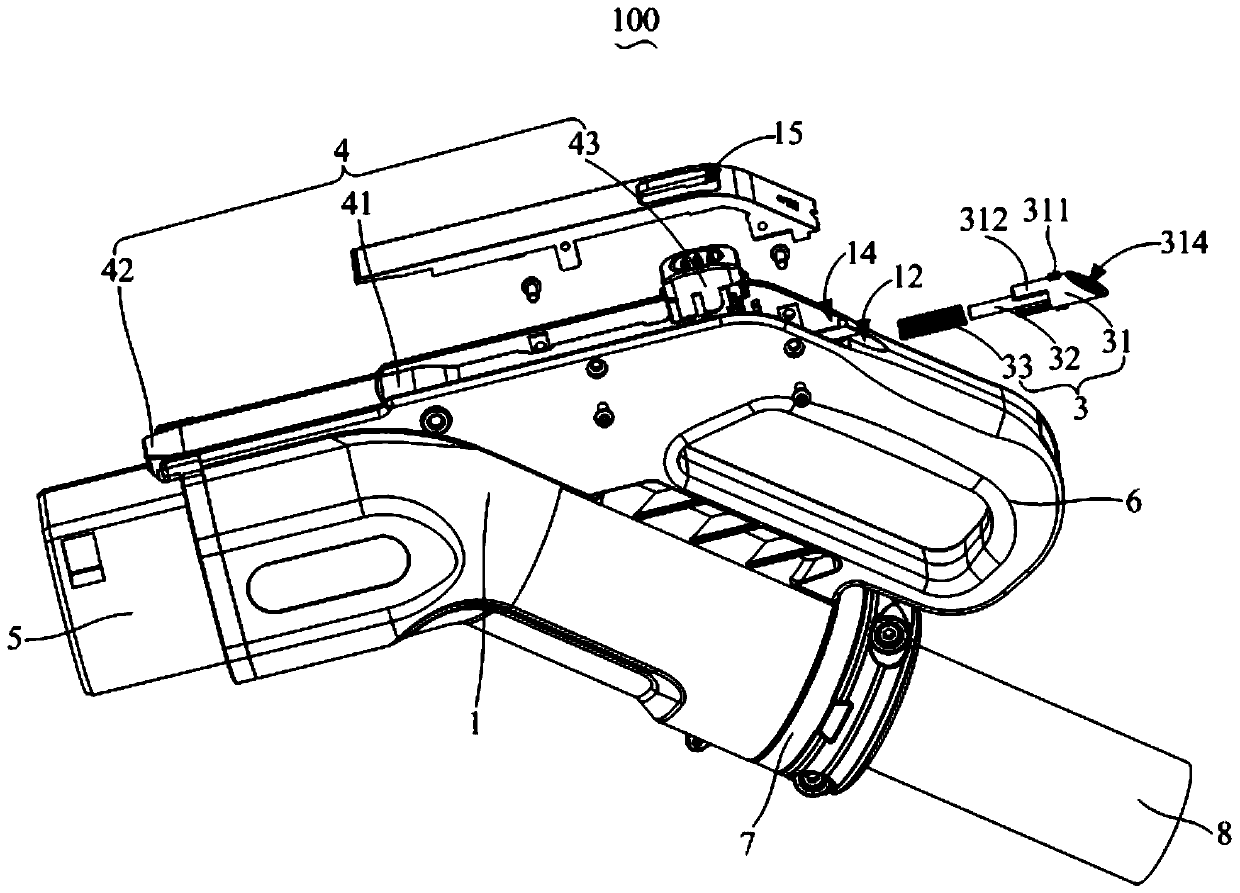

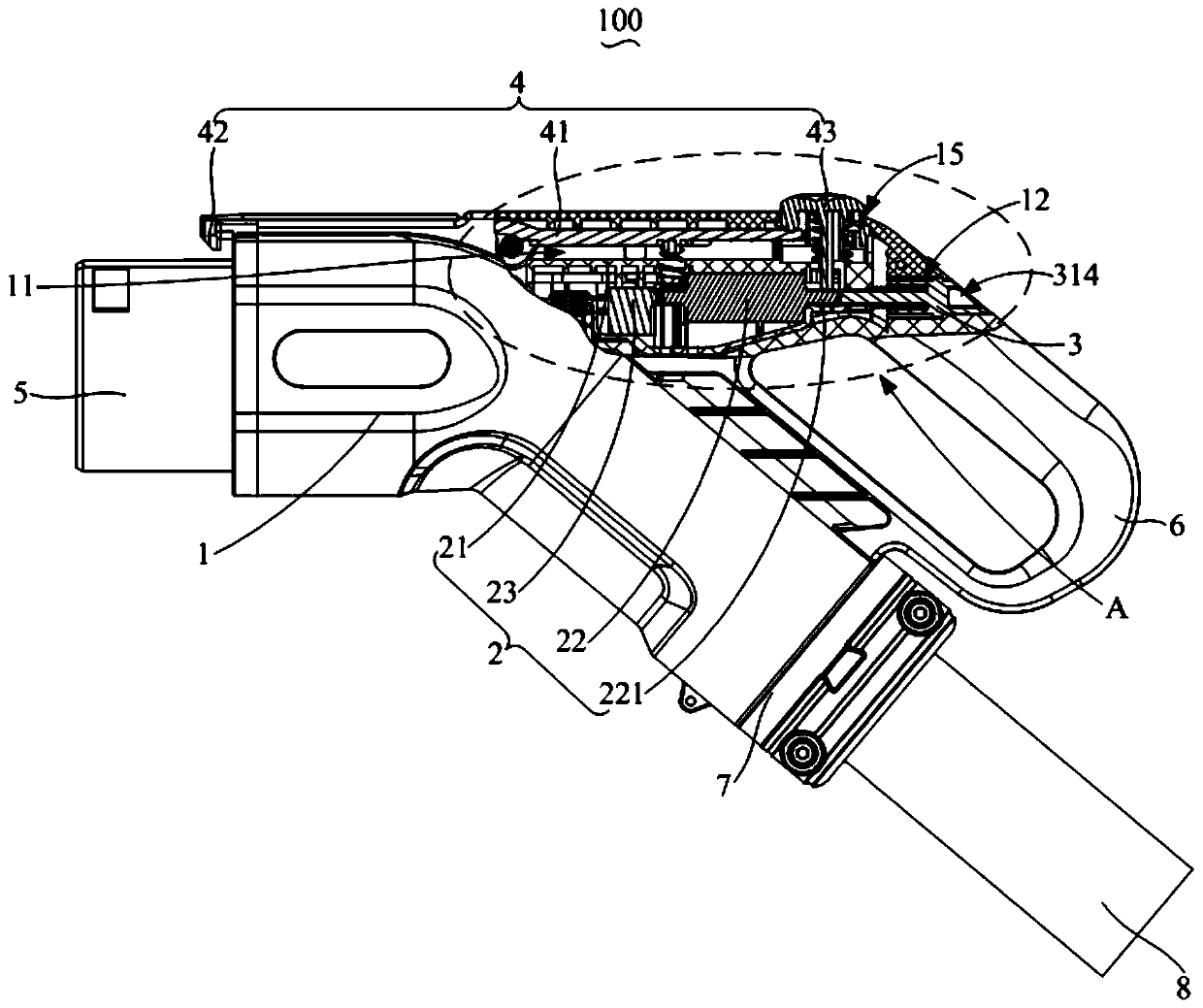

Charging gun

PendingCN111478117AReduce weightWon't shakeVehicle connectorsCharging stationsElectromagnetic lockEngineering

The invention discloses a charging gun, and the charging gun comprises: a housing which is provided with an installation cavity and a movable groove communicated with the installation cavity; an electromagnetic lock assembly which is arranged in the mounting cavity, wherein an unlocking hole is formed in the position, corresponding to the movable groove, of the electromagnetic lock assembly; and an unlocking piece which is movably arranged in the movable groove, wherein the end, away from a groove opening of the movable groove, of the unlocking piece is inserted into the unlocking hole, and the unlocking piece moves relative to the movable groove so as to unlock the electromagnetic lock assembly. The invention aims to solve the problems that an emergency unlocking tool of a charging gun isinconvenient to find and easy to lose, and provides the charging gun which has the advantages that an unlocking piece does not shake, loss is prevented, the structure is simple, and the cost is low.

