Artificial wetland phosphorous removal porous composite substrate filler and preparation method thereof

A technology of constructed wetlands and composite substrates, applied in chemical instruments and methods, water treatment of special compounds, water pollutants, etc., can solve problems such as pH increase and blockage, achieve increased porosity, good environmental benefits, and improved removal efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

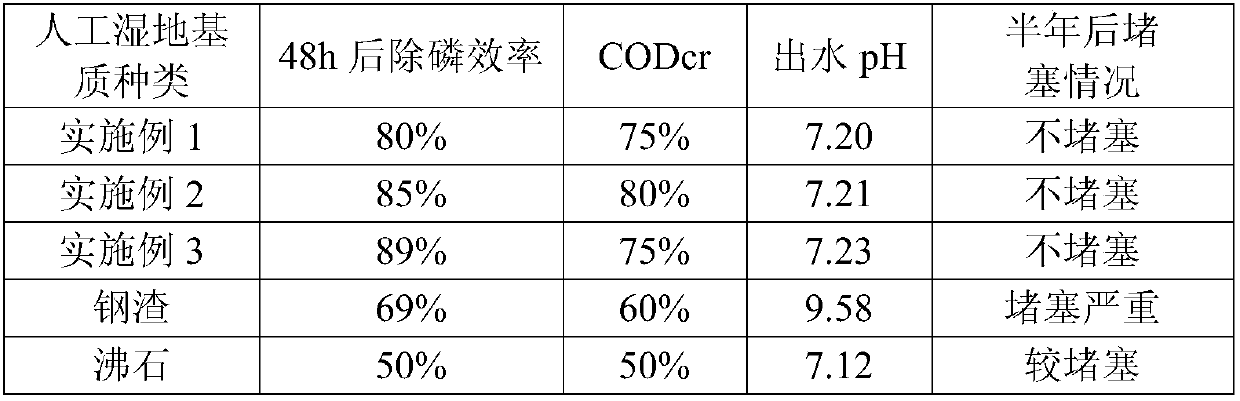

Examples

Embodiment 1

[0024] A porous composite matrix filler for phosphorus removal in artificial wetlands is prepared by adding water to the following raw materials in weight percentages: 40% steel slag, 25% calcium carbonate powder, 25% crop straw and leaves, and 10% binder. The particle size of the steel slag is not greater than 1mm. The particle size of the calcium carbonate powder is 5-10 μm. The straws are corn and soybean plant straws, the leaves are street fallen leaves, and the straw:leaves weight ratio is 3:2. The binder is Na 2 SiO 3 A mixture of polyacrylamide and polyacrylamide, the weight ratio of the two is 5:1.

[0025] Its preparation method comprises the following steps:

[0026] 1) Naturally air-dry the stalks and leaves, then pulverize them, pass through a 1mm sieve, and take the sieved matter to obtain the stalks and leaves powder;

[0027] 2) Stir and mix steel slag, calcium carbonate powder, straw and leaf powder, add binder and water and continue to stir and mix to obt...

Embodiment 2

[0030] A porous composite matrix filler for phosphorus removal in artificial wetlands is prepared by adding water to the following raw materials in weight percentage: 45% steel slag, 15% calcium carbonate powder, 20% crop straw and leaves, and 20% binder. The particle size of the steel slag is not greater than 1mm. The particle size of the calcium carbonate powder is 5-10 μm. The straw is wheat plant straw, the leaves are forest farm leaves, and the straw:leaves weight ratio is 1:1. The binder is Na 2 SiO 3 A mixture of polyacrylamide and polyacrylamide, the weight ratio of the two is 7:1.

[0031] Its preparation method comprises the following steps:

[0032] 1) Naturally air-dry the stalks and leaves, then pulverize them, pass through a 1mm sieve, and take the sieved matter to obtain the stalks and leaves powder;

[0033] 2) Stir and mix steel slag, calcium carbonate powder, straw and leaf powder, add binder and water and continue to stir and mix to obtain a mixed slurr...

Embodiment 3

[0036] A porous composite matrix filler for phosphorus removal in artificial wetlands is prepared by adding water to the following raw materials in weight percentages: 50% steel slag, 20% calcium carbonate powder, 10% crop straw and leaves, and 20% binder. The particle size of the steel slag is not greater than 1mm. The particle size of the calcium carbonate powder is 5-10 μm. The straw is rice plant straw, the leaves are fallen leaves from the street, and the weight ratio of straw:leaves is 2:1. The binder is Na 2 SiO 3 A mixture of polyacrylamide and polyacrylamide, the weight ratio of the two is 9:1.

[0037] Its preparation method comprises the following steps:

[0038] 1) Naturally air-dry the stalks and leaves, then pulverize them, pass through a 1mm sieve, and take the sieved matter to obtain the stalks and leaves powder;

[0039] 2) Stir and mix steel slag, calcium carbonate powder, straw and leaf powder, add binder and water and continue to stir and mix to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com