Liquid crystal panel module with coated film limiting device

A liquid crystal panel and chip-on-film technology, which is applied in the field of position-limitable chip-on-film, can solve the problems of lowering the product quality rate, affecting the normal function of the chip-on-film 11, and scratching the chip-on-film 11, etc., so as to improve the quality of the products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Regarding the foregoing and other technical contents, features, and effects of the present invention, the following detailed descriptions of three preferred embodiments with reference to the accompanying drawings will be more clearly understood.

[0034] Before the present invention is described in detail, it should be noted that in the following description, the same elements are represented by the same numbers.

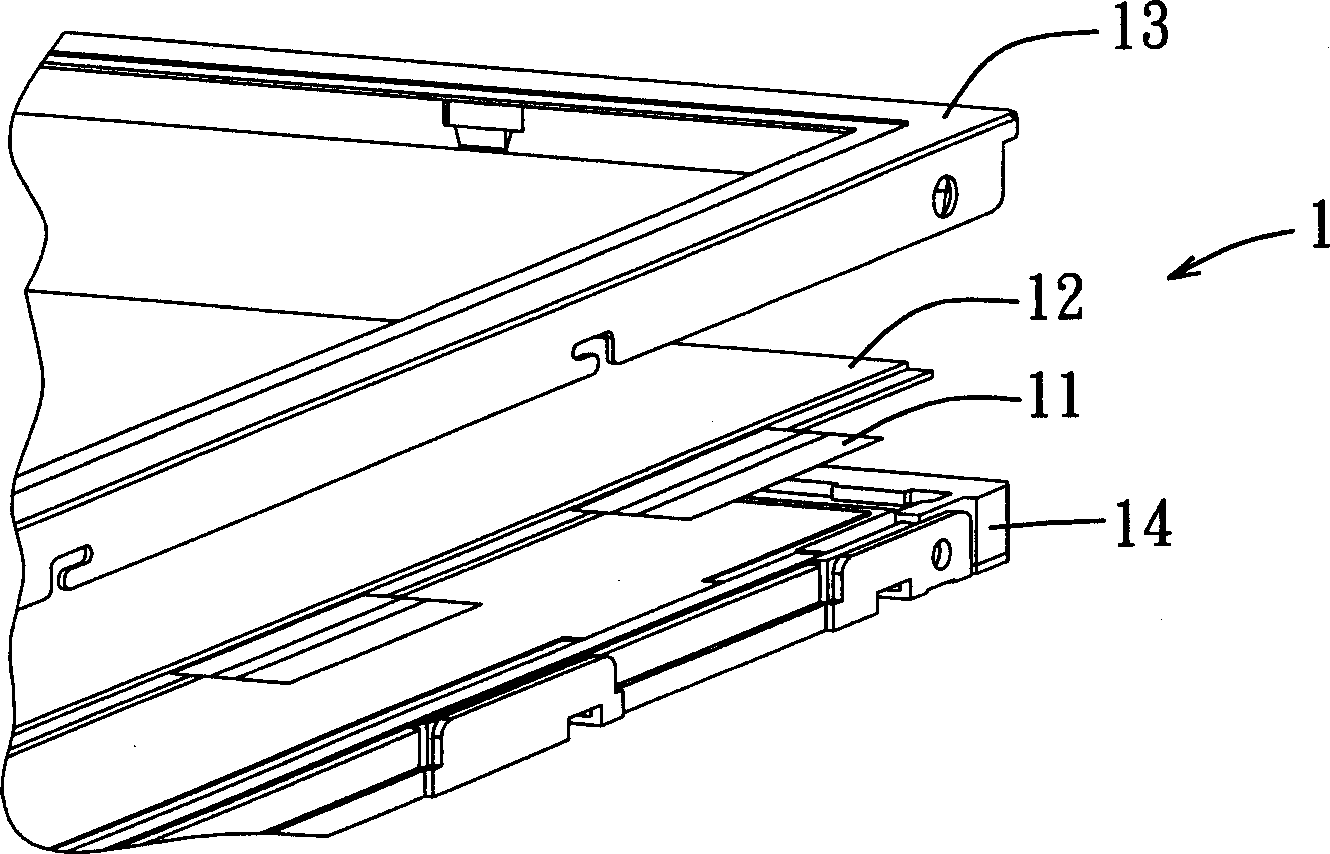

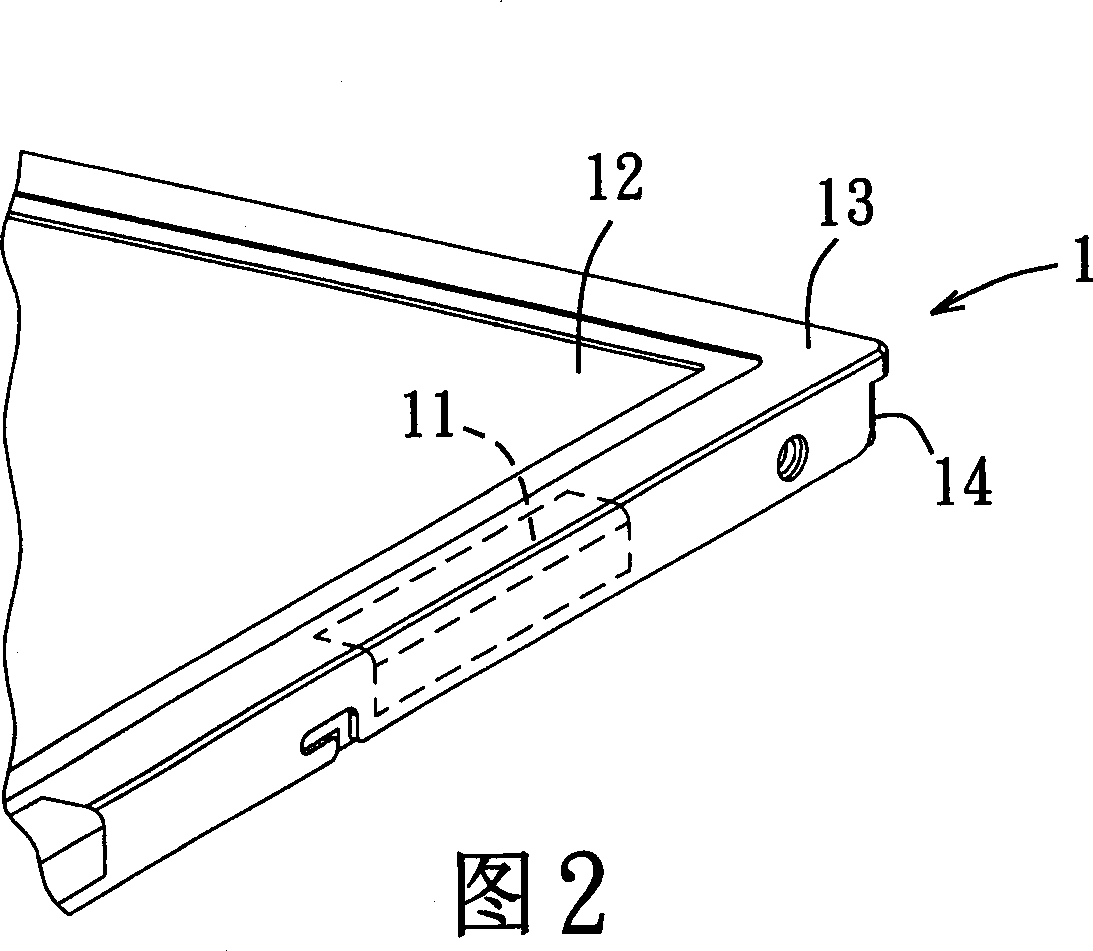

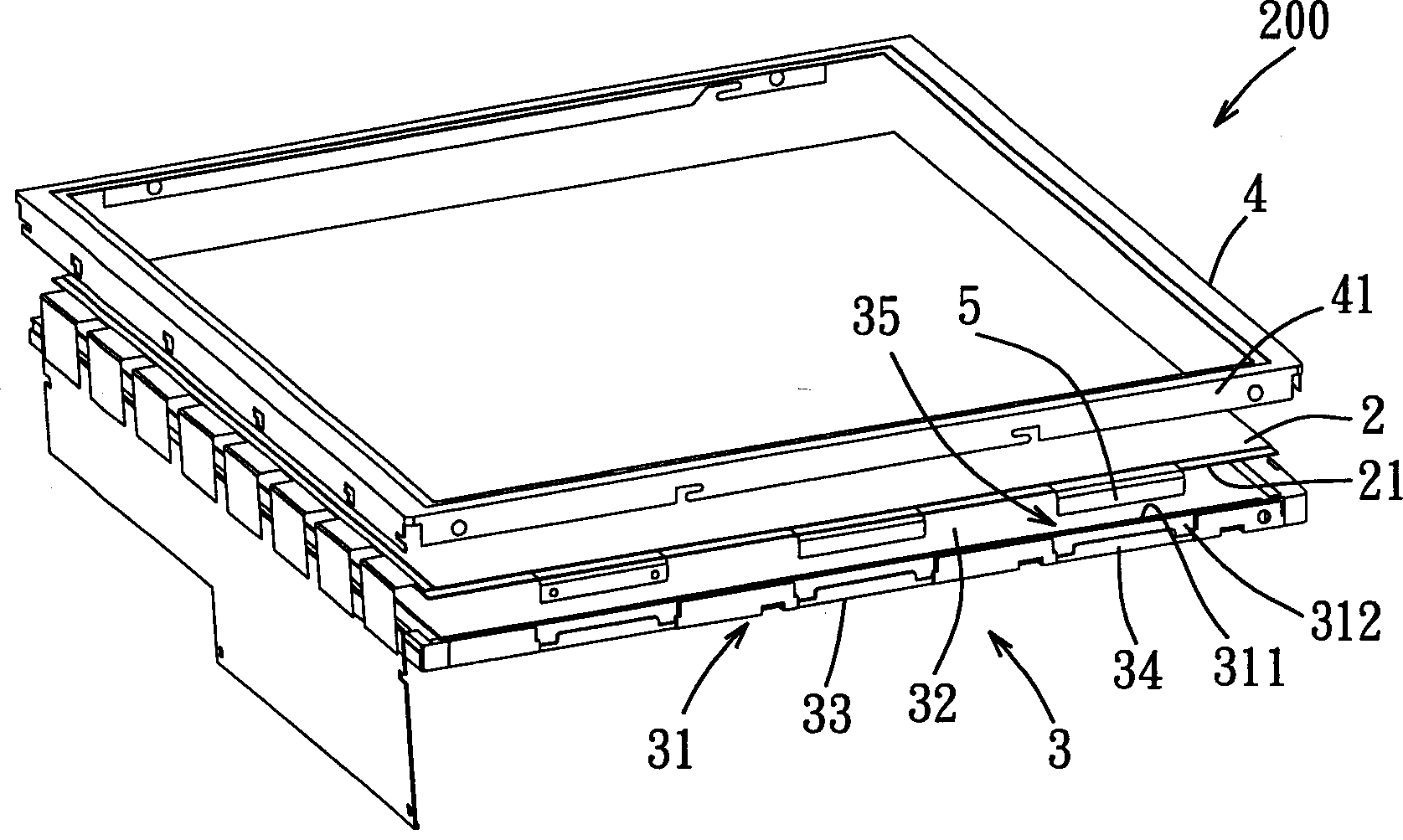

[0035] Refer to image 3 4, the liquid crystal panel module 200 with the flip-chip film limiting device in the first preferred embodiment of the present invention includes a liquid crystal panel 2, a base 3, and an outer frame 4. The liquid crystal panel 2 is electrically connected with several chips on film (COF) 5 on a selected side 21 at intervals and thermally pressed. Each chip on film 5 includes a driveable liquid crystal panel. Since the structure, composition and function of the chip 2 (not shown) and the film covering the chip are known to those skilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com