Efficient protective agent special for gas pump

A protective agent and gas pump technology, which is applied in the field of high-efficiency protective agent for gas pumps, can solve problems such as corrosion, waste, and environmental pollution, and achieve the effects of slowing down severe corrosion, solving scaling problems, and solving corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

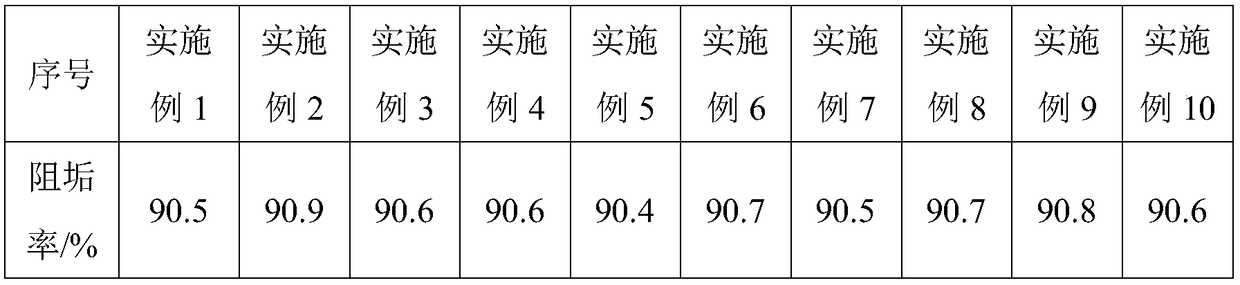

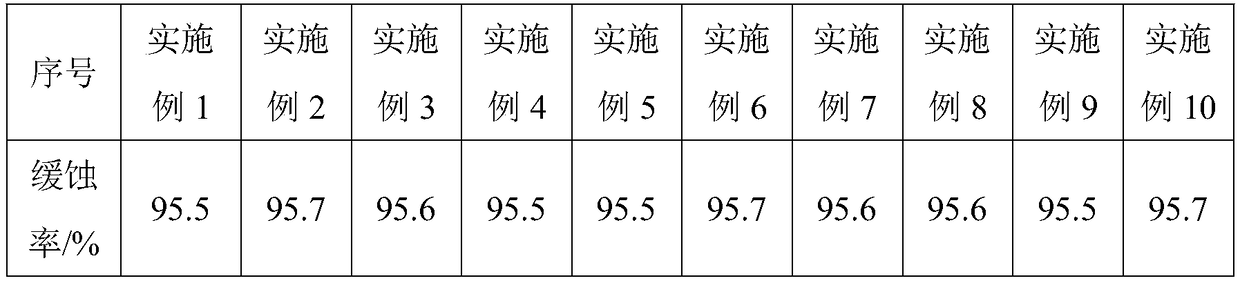

Examples

Embodiment 1

[0015] Example 1 The special high-efficiency protective agent for gas pumps in this example includes cetylpyridinium bromide, sodium citrate, sodium lignosulfonate, sodium gluconate, imidazoline quaternary ammonium salt, and benzotriazole And water, the weight percentage of each component is: cetylpyridinium bromide 10%, sodium citrate 8%, sodium lignosulfonate 20%, sodium gluconate 8%, imidazoline quaternary ammonium salt 15%, benzo Triazole 10%, water 29%.

Embodiment 2

[0017] The high-efficiency protective agent for gas pumps of this embodiment includes cetylpyridinium bromide, sodium citrate, sodium lignosulfonate, sodium gluconate, imidazoline quaternary ammonium salt, benzotriazole and water. The weight percentage of each component is: cetylpyridinium bromide 10%, sodium citrate 5%, sodium lignosulfonate 30%, sodium gluconate 5%, imidazoline quaternary ammonium salt 15%, benzotriazole 8%, water 27%.

Embodiment 3

[0019] The high-efficiency protective agent for gas pumps of this embodiment includes cetylpyridinium bromide, sodium citrate, sodium lignosulfonate, sodium gluconate, imidazoline quaternary ammonium salt, benzotriazole and water. The weight percentage of each component is: 15% cetylpyridinium bromide, 5% sodium citrate, 20% sodium lignosulfonate, 10% sodium gluconate, 10% imidazoline quaternary ammonium salt, benzotriazole 10%, water 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com