Curtain rod track with low friction coefficient and a preparation method thereof

A low-friction, curtain rod technology, applied in the field of automatic curtain adjustment devices for smart homes, can solve the problem of increasing the friction coefficient of traction sliders, positioning sliders and guide rails, inaccurate movement control of traction sliders, and the use of motors Short service life and other problems, to achieve good slippery and hydrophobic and oleophobic properties, small surface friction coefficient, and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

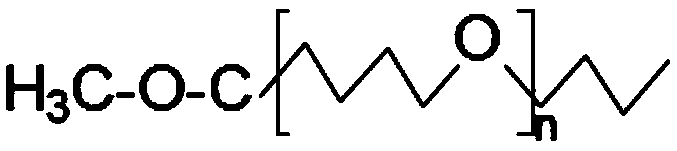

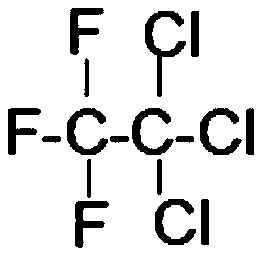

[0027] A curtain rod track with a low coefficient of friction, which comprises an aluminum alloy curtain rod track, and a coating with a low coefficient of friction attached to the surface of the aluminum alloy curtain rod track, the thickness of the coating with a low coefficient of friction is 5um, wherein The coating with low coefficient of friction is perfluoropolyetheryl fluoride containing aminosilane.

[0028] The preparation method of the above curtain rod track with low coefficient of friction comprises the steps:

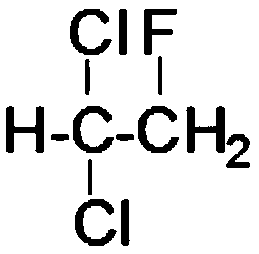

[0029] S1, put the modified perfluoropolyether, fluorocarbon solvent I and aminosilane into the reaction kettle according to the mass percentage of 10:10:1 for reaction, control the reaction temperature to 30°C, and the reaction time to 2 hours, while controlling the environment Humidity is 30±5%, temperature is 20±5℃;

[0030] S2, adding anhydrous methanol to the reaction kettle in step S1, wherein the amount of anhydrous methanol is 10 times the mass of...

specific Embodiment example 2

[0039] A curtain rod track with a low coefficient of friction, which includes an aluminum alloy curtain rod track, and a coating with a low coefficient of friction attached to the surface of the aluminum alloy curtain rod track, the thickness of the coating with a low coefficient of friction is 5.5um, The coating with low coefficient of friction is perfluoropolyetheryl fluoride containing aminosilane.

[0040] The preparation method of the above curtain rod track with low coefficient of friction comprises the steps:

[0041] S1, put the modified perfluoropolyether, fluorocarbon solvent I and aminosilane into the reaction kettle according to the mass percentage of 10:10:1 for reaction, control the reaction temperature to 30°C, and the reaction time to 2 hours, while controlling the environment Humidity is 30±5%, temperature is 20±5℃;

[0042] S2, adding anhydrous methanol to the reaction kettle in step S1, wherein the amount of anhydrous methanol is 10 times the mass of aminos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com