Tundish covering agent for continuous casting of low-carbon steel containing Al and Ti and application thereof

A continuous casting tundish and covering agent technology, applied in the field of steel continuous casting, can solve the problems of inapplicability to low-carbon steel, not considering special problems, not considering the carbonization of the covering agent, etc., so as to improve the cleanliness and the quality of the casting billet. , the effect of preventing carbon increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A low-carbon steel continuous casting tundish covering agent containing Al and Ti, which includes the following components in mass percentage: CaO: 37.3%, SiO 2 : 9.9%, Al 2 o 3 : 28.3%, MgO: 8.1%, (Na 2 O+Li 2 O): 9.4%, B 2 o 3 : 3.9%, C: 1.4%, TiO 2 : 1.7%. The basicity of the tundish covering agent CaO / SiO 2 It is 3.77:1. In the tundish covering agent, Na 2 O and Li 2 The mass ratio of O is 8:1.

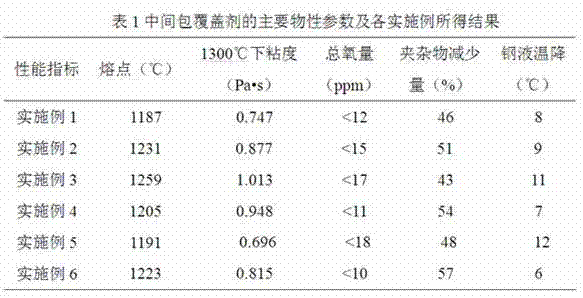

[0039] The main physical properties of the tundish covering agent measured by the above method are shown in Table 1.

[0040] The tundish covering agent of this embodiment is used for carbon content is 0.03wt%, and Al content is 0.3wt%, and Ti content is the continuous casting process of containing Al, Ti low carbon steel of 0.3wt%; The oxygen content is less than 12ppm, the total amount of inclusions in the molten steel is reduced by 46% before and after passing through the tundish, and the temperature of the molten steel drops by 8°C.

Embodiment 2

[0042] A low-carbon steel continuous casting tundish covering agent containing Al and Ti, which includes the following components in mass percentage: CaO: 33.6%, SiO 2 : 13.3%, Al 2 o 3 : 27.1%, MgO: 9.1%, (Na 2 O+Li 2 O): 9.9%, B 2 o 3 : 4.6%, C: 0.8%, TiO 2 : 1.6%. The basicity of the tundish covering agent CaO / SiO 2 It is 2.53:1. In the tundish covering agent, Na 2 O and Li 2 The mass ratio of O is 12:1.

[0043] The main physical properties of the tundish covering agent measured by the above method are shown in Table 1.

[0044] The tundish covering agent of this embodiment is used for carbon content is 0.03wt%, and Al content is 0.3wt%, and Ti content is the continuous casting process of containing Al, Ti low carbon steel of 0.3wt%; When the oxygen content is less than 15ppm, the total amount of inclusions in the molten steel is reduced by 51% before and after passing through the tundish, and the temperature of the molten steel drops by 9°C.

Embodiment 3

[0046] A low-carbon steel continuous casting tundish covering agent containing Al and Ti, which includes the following components in mass percentage: CaO: 41.8%, SiO 2 : 7.9%, Al 2 o 3 : 30.6%, MgO: 6.3%, (Na 2 O+Li 2 O): 7.2%, B 2 o 3 : 4.1%, C: 0.6%, TiO 2 : 1.5%. The basicity of the tundish covering agent CaO / SiO 2 It is 5.29:1. In the tundish covering agent, Na 2 O and Li 2 The mass ratio of O is 20:1.

[0047] The main physical properties of the tundish covering agent measured by the above method are shown in Table 1.

[0048] The tundish covering agent of this embodiment is used for carbon content is 0.03wt%, and Al content is 0.3wt%, and Ti content is the continuous casting process of containing Al, Ti low carbon steel of 0.3wt%; The oxygen content is less than 17ppm, the total amount of inclusions in the molten steel is reduced by 43% before and after passing through the tundish, and the temperature of the molten steel drops by 11°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com