Owner:SHENZHEN WOER NEW ENERGY ELECTRICAL TECH CO LTD

Horizontal continuous casting graphite crystallizer by aid of nitrogen protection method

The invention discloses a horizontal continuous casting graphite crystallizer by the aid of a nitrogen protection method, and belongs to the technical field of metallurgical equipment. The horizontal continuous casting graphite crystallizer is used for copper continuous casting equipment and comprises a tubular graphite sleeve, a crystallizing cavity is formed inside the graphite sleeve, an annular groove is milled at the lower end of the graphite sleeve, through holes which are communicated with the crystallizing cavity are drilled on the annular groove, a communicating hole is drilled at the bottom of the graphite sleeve and communicated with the through holes, and a capillary tube is further disposed in the communicating hole and connected to an external nitrogen tube. After the structure is adopted, oxidation of the graphite crystallizer is effectively stopped, and the service life of the graphite crystallizer is prolonged. Besides, air behind a crystallization point of the graphite crystallizer is isolated by nitrogen, a copper billet is effectively prevented from contacting with the air when in crystallization, oxidation of a tube billet is prevented, and accordingly problems that an existing graphite crystallizer is short in service life, the surface of a copper billet is oxidized and has severe convex marks and a copper crystallization effect is poor are solved.

Owner:青岛中冶新材料科技有限公司

Numerical control plate shearing machine capable of preventing reduction of cutting precision

InactiveCN112846346AReduced cutting accuracyWon't scratchShearing machinesMetal working apparatusStructural engineeringIndustrial engineering

The invention relates to the technical field of numerical control, and discloses a numerical control plate shearing machine capable of preventing reduction of cutting precision. The numerical control plate shearing machine comprises a bottom box, supporting columns, a plate shearing cutter, a top plate, a base, transmission assemblies and an anti-scratching assembly; the top end of the bottom box is fixedly connected with the base, and the top end of the bottom box is located at the top end of the base and fixedly connected with the supporting columns; the left sides of the supporting columns are movably connected with the plate shearing cutter, the top end of the plate shearing cutter is movably connected with the top plate, and the transmission assemblies are movably connected with the left sides of the inner walls of the supporting columns; and when the plate shearing cutter moves downwards, the transmission assemblies drive the anti-scratching assembly to operate, a fixed rod drives a movable rod to move through a connecting rod, the movable rod drives a movable block to slide at the bottom end of a cutter groove, a guide rod moves downwards under the acting force of spring push rods, the movable block pushes metal residues, at the moment, the movable plate and the fixed plate are separated, the metal residues fall into a material collecting block, therefore, the surface of a metal plate cannot be scratched, and the cutting precision cannot be greatly reduced.

