Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Lattice deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

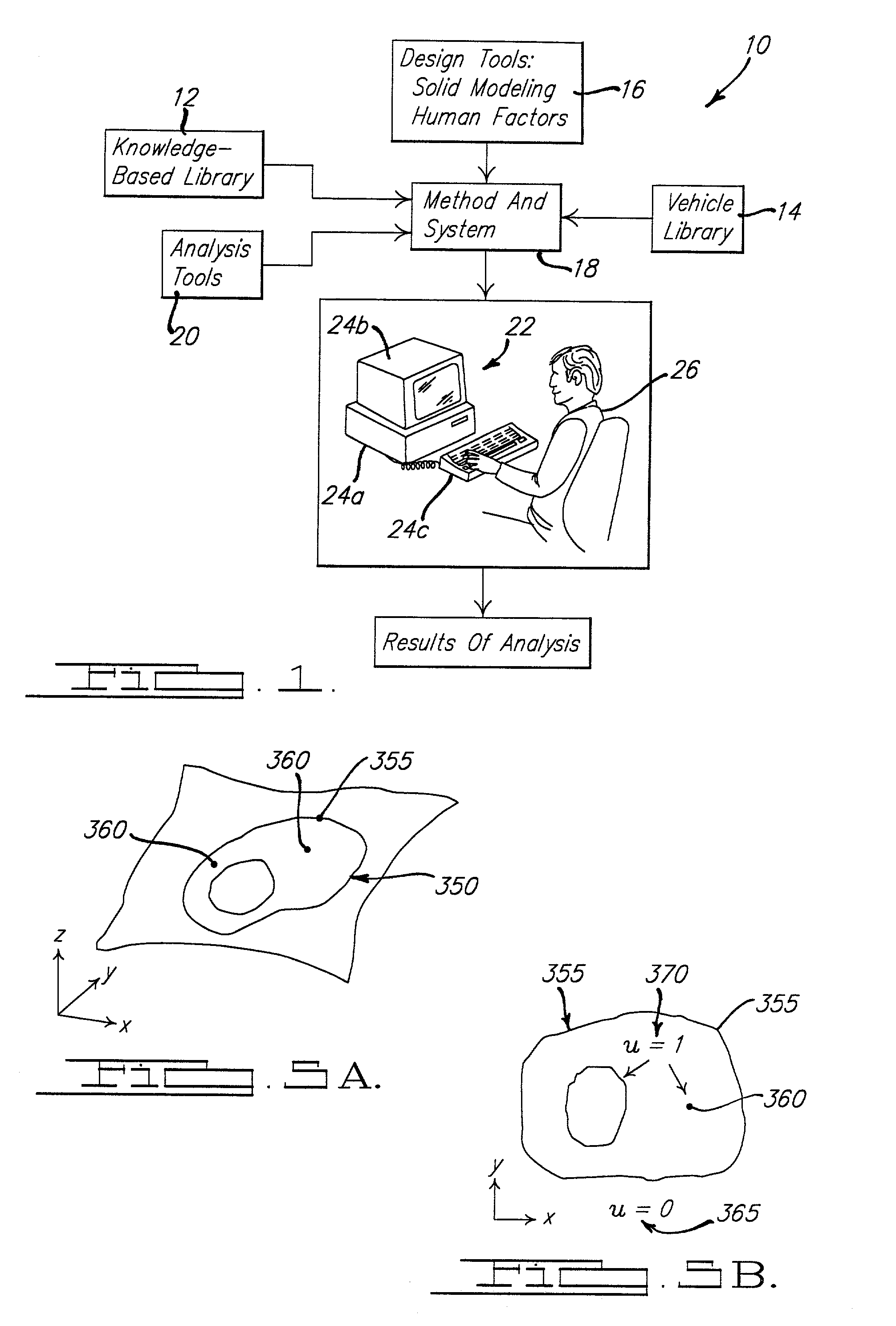

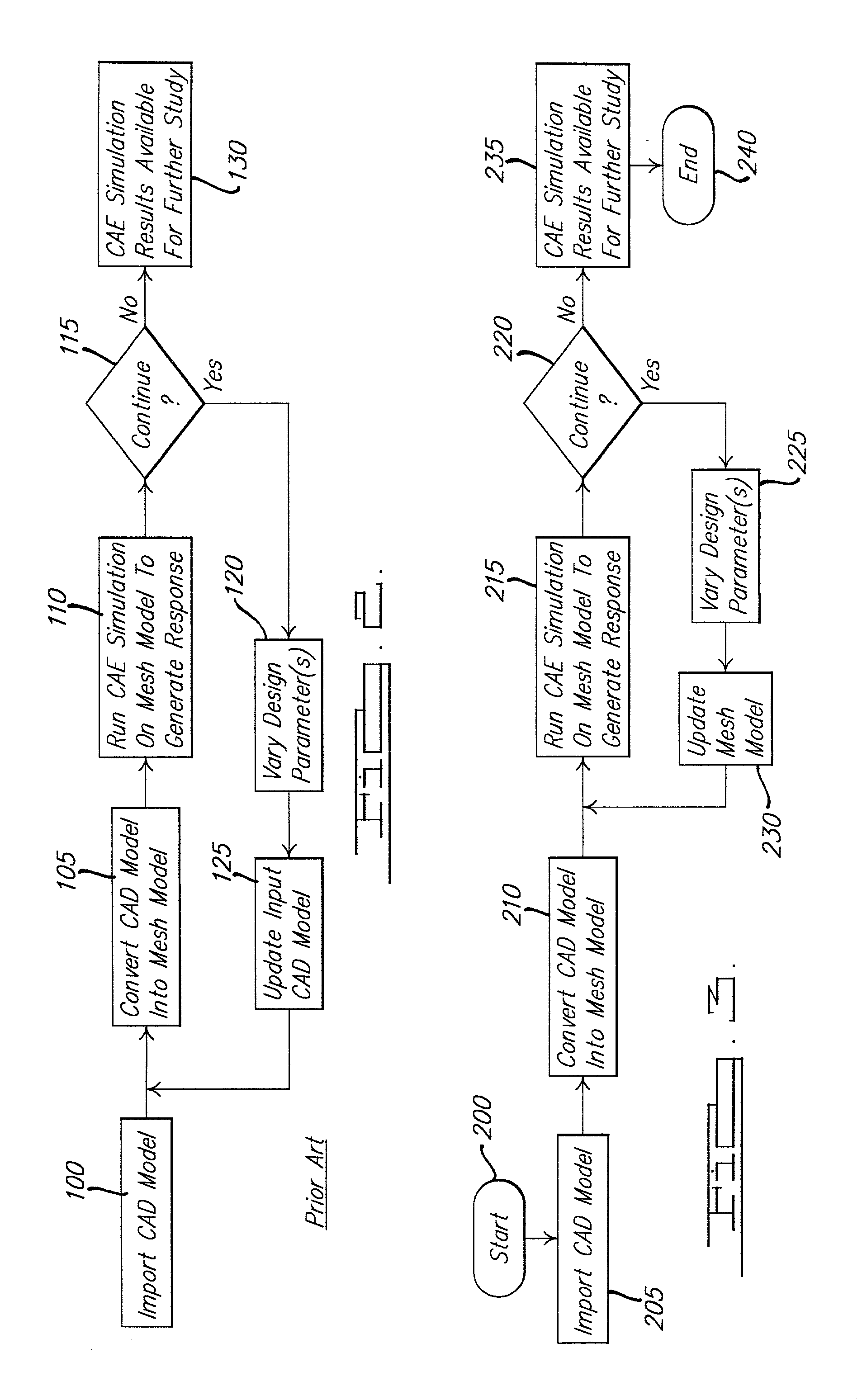

System and method of direct mesh manipulation

ActiveUS20030080957A1Geometric CADData processing applicationsComputer Aided DesignComputer graphics (images)

