Flash memory manufacturing method

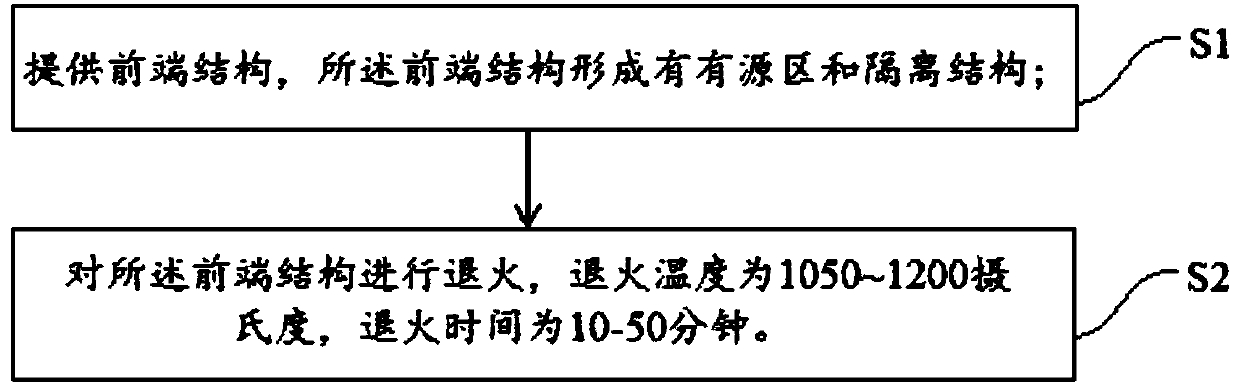

A manufacturing method and technology of flash memory, which is applied in the field of flash memory manufacturing, can solve the problems affecting the programming and writing of memory cells, programming and writing function errors, etc., and achieve the effects of long annealing time, reducing leakage current, improving yield rate and electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0030] The inventors have found that: figure 2 As shown, it is the flash memory structure in one embodiment of the present invention. When using the existing shallow trench isolation process to etch the trenches 12 to isolate multiple active regions 11, the incident ions with high energy and high density are more or less The ground will enter the active area 11. The high-energy incident ions will collide with the atoms on the lattice of the active region 11, causing some lattice atoms to be displaced, making t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com