Control method for core lattice deformation in honeycomb core bending process

A control method and honeycomb core technology, applied in the direction of control lamination, chemical instruments and methods, lamination devices, etc., can solve the problems of unstable product quality, low efficiency, poor consistency, etc., and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

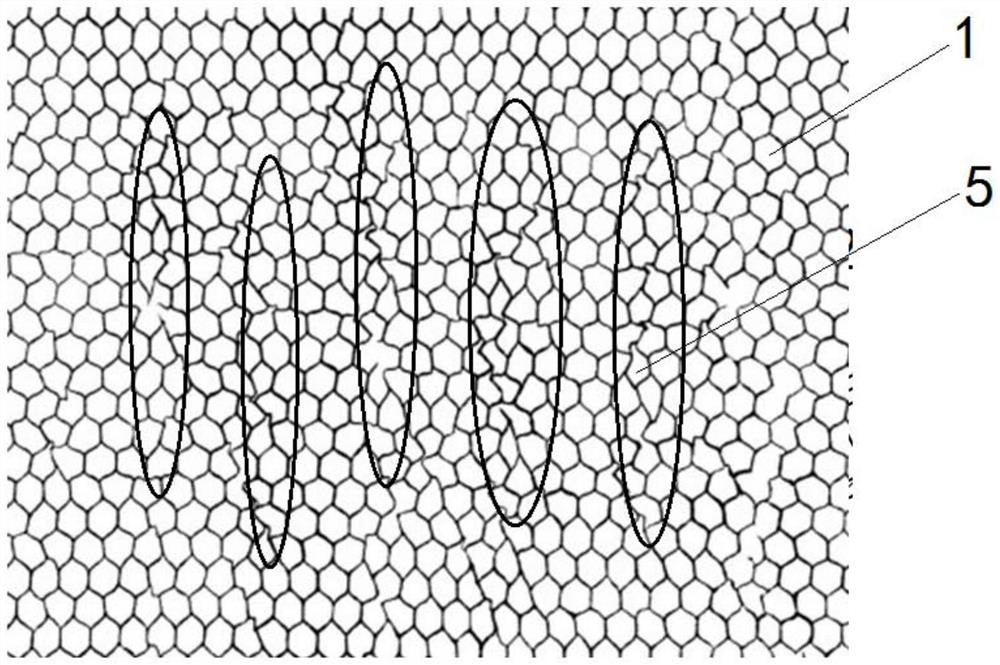

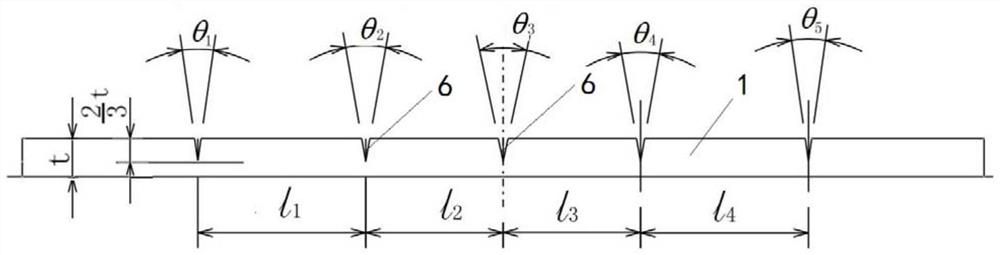

[0017] In order to solve the severe stretching and extrusion deformation between the honeycomb core cells due to bending in the manufacturing process of the honeycomb sandwich structure with a complex shape, the present invention proposes a method for controlling the cell deformation and slotting during the bending process of the honeycomb core. The process is: for honeycomb cores of different thicknesses, carry out bending tests under different bending radii; evaluate the deformation of the upper surface of the honeycomb core, count the number of cell collapses, and determine the groove spacing of the honeycomb cores of different thicknesses under different bending radii.

[0018] On the basis of determining the slotting spacing of different thickness honeycombs under different bending radii, assuming that the slotting depth is 2 / 3 of the honeycomb thickness, and the slotting honeycomb is completely closed after bending, the slotting angle, slotting spacing and bending radius ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com