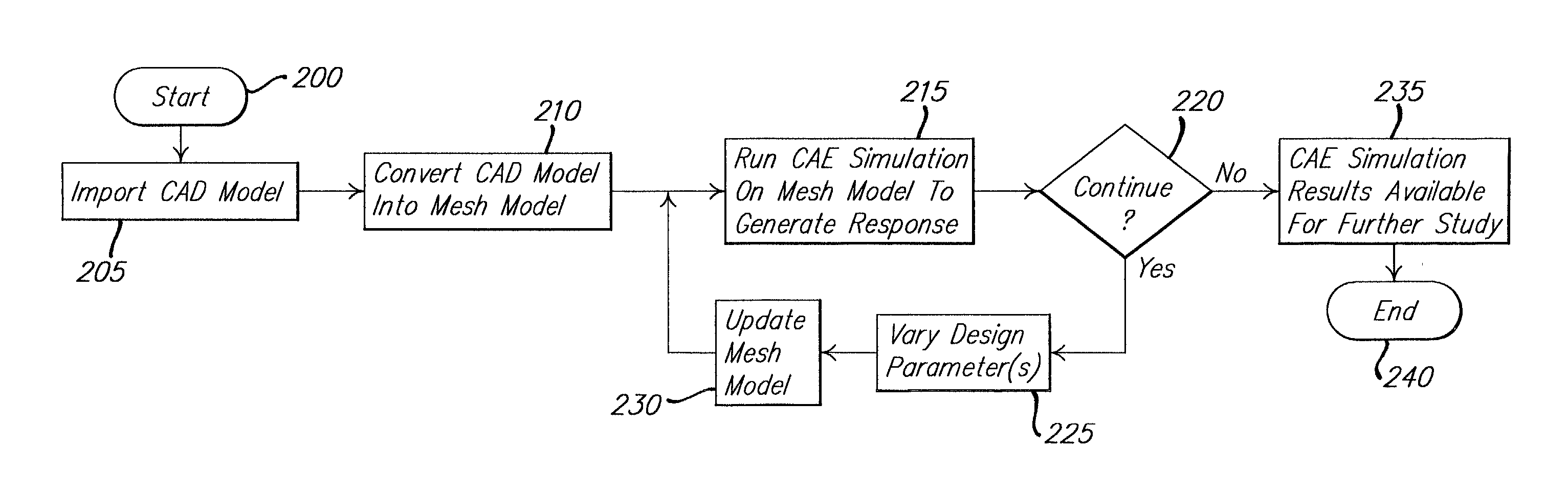

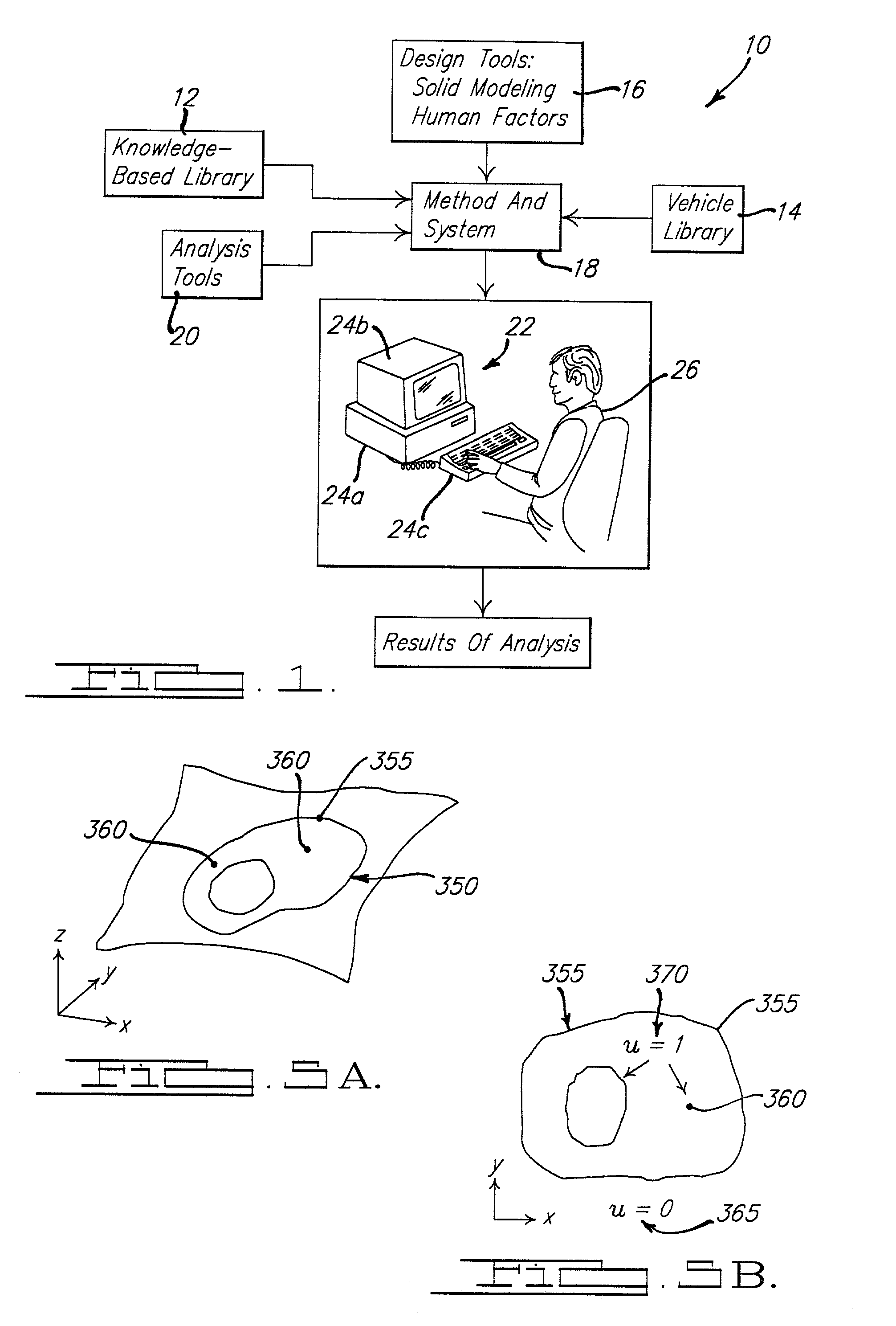

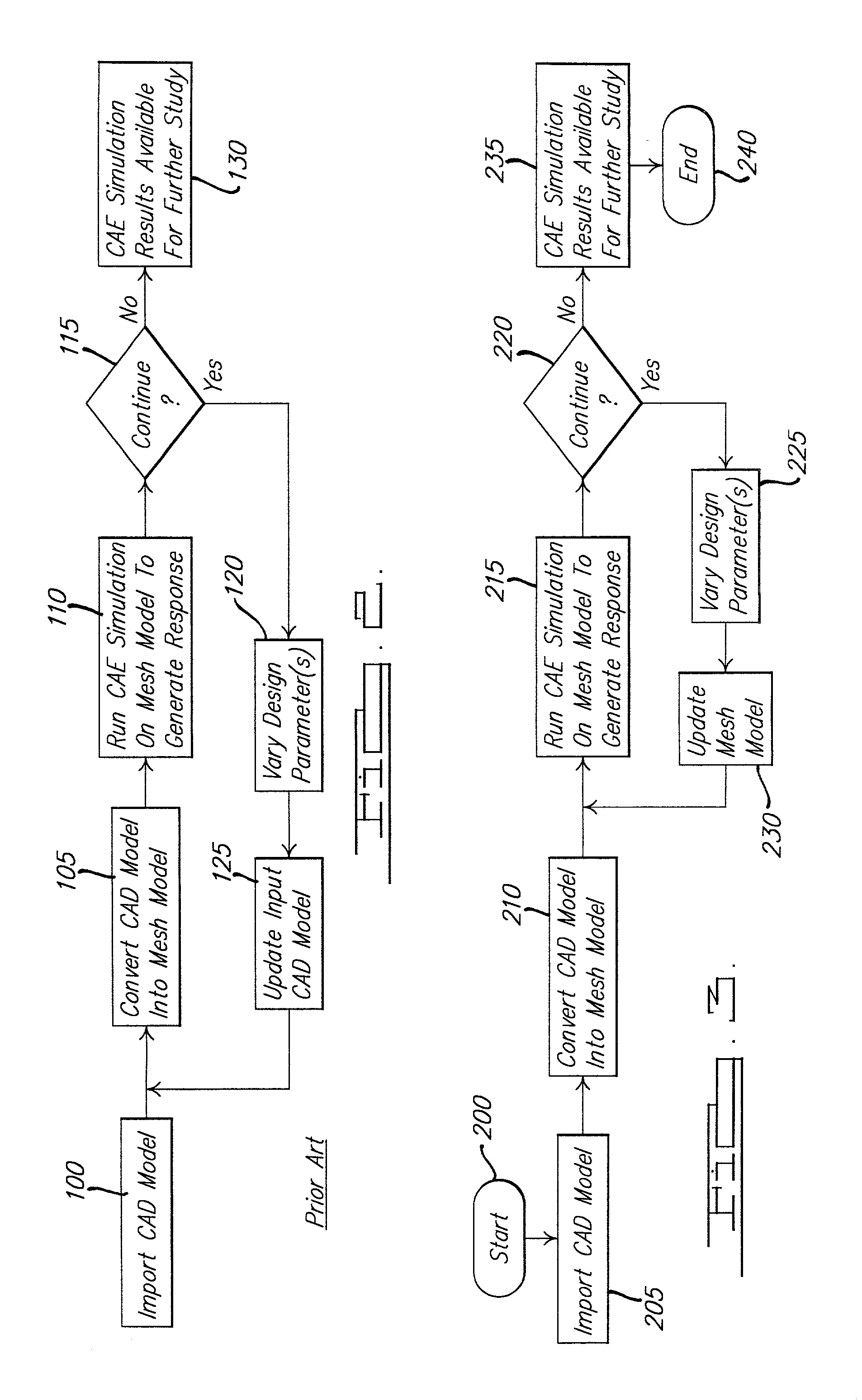

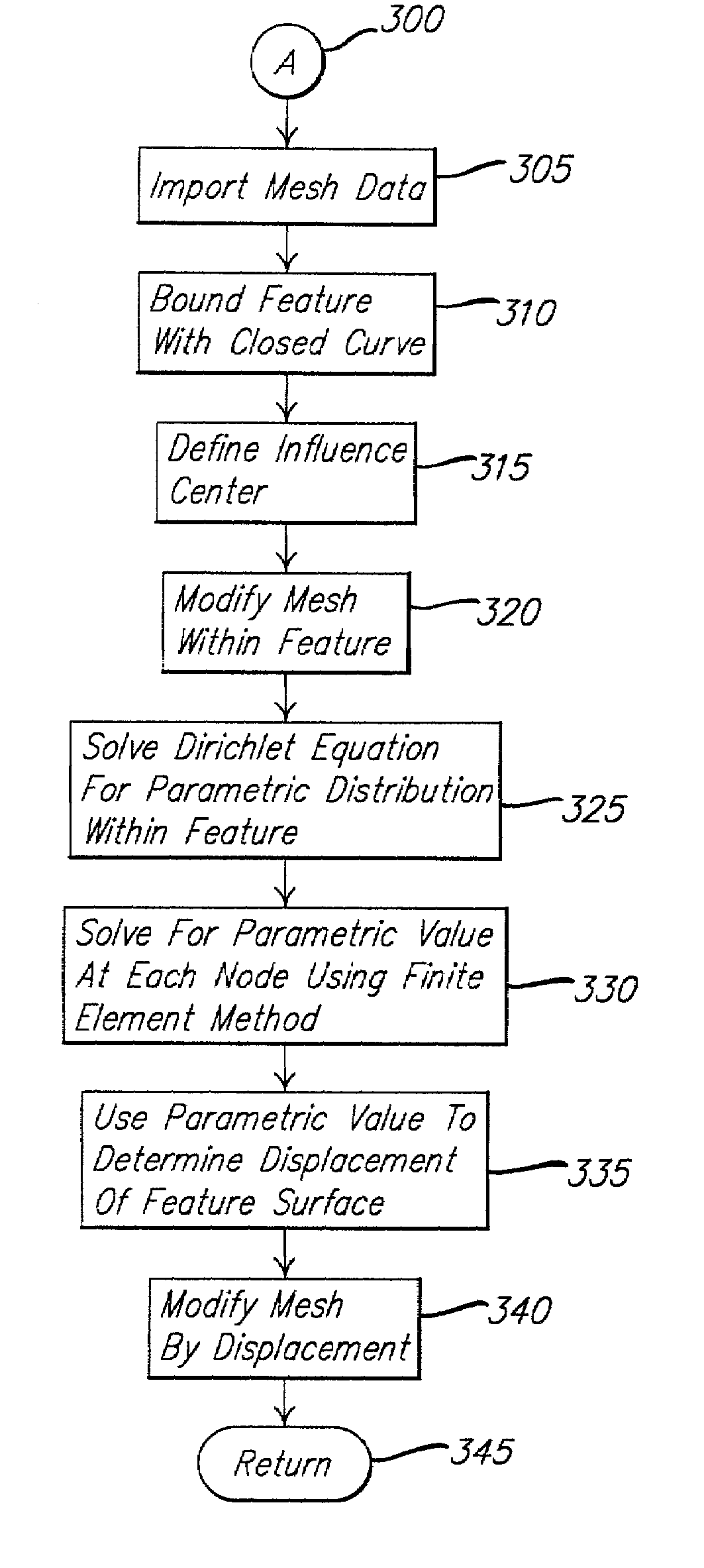

A system and method for computer-aided engineering analysis using direct mesh manipulation of a mesh model is provided. The system includes a computer system having a memory, a processor, a user input device and a display device. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the CAD model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of modifying a surface of the mesh model by varying a predetermined parameter using direct surface manipulation (DSM), updating the mesh model and using the updated mesh model in further CAE analysis. Three techniques are provided for modifying a surface feature, including using a Dirichlet parameter distribution to determine the displacement of the surface feature; modeling the surface feature as an elastic sheet to determine deformation; and enclosing the feature within a lattice structure and using lattice deformation to determine surface deformation.

Owner:FORD GLOBAL TECH LLC

System and method of direct mesh manipulation

ActiveUS7324103B2Geometric CADData processing applicationsComputer Aided DesignComputer graphics (images)

A system and method for computer-aided engineering analysis using direct mesh manipulation of a mesh model is provided. The system includes a computer system having a memory, a processor, a user input device and a display device. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the CAD model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of modifying a surface of the mesh model by varying a predetermined parameter using direct surface manipulation (DSM), updating the mesh model and using the updated mesh model in further CAE analysis. Three techniques are provided for modifying a surface feature, including using a Dirichlet parameter distribution to determine the displacement of the surface feature; modeling the surface feature as an elastic sheet to determine deformation; and enclosing the feature within a lattice structure and using lattice deformation to determine surface deformation.

Owner:FORD GLOBAL TECH LLC

High-aluminum thin electrical steel and producing method thereof

The invention provides high-aluminum thin electrical steel and a producing method thereof. The steel comprises following chemical components by weight: not more than 0.0030% of C, 1.5-2.0% of Si, 0.10-0.30% of Mn, not more than 0.008% of P, not more than 0.0020% of S, not more than 0.0025% of N, 1.5-2.0% of Als, not more than 0.001% of Ti, not more than 0.0020% of Nb and not more than 0.0020% of V, with the balance being Fe and other unavoidable residual elements. The producing method includes smelting, continuous casting, hot rolling, normalizing, cold rolling and annealing. By high-aluminum alloying, the sensitivity of the steel in hot conditions is reduced and lattice deformation is relieved, thus facilitating stability of the product producing process. The Al element increases the specific resistance, allows the (100) component to be increased and the (111) component to be reduced, reduces the iron loss and achieves high silicon effects. The plate shape is controlled by rolling with heat and a secondary cold rolling method. The electrical steel and the producing method are suitable for producing cold-rolled non-oriented silicon steel thin strips having a thickness of 0.2-0.3 mm, and meet the technical requirements of frequency conversion.

Owner:ANGANG STEEL CO LTD

Semiconductor device having vertical channel, resistive memory device including the same, and method of manufacturing the same

ActiveUS20150372135A1Solid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

A semiconductor device includes a semiconductor substrate having a first conductivity type, a plurality of pillars extending to a direction perpendicular to a surface of the semiconductor substrate, a stress providing layer formed in the semiconductor substrate between pillars and forming a junction with the semiconductor substrate below each pillar to cause lattice deformation in the pillar, a source region having a second conductivity type opposite to the first conductivity type formed in the semiconductor substrate below the pillar, a drain region having the second conductivity type formed in an upper portion of the pillar, a gate insulating layer formed on a lateral surface of the pillar and a surface of the stress providing layer, and a gate electrode formed to surround the lateral surface of the pillar.

