Aluminum alloy welding method based on SiCp/Al composite strengthening mechanism

A welding method and composite material technology, applied in the field of aluminum alloy welding, can solve the problems of limited types and size of welding workpieces, unfavorable discharge effect and tungsten electrode life, affecting the stability of the powder feeding process, etc., so as to solve the problem of softening of welded joints. , the effect of high strength, high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

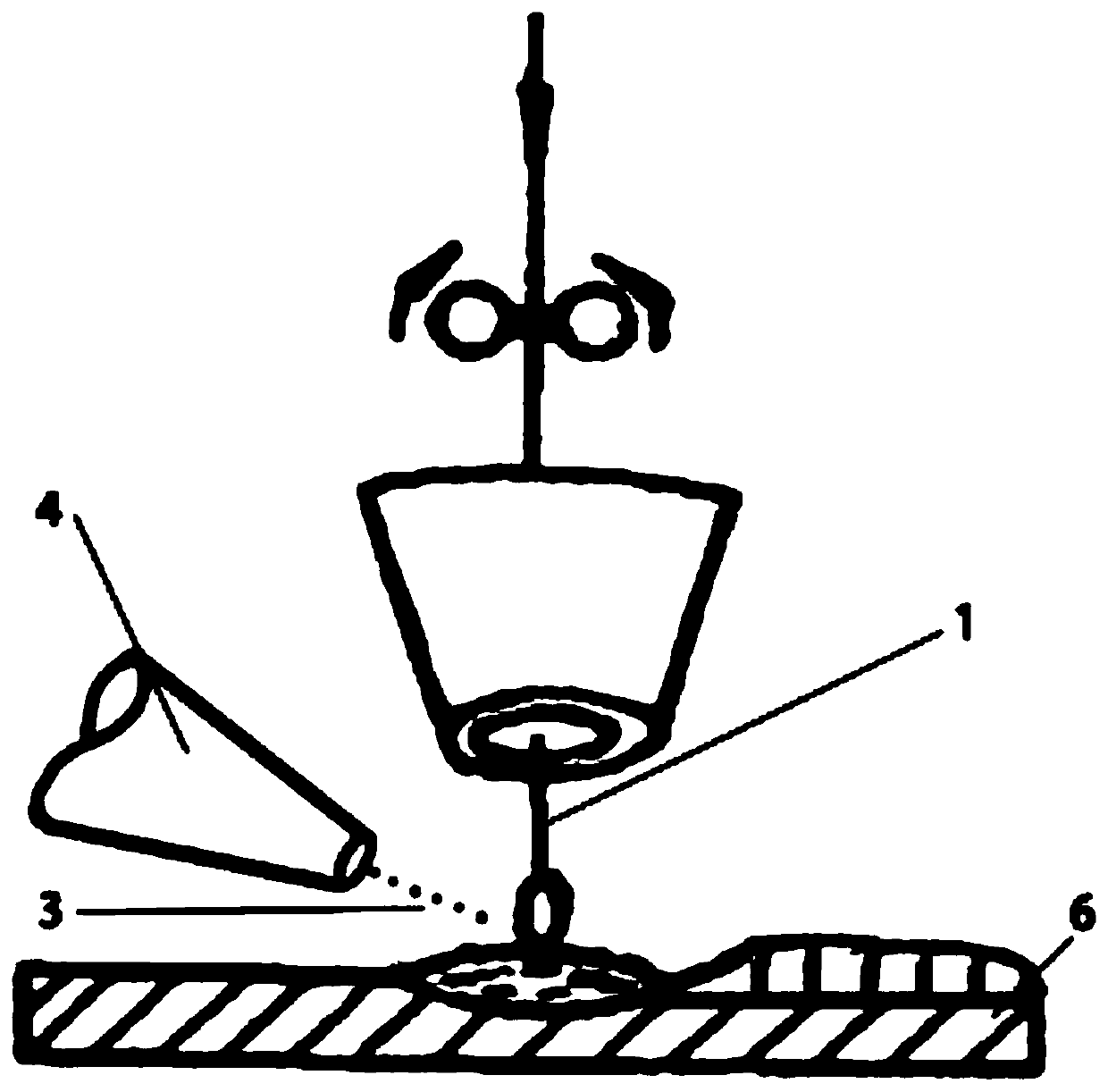

[0031] see figure 1 , the present invention provides a SiC-based p The aluminum alloy welding method of / Al composite material strengthening mechanism, comprises the following steps:

[0032] Step 1: Use 6061-T651 aluminum alloy plate 6 with a size of 5mm×100mm×200mm, select ER4043 coiled aluminum alloy welding wire 1, and process the groove of aluminum alloy plate 6 into a double-sided V-shaped groove with a groove angle of 60°, using a combination of mechanical cleaning and chemical cleaning to remove the oxide film on the aluminum alloy surface, for SiC p 3 pretreatment and SiC p 3 into the powder feeder;

[0033]Step 2: Butt the two aluminum alloy plates 6 to be welded and fix them on the workbench through the fixture, adjust the relative position between the wire feed nozzle 2, the powder feed nozzle 4, and the welding torch (including the tungsten electrode 5), and the three are in the In the same plane, the wire feed nozzle 2 is 20° to the horizontal plane, the angl...

Embodiment 2

[0037] see figure 2 , the present invention provides a kind of aluminum alloy welding method based on SiCp / Al composite material strengthening mechanism, comprises the following steps:

[0038] Step 1: Use 6082-T6 aluminum alloy plate 6 with a size of 6mm×150mm×300mm, select ER5087 coiled aluminum alloy welding wire 1, and process the groove of aluminum alloy plate 6 into a double-sided V-shaped groove with a groove angle of 40°, using a combination of mechanical cleaning and chemical cleaning to remove the oxide film on the aluminum alloy surface, for SiC p 3 pretreatment and SiC p 3 into the powder feeder;

[0039] Step 2: Butt the two aluminum alloy plates 6 to be welded and fix them on the workbench through clamps, adjust the relative position between the powder feeding nozzle 4 and the welding torch, the powder feeding nozzle 4 is 30° from the horizontal plane, and the powder feeding nozzle 4 The included angle with the welding torch is 60°;

[0040] Step 3: Turn on ...

Embodiment 3

[0043] see image 3 , the present invention provides a SiC-based p The aluminum alloy welding method of / Al composite material strengthening mechanism, comprises the following steps:

[0044] Step 1: Use 6082-T6 aluminum alloy plate 6 with a size of 6mm×50mm×250mm, select ER4047 coiled aluminum alloy welding wire 1, process the groove of aluminum alloy plate 6 into a bilateral V-shaped groove, and the groove angle is 50°, using a combination of mechanical cleaning and chemical cleaning to remove the oxide film on the aluminum alloy surface, for SiC p 3 pretreatment and SiC p 3 into the powder feeder;

[0045] Step 2: Butt the two aluminum alloy plates 6 to be welded and fix them on the workbench through the fixture, adjust the relative position between the wire feed nozzle 2, the powder feed nozzle 4, and the laser (emitting the laser beam 7), and the three are in the In the same plane, the wire feed nozzle 2 is 20° to the horizontal plane, the angle between the wire feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com