Pipe joint leakage detector

A leak detection and pipe joint technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of undetectable pipe joints, high detection sensitivity and high detection accuracy, Achieve the effect of shortening detection time, high detection sensitivity and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

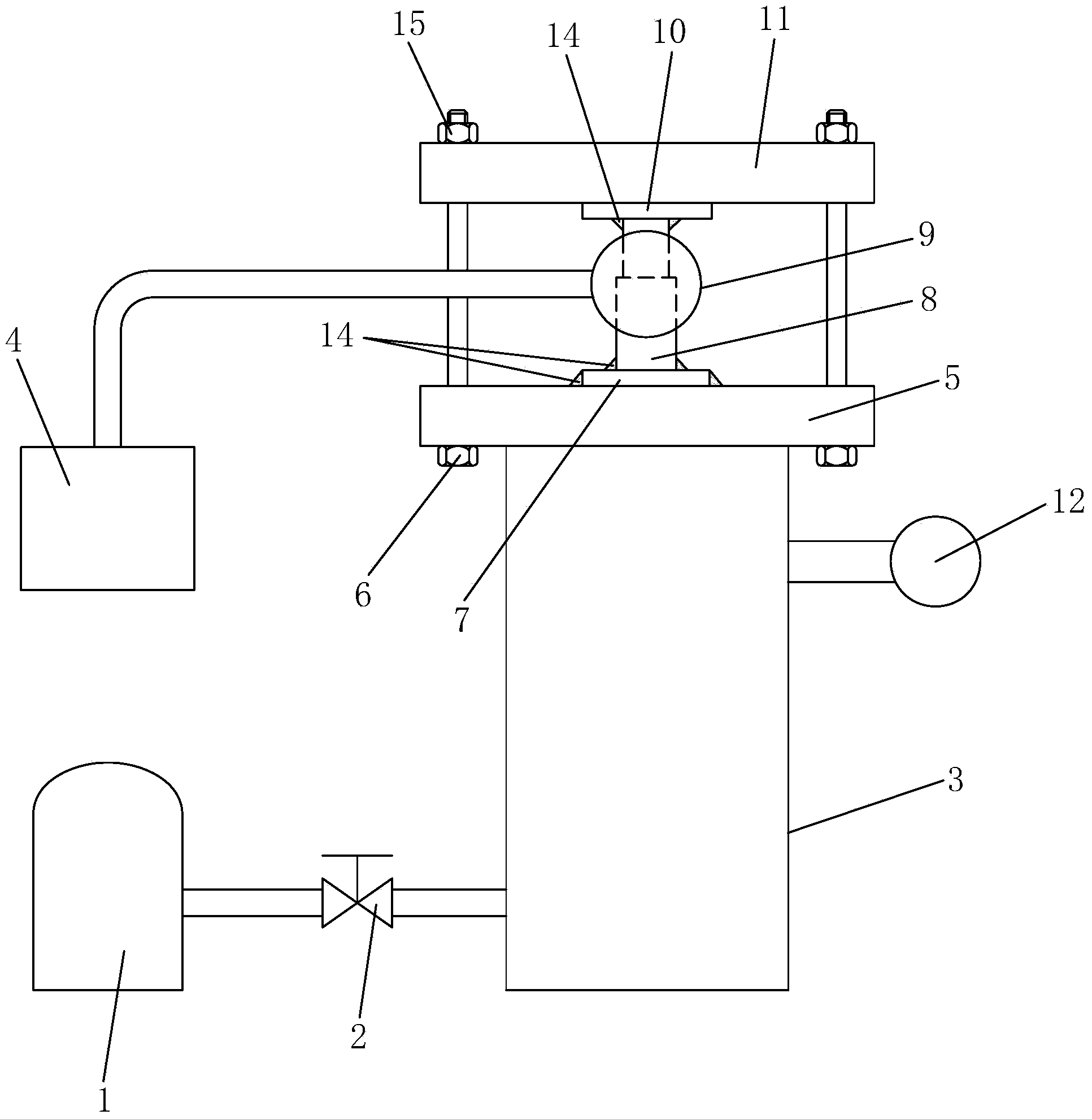

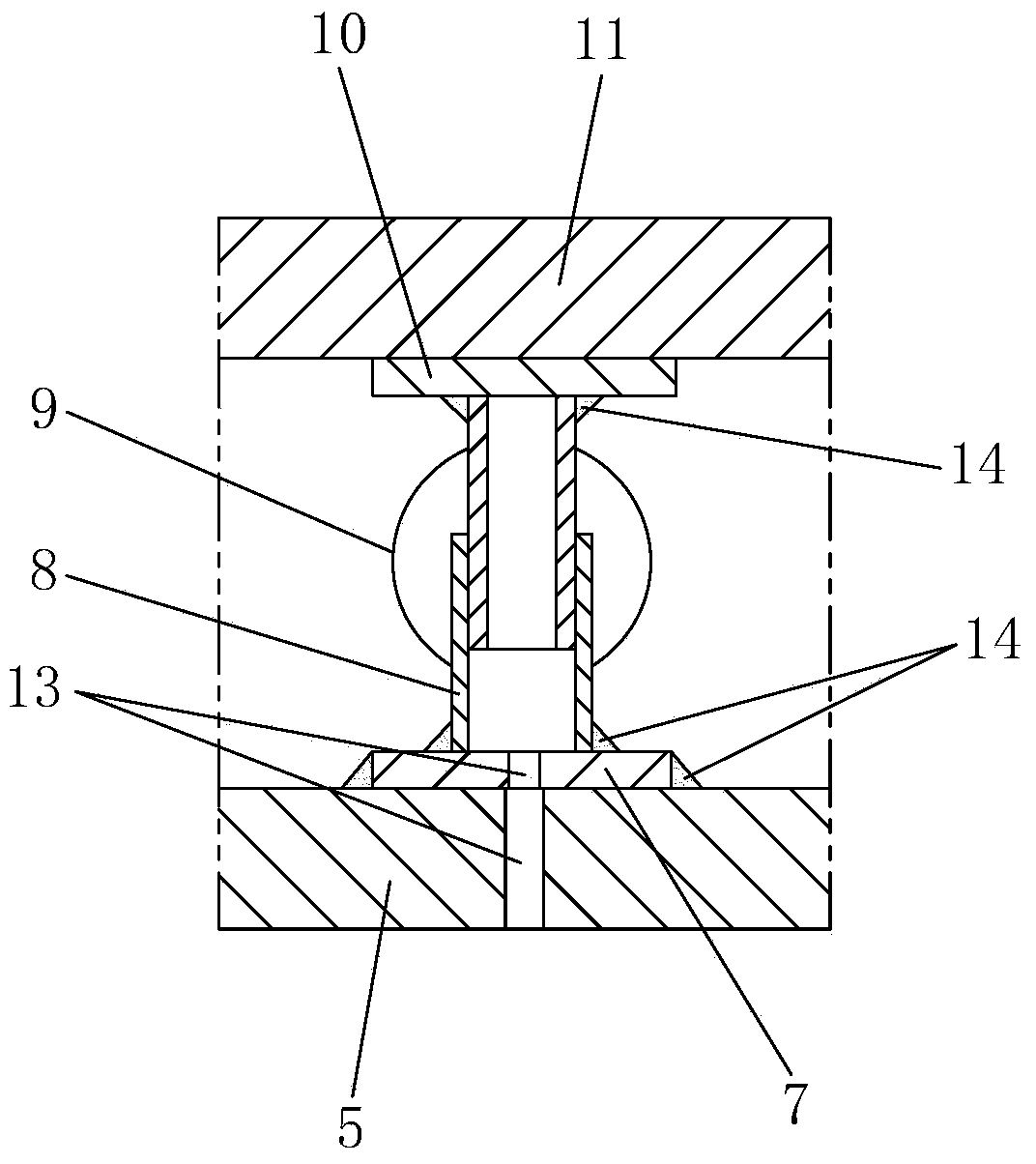

[0024] Such as figure 1 and figure 2 As shown, the present invention comprises a helium gas bottle 1, a stop valve 2, a buffer tank 3, a collection air bag 9 and a helium mass spectrometer leak detector 4, and the outlet of the helium gas bottle 1 is connected with one end of the stop valve 2, and the stop valve The other end of 2 is connected to the inlet of the buffer tank 3, the buffer tank 3 is connected with a pressure gauge 12, the top of the buffer tank 3 is provided with a pipe joint connection mechanism for connecting the pipe joint 8, and the pipe joint connection mechanism It includes a connection flange 5, a pressure plate 11, a first gasket 7 and a second gasket 10, the connection flange 5 is sealed and fixed on the top of the buffer tank 3, the pressure plate 11 is arranged above the connection flange 5, the The second gasket 10 is arranged on the lower end surface of the pressure plate 11, the first gasket 7 is arranged on the upper end surface of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com