Owner:SK HYNIX INC

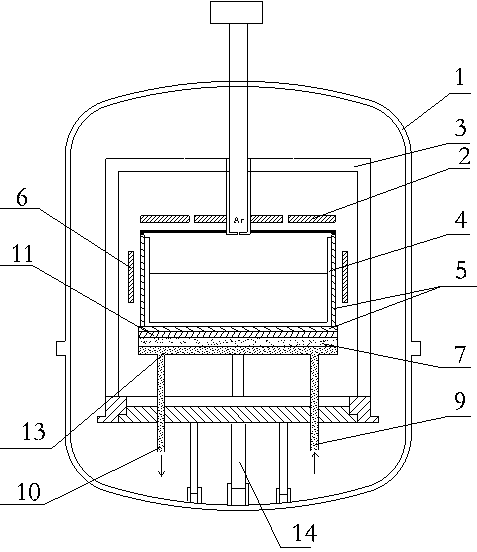

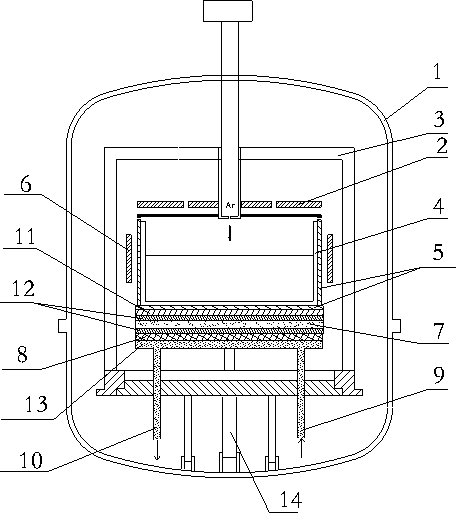

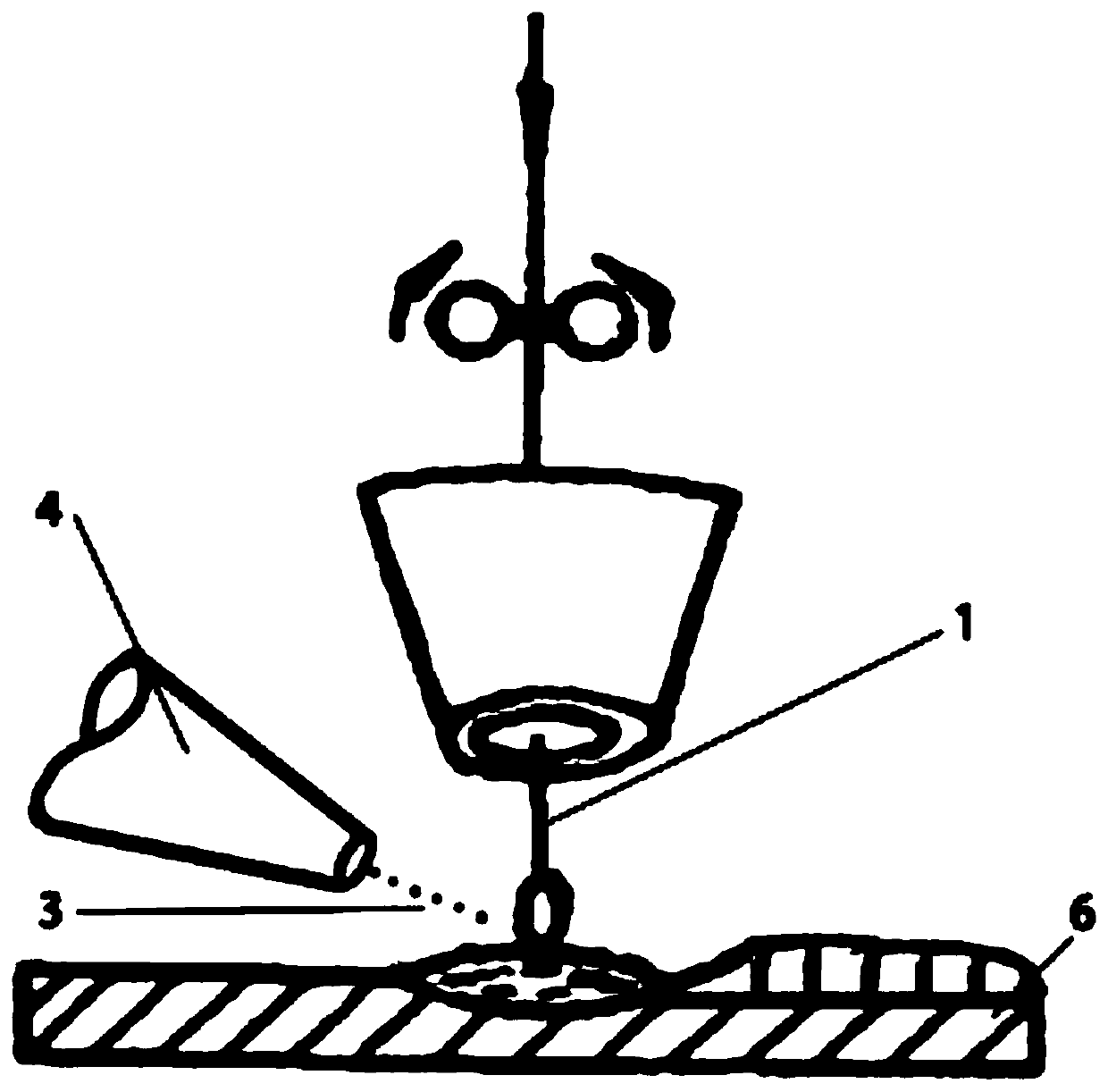

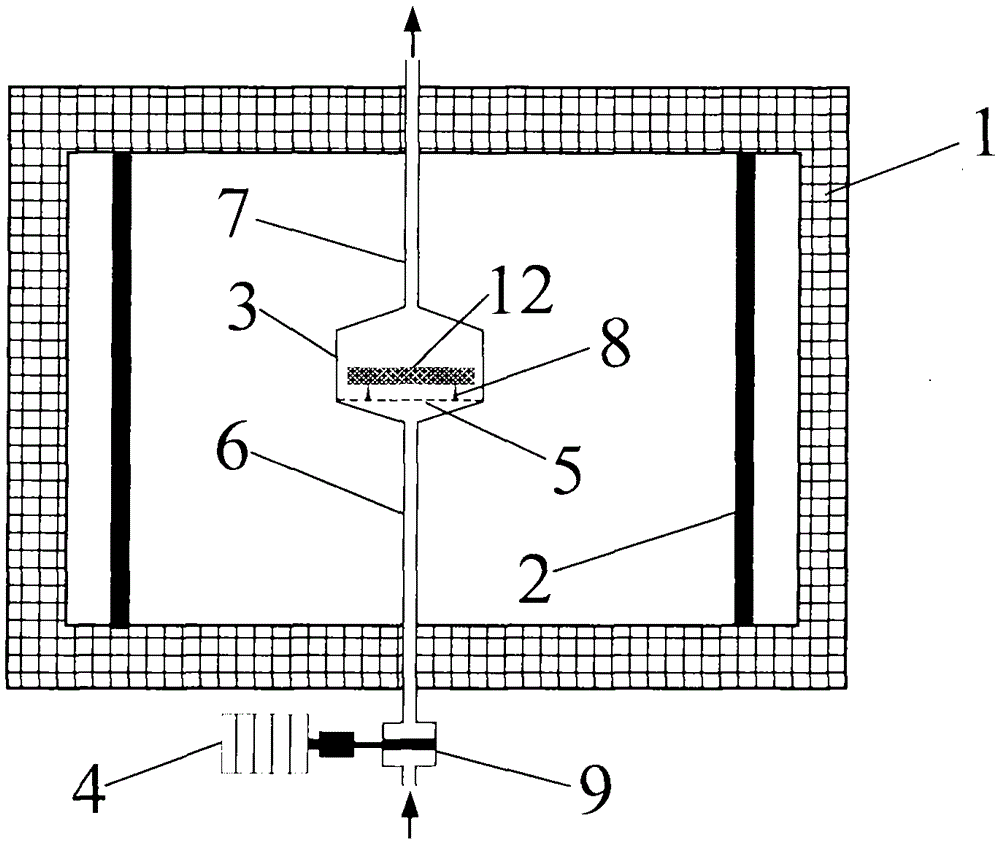

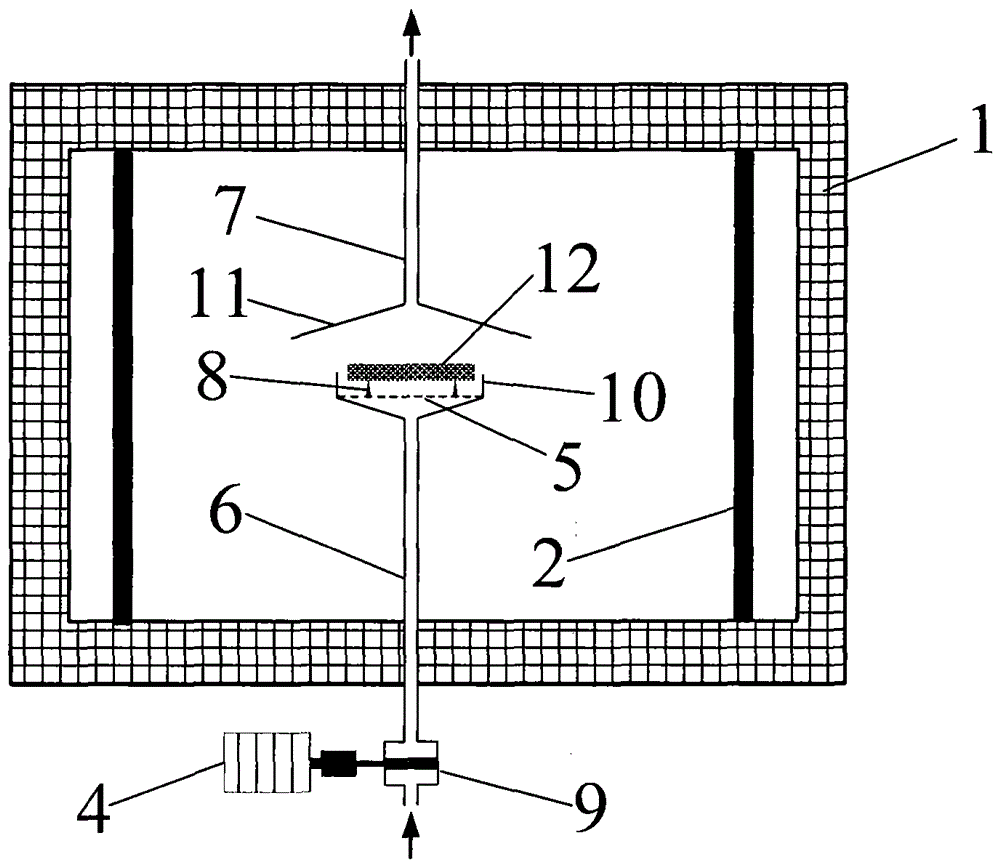

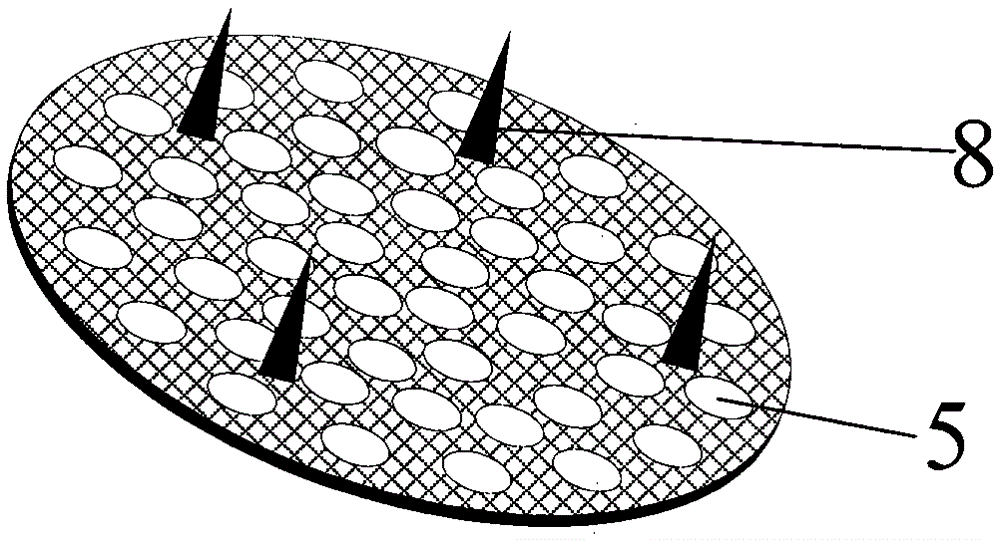

Water chilling ingot furnace and ingot casting process thereof

InactiveCN103451726AFacilitated releaseImprove yieldPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention discloses a water chilling ingot furnace and an ingot casting process thereof. A water cooling disc (13) is arranged at the lower end of a heat exchange table (11), located at the lower end of a bottom heater (7), internally provided with a flow cavity and provided with a water inlet (9) and a water outlet (10), wherein the water inlet (9) and the water outlet (10) are communicated through the flow cavity, and are respectively communicated with the outer end of a furnace body (1). The water chilling ingot furnace disclosed by the invention has the beneficial effects that the problem of influence on formation of columnar crystals due to transfer of heat of a crucible in a radial direction caused by lifting an insulating cage to dissipate heat from a side is solved by way of replacing the original mode of lifting the insulating cage to dissipate heat by water cooling; an insulating cage body in a lifting process is prevented from rubbing with the top of the insulating cage to generate carbon dust which is easy to enter the crucible to increase carbon impurity content of a silicon ingot so as to cause lattice deformation.

