Dacron FDY oiling agent and preparation method thereof

A technology of oil agent and polyester, applied in the field of polyester FDY oil agent and its preparation, can solve problems such as tension fluctuation, winding spinning, uneven dyeing, and reduced fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of polyester FDY oil agent comprises the following preparation steps:

[0037] (1) Put the emulsifier, sizing agent, antistatic agent, and penetrant into the reaction kettle in proportion, and stir at 40-70°C at a stirring rate of 500-600r / min for 0.5-1h;

[0038] (2) Put base oil and smoothing agent into the reaction kettle, continue to stir for 45-60min, then put in additives, stir evenly, cool naturally and filter to obtain polyester FDY oil;

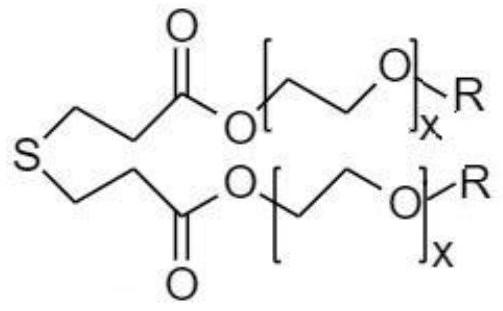

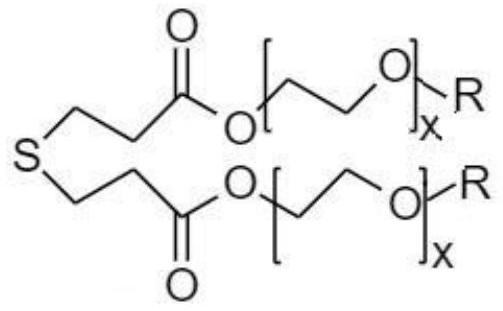

[0039] The additive of the oil agent also includes an anti-yellowing agent, the amount of the anti-yellowing agent is 0.1-2wt% of the total amount of the oil agent, and the molecular weight of the anti-yellowing agent is 1000-1500; the preparation method of the anti-yellowing agent For: the condensation reaction of methyl acrylate and hydrogen sulfide at 65-70°C, 1-3 bar, and sodium acetate catalyzes to prepare the intermediate product dimethyl thiodipropionate; then the intermediate product thiodipropio...

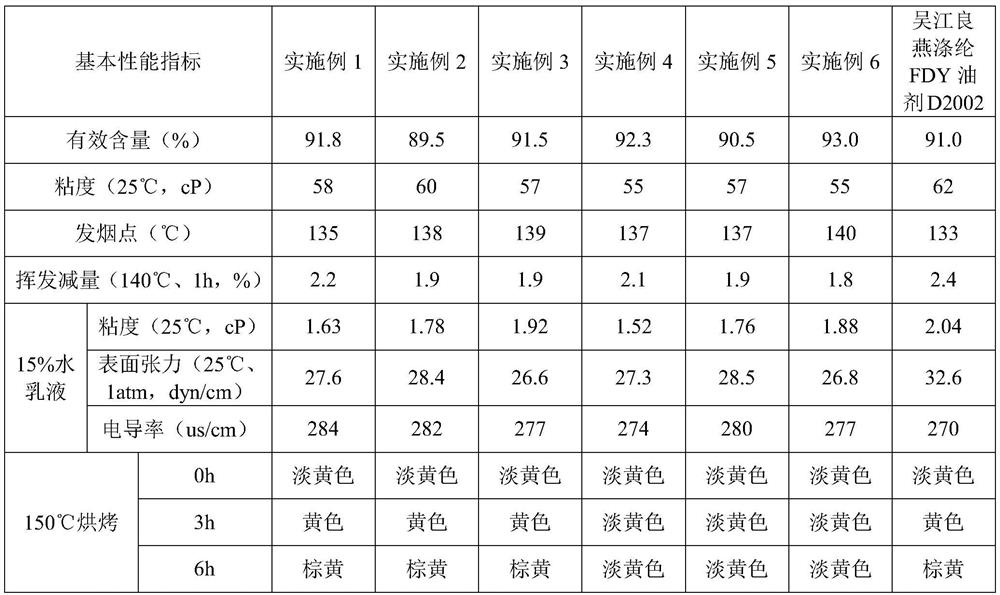

Embodiment 1

[0040] Embodiment 1: a kind of polyester FDY oil agent, by weight percentage, is made up of following components:

[0041] Base oil 31%, of which trimethylolpropane oleate 19%, industrial white oil 12%;

[0042] Smoothing agent 35%, including oleic acid polyethylene glycol 600 diester 25%, C12-C14 fatty alcohol block polyoxyethylene polyoxypropylene ether 10%;

[0043] 11% of sizing agent, including 8% of oleic acid polyethylene glycol 400 diester, and 3% of isomeric tridecyl alcohol polyoxyethylene (6) ether;

[0044] Emulsifier 11%, wherein sorbitan polyoxyethylene (80) ether stearate 5%, polyoxyethylene laurate (9) 6%;

[0045] Antistatic agent 7%, wherein C12-C14 fatty alcohol polyoxyethylene (3) ether phosphate potassium salt 7%;

[0046] Penetrant 3%, that is, C12-C14 fatty alcohol block polyoxyethylene polyoxypropylene ether 3%;

[0047] Additives 1.5%, including 0.1% p-hydroxyacetophenone, 0.1% polyether modified silicone oil, 0.5% polyoxypropylene (5) stearate, 0.6...

Embodiment 2

[0051] Embodiment 2: a kind of polyester FDY oil agent, by weight percentage, is made up of following components:

[0052] 30% base oil, including 10% isooctyl stearate, 10% trimethylolpropane oleate, and 10% industrial white oil;

[0053] Smoothing agent 38%, of which lauric acid macrogol 400 diester 20%, C 12 -C 14 Fatty alcohol block polyoxyethylene polyoxypropylene ether 18%;

[0054] Stimulant 11%, of which ricinoleic acid polyoxyethylene (20) ester 7%, C 4 -C 12 Fatty alcohol atactic polyoxyethylene polyoxypropylene ether 4%;

[0055] Emulsifier 10%, wherein polyoxyethylene (80) sorbitan ether stearate 3%, polyoxyethylene (3) oleate 3%, polyoxyethylene (9) laurate 4%;

[0056] Antistatic agent 7%, where C 12 -C 14 Fatty alcohol polyoxyethylene (3) ether phosphate potassium salt 3%, C 12 -C 14 Fatty alcohol polyoxyethylene (3) ether sulfate sodium salt 4%;

[0057] Penetrant 2%, ie C 12 -C 14 Fatty alcohol block polyoxyethylene polyoxypropylene ether 2%;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com