Owner:李会青

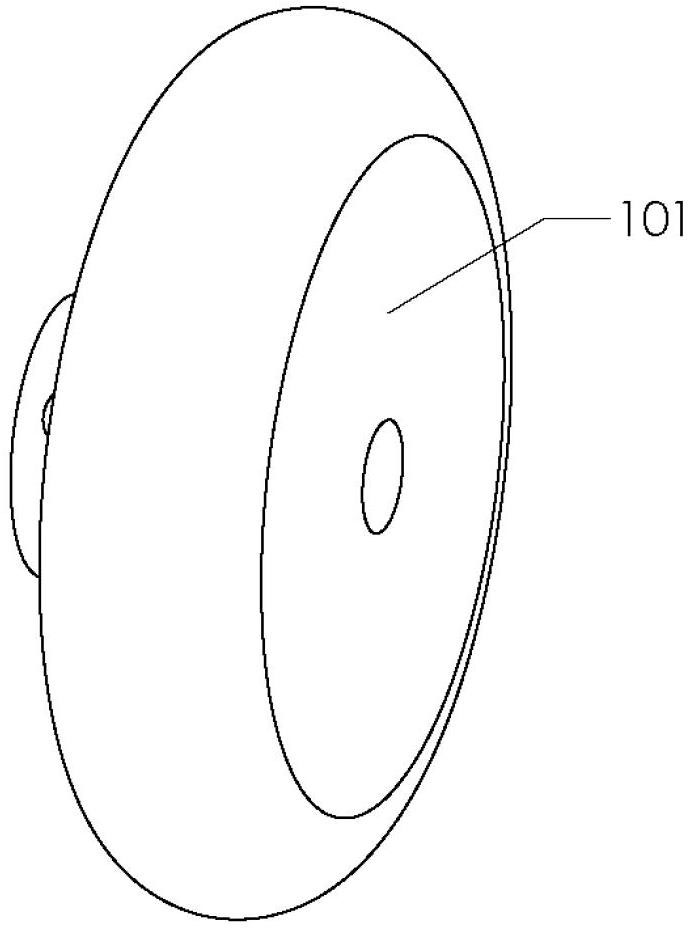

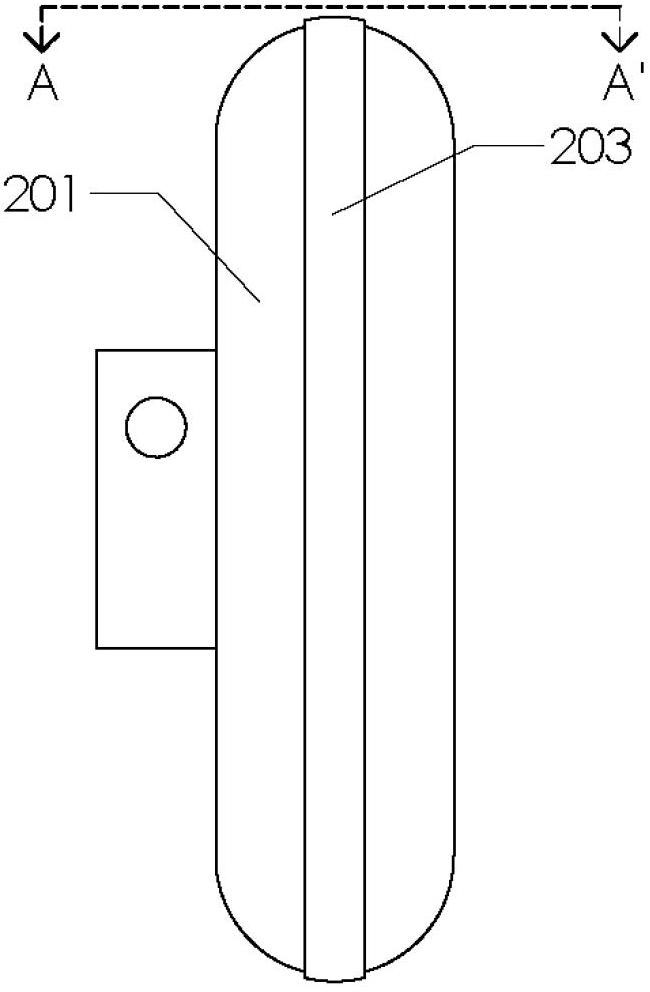

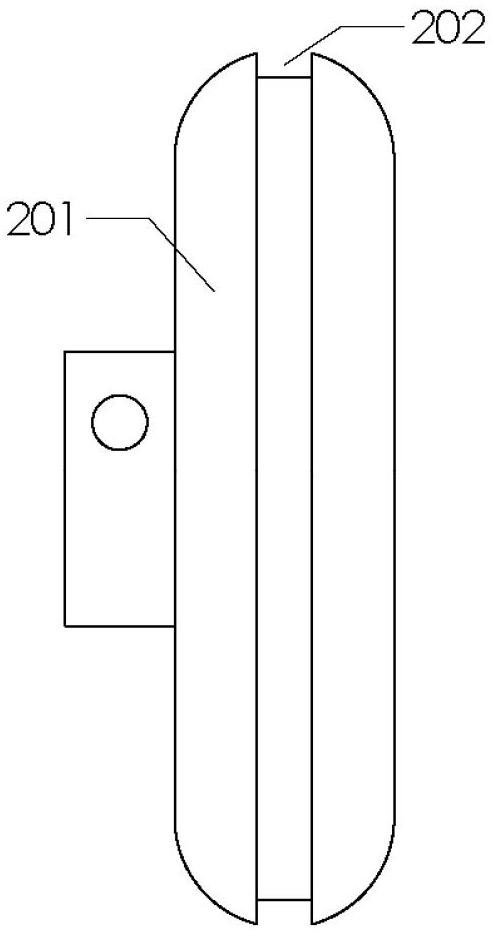

Swivel head cover of electric centrifuge

InactiveCN103056039AAvoid safety accidentsAvoid getting stuckCentrifugesEngineeringLaboratory facility