Owner:TIANWEI NEW ENERGY HLDG

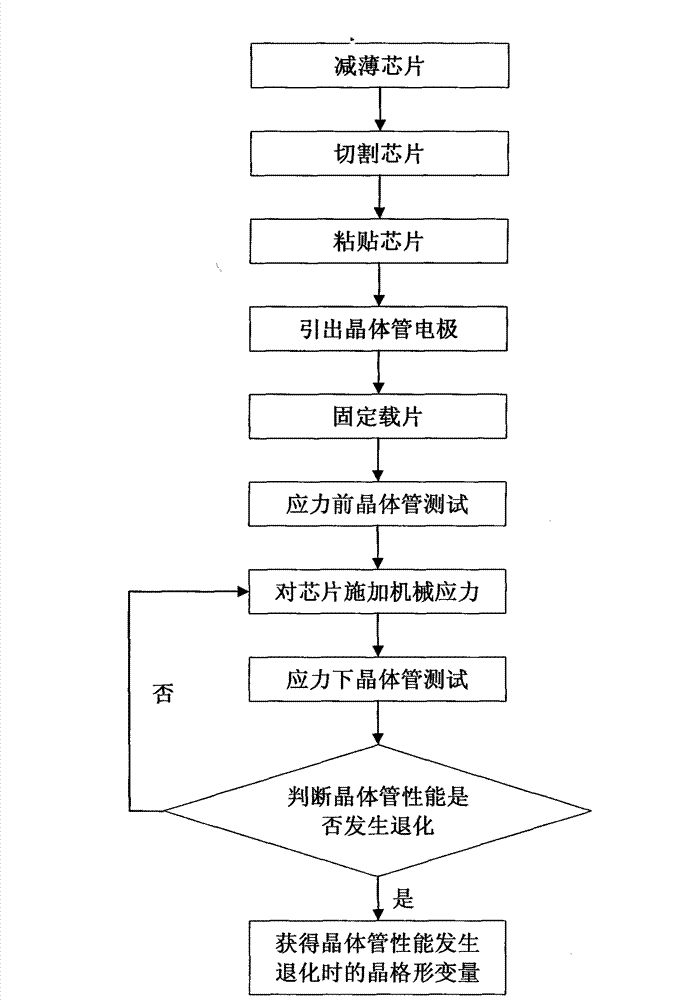

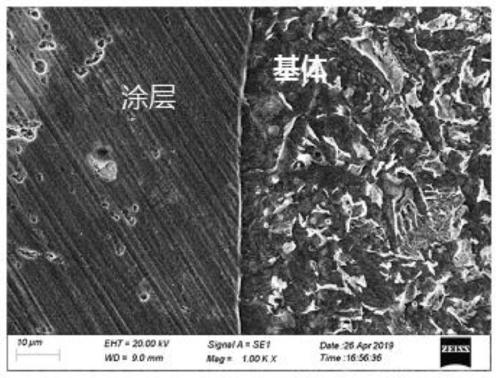

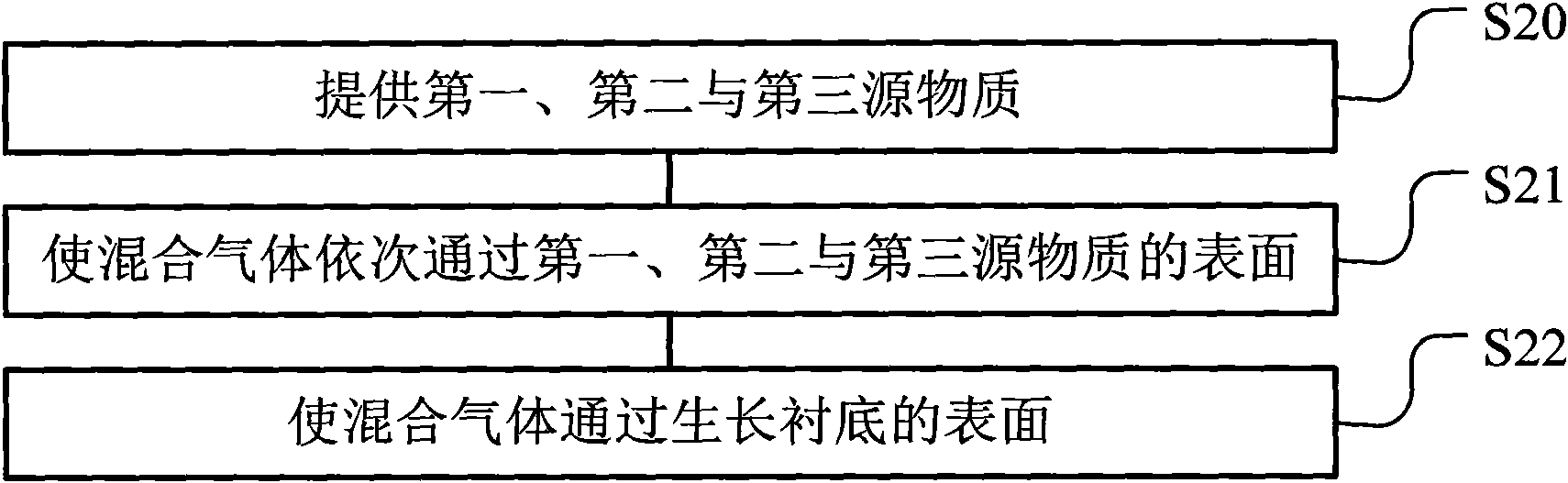

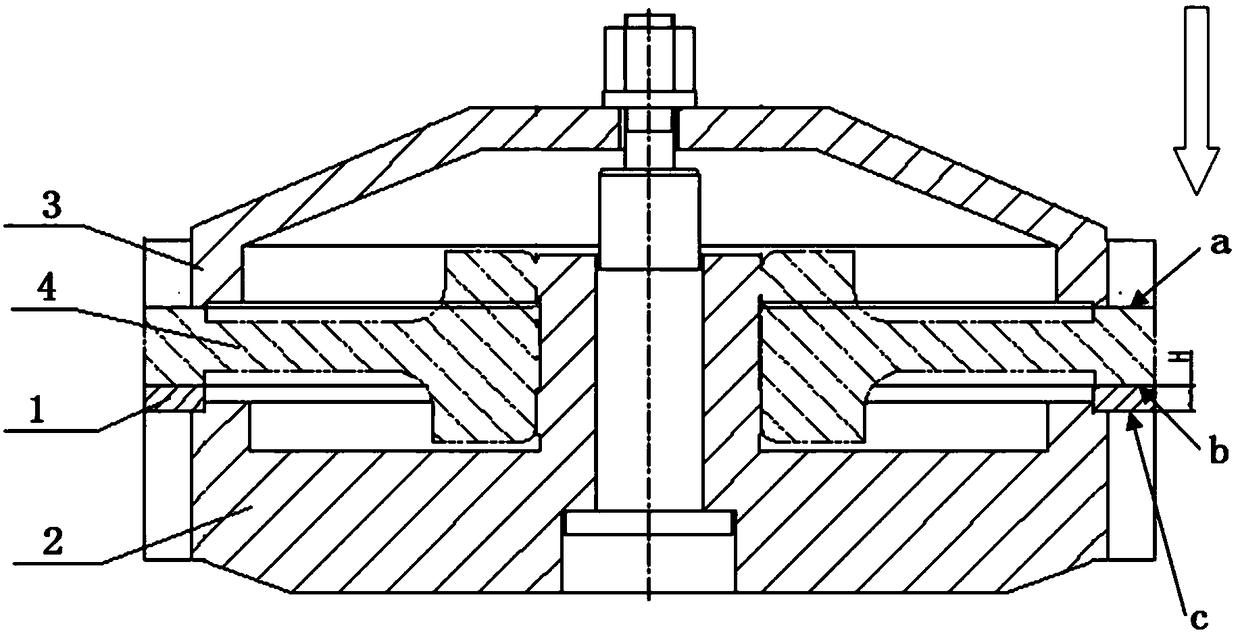

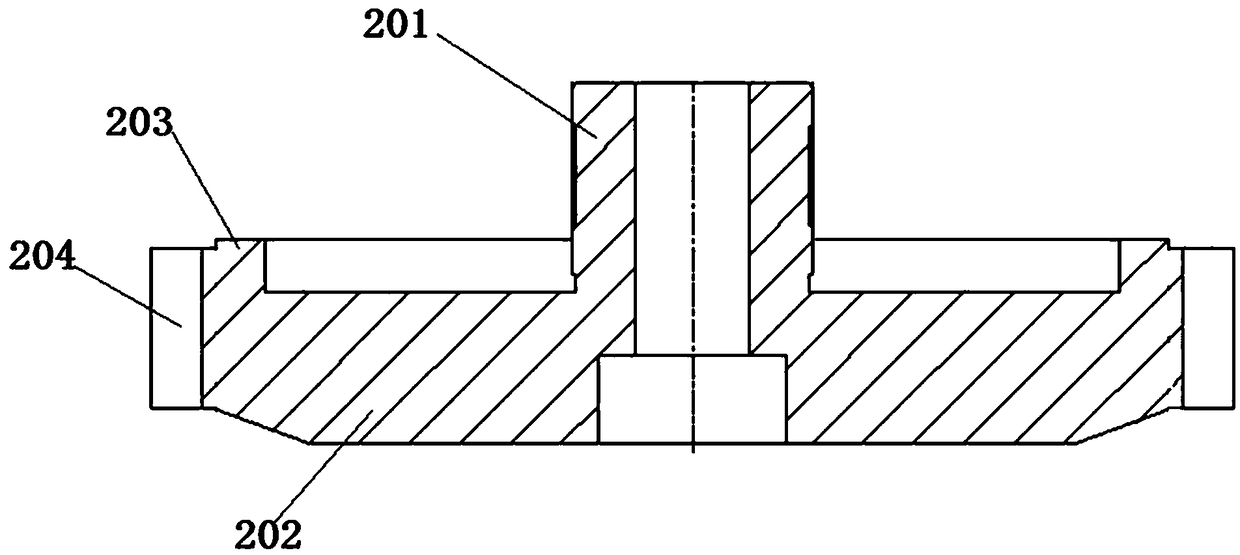

Device and method for testing performance degradation caused by transistor lattice deformation

ActiveCN102967814ASimple and convenient application of mechanical stressRealize analysisIndividual semiconductor device testingTest performanceEngineering

The invention discloses a device and method for testing performance degradation caused by transistor lattice deformation. The device for testing the performance degradation caused by the transistor lattice deformation comprises a base, a precise displacement platform, a cushion block, a carrier and a pressing block. The method for testing the performance degradation caused by the transistor lattice deformation comprises the following steps of (1) thinning a chip; (2) cutting the chip; (3) sticking the chip; (4) leading an electrode out of a transistor; (5) fixing the carrier; (6) testing the transistor before applying the stress; (7) applying the mechanical stress onto the chip; (8) testing the transistor under the stress; (9) judging whether the performance of the transistor degrades; and (10) obtaining the lattice deformation value when the performance of the transistor degrades. The device and method for testing the performance degradation caused by the transistor lattice deformation has the advantages of easily applying compression stress onto the chip, and being large in range of the applicable mechanical stress, good in chip bend uniform, simple and accurate in lattice tension amount calculation, and is suitable for analyzing the influence of the transistor lattice deformation on the performance of the transistor.

