A Flowing Atmosphere Cold and Heat Impact Sintering Resistance Furnace

A technology of thermal shock and resistance furnace, applied in the direction of furnace, crucible furnace, furnace type, etc., can solve the problems of lowering sintering temperature, difficulty in realizing rapid and non-uniform heat transfer, etc., and achieves the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

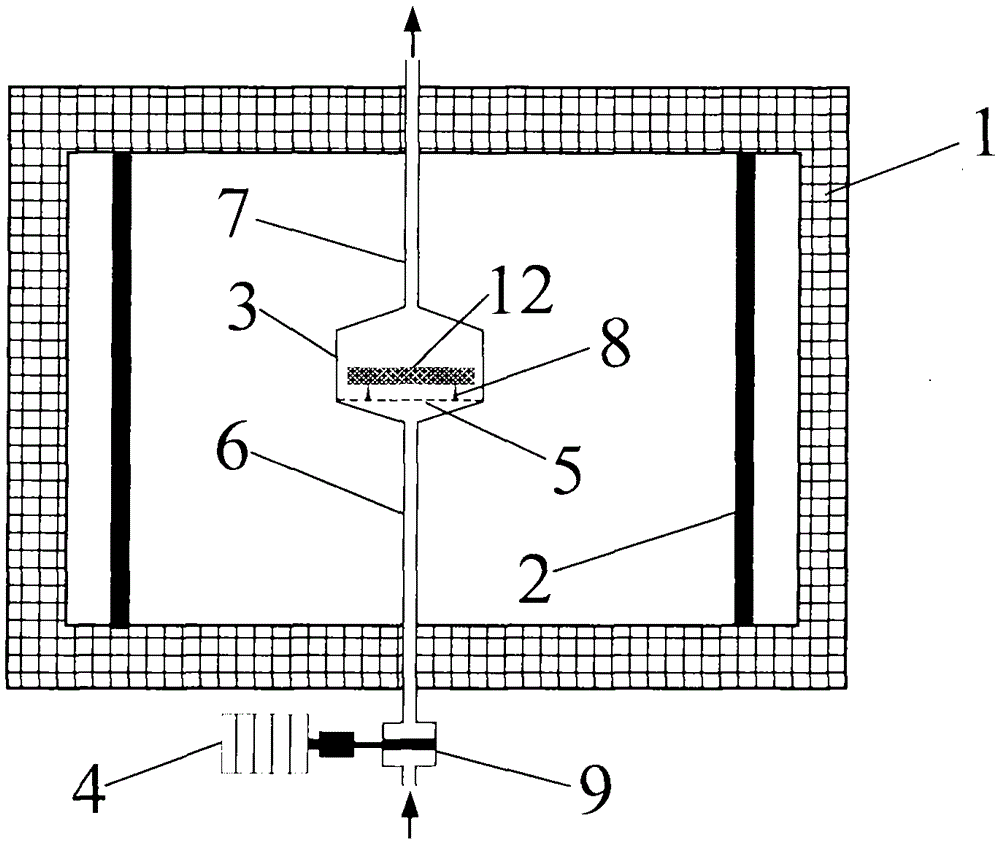

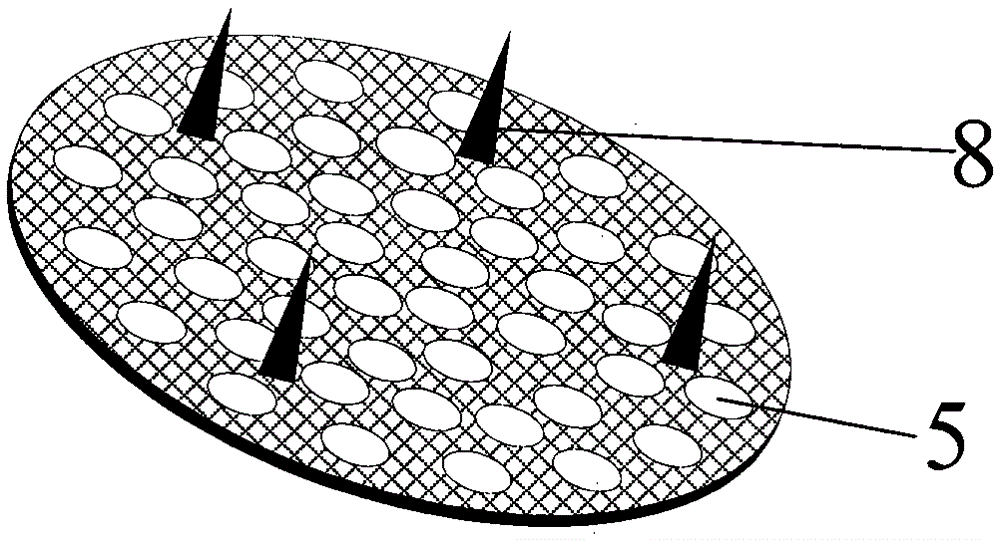

[0021] Such as figure 1 As shown in the closed sintering schematic diagram of the flow atmosphere cold and heat impact sintering resistance furnace, the flow atmosphere cold and heat impact sintering resistance furnace provided by the present invention is a closed sintering method, and the upper part of the furnace shell 1 is provided with a small hole, and the ventilation support rod 6, row The gas rod 7 passes through the furnace shell through the small holes in the bottom center and top center of the furnace shell 1 respectively. The ventilation support rod 6 and the exhaust rod 7 are parallel to the heating element 2. The closed ventilated crucible 3, the ventilated stage 5, and the ventilated support The rod 6, the exhaust rod 7, and the sample support frame 8 are all made of aluminum oxide. Compressed air enters the closed ventilated crucible 3 through the microcomputer time-controlled switch 9 installed on the lower part of the ventilation support rod 6 outside the furn...

