Swivel head cover of electric centrifuge

A technology of rotor cover and centrifuge, which is applied in the direction of centrifuge, etc. It can solve the problems of not tight fit of thread, poor sealing effect, corrosion of gasket, etc., so as to avoid scratches, reduce the difficulty and workload of installation and maintenance, Ease of centering installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

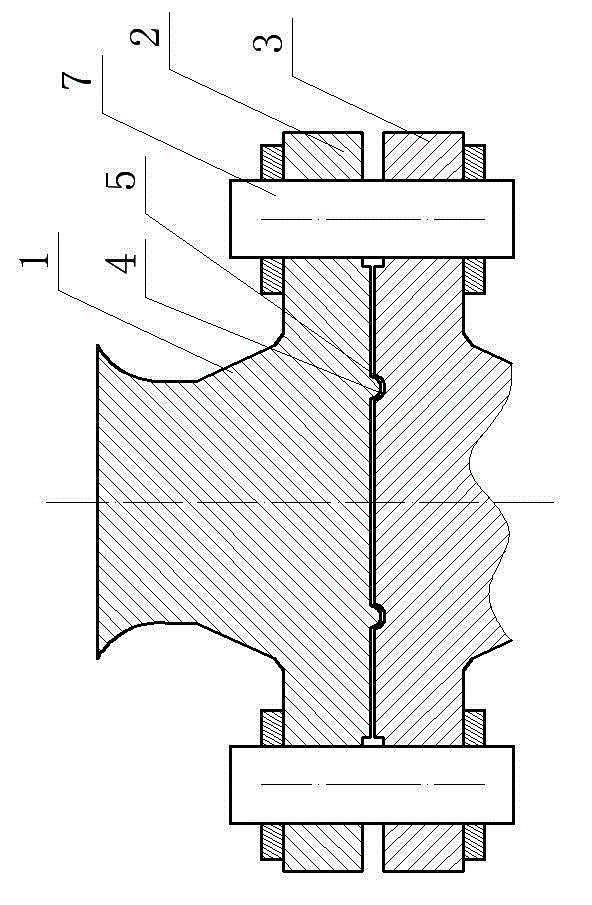

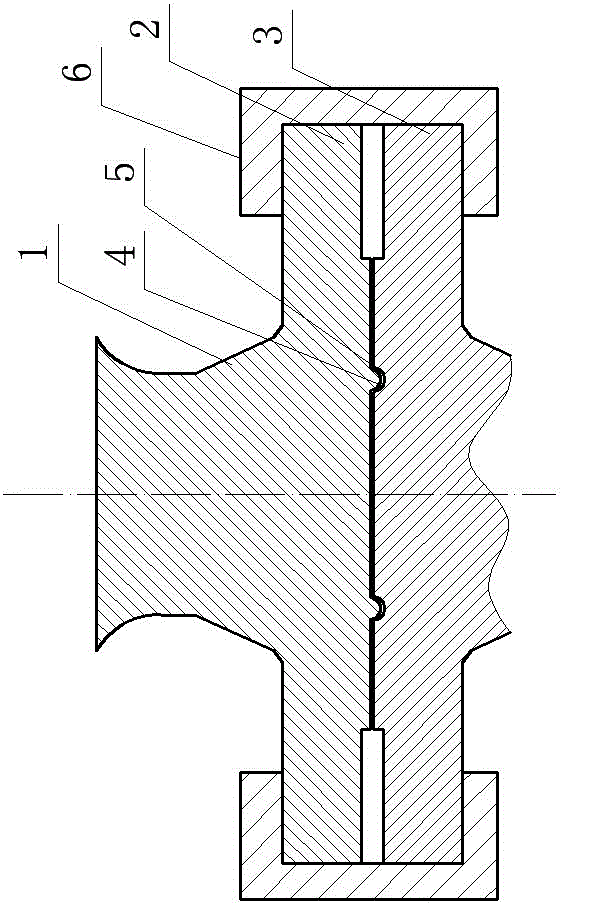

[0016] as attached figure 1 Or as shown in 2: the electric centrifuge rotor cover of the present invention includes a rotor cover body 1, the rotor cover body is connected to the rotor cover flange 2, and the rotor cover flange and the rotor flange 3, the turret cover flange has an annular protrusion 4, the annular protrusion is located on the surface that fits with the turret flange and is in contact with an annular groove 5 on the turret flange match.

Embodiment 2

[0018] As for the rotor cover of the electric centrifuge, the flange of the rotor cover and the flange of the rotor are connected by a clip 6 in a clamping manner.

Embodiment 3

[0020] As for the rotor cover of the electric centrifuge, the rotor cover flange and the rotor flange respectively have fastener holes corresponding to each other, and the rotor cover flange and the rotor The head flanges are connected by fastening bolts 7 installed in the fastener holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com