Owner:云南凝慧电子科技有限公司

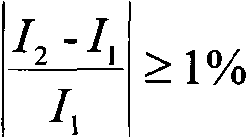

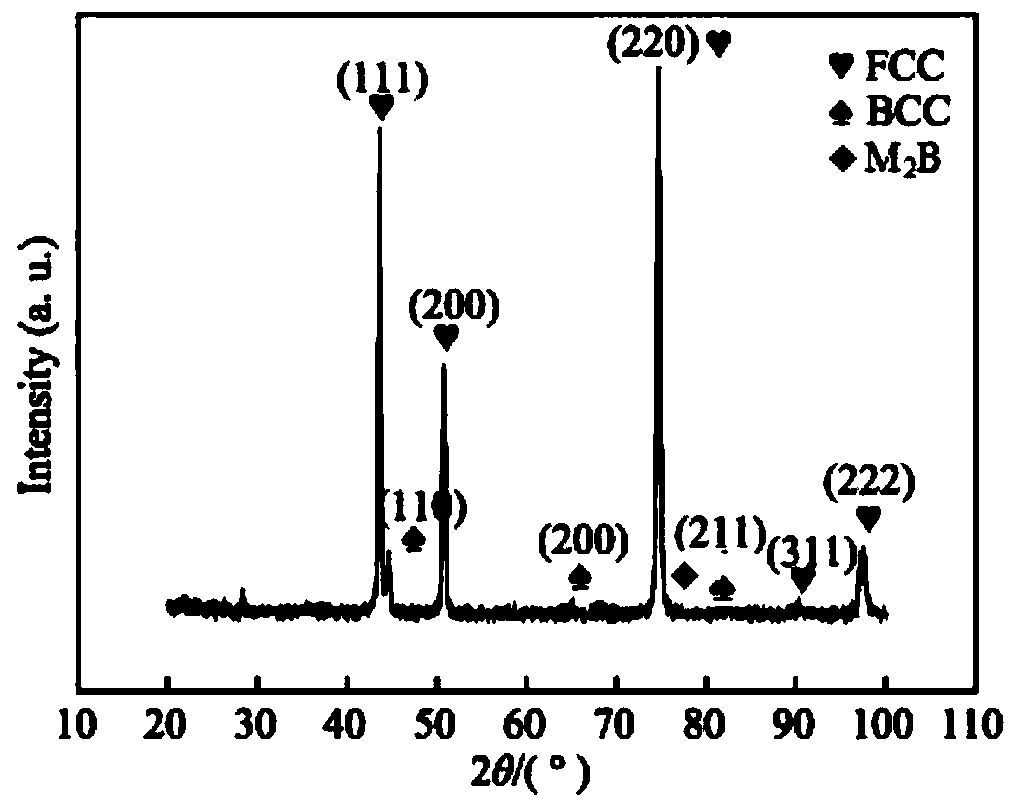

Boron-containing high-entropy alloy coating and preparation method thereof

InactiveCN110273153AIncrease the solid solution limitImprove distortionMetallic material coating processesBorideHigh entropy alloys

The invention provides a boron-containing high-entropy alloy coating and a preparation method thereof, and belongs to the field of alloy coatings. Some B atoms are adopted as self-fluxing atoms to be subjected to solid solution in a solid solution body of the face-centered cubic structure, the hardness of the coating is improved, granular and short rod-like M2B hard phases are separated out in a coating base, and due to separation of the hard phases, one one hand, the dispersion strengthening effect is achieved; on the other hand, the solid solution reinforcing effect is lowered, the coating hardness is lowered, and due to the hardness improving effect of dispersion strengthening, solid phase strengthening is greatly offset, the influence of the coating hardness is lowered, finally, the coating hardness is still improved, and a boron element is adopted as a secondary element to be added into high-entropy alloy; due to the gap effect of non-metal elements, the alloy stacking fault energy is improved, lattice deformation is increased, the solid solution strengthening effect is achieved, the non-metal element and the main element can form borides to be dispersed into alloy tissue, the dispersion strengthening effect is generated, and therefore the hardness and corrosion resistance of the high-entropy alloy are improved.

Owner:NANCHANG UNIV +1

Self-lubricating diamond wire and production method thereof

InactiveCN107378814ASelf-lubricatingReduce frictional resistanceElectrolytic coatingsGrinding devicesSurface cleaningHardness

The invention relates to the technical field of diamond wires, in particular to a self-lubricating diamond wire and a production method thereof. The method comprises the following steps of (1) paying off, (2) surface cleaning, (3) surface pretreatment, (4) diamond adhering, (5) diamond solidification, (6) coating of an antifriction coating and (7) drying. After the structure and method are adopted, the self-lubricating diamond wire and the production method have the following advantages that firstly, compared with common electroplated diamond wires, the diamond wire produced through the technique has the self-lubricating performance, the friction resistance during cutting can be reduced, and the cutting process is smoother; secondly, the diamond particle holding strength is not obviously influenced after the surface antifriction coating is adopted, and the wire breakage risk can be effectively reduced; thirdly, by controlling technique parameters, nickel lattices in the antifriction coating are distorted, dislocation motion is hindered, thus, lattice deformation resistance is increased, the surface hardness is improved while the friction resistance is lowered, and the diamond holding force is improved; and fourthly, the production technique does not need to be adjusted greatly, and the quality can be greatly improved.

Owner:盛利维尔(常州)金属材料有限公司

Quenching oil for gear shift connection rod

InactiveCN105821186AEnhance crystal densityHigh strengthFurnace typesQuenching agentsTangential stressPhenol

The invention discloses quenching oil for a gear shift connection rod. The quenching oil is prepared from the following raw materials in parts by weight: 65-75 parts of 150N Group II base oil, 2-5 parts of high molecular weight succinimide, 10-15 parts of palm wax, 35-40 parts of refined paraffin base mineral oil, 2-3 parts of sulfide base phenol, 2-3 parts of dimethylmethane petroleum asphalt resin, 4-5 parts of epoxidation castor oil, 1-2 parts of alkylene polyether and 3-8 parts of modified antioxygen. By adopting the quenching oil, the internal crystalline phase density of metal can be reinforced, and lattice deformation torsion resistance is improved, so that metal strength is obviously improved; the tensile property and tangential stress resistance of the manufactured gear shift connection rod are greatly improved; and the service life of the connection rod is greatly prolonged.

Owner:CHANGLI FORGING

Oxide-based high-entropy alloy ceramic binding agent special for PCBN

The invention discloses an oxide-based high-entropy alloy ceramic binding agent special for PCBN. The binding agent is composed of, by mass, 30-65% of high-entropy alloy and 35-70% of oxide ceramic. The high-entropy alloy in the binding agent can form a high-mixing-entropy stable solid solution, multiple types of special effects are generated, such as a high-entropy effect on thermodynamics, a lattice deformation effect in structure, a synergistic effect among multiple components and a 'cocktail' effect in performance. Therefore, compared with traditional alloy, the high-entropy alloy can achieve homogenization and alloying more easily, the alloy melting point is lower, and excellent performance, such as high strength, high hardness, high abrasion resistance, high electric resistance, high thermal resistance and corrosion resistance, to which the traditional alloy is inferior is achieved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

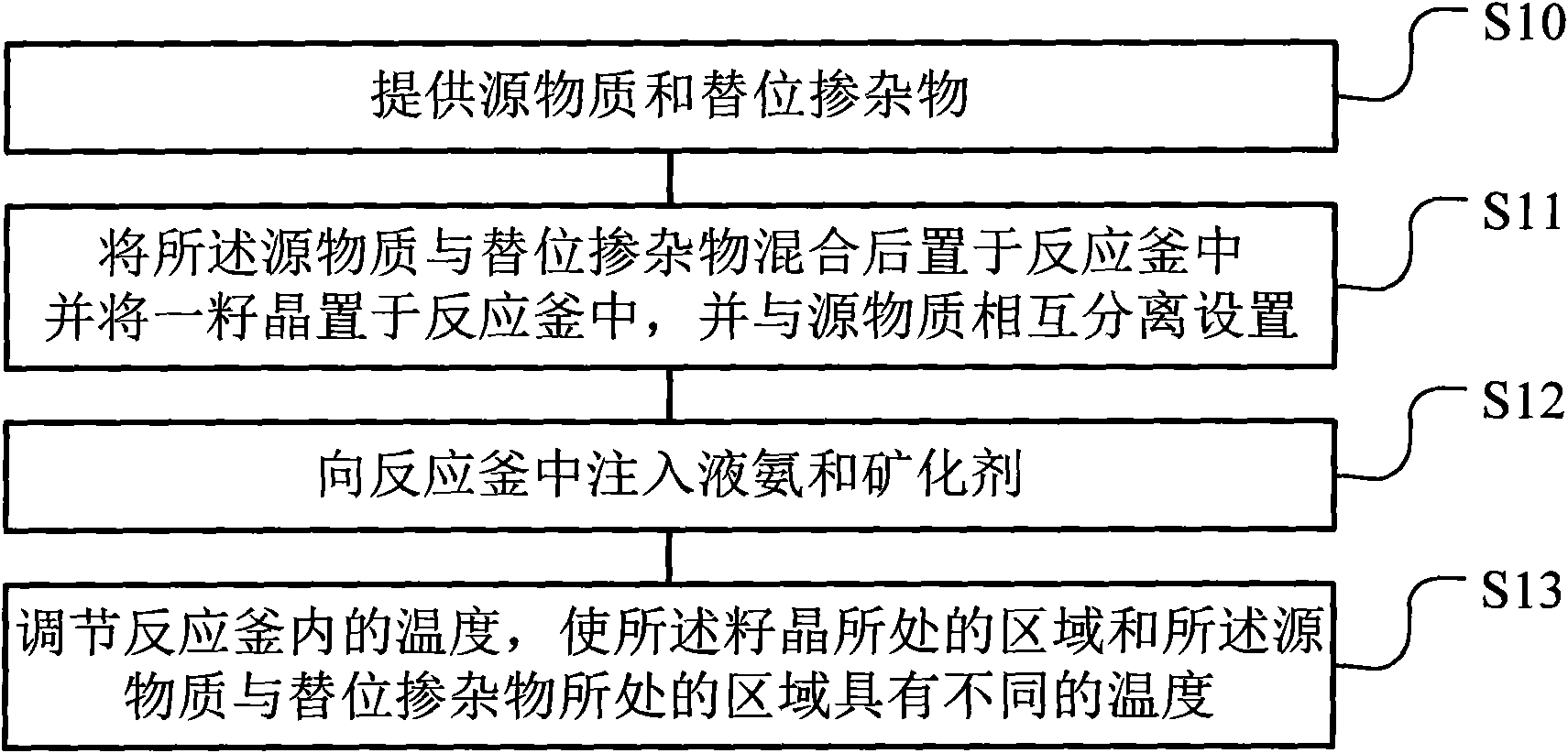

Compound semiconductor material doped with rare-earth elements and growth method thereof

InactiveCN101775658AImprove luminous efficiencyImprove lattice distortionPolycrystalline material growthSemiconductor/solid-state device manufacturingRare-earth elementSemiconductor materials

The invention discloses a compound semiconductor material doped with rare-earth elements, which is a crystal material being composed of III group elements and V group elements and doped with the rare-earth elements. The crystal material further comprises displacement adulterant which is an III group element or the combination of a plurality of III group elements, the atomic numbers of the III group elements contained in the displacement adulterant are smaller than those of the III group elements forming the crystal material, and the displacement adulterant substitutes original III group elements in crystal to form a displacement defect. The invention also provides a preparation method of the material. The invention has the advantages that the displacement defect is formed by doping elements with smaller atomic numbers in the material so as to improve the lattice deformation of the semiconductor material caused by doping the rare-earth element, thus improving the luminous efficiency of the material.

Owner:SUZHOU NANOWIN SCI & TECH

Growth method of neodymium-doped gadolinium gallium garnet laser crystal

InactiveCN1621576AReduce dislocation densityImprove radiation resistancePolycrystalline material growthBy pulling from meltGadolinium gallium garnetNitrogen gas

The Nd doped gadolinium gallium garnet laser (Nd:GGG) crystal has the material including gadolinium oxide, gallium oxide, neodymium oxide and cerium oxide in certain proportion prepared in two-step composing process. The Nd doped gadolinium gallium garnet laser crystal is grown in a Czochrolski process under the 98 % N2+2% O2 condition. The present invention solves the problem of doping Nd2O3 to cause lattice deformation, and the Nd:GGG crystal has raised radiation resistance and improved spectral and laser performance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Burr removal device for mortise outlet

ActiveCN109454290AExtended service lifeReduce depthBroaching accessoriesEngineeringLattice deformation

The invention provides a burr removal device for a mortise outlet. The burr removal device comprises a chip breaking ring which is of a circular ring structure, and the chip breaking ring is fixed tothe part below a cleaned plate-part; through arrangement of the chip breaking ring below the plate-part, the outlet end, during broaching of a mortise, extends to the position of the chip breaking ring, so that hard burrs are not liable to generate at the outlet end of the plate-part and the depth of a lattice deformation layer is reduced effectively; and thus the service life of the plate-part isprolonged.

