Method for manufacturing electric steel with excellent longitudinal magnetic performance

A manufacturing method and technology of magnetic properties, applied in the field of electrical steel manufacturing, can solve problems such as difficulty in controlling the nucleation of oriented grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

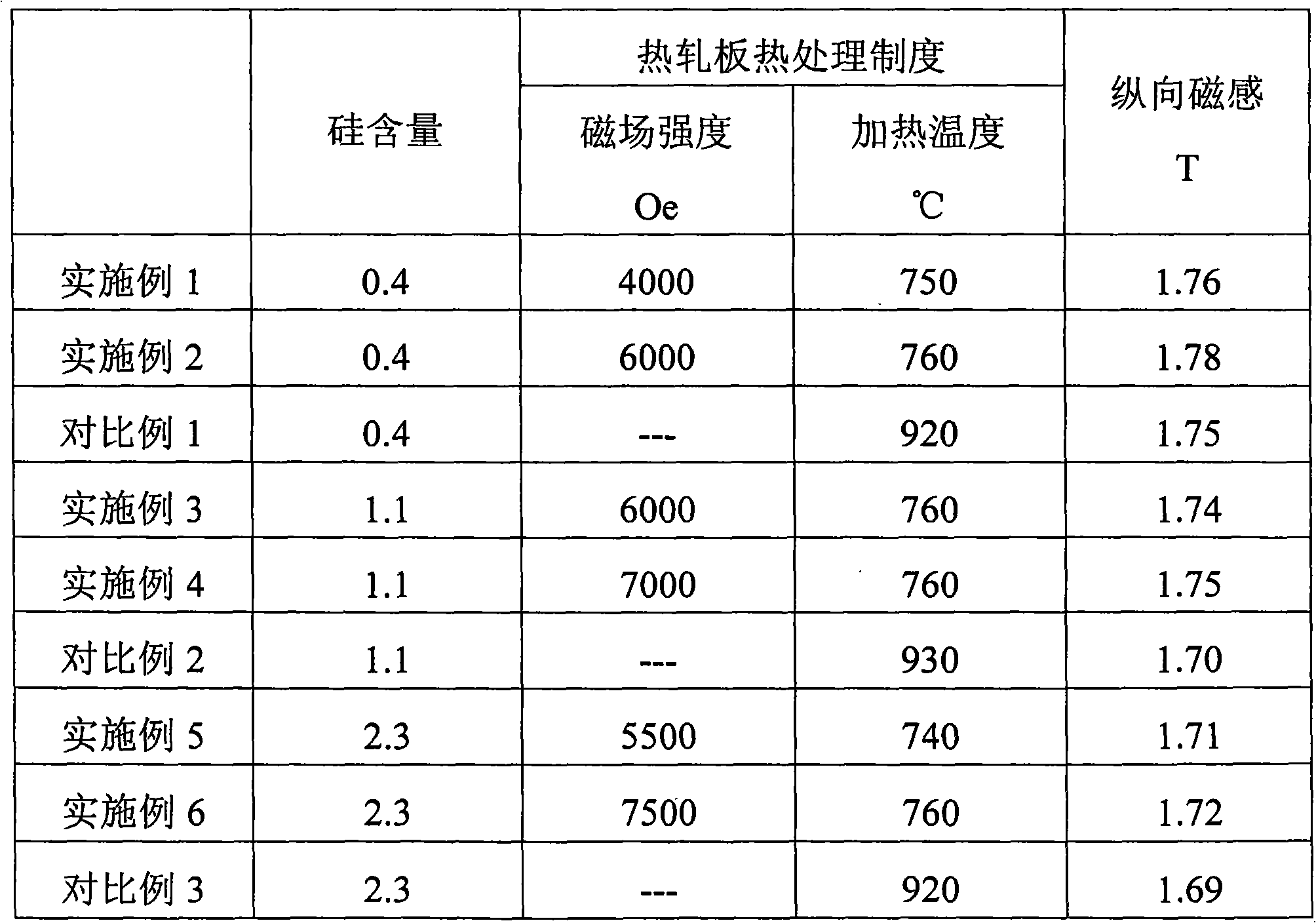

Examples

Embodiment Construction

[0010] A kind of manufacturing method of electrical steel with excellent longitudinal magnetic performance of the present invention, the technological route adopted is: smelting, continuous casting, hot rolling, hot-rolled sheet normalization, cold rolling and annealing, it is characterized in that the hot-rolled sheet normalization treatment is in It is carried out in the same external magnetic field as the rolling direction, the normalization treatment temperature is lower than the Curie temperature of the steel, and the heating temperature is 700-760°C. The external magnetic field can be a DC magnetic field, an AC magnetic field or a pulsed magnetic field. Normalization treatment is isothermal treatment below the Curie temperature.

[0011] The non-extractable electrical steel with different silicon content is smelted by converter, RH refining treatment, and continuous casting into 250mm thick continuous casting slab. The slab is heated and rolled to 2.5mm thick. Without h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com