The invention provides a swivel head cover of an electric centrifuge. According to the electric centrifuge frequently used in the laboratory presently, the swivel head cover flies out if the swivel head cover is not screwed tight, and accidents can be caused. The swivel head and the swivel head cover of the existing electric centrifuge are generally connected through threads and have the defect of being poor in sealing effect. The swivel head cover of the electric centrifuge comprises a swivel head cover body (1) connected with a swivel head cover flange (2), the swivel head cover flange is matched with a swivel head flange, and an annular protrusion (4) is arranged on the swivel head cover flange, located on the attachment surface of the swivel head cover flange and the swivel head flange and matched with an annular groove (5) arranged on the swivel head flange. The swivel head cover is applied to ancillary facilities of the electric centrifuge.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

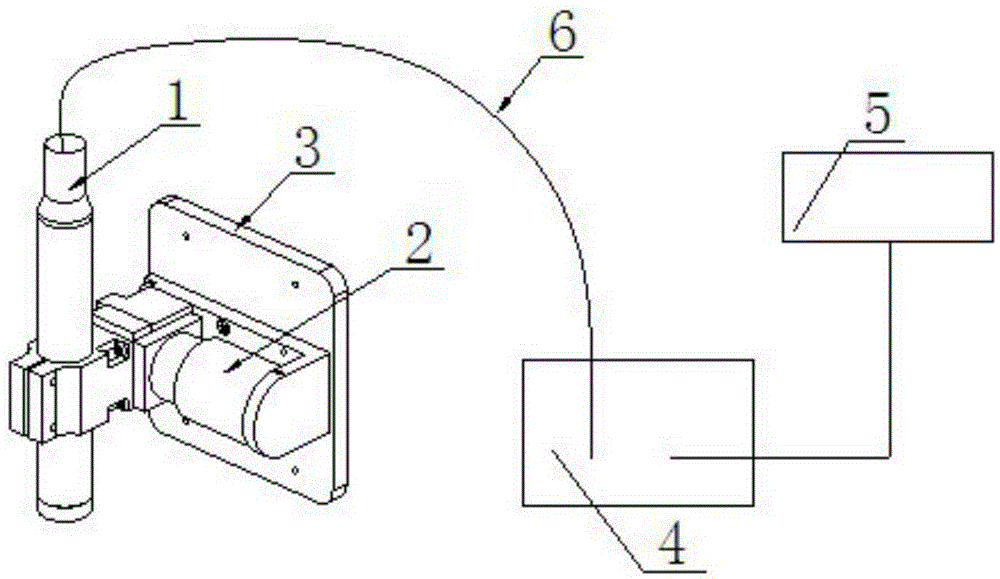

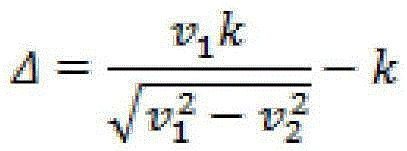

3D contour online measuring instrument

InactiveCN106556354ACause scratchesExcellent Angle CharacteristicsUsing optical meansMeasuring instrumentContact mode

The invention discloses a 3D contour online measuring instrument which comprises a confocal displacement measuring probe and a piezoelectric linear driver wherein the confocal displacement measuring probe is installed on the piezoelectric linear driver. The confocal displacement measuring probe is installed on the detection work position of a piece of manufacturing equipment through a connection plate. When a sample is moved under the confocal displacement measuring probe, a measuring signal is sent to the confocal displacement measuring probe controller; and the piezoelectric linear driver brings the confocal displacement measuring probe to do reciprocal motions for the scanning of 2D contour and finally draws up the 3D contour. The 3D contour online measuring instrument of the invention uses a non-contact mode for measurement and is free of the influence of the rigidness of a sample surface, and does not cause any scratch to the sample. Compared with the interferometry method to measure the change in height, the instrument of the invention has more excellent angle characteristics with the lens surface measured reaching from plus and minus 25 degrees to plus and minus 45 degrees; the measured reflection surface can be within the scope of 87 degrees at the most.

Owner:SHANGHAI THIKFOCUS SCI INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com