Owner:AECC AVIATION POWER CO LTD

Multi-principal element alloy containing trace B and method for surface treatment of titanium alloy

ActiveCN105331870AImprove wear resistanceImprove high temperature oxidation resistanceMolten spray coatingSand blastingTitanium

The invention discloses a multi-principal element alloy containing trace B and a method for surface treatment of a titanium alloy. The multi-principal element alloy comprises, by mole, 23-30 parts of Al, 23-30 parts of Si, 23-30 parts of Cu, 1-5 parts of Ti, 21-30 parts of Zr and 1-4 parts of B. According to the method, a titanium alloy base material is cleaned and subjected to sand blasting roughening treatment, then plasma spraying equipment is used for spraying multi-principal element alloy powder on the surface of the titanium alloy base material, finally the plasma-sprayed surface is subjected to remelting treatment through a CO2 laser device, and a coating is obtained. The prepared multi-principal element alloy coating adopts characteristics of high-entropy effect, slow diffusion effect, nanophase reinforcement, super-high lattice deformation, cocktail effect and the like of the multi-principal element alloy, abrasion resistance and high temperature oxidation resistance of the titanium alloy are remarkably improved, and titanium fire can be prevented.

Owner:陕西揽星科技有限公司

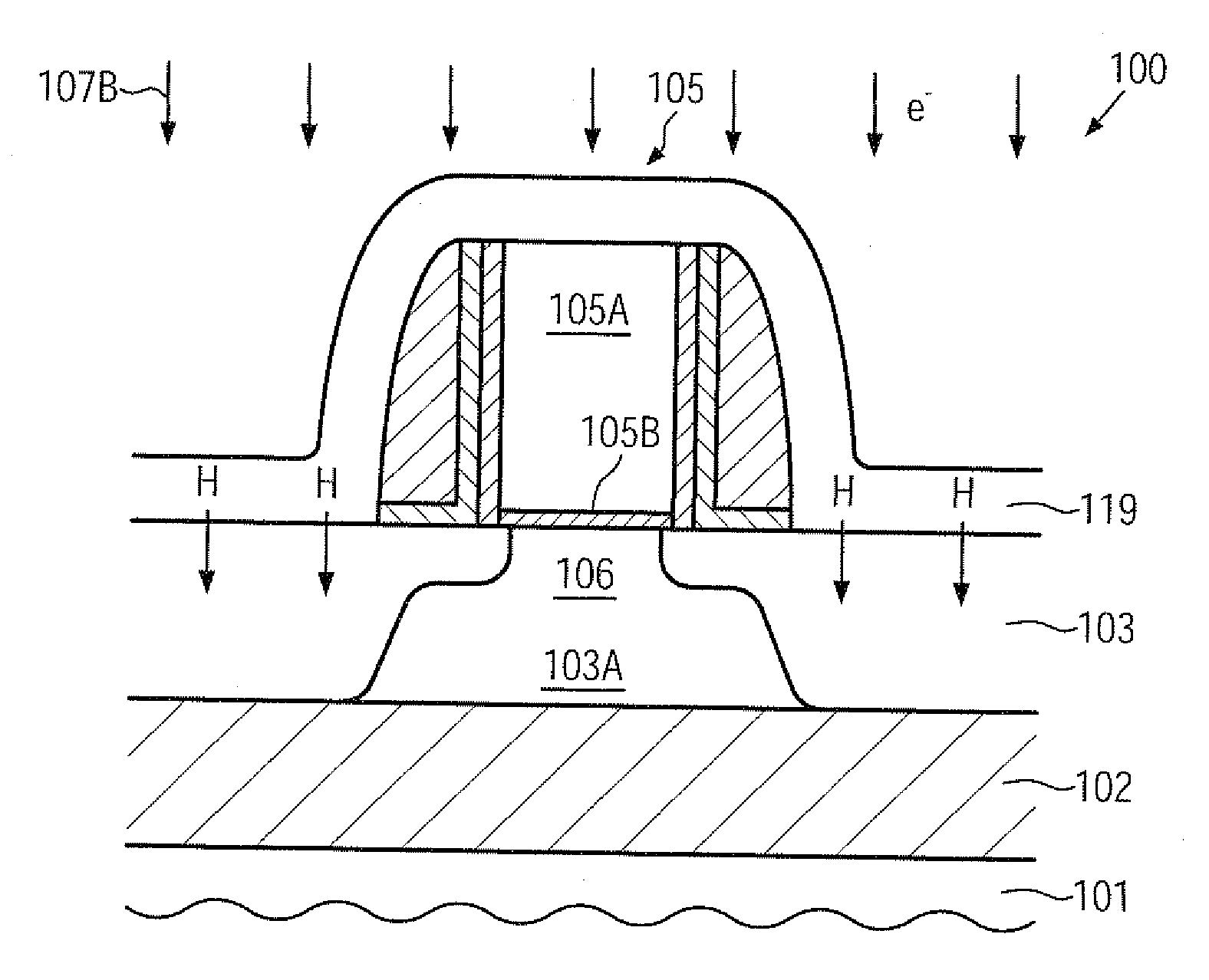

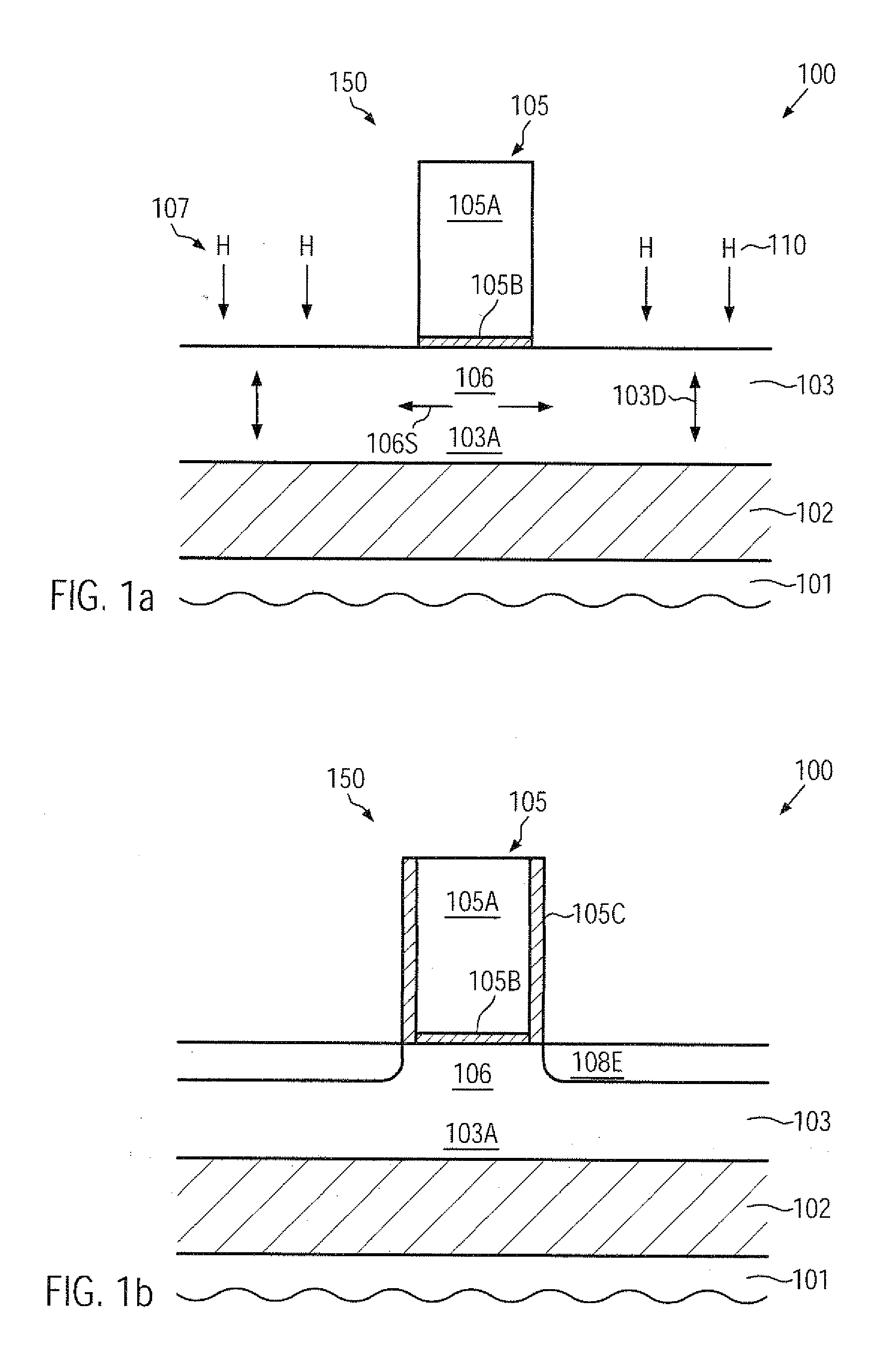

Transistor having a strained channel region caused by hydrogen-induced lattice deformation

InactiveUS20100025742A1TransistorSemiconductor/solid-state device manufacturingTensile strainSemiconductor materials

A lattice distortion may be achieved by incorporating a hydrogen species into a semiconductor material, such as silicon, without destroying the lattice structure. For example, by incorporating the hydrogen species on the basis of an electron shower, a tensile strain component may be obtained in the channel of N-channel transistors.

Owner:ADVANCED MICRO DEVICES INC

Aluminum alloy welding method based on SiCp/Al composite strengthening mechanism

InactiveCN110497066AWide varietyWide range of sizesArc welding apparatusPlasma welding apparatusMelting tankHardness

The invention discloses an aluminum alloy welding method based on a SiCp / Al composite strengthening mechanism and belongs to the technical field of aluminum alloy welding. By means of the method, on the basis that a conventional welding method is used for welding an aluminum alloy, a synchronous powder sending manner is used for evenly adding SiCp into a molten pool at the same time, and a weldingconnector with a SiCp / Al composite as the main part is formed; and the SiCp / Al composite strengthening mechanism is utilized, the added SiCp can cause lattice deformation of base metal, the dislocation density is improved, in addition, the SiCp has high hardness and wear resistance, the welding connector softening problem happening when the conventional welding method is used for welding the aluminum alloy can be solved, and the welding connector can have high strength, hardness and good wear resistance.

Owner:DALIAN UNIV OF TECH

Efficient protective agent special for gas pump

The invention relates to an efficient protective agent special for a gas pump. The efficient protective agent is prepared from the compositions in percentage by weight: 10-30% of bromination cetyl pyridine, 5-15% citrate, 15-30% sodium lignosulfonate, 5-10% of sodium gluconate, 10-20% of imidazoline quaternary ammonium salt, 5-15% of benzotriazole, and 10-50% water. Under dispersal, lattice deformation, threshold value effect and other actions of the sodium lignosulfonate, the bromination cetyl pyridine and the sodium gluconate, the solubility of calcium carbonate and magnesium carbonate in ahigh-turbidity gas pump water seal cooling system is greatly increased, and thus the serious problem of scale formation of the gas pump can be solved. Under the action of negative pole corrosion inhibition of the imidazoline quaternary ammonium salt, the citrate, the sodium gluconate, and the benzotriazole, a compact deposited film is rapidly formed in metal surface, the serious corrosion of metal, particularly, carbon steel and other gas pump body equipment materials caused by various corrosive ions is reduced, and thus the problem of corrosion in the long-term high-temperature operation is solved.

Owner:山西聚亨科技有限公司

Semiconductor device having vertical channel, resistive memory device including the same, and method of manufacturing the same

A semiconductor device includes a semiconductor substrate having a first conductivity type, a plurality of pillars extending to a direction perpendicular to a surface of the semiconductor substrate, a stress providing layer formed in the semiconductor substrate between pillars and forming a junction with the semiconductor substrate below each pillar to cause lattice deformation in the pillar, a source region having a second conductivity type opposite to the first conductivity type formed in the semiconductor substrate below the pillar, a drain region having the second conductivity type formed in an upper portion of the pillar, a gate insulating layer formed on a lateral surface of the pillar and a surface of the stress providing layer, and a gate electrode formed to surround the lateral surface of the pillar.

Owner:SK HYNIX INC

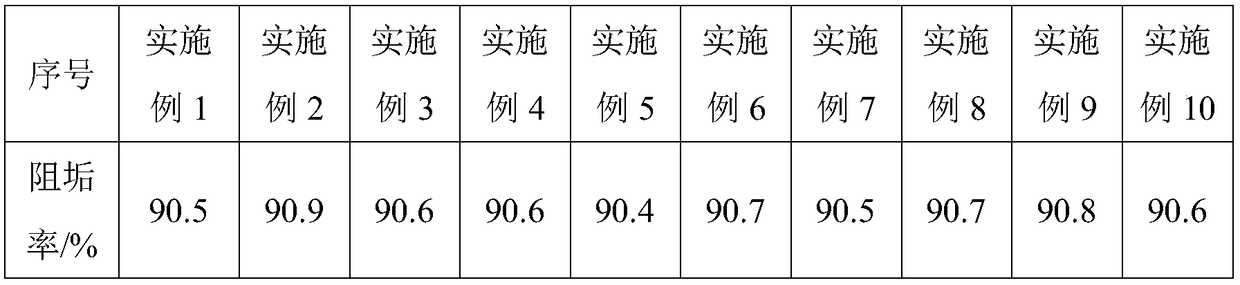

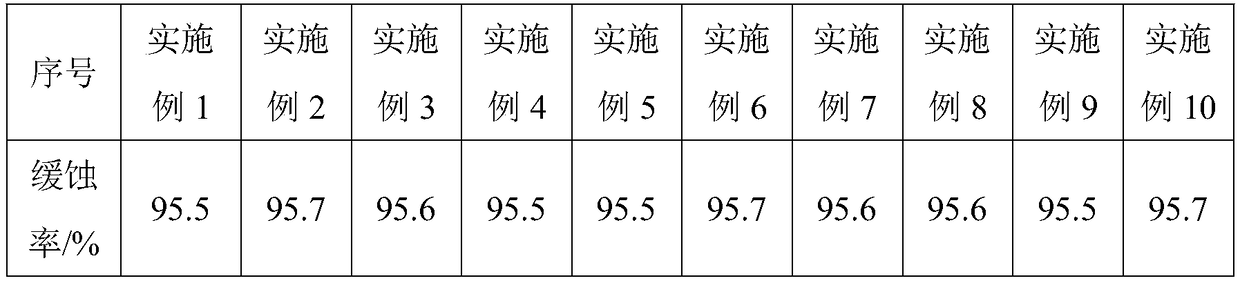

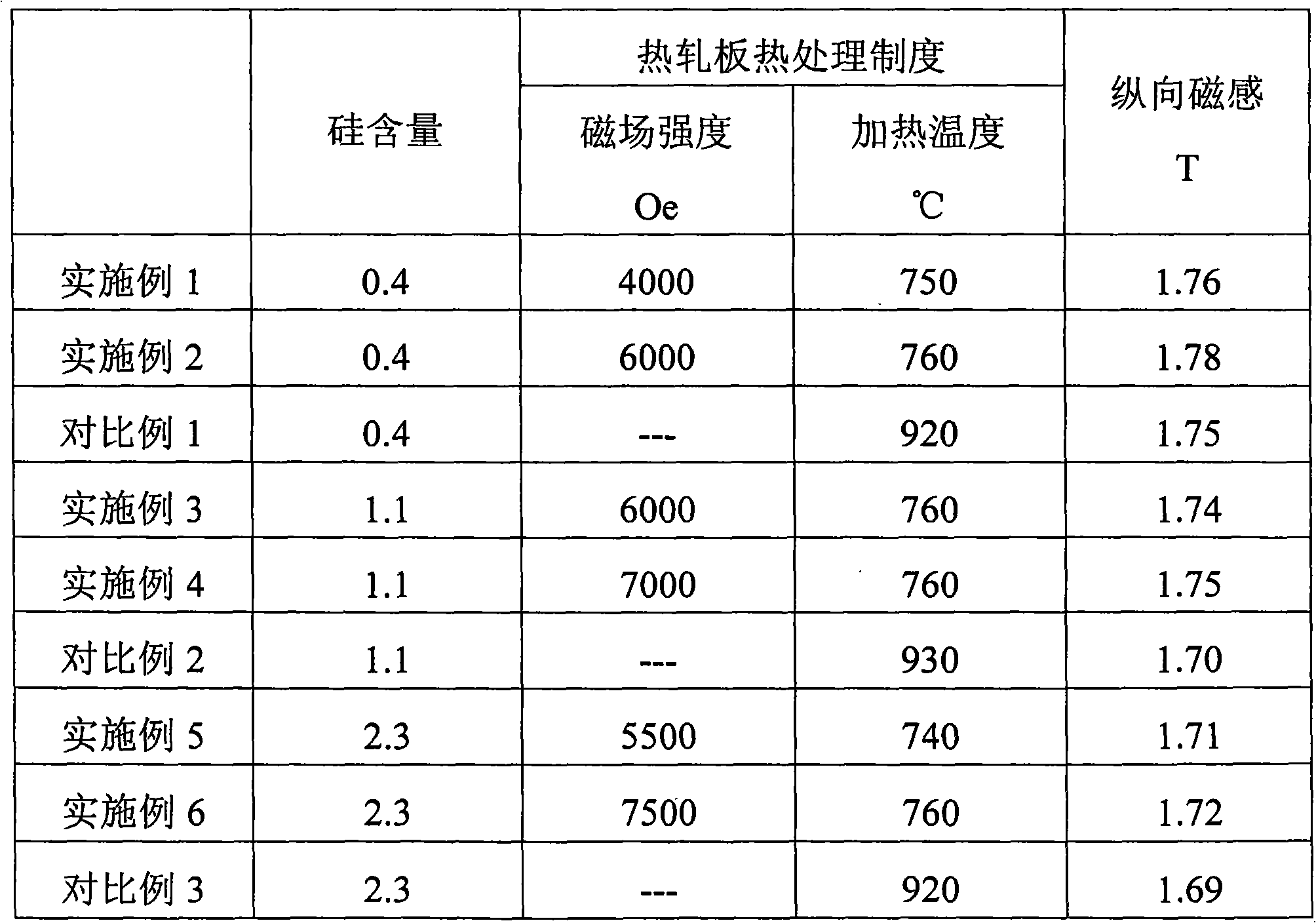

Method for manufacturing electric steel with excellent longitudinal magnetic performance

ActiveCN101660035AReduce the difficulty of manufacturing process controlImprove longitudinal magnetic propertiesCurie temperaturePrecipitation

The invention discloses a method for manufacturing electric steel with excellent longitudinal magnetic performance, which adopts a process route of smelting, continuous casting, hot rolling, normalizing of a hot-rolled sheet, cold rolling and annealing, and is characterized in that: the temperature in the normalizing of the hot-rolled sheet is lower than Curie temperature of the steel, the heatingtemperature is between 700 and 760DEG C, and the normalizing is performed in a magnetic field with an applied field strength between 3,000 and 9,000e in the rolling direction. Under the action of themagnetic field, complex magnetic domains generated by the influence of lattice deformation, precipitation and micro-area defects in a material are oriented in micro magnetic areas in the outer magnetic field direction, partial micro-area structures are restored and changed because of the action of thermokinetics, magnetic domains vertical to the outer magnetic field direction are decreased, and magnetic domains parallel to the outer magnetic filed direction are increased, so the uniaxial anisotropy along the outer magnetic field direction is induced and the longitudinal magnetic performance of products is improved.

Owner:ANGANG STEEL CO LTD

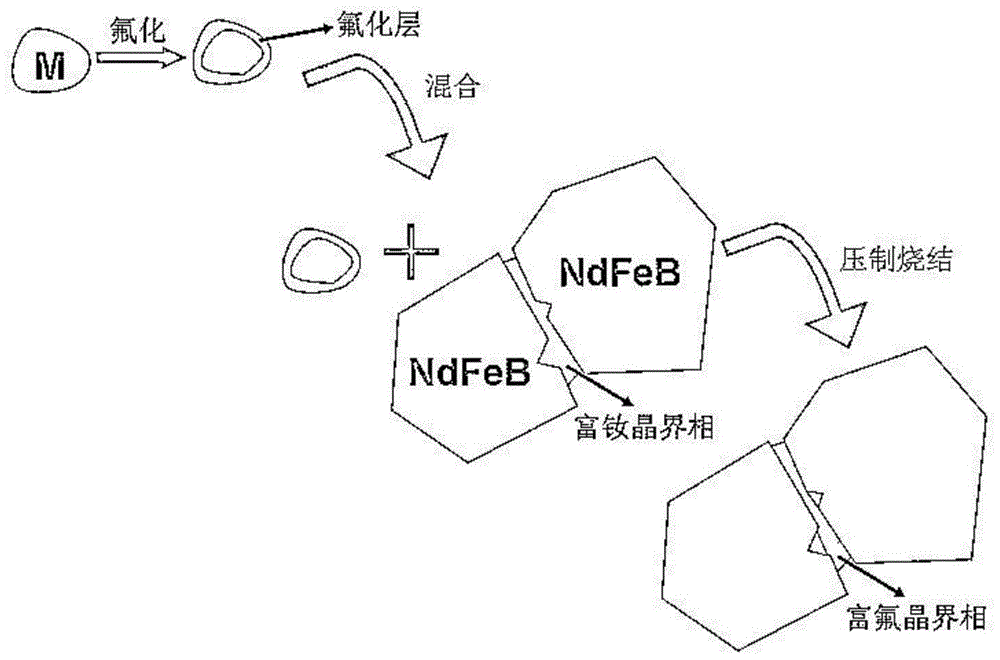

Method for improving sintered nd-fe-b magnet crystal boundary

ActiveCN105206412AImprove coercive forceReduce Distortion ThicknessInductances/transformers/magnets manufactureMagnetic materialsAlloyMetal

The invention discloses a method for improving the sintered nd-fe-b magnet crystal boundary. The method includes the following specific operation steps that 1, nd-fe-b powder is prepared through a conventional method; 2, a sort of metal or alloy powder M is collected, and surface fluorinated treatment is conducted on the powder M; 3, the surface-fluorinated powder is doped into the nd-fe-b powder through a double-alloy method; 4, the evenly-mixed powder is sintered after being formed and pressed, a sintered sample is then subjected to annealing treatment, and accordingly a sintered nd-fe-b magnet is obtained. The method has the advantages that on one hand, F elements are aptly added in the crystal boundary, accordingly, an ordered NdOF phase can be generated, and thus the coercivity of the magnet is improved; on the other hand, the exchange coupling action between crystals is weakened by adding the F elements; furthermore, the lattice deformation thickness can be effectively reduced by adding the F elements, and the coercivity of the magnet can be effectively improved as well.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

High-entropy alloy extruding and mounding composite modification technology

InactiveCN107881443AEasy to implementUniform and excellent tissue performanceStructure propertyHigh entropy alloys

The invention relates to a hot working and grain refinement plasticity modification technology dedicated to high-entropy alloy material and a method to prepare high-performance high-entropy alloy material. The invention aims to provide an extruding and mounding composite plasticity modification method dedicated to the service requirement of high-entropy alloy. Aiming at the hot-working characteristic of high-entropy alloy, the method of first mounding and then extruding, mounding after extruding and repeated mounding and extruding is adopted, so that the stress state in the high-entropy alloymaterial during the deformation process is effectively controlled, the three-directional compression stress is increased, generation and expansion of microcracks evoked by lattice deformation are effectively restrained, the grain is refined, the comprehensive mechanical performance is improved, and effective modification of the high-entropy alloy is realized. The extruding and mounding composite technology is easy to realize and low in cost; high-entropy alloy ingot blank material with uniform and excellent structure property can be obtained, and the service capacity is effectively improved; and with adoption of the method, large-scale application of the high-entropy alloy is promoted, and the mechanical performance of the high-entropy alloy can be effectively improved and controlled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Device and method for testing performance degradation caused by transistor lattice deformation

ActiveCN102967814BSimple and convenient application of mechanical stressRealize analysisIndividual semiconductor device testingTest performanceEngineering

The invention discloses a device and method for testing performance degradation caused by transistor lattice deformation. The device for testing the performance degradation caused by the transistor lattice deformation comprises a base, a precise displacement platform, a cushion block, a carrier and a pressing block. The method for testing the performance degradation caused by the transistor lattice deformation comprises the following steps of (1) thinning a chip; (2) cutting the chip; (3) sticking the chip; (4) leading an electrode out of a transistor; (5) fixing the carrier; (6) testing the transistor before applying the stress; (7) applying the mechanical stress onto the chip; (8) testing the transistor under the stress; (9) judging whether the performance of the transistor degrades; and (10) obtaining the lattice deformation value when the performance of the transistor degrades. The device and method for testing the performance degradation caused by the transistor lattice deformation has the advantages of easily applying compression stress onto the chip, and being large in range of the applicable mechanical stress, good in chip bend uniform, simple and accurate in lattice tension amount calculation, and is suitable for analyzing the influence of the transistor lattice deformation on the performance of the transistor.

Owner:云南凝慧电子科技有限公司

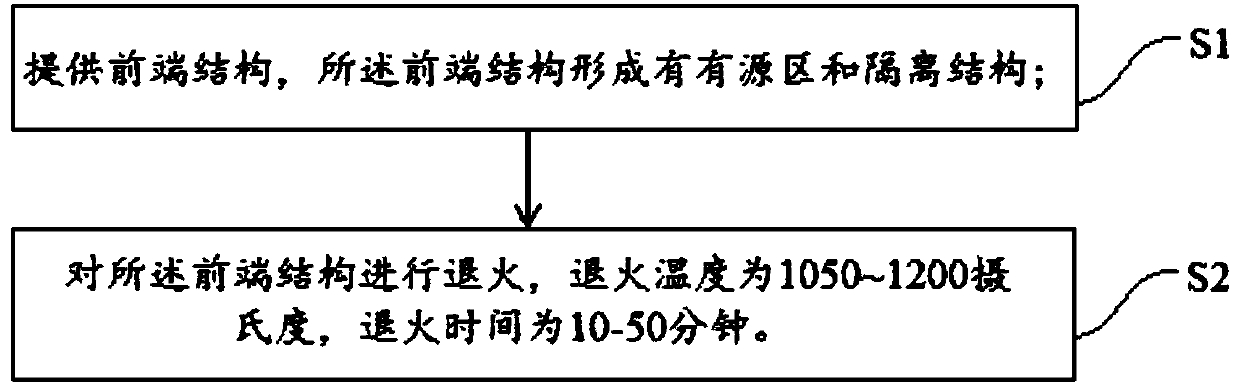

Flash memory manufacturing method

InactiveCN107658300AImprove yieldImprove electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingLattice defectsElectrical performance

The invention discloses a flash memory manufacturing method, which comprises the steps of providing a front-end structure, wherein the front-end structure is provided with an active region and an isolation structure; and performing annealing on the front-end structure, wherein the annealing temperature is 1050-1200 DEG C, and the annealing time is 10-50 minutes. According to the invention, annealing processing is performed on the front-end structure which is provided with the active region and the isolation structure, and the stress generated by crystal lattice deformation of the active regioncaused by groove etching or filling in the process of forming the isolation structure is released. Meanwhile, the split level of crystal lattices is reduced, crystal lattice defects of the active region are repaired, leakage current caused by the crystal lattice defects of the active region is reduced, and the electrical performance and the product yield of a flash memory are improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A kind of multi-principal alloy containing trace b and method for surface treatment of titanium alloy

ActiveCN105331870BImprove wear resistancePrevent titanium fireMolten spray coatingAlloy coatingTitanium alloy

The invention discloses a multi-principal element alloy containing trace B and a method for surface treatment of a titanium alloy. The multi-principal element alloy comprises, by mole, 23-30 parts of Al, 23-30 parts of Si, 23-30 parts of Cu, 1-5 parts of Ti, 21-30 parts of Zr and 1-4 parts of B. According to the method, a titanium alloy base material is cleaned and subjected to sand blasting roughening treatment, then plasma spraying equipment is used for spraying multi-principal element alloy powder on the surface of the titanium alloy base material, finally the plasma-sprayed surface is subjected to remelting treatment through a CO2 laser device, and a coating is obtained. The prepared multi-principal element alloy coating adopts characteristics of high-entropy effect, slow diffusion effect, nanophase reinforcement, super-high lattice deformation, cocktail effect and the like of the multi-principal element alloy, abrasion resistance and high temperature oxidation resistance of the titanium alloy are remarkably improved, and titanium fire can be prevented.

Owner:陕西揽星科技有限公司

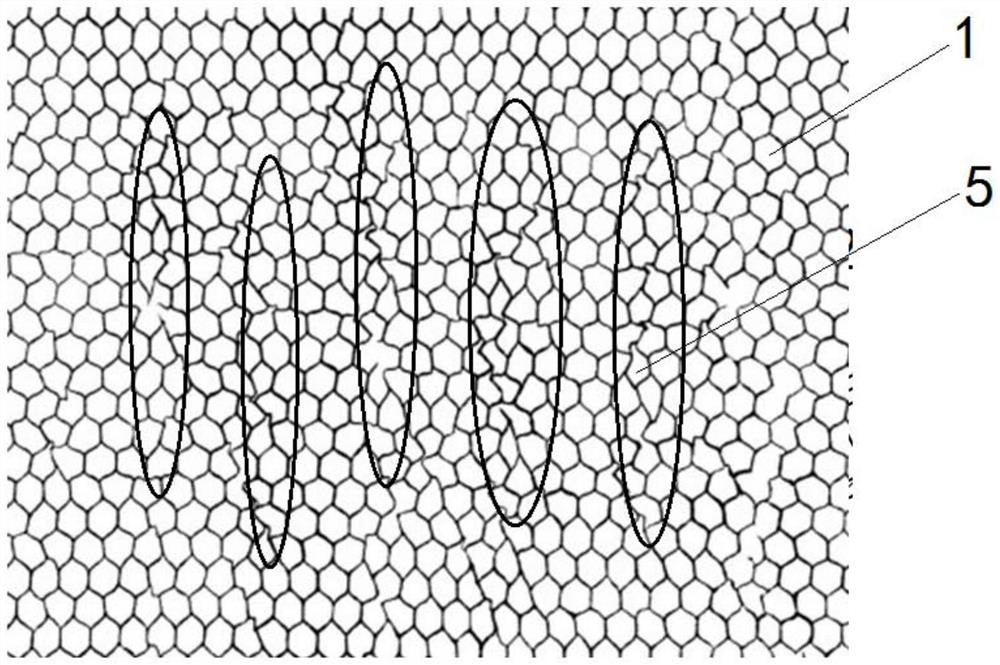

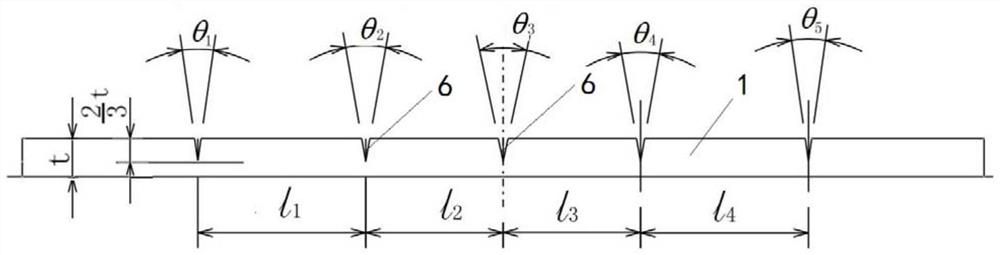

Control method for core lattice deformation in honeycomb core bending process

ActiveCN114132046AExcellent mechanical propertiesLamination ancillary operationsControlling laminationClassical mechanicsHoneycomb

A control method for core lattice deformation in the honeycomb core bending process comprises the steps that bending tests are conducted on honeycomb cores with different thicknesses under different bending radiuses, the inner surfaces of the honeycomb cores are deformed and collapsed in the bending state, and the number of the deformed and collapsed core lattices on the inner surfaces of the honeycomb cores is counted; measuring and counting the collapse quantity and deformation quantity of the honeycomb cores with different thicknesses under different bending radiuses, and determining the slotting spacing of the honeycomb cores with different thicknesses under different bending radiuses according to the deformation requirement of the honeycomb core bending process on the premise of ensuring that the core grids do not collapse in the honeycomb core bending process; the collapsing quantity and the deformation quantity of the core grids are compensated through the slotting spacing; on the premise of determining the grooving distances of the honeycombs with different thicknesses under different bending radiuses, the grooving angle is further determined.

Owner:XI'AN AIRCRAFT INTERNATIONAL

A kind of multi-principal element alloy and its method for treating the surface of titanium alloy

ActiveCN105331869BImprove wear resistancePrevent titanium fireMolten spray coatingSand blastingTitanium

Owner:宝鸡市中宇稀有金属有限公司

Method of growing GaN-based luminescent crystalline membrane for molecular beam epitaxy

InactiveCN101748382BImprove lattice distortionImprove luminous performanceChemical vapor deposition coatingRare earth ionsPhysical chemistry

The invention discloses a method of growing GaN-based luminescent crystalline membrane for molecular beam epitaxy, which dopes rare earth ions in the growth process to replace part of lattice site of Ga3+ and is characterized by comprising the following steps: doping III group element boron or aluminum in the raw material formula of the GaN crystalline membrane according to a certain ratio, wherein the III group element boron or aluminum enters into GaN lattice site via a mode of trivalent ion in the growth process; preparing ion radius difference between the rare earth ion and the Ga3+, wherein the molar ratio of the raw material formula is as follows: Ga:Re:A=(1-x-y):x:y, x represents rare earth metal, A represents III group element boron or aluminum, x is more than or equal to 0.1% andless than or equal to 10.0%, and y is more than or equal to 0.1x and less than or equal to x. In the invention, III group element boron or aluminum is doped with rare earth metal together according to a certain ratio so as to greatly improve lattice deformation of the GaN crystalline membrane caused by larger radius mismatch of Re3+ and Ga3+, and increase luminescent performance of the GaN crystalline membrane.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Growth method of neodymium-doped gadolinium gallium garnet laser crystal

InactiveCN1292107CReduce dislocation densityImprove radiation resistancePolycrystalline material growthBy pulling from meltGadolinium gallium garnetNitrogen gas

The Nd doped gadolinium gallium garnet laser (Nd:GGG) crystal has the material including gadolinium oxide, gallium oxide, neodymium oxide and cerium oxide in certain proportion prepared in two-step composing process. The Nd doped gadolinium gallium garnet laser crystal is grown in a Czochrolski process under the 98 % N2+2% O2 condition. The present invention solves the problem of doping Nd2O3 to cause lattice deformation, and the Nd:GGG crystal has raised radiation resistance and improved spectral and laser performance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A kind of lanthanide metal catalyst

ActiveCN106834863BImprove conductivityLower the resistance valueVacuum evaporation coatingSputtering coatingFree energiesHigh energy

The invention discloses a lanthanide metal catalyst. The lanthanide metal catalyst comprises, by weight, 3-20 parts of La, 4-8 parts of Ce, 1-6 parts of Yb, 0-5 parts of Gd, 0-3 parts of Lu, 0-3 parts of Lu, and 0-3 parts of Tb, and all of the components are integrally melted in vacuum to form the lanthanide metal catalyst. The lanthanide metal catalyst acts on a target material, and is fused with a matrix of the target material, atoms of the lanthanide metal in the catalyst enter into crystal lattices of matrix of the target material, so that larger crystal lattice deformation is caused, distortion energy is generated, and system energy is increased; the rare earth atoms can only be enriched at high-energy crystal boundaries so that at the lowest free energy of the system is kept, thus, the conductivity of the target material is increased, the resistance value of the target material is reduced, the adhesion of the target material is enhanced; and more than 0.1WT% of the lanthanide metal catalyst is added to an ITO target material and a copper silver alloy target material, and the conductivity of the target material can be increased by 10-15%.

Owner:GUANGZHOU QIHONG ELECTRONICS TECH

A Flowing Atmosphere Cold and Heat Impact Sintering Resistance Furnace

The invention provides a flowing atmosphere hot / cold impact sintering resistance furnace which is designed for inherent defects of an existing resistance sintering furnace and the requirement for a special sintering technology of research and development of new inorganic materials. The flowing atmosphere hot / cold impact sintering resistance furnace comprises a furnace shell and hearth, a heating body, a ventilation crucible, a ventilation objective table, a hollow ventilation supporting rod, a hollow exhaust rod, a sample supporting frame, a microcomputer time switch and an electrically-controlled ventilation switch. The microcomputer time switch controls the electrically-controlled ventilation switch to be switched on so that air can flow into a sample to be sintered on the sample supporting frame of the ventilation objective table in the ventilation crucible, the sintering temperature of the sample to be sintered is lowered, the sintering temperature of the sample to be sintered is made to fluctuate from 5 DEG C to 100 DEG C periodically, and the periodical cold / hot impact function is generated for the sample to be sintered. The flowing atmosphere hot / cold impact sintering resistance furnace has the advantages that crystalline grains of the sintered sample can be made to grow coordinately in the sintering process, the crystalline grains are even in size, the phase is stably and evenly distributed, the density is high, the porosity is low, lattice deformation is lowered, and performance is better.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com