Embodiment 2

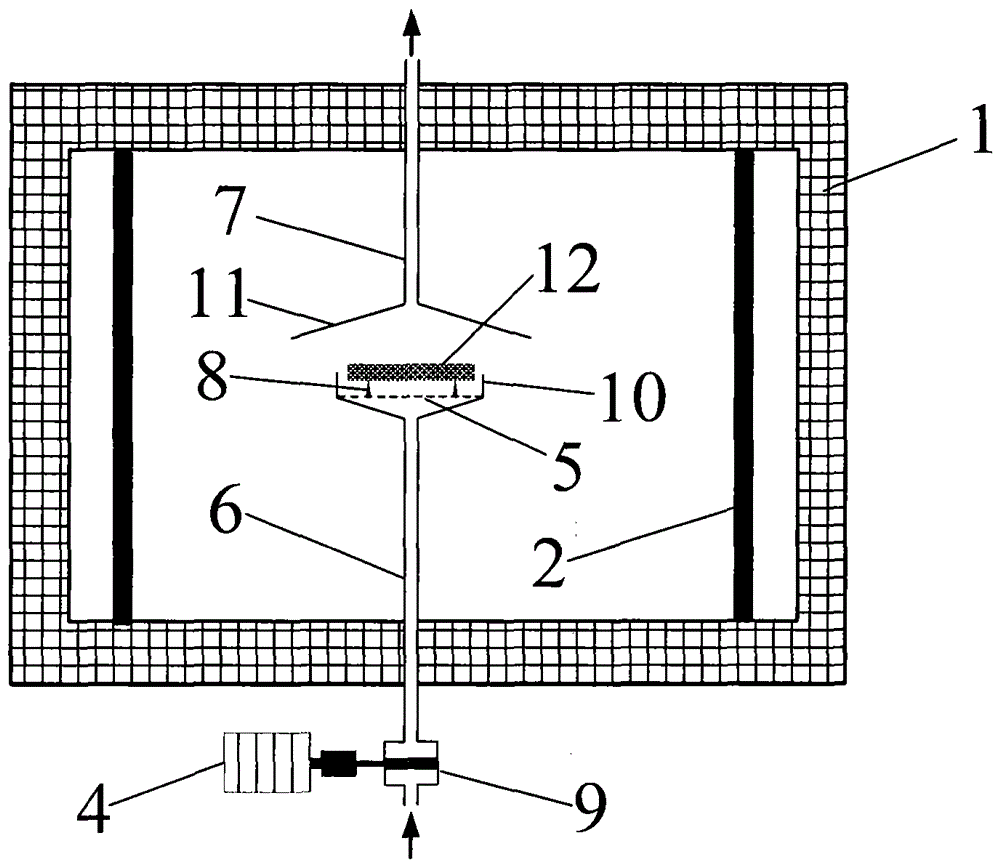

[0023] Such as figure 2 As shown in the schematic diagram of the open sintering front view of the flow atmosphere cold and heat impact sintering resistance furnace, the flow atmosphere cold and heat impact sintering resistance furnace provided by the present invention is an open sintering form. The gas rod 7 passes through the furnace shell through the small holes in the bottom center and top center of the furnace shell 1 respectively. The ventilation support rod 6 and the exhaust rod 7 are parallel to the heating element 2. The open ventilated crucible 3, the ventilated stage 5, and the ventilated The supporting rod 6, the exhaust rod 7, and the sample support frame 8 are all made of aluminum oxide. The volume content was 8% O 2 , 92% N 2 The mixed gas is passed into the open ventilated crucible 3 through the electric control ventilation switch 9 installed on the lower part of the ventilation support rod 6 outside the furnace, and is discharged out